In an old Motorola power semiconductor databook I used to have (pre-internet age) there was a section that discussed heatsink effinciency wrt both color and, more importantly, surface roughness. Black rough surface won, IIRC ;-)

A recent study I could dig up, wrt to roughness: Improved thermal management of computer microprocessors using cylindrical-coordinate micro-fin heat sink with artificial surface roughness - ScienceDirect

A recent study I could dig up, wrt to roughness: Improved thermal management of computer microprocessors using cylindrical-coordinate micro-fin heat sink with artificial surface roughness - ScienceDirect

I remember vaguely that Motorola source. I don't think I have a copy. Also I learned of this from an in-house seminar on thermal management given by an HP Labs expert more years ago than I'll put in print. He wasn't big on lighter colors but red, blue, black, brown, green, violet, as long as 'dark', had little difference from the black.

It is more significant than I at first thought. For natural convection, black anodizing contributes 30% via radiation of the total dissipation (for vertical fins) and convection 70%. Almost independent on power dissipation.

For forced air cooling, the heatsink colour is irrelevant, with radiation only contributing about 2%.

The importance of radiation in heat sink design | Heat Sink Calculator-Blog: Focused on Heat Sink Analysis, Design and Optimization

The link in that web page is to a full CFD thermal analysis package you have to pay for.

Craig

For forced air cooling, the heatsink colour is irrelevant, with radiation only contributing about 2%.

The importance of radiation in heat sink design | Heat Sink Calculator-Blog: Focused on Heat Sink Analysis, Design and Optimization

The link in that web page is to a full CFD thermal analysis package you have to pay for.

Craig

Inevitably a good reference is ESP - Heatsink design and transistor mounting , with a rule of thumb that the thermal performance is 50/(root area in cm^2) which seems to work.

He also has a calculator, that I have not yet downloaded and tried.

Craig

He also has a calculator, that I have not yet downloaded and tried.

Craig

Sweet. Thank you.

I also dug up this handy summary:

Anodized Aluminum Heatsinks: What You Need to Know - Gabrian

Tom

I also dug up this handy summary:

Anodized Aluminum Heatsinks: What You Need to Know - Gabrian

Tom

Inevitably a good reference is ESP - Heatsink design and transistor mounting , with a rule of thumb that the thermal performance is 50/(root area in cm^2) which seems to work.

He also has a calculator, that I have not yet downloaded and tried.

Craig

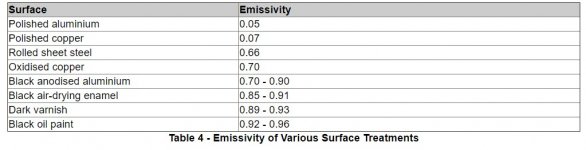

This is the table of emissivity from that link which is the part that is improved with the colour.

I have tried the calculator before and it works very well. I use it for Ebay cases where there is never going to be a reliable value for the heatsink from the vendor.

https://sound-au.com/heatsink.zip

Attachments

This is the table of emissivity from that link which is the part that is improved with the colour.

Right. Black anodized aluminum: 0.70-0.90. Then here and here it's simply listed as "anodized aluminum: 0.85" with no mention of colour.

By contrast, extruded aluminum and untreated aluminum sheet has a relative emissivity of 0.09.

Also, Gabrian mentions the advantages of anodization:

And expands further:

- Improved Corrosion Resistance

- Improved Wear Resistance

- Increased Electrical Isolation

- Improved Surface Emissivity

The microscopic texturing is from the anodizing process itself. The colour is just a dye that's introduced to the anodization soup. While the emissivity does depend some on the colour, it seems to be a rater weak function.Emissivity improves as a result of its microscopic texturing and increased surface area.

The next thing to consider is whether you're using forced air or convection cooling. As these guys determine, only ~5% of the heat is radiated away in a forced air application. The rest is carried by convection. Thus, in a forced air application, the colour of the heat sink is utterly irrelevant. I would further argue that whether the heat sink is even anodized is only marginally important in a forced air application as well.

For natural convection cooling (which is what most of us do in audio as we don't like noisy fans, or any fans really) the game changes. For natural convection, about 30% of the heat is radiated. In that case, you definitely want the heat sink to be anodized. You probably also want it black ... or you can just make it a few percent larger in surface area.

Tom

I was trying to point to the emissivity being the improvement but made it sound like it was directly due to the colour which is not what the table shows. The change from polished copper to oxidised copper shows the big change clearly, 0.07 to 0.7.

Black paint being better than black dye would seem to be for the same reason an increase in surface area from the texture of the paint.

A black anodized heatsink happens to look nice so it seems a good choice all round

Black paint being better than black dye would seem to be for the same reason an increase in surface area from the texture of the paint.

A black anodized heatsink happens to look nice so it seems a good choice all round

Only drawback of paint is that it forms an insulating layer, hence, reduces convection. As Elliott points out, if you do paint, keep the coat as light as possible.Black paint being better than black dye would seem to be for the same reason an increase in surface area from the texture of the paint.

Tom

For natural convection cooling (which is what most of us do in audio as we don't like noisy fans, or any fans really) the game changes. For natural convection, about 30% of the heat is radiated. In that case, you definitely want the heat sink to be anodized. You probably also want it black ... or you can just make it a few percent larger in surface area.

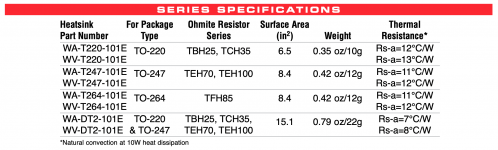

Does this mean that WV-T247-101E should be avoided for the Power-686? I've already got them soldered on the board - I guess i could pull them and try to get the black versions from the EU.

edit: digikey has them in stock.

Last edited:

There's hardly any difference between the black anodized and the natural aluminum. The first page of the data sheet gives the thermal resistance for the two types.

If the black heat sink is available when you build the board, get that. But if it isn't, get the degreased natural aluminum one. There's certainly no need to swap them out now that you have them on the board already.

Tom

If the black heat sink is available when you build the board, get that. But if it isn't, get the degreased natural aluminum one. There's certainly no need to swap them out now that you have them on the board already.

Tom

Attachments

OK - I ran some calculations. This is based on a 1986 paper that covered various passive convection cooling scenarios for finned heatsinks with vertical fins. It involves things like Reynolds and Knusselt numbers and the thermal properties of air.

Without going through the gory details, a heatsink 0.18m x 0.12m with fins along the short length a typical 24mm high. Ambient 30C, heatsink temperature 80C (so an increase in temperature of 50C).

That works out at an optimum number of fins of 15, spaced by 7.45mm.

The power dissipated purely by convection is 32W, or a thermal resistance of 50/32 = 1.56C/W

Doing a Stefan/Boltzmann on this heatsink if it were black anodized suggests that it will thermally radiate a further 11W, giving a total power of 32 +11 = 43W and a thermal resistance of 50/43 = 1.16C/W

So for a convection cooled (as opposed to fan cooled) anodized heatsink, 74% of the power is from convection and 26% from radiation.

Craig

Without going through the gory details, a heatsink 0.18m x 0.12m with fins along the short length a typical 24mm high. Ambient 30C, heatsink temperature 80C (so an increase in temperature of 50C).

That works out at an optimum number of fins of 15, spaced by 7.45mm.

The power dissipated purely by convection is 32W, or a thermal resistance of 50/32 = 1.56C/W

Doing a Stefan/Boltzmann on this heatsink if it were black anodized suggests that it will thermally radiate a further 11W, giving a total power of 32 +11 = 43W and a thermal resistance of 50/43 = 1.16C/W

So for a convection cooled (as opposed to fan cooled) anodized heatsink, 74% of the power is from convection and 26% from radiation.

Craig

It is more significant than I at first thought. For natural convection, black anodizing contributes 30% via radiation of the total dissipation (for vertical fins) and convection 70%. Almost independent on power dissipation.

For forced air cooling, the heatsink colour is irrelevant, with radiation only contributing about 2%.

The importance of radiation in heat sink design | Heat Sink Calculator-Blog: Focused on Heat Sink Analysis, Design and Optimization

The link in that web page is to a full CFD thermal analysis package you have to pay for.

Craig

- Home

- Vendor's Bazaar

- Modulus-686: 380W (4Ω); 220W (8Ω) Balanced Composite Power Amp with extremely low THD