This afternoon a measurement session possible, primarely to check if driver mounting went ok.

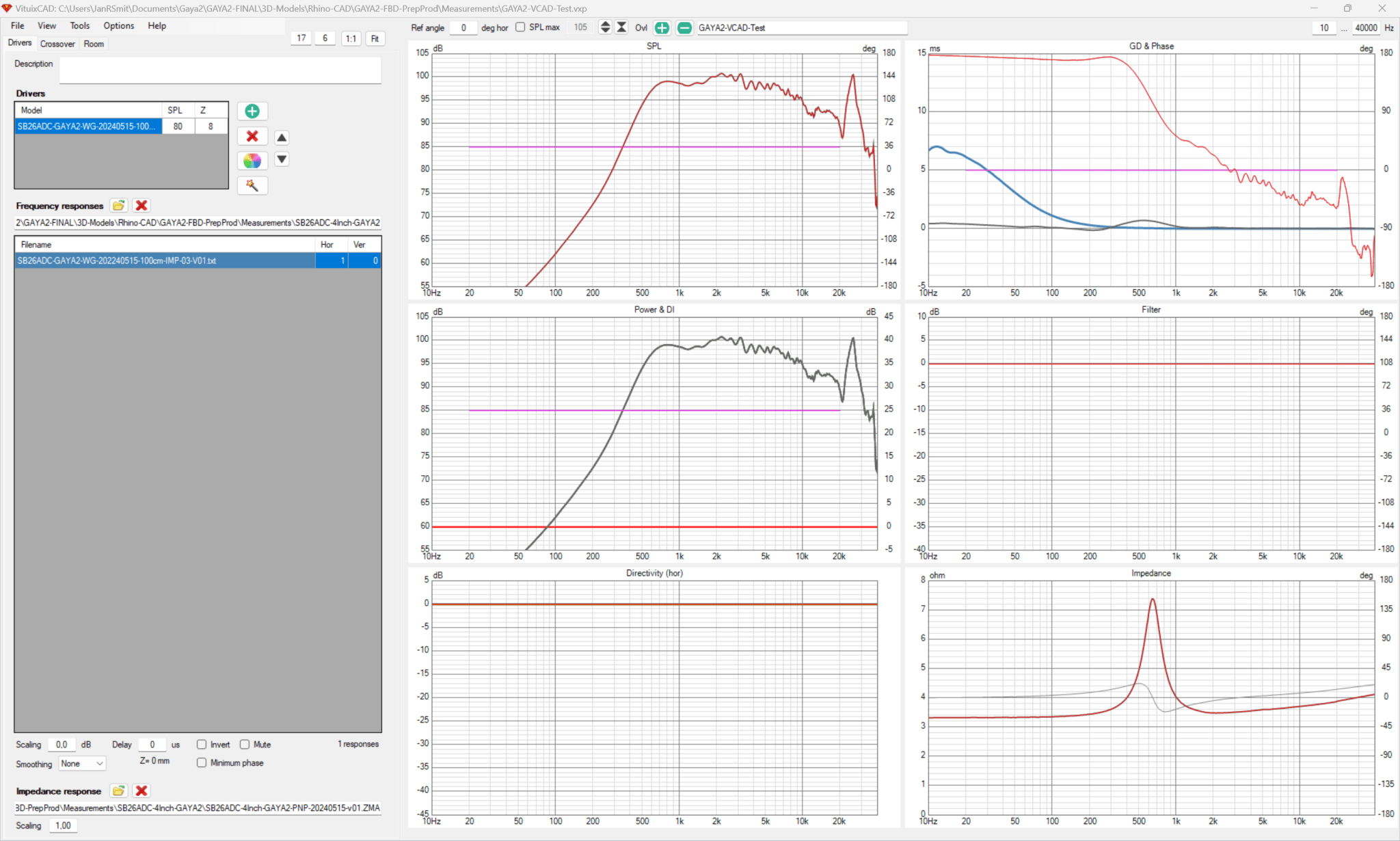

Tweeter at 100cm, with mounting holes and edge covered with tape:

Serious spike at 28kHz, hump at res-frequency. But else ok.

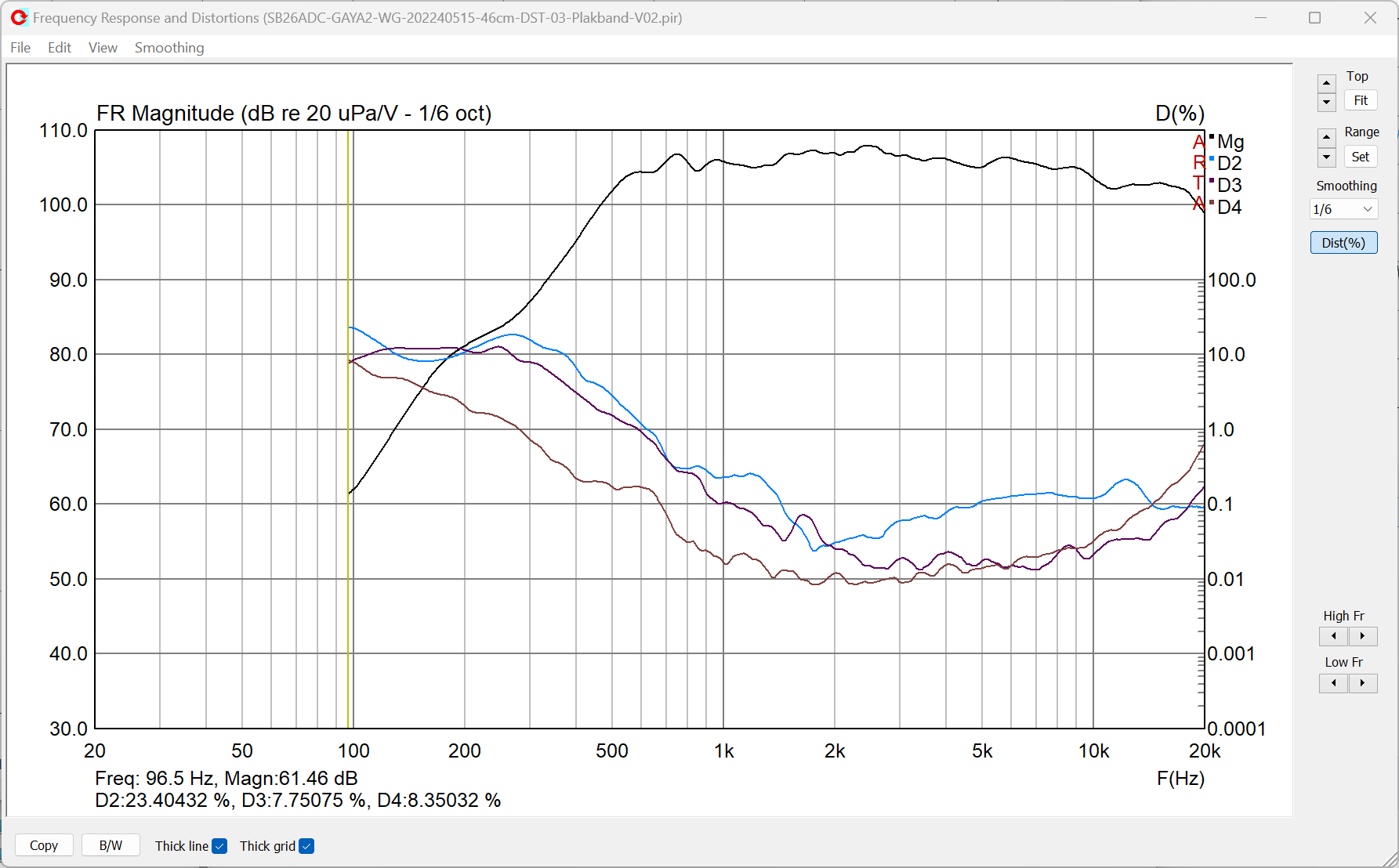

Distortion via ARTA at 46cm en 2,84Vrms:

Not bad ;-)

Tweeter at 100cm, with mounting holes and edge covered with tape:

Serious spike at 28kHz, hump at res-frequency. But else ok.

Distortion via ARTA at 46cm en 2,84Vrms:

Not bad ;-)

On the Bliesma drivers the surrround is glued to the face plate and extents some way out from the roll. If a waveguide makes direct contact with the surround and it is tightened down enough it can cause the driver to misbehave and not perform as well as it can. @jcga had this problem early on when experimenting with waveguides. 3D printing has tolerances and it could be that the tolerance helps or hurts depending on where it is. I prefer to avoid finding out so in my designs there is either a small gap designed in or a spacer to put in place to make sure the surround isn't under pressure.

Thanks for the heads-up. Turns out the surround is less than one thickness of painter's tape, .005 inch / .125 mm, so two layers of painter's tape on the waveguide would be more than adequate. Cutting away 1 7/8 inch / 48 mm diameter (I used my tweeter mount as a template) from the centre gives lots of room for the surround, which is about 1 5/8 inch / 41 mm diameter.