perforatedmetal

http://www.marcospecialtysteel.com/perforatedmetal.htm

if you have ever worked with sheetmetal it should be a snap.

cheer's

http://www.marcospecialtysteel.com/perforatedmetal.htm

if you have ever worked with sheetmetal it should be a snap.

cheer's

Sorry about digging up an old thread.

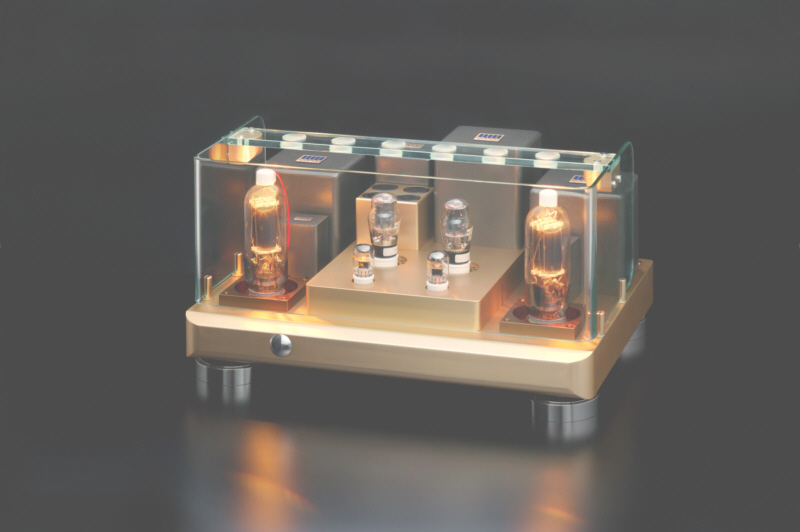

I've got a Jolida amp that I'd like to put a cage on (2 year old in the house), but I like the look of the tubes. Most cages cover them up so much. I don't like the look of the acrylic much, and wouldn't it get really hot? I have no sheet metal working experience, but I will try anything. Where can I get the materials? The link above doesn't work.

I like the "screen" look that guys use for their headphones, but I don't know if it has enough structural stability to work:

I've got a Jolida amp that I'd like to put a cage on (2 year old in the house), but I like the look of the tubes. Most cages cover them up so much. I don't like the look of the acrylic much, and wouldn't it get really hot? I have no sheet metal working experience, but I will try anything. Where can I get the materials? The link above doesn't work.

I like the "screen" look that guys use for their headphones, but I don't know if it has enough structural stability to work:

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Try onlinemetals for perforated aluminum sheet stock. I don't have any suggestions on where to get wire mesh unfortunately.

Online Metal Store

Online Metal Store

wire mesh? McMaster-Carr

McMaster-Carr

lots of .. well..... everything: expanded metal, perforated metal, etc etc.

McMaster-Carr

lots of .. well..... everything: expanded metal, perforated metal, etc etc.

Yes, include a malware for free!

Attachments

Yes, include a malware for free!

I would guess that's an issue with your virus checker, not the site. There's some little Javascripts running on the site that your checker is wrongly picking up.

That's part of the reason I like Macs. Stupid virus checker programs.

Does anyone have more ideas or pictures on how a cage could be constructed? I do not have welding experience... I could bring it somewhere though. I'm sure I could figure out how to bend metal in straight lines.

I'd want to have the cage be open in back. The transformer covers on the 202A would get in the way if the cage had a backside.

So a sheet would be cut something like this, what options do I have for finishing the edges?

I'd want to have the cage be open in back. The transformer covers on the 202A would get in the way if the cage had a backside.

So a sheet would be cut something like this, what options do I have for finishing the edges?

An externally hosted image should be here but it was not working when we last tested it.

Maybe I could do somehing like this on the corners?:

With this for the sheets (I'll see if they have something thicker if I do it):

Do you think rivets would work to fasten everything together? Or is welding the only way to make if work and not look like crap?

An externally hosted image should be here but it was not working when we last tested it.

With this for the sheets (I'll see if they have something thicker if I do it):

An externally hosted image should be here but it was not working when we last tested it.

Do you think rivets would work to fasten everything together? Or is welding the only way to make if work and not look like crap?

Maybe I could do somehing like this on the corners?:

An externally hosted image should be here but it was not working when we last tested it.

With this for the sheets (I'll see if they have something thicker if I do it):

An externally hosted image should be here but it was not working when we last tested it.

Do you think rivets would work to fasten everything together? Or is welding the only way to make if work and not look like crap?

I figure you could clamp the pieces of wire mesh to the angle brackets you show. Small pieces of thin bar stock would work, i.e. angle bracket on the outside, then wire mesh, and finally bar stock on the inside. (A sandwich with the wire mesh in the middle.) You could pop rivet the angle brackets and bar stock together, or use screws. Riveting mesh directly IME is not the way to go.. You are probably best off cutting the mesh to make a small square hole where the screw or rivet passes through it.

I would guess that's an issue with your virus checker, not the site. There's some little Javascripts running on the site that your checker is wrongly picking up.

That's part of the reason I like Macs. Stupid virus checker programs.

Some of those programs are a bit overzealous.

McMaster - Carr is major vendor of supplies and materials to a wide range of industries so if their site was infected you can be sure it would be fixed immediately. I use their site regularly at work and have never received an alert or drive by download.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- 300b tube cage