Presenting thread here:

LuDEF

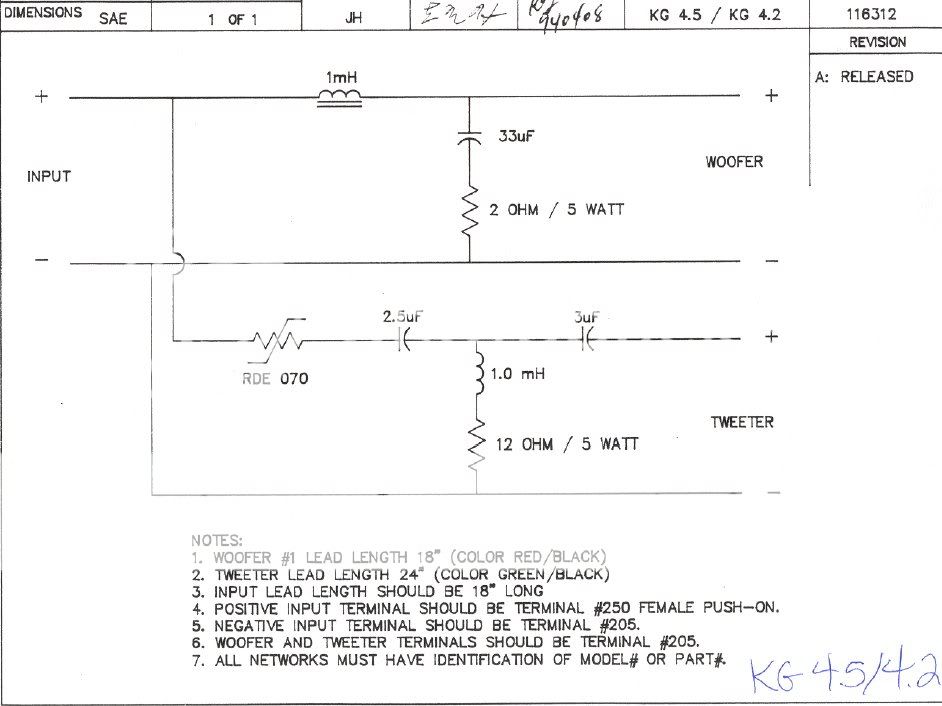

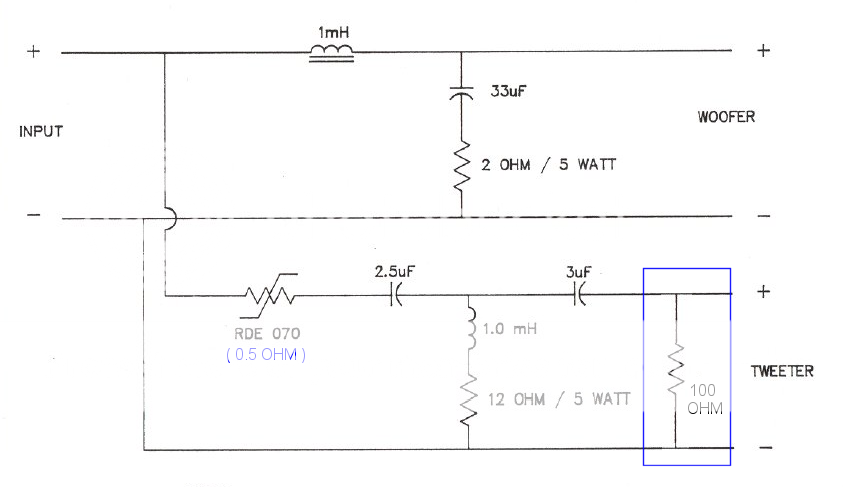

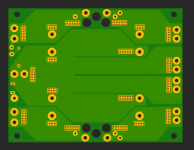

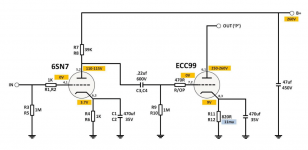

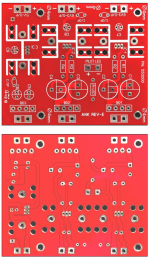

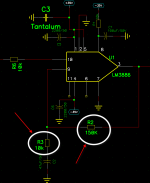

Schematic and pcb screenshot post #1 , plenty of pictures after .

Tips and Tricks thread - will open, sooner or later

Reading entire thread is advisable , same as inquiring any technical question there : Be sure that you are aware of all things electrical and mechanical !

Pcbs are made for UMS , mounting directly to heatsink

Do not hurry - read , think , ask and only when you feel that you want it and can make it , proceed ...... advice which I'm finding applicable on practically anything .

For anything else , write either here , send PM or directly to >zenmodiyaudio@gmail.com<

Prices are mostly dictated with small scale nature of operation (as always is case) and time/work involved in matching and soldering little buggers.

For ordering , contact me at above written e-mail addy .

edit on 27.11.2021. : pcbs changed for easier LU mounting; see

(see post #620)

Kit options :

Option 1.

- LCH pcb ,

- RCH pcb ,

- all smd buffer JFets (Toshiba 2SK2145BL) presoldered ,

- smd precision CCS chips presoldered

- all smd caps and resistors presoldered ,

- 4pcs of 1uF MKC caps (for important bypass positions) enclosed.

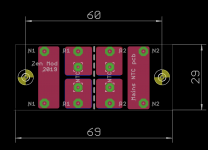

-pair of small Daughter boards for LU

(see post #620)

-mica for BD cascodes heatsink mount

Full price , including Paypal fee and P&P for registered shipping all around the Globe - 135E

Option 2.

- LCH pcb ,

- RCH pcb ,

- all smd buffer JFets (Toshiba 2SK2145BL) presoldered ,

- smd precision CCS chips presoldered

- all smd caps and resistors presoldered ,

- 4pcs of 1uF MKC caps (for important bypass positions) enclosed.

-all multiturn trimpots

-output mosfets , 2 pairs , IRFP240 & IRFP9140

-IRF510 & BD 139 - source follower/level shifter duty

-cascode bjts

-optocouplers

-all electrolytic caps (all Panasonics ,except Elna Silmic II for one signal route position)

-one-pin sockets for special resistor positions

-all (MF 600mW) resistors

-T0220 heatsinks - 6pcs

-pair of small Daughter boards for LU

(see post #620)

-mica for BD cascodes heatsink mount

-etc.

to recapitulate -

everything what goes on pcbs , excluding signal xformers and pcb/mosfet mounting screws/nuts/washers ; also excluding LU1014**

Full price , including Paypal fee and P&P for registered shipping all around the Globe - 185E

**LU1014 - in this moment I have quantity for, say, 35 kits; ask for them - tested and Ids matched, if you don't have them already; matched pair ( you'll get them soldered to Al boards) is 8E

If I have everything in drawers in moment of order , can ship in a week time;

If I don't have any of normal parts in drawer , shipping could be delayed up to 3 days;

If I don't have pcbs in drawer , shipping could be delayed up to 2 weeks;

If I don't have most critical part for getting in my neck of wood - CCS precision chips , shipping could be delayed up to 3 weeks.

All in all - you all know that ZM is slow, but inevitable

Handy

Addendum (in short :

HA!):

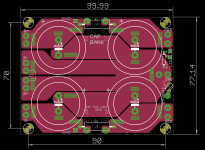

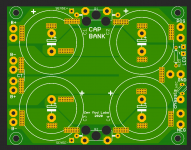

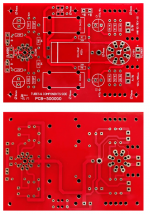

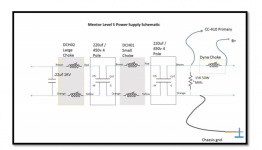

-Cap Bank pcbs - set of 2pcs; dual rail, CRC (pads, if you want differential CLC), snap-in up to 35mm Dia, resistor and pads for LED, position for 10mm NTC connecting Audio GND to chassis;

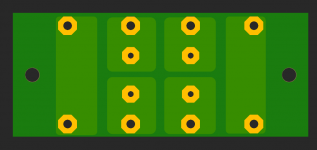

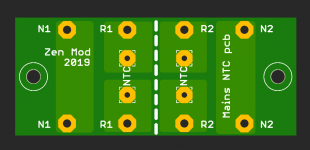

-NTC pcb/ FW style Soft Start - set of 2pcs; each having place for 2 independent NTCs;depending of arrangement of primaries of Donuts you're using. you'll need either one pcb for two Donuts, or one pcb per Donut

HA! set is 25E more

see pics for HA!; lazy to search do I have photo of NTC pcb, but who cares