Arcam products automatically turn off (spontaneously).

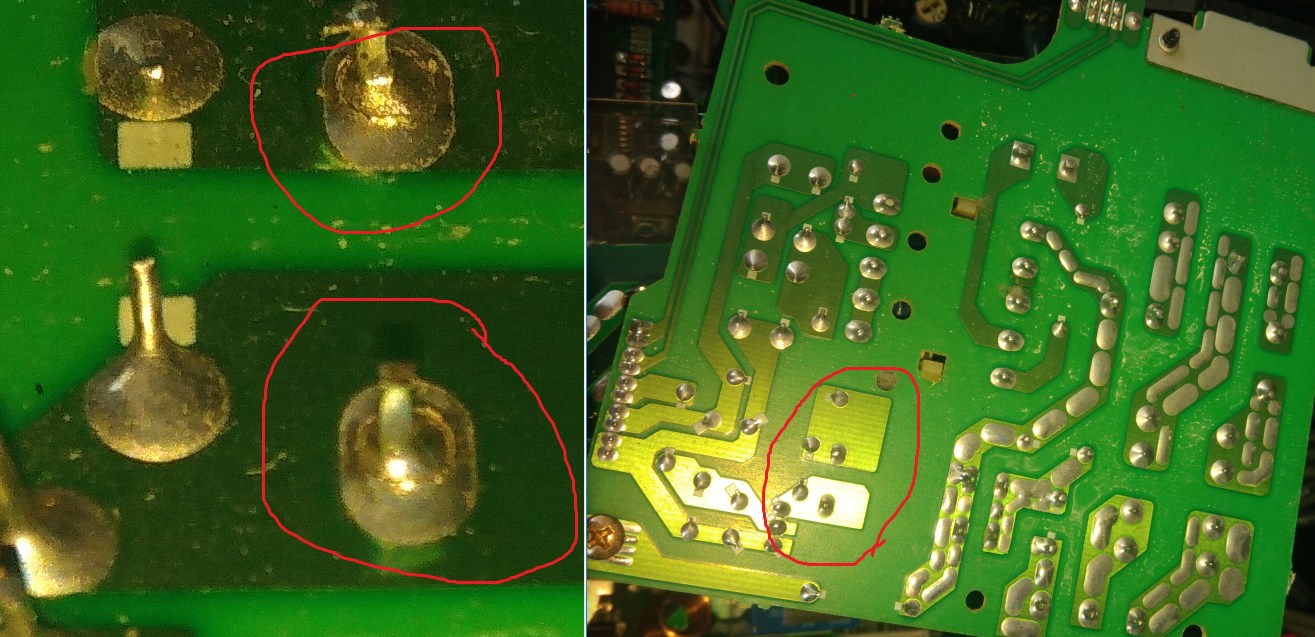

I found the problem. The reason is the destruction of the soldering of the Relay contacts in the power supply unit. As an example (picture) repair of the AVR 300 receiver. I hope I helped

I found the problem. The reason is the destruction of the soldering of the Relay contacts in the power supply unit. As an example (picture) repair of the AVR 300 receiver. I hope I helped

Attachments

There are a number of other soldered connections that look suspicious too. That's slack inspection work and the board should have been sent to rework, following the appropriate inspection, IMHO.

This could be fatigue failure over time I think, not lack of inspection. Probably due to thermal expansion of PCB and relay differing (relays heat up internally when active).

I continue to show defects Arcam:

there is a lot of soldering destruction on the motherboard,

a swollen 1000x10V capacitor on the DSP board

so-look for soldering defects (relays, diodes), inspect the capacitors for BLOATING.

PS the receiver's operability has been restored

there is a lot of soldering destruction on the motherboard,

a swollen 1000x10V capacitor on the DSP board

so-look for soldering defects (relays, diodes), inspect the capacitors for BLOATING.

PS the receiver's operability has been restored

I will especially note a common problem in many amplifiers - a weak level of RF frequencies when turned on (eliminated by increasing the volume). Often the cause of this problem is the oxidation of the Relay contacts. It is solved with the help of excellent German -wurth contact cleaner (attention-do not use surrogates of Eastern Europe, etc.!! Only Germans!).

In Arcam, this is done very conveniently - through the technological holes in the relay, the OL Wurth Contact Cleaner (200 ml) is injected with a medical needle (do it carefully - do not stick the needle deep !!) .

+

After that, the Receiver rotates vertically for half an hour so that OL Wurth Contact Cleaner fills the contacts inside the relay. at the end, the receiver is turned upside down and left for a day - excess liquid will flow out.. The problem has been solved for.

PS by the way, I am also processing the output terminals for the speakers with this liquid and the cable to the acoustics, this will improve the sound.

In Arcam, this is done very conveniently - through the technological holes in the relay, the OL Wurth Contact Cleaner (200 ml) is injected with a medical needle (do it carefully - do not stick the needle deep !!) .

+

After that, the Receiver rotates vertically for half an hour so that OL Wurth Contact Cleaner fills the contacts inside the relay. at the end, the receiver is turned upside down and left for a day - excess liquid will flow out.. The problem has been solved for.

PS by the way, I am also processing the output terminals for the speakers with this liquid and the cable to the acoustics, this will improve the sound.

sorry for the bad English. I will specifically note that the destruction of soldering was in places where there was little tin. There was more tin on the sound boards on the contacts and there is no destruction there! Probably a thin layer of tin together with large load currents lead to the destruction of soldering. To avoid this, it was necessary to increase the amount of Tin (solder). I am very surprised that the Arcam specialists did not calculate this themselves over the years of work. Or maybe the reason is the assembly in China ? I repeat - I do not understand why there was not enough tin in the critical areas of the amplifier. By the way: very cheap samwha capacitors are used in Arcam products (I repeat - these are expensive products) (power capacitors cost only$ 2!!!). This is all very sad.

PS Attention! if you are inexperienced, then do not deal with Wurth Contact Cleaner and relays !!!

In the case of the Arcam AVR300, limit yourself only to soldering the destroyed soldering, and replacing two capacitors 3300x25V 2200x1000V

In the case of the Arcam AVR300, limit yourself only to soldering the destroyed soldering, and replacing two capacitors 3300x25V 2200x1000V

Chinese solder contains less tin than is desired, and Arcam is partly to blame, for cutting the price to unprofitable levels for the supplier, who is left with little choice but to reduce quality.

If it is RoHS lead free solder, reflow all joints with leaded solder, as lead free tends to crack after some years, it is brittle.

Better to replace all Samhwa caps, good or bad, with standard 105 degree capacitors.

Change the relay too if it is not a standard make.

This issue of cost cutting has also been seen in Bose products made in China, the branded units are made and packed in China by contract manufacturers, with sometimes no inspector present from the buyer.

That is why the companies are getting a bad reputation, and seeing a decline in business.

If it is RoHS lead free solder, reflow all joints with leaded solder, as lead free tends to crack after some years, it is brittle.

Better to replace all Samhwa caps, good or bad, with standard 105 degree capacitors.

Change the relay too if it is not a standard make.

This issue of cost cutting has also been seen in Bose products made in China, the branded units are made and packed in China by contract manufacturers, with sometimes no inspector present from the buyer.

That is why the companies are getting a bad reputation, and seeing a decline in business.

Last edited:

2200 x 1000V?

Check it please...1000 is maybe a typo.

3300/ 25V can be replaced by 3300/35V for more safety.

Check it please...1000 is maybe a typo.

3300/ 25V can be replaced by 3300/35V for more safety.

Some years back brake pedals made of glass reinforced plastic broke on Aston Martin cars.

It was traced to a Chinese supplier who squeezed his sub contractor for price, so he used cheapest recycled scrap, and they looked and tested okay.

Only they started breaking after a few months.

A few pounds worth material on a very expensive car.

That makes me question the wisdom of buying the fastest lorry in Europe, or any British electronics for that matter, I think NAD also sources from China.

'Ferrari and Lamborghini owners have been known to call the Aston Martin the fastest lorry in Europe...carping critics have maintained that engines meant for the David Brown tractor division occasionally found their way into the wrong machines...'

From a novel by Alistair MacLean.

It seems British quality was never that good.

No, I do not want to start a rant or new thread about British quality, just an observation that many famous names simply do not have the same levels of sales volumes now, and there has been cost cutting for business efficiency, if it goes too far, the quality suffers.

It was traced to a Chinese supplier who squeezed his sub contractor for price, so he used cheapest recycled scrap, and they looked and tested okay.

Only they started breaking after a few months.

A few pounds worth material on a very expensive car.

That makes me question the wisdom of buying the fastest lorry in Europe, or any British electronics for that matter, I think NAD also sources from China.

'Ferrari and Lamborghini owners have been known to call the Aston Martin the fastest lorry in Europe...carping critics have maintained that engines meant for the David Brown tractor division occasionally found their way into the wrong machines...'

From a novel by Alistair MacLean.

It seems British quality was never that good.

No, I do not want to start a rant or new thread about British quality, just an observation that many famous names simply do not have the same levels of sales volumes now, and there has been cost cutting for business efficiency, if it goes too far, the quality suffers.

Last edited:

I worked on Aston Martin's back in the 70's (DB4's) and they were well made but needed a lot of maintenance. Ferrari's of that era didnt exactly have a good reputation for reliability.

By the way the high speed lorry anecdote was coined by Enzo Ferrari when he was running Alfa Romeo's and was about Bentley,s in the 1920's. They were high speed lorries but won Le Mans.

The cap failures might be due to the Capacitor Plague a few years back. The formula for cap electrolyte was stolen from Elna and used by some Chinese start up cap companies.

Unfortunately they didnt get all of the formula and didnt include the additives that inhibit corrosion. I think it caught out quite few well know companies.

By the way the high speed lorry anecdote was coined by Enzo Ferrari when he was running Alfa Romeo's and was about Bentley,s in the 1920's. They were high speed lorries but won Le Mans.

The cap failures might be due to the Capacitor Plague a few years back. The formula for cap electrolyte was stolen from Elna and used by some Chinese start up cap companies.

Unfortunately they didnt get all of the formula and didnt include the additives that inhibit corrosion. I think it caught out quite few well know companies.

Samhwa and Samsung. I don't remember, one took over the other's capacitor business.

Not known for quality, capacitor formula theft not relevant.

Top quality 105 degree capacitors are usually much closer to actual specified values than the 20% allowed, so you have a better result.

The volumes for mass produced German and American muscle cars are in multiples of those for Aston Martin. My point was that saving a few quid on a car selling for more than 100,000 quid was foolish.

Arcam are also priced in multiples of Japanese brands. Is the price justified?

At least they could have used standard or good quality parts rather than cheating the customer, bu using junk or mediocre quality materials.

It is like paying for a Harley Street specialist and being treated by a NHS trainee.

Cheating is a strong word, justified in this case I think.

Not known for quality, capacitor formula theft not relevant.

Top quality 105 degree capacitors are usually much closer to actual specified values than the 20% allowed, so you have a better result.

The volumes for mass produced German and American muscle cars are in multiples of those for Aston Martin. My point was that saving a few quid on a car selling for more than 100,000 quid was foolish.

Arcam are also priced in multiples of Japanese brands. Is the price justified?

At least they could have used standard or good quality parts rather than cheating the customer, bu using junk or mediocre quality materials.

It is like paying for a Harley Street specialist and being treated by a NHS trainee.

Cheating is a strong word, justified in this case I think.

Last edited:

yes,2200 x 1000V?

Check it please...1000 is maybe a typo.

3300/ 25V can be replaced by 3300/35V for more safety.

1. 1000x10V

2. 3300 x25v ( x35v); t-105C

if your capacitor is not swollen, then first just solder the contacts of the power relay (the first message is at the top, a small side board). build arcam and turn it on. if it works (and via digital input ) then finish the repair on this.

if your capacitor is swollen, then replace the 3300x25 capacitor, a new one (necessarily at 105С !) place it vertically in the standard holes.

be extremely careful !!!!

PS Attention! if you are inexperienced, then do not deal with Wurth Contact Cleaner and relays !!!

Last edited:

Contact cleaner - any brand - is only good for a short period of time, perhaps 12 months in regular use. Cleaners are not magic, just a little light oil, hydrocarbon solvent, compressed propellant gas and maybe a small percentage of specific dispersant compounds to aid the removal of arcing debris and grime. The problem though, is not only a build-up of debris on the contacts but pitting of the plated faces which spells their end of life.

Sealed relays can last longer than removable cover types but are "throw-aways" when they prove troublesome. Older, serviceable types had removable covers where you could clean and burnish the original contacts for an extended life but eventually, you still need to replace them if you want reliable, high quality sound as they would originally have delivered.

Too often though, I have seen both pro. and amateur repairs attempted by just cleaning the contacts and sure enough, they were either back for more repairs or the whole amp. was scrapped or sold off as a wreck within twelve months. That's just not good enough if someone was charging for the repair service but for your own use, you can do as you please but just be aware that that don't get back those years in which the contacts accumulated the damage.

Clean away the mess and burnish with something gentle like strips of raw cardboard but also look around for replacement(s) before next time.

Sealed relays can last longer than removable cover types but are "throw-aways" when they prove troublesome. Older, serviceable types had removable covers where you could clean and burnish the original contacts for an extended life but eventually, you still need to replace them if you want reliable, high quality sound as they would originally have delivered.

Too often though, I have seen both pro. and amateur repairs attempted by just cleaning the contacts and sure enough, they were either back for more repairs or the whole amp. was scrapped or sold off as a wreck within twelve months. That's just not good enough if someone was charging for the repair service but for your own use, you can do as you please but just be aware that that don't get back those years in which the contacts accumulated the damage.

Clean away the mess and burnish with something gentle like strips of raw cardboard but also look around for replacement(s) before next time.

I second that.

As it is I suspect the quality.

Replace with a higher rated relay, the biggest that will fit.

Put a MOV across contacts as arc quencher.

As it is I suspect the quality.

Replace with a higher rated relay, the biggest that will fit.

Put a MOV across contacts as arc quencher.

I've found Arcam to be both over priced and poor.. both in Design and Construction.

Unsurprisingly they don't sound overly good either, most gear does better.

Always amazed that this maker is still in business... power of Advertising ??

Unsurprisingly they don't sound overly good either, most gear does better.

Always amazed that this maker is still in business... power of Advertising ??

Arcam is no longer a British company... they are owned by Harman (in turn owned by Samsung) and the quality slide started around about then. The older Arcam products were good quality stuff and well designed.

Arcam ---> Harman = Samsung.

it is sad. but it would be worse if China bought it !

on the photo of the Arcam AVR600 (2010 years, China) . it is clear that cheap samwha (samsung) capacitors are installed.

the Chinese Arcam AVR600 had a lot of breakdowns ! I don't think that because of the capacitors, the symptoms- Clicks, loss of sound or timbre - it was a horror.

it is sad. but it would be worse if China bought it !

on the photo of the Arcam AVR600 (2010 years, China) . it is clear that cheap samwha (samsung) capacitors are installed.

the Chinese Arcam AVR600 had a lot of breakdowns ! I don't think that because of the capacitors, the symptoms- Clicks, loss of sound or timbre - it was a horror.

Attachments

Last edited:

Contact cleaner - any brand - is only good for a short period of time, perhaps 12 months in regular use.

I was repairing the relay in the PIONEER AX10.

The defect was as follows - when turned on in one channel, the sound was quiet (or there seemed to be few high-frequency frequencies), when the volume was increased, the problem disappeared. I was removing the relay. I turned the relay upside down and drilled (with a dental drill) holes in the relay cover, injected a wurth contact cleaner. I turned the relay upside down for one day so that the liquid would leak out. Soldered the relay back. the result is that the relay has been working well for 2 years.

I didn't want to buy Chinese relays in China and I want to leave my native relays. I don't believe in Chinese goods at all - they save money everywhere and spoil the native (original) product. The Chinese are the complete opposite of the Japanese.

in 2015, I repaired the Marantz 6xxx amplifier (made in China) - a rustle was heard in the volume control. I also eliminated it with the wurth contact cleaner.

The German wurth contact cleaner is the best I've seen.

the photo shows the exact analogs of the relay from China - maybe someone will need it

Attachments

Last edited:

What do you think of the idea to put solid state relays instead?

I paid 500 Rupees, for a 50A / 240 volt single pole relay with heat sink, short circuit protected. Control side is 5 - 32 V DC. DIN Channel mounting

That is about $ 6.50 US.

PCB mounted ones, 16A are about $3...

More reliable, and no chance of contact noise...or wear.

I paid 500 Rupees, for a 50A / 240 volt single pole relay with heat sink, short circuit protected. Control side is 5 - 32 V DC. DIN Channel mounting

That is about $ 6.50 US.

PCB mounted ones, 16A are about $3...

More reliable, and no chance of contact noise...or wear.

- Home

- Amplifiers

- Solid State

- Arcam is being disabled (resolved)