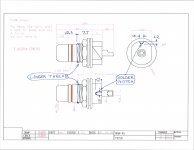

I had 500 pairs of chassis-mount RCA jacks custom manufactured for a project that was cancelled. The markups you see on the mechanical drawing were made by me, and show the customizations.

These jacks are real beauties, sporting pure rhodium plating. I insisted upon longer threads to accommodate a thicker panel, and a body notch to accept a shield conductor directly, eliminating the usual ground lug, which can loosen and compromise the signal path. The bushing is uncolored Teflon, and the connector body has a stripe denoting channel: white for left; red for right. This is far more attractive than coloring the bushing, since Teflon dyed red usually comes out looking pink. These jacks mate in an airtight fashion; you can hear a suction "pop" when you withdraw a plug!

Each RCA jack includes an insulating shoulder washer and an insulating flat washer that, when used, call for a 0.500" mounting hole and accommodate panels up to 0.125" thick. If you mount the RCA jacks without the insulating washers, the required mounting hole diameter drops to 0.390", and panels up to 0.200" thick are accommodated.

The RCA jacks are $11.99 for a pair, comprising one jack with a white stripe, and one jack with a red stripe. Up to fifteen pairs fit into a small, flat-rate Priority Mail box. I am negotiable on Larger quantities. Below is a link to the eBay listing:

Rhodium Plated Teflon Insulated Air Tight RCA Jacks Chassis Socket Connectors | eBay

These jacks are real beauties, sporting pure rhodium plating. I insisted upon longer threads to accommodate a thicker panel, and a body notch to accept a shield conductor directly, eliminating the usual ground lug, which can loosen and compromise the signal path. The bushing is uncolored Teflon, and the connector body has a stripe denoting channel: white for left; red for right. This is far more attractive than coloring the bushing, since Teflon dyed red usually comes out looking pink. These jacks mate in an airtight fashion; you can hear a suction "pop" when you withdraw a plug!

Each RCA jack includes an insulating shoulder washer and an insulating flat washer that, when used, call for a 0.500" mounting hole and accommodate panels up to 0.125" thick. If you mount the RCA jacks without the insulating washers, the required mounting hole diameter drops to 0.390", and panels up to 0.200" thick are accommodated.

The RCA jacks are $11.99 for a pair, comprising one jack with a white stripe, and one jack with a red stripe. Up to fifteen pairs fit into a small, flat-rate Priority Mail box. I am negotiable on Larger quantities. Below is a link to the eBay listing:

Rhodium Plated Teflon Insulated Air Tight RCA Jacks Chassis Socket Connectors | eBay

Attachments

Last edited by a moderator:

I used one for a monoblock and made the hex nut pretty tight. I would have expected the thread to strip if there were a hardness issue with copper. Brass and copper score similarly on the mohs hardness scale, as shown on the web pages linked below:

Metals Mohs Scale of Hardness! Gold, Silver, Platinum, Titanium, Tungsten Hardness and Durability! Mohs Scale! - Jewelry-Secrets.com

Material Hardness Tables, Ted Pella, Inc.

10 Hardest Metals | eHow.com

Metals Mohs Scale of Hardness! Gold, Silver, Platinum, Titanium, Tungsten Hardness and Durability! Mohs Scale! - Jewelry-Secrets.com

Material Hardness Tables, Ted Pella, Inc.

10 Hardest Metals | eHow.com

They do look nice, but it seems back-to-front to have the thread and nut visible on the outside

Bolt outside the chassis is my preferred arrangement.

dave

USPS web site says that a small flat rate box costs $16.95 to send to Australia. Adjusting for PayPal fees brings that to $17.75. Six pairs is $71.94, so the grand total would be $89.69. This assumes that there is no issue with sending merchandise to Australia, such as customs.

The presence of customs between myself and the buyer poses potential problems that might unfairly reflect upon me, the seller. As eBay puts it, "Make sure all your international listings include a clear message to buyers about their responsibility for customs fees. If you include this message, eBay will remove negative or neutral Feedback given on those listings due to customs delays or fees. Please make sure you read and follow the requirements for this message so that you are fully protected. Represent the value of the item (closing price) accurately on customs forms. And don't mark an international item as a gift on customs forms. It's against the law."

There is no way for me to know how every destination country would handle U.S. goods, e.g., whether they would delay/stop a package, whether they would charge duties, or the cost of duties. I would ask any potential international buyer to look into this with respect to his/her country of residence. If the buyer still wished to complete a transaction, I would send a PayPal invoice directly to their email address. Such a transaction is not prohibited by eBay, as the buyer found the seller via DIY Audio. eBay policy reads, "We don't allow our members to use eBay to contact each other to make offers to buy or sell items outside of eBay. Also, members can't use information obtained from eBay to contact each other about buying or selling outside of eBay."

There is no way for me to know how every destination country would handle U.S. goods, e.g., whether they would delay/stop a package, whether they would charge duties, or the cost of duties. I would ask any potential international buyer to look into this with respect to his/her country of residence. If the buyer still wished to complete a transaction, I would send a PayPal invoice directly to their email address. Such a transaction is not prohibited by eBay, as the buyer found the seller via DIY Audio. eBay policy reads, "We don't allow our members to use eBay to contact each other to make offers to buy or sell items outside of eBay. Also, members can't use information obtained from eBay to contact each other about buying or selling outside of eBay."

Last edited:

Good question. Yes, and that is one of the advantages of these connectors. With more conventional RCA sockets, the ground is reliant upon the torque of the mounting hardware and the cleanliness of the solder lug. By using a body notch instead, a non-soldered interface is eliminated from the signal path.

A member recently posted a query about the mounting nut being positioned outside of the chassis. The external mounting nut is what makes the body notch possible, because during assembly, the connector body does not have to be passed through the mounting hole, which would be obstructed by the solder joint.

A member recently posted a query about the mounting nut being positioned outside of the chassis. The external mounting nut is what makes the body notch possible, because during assembly, the connector body does not have to be passed through the mounting hole, which would be obstructed by the solder joint.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Vendor's Bazaar

- Rhodium Plated RCA Jacks