Pair 3.5kOhms Single Ended Output Transformers

This is a one-off, exquisite pair of output transformers proposed for Single Ended Tube amplifier (SET). Most likely you have never come across such a product and chances are that you will never see anything like this. It is a truly unique product for the real SET aficionado. It is the ideal pair for those who seek for the absolute best and do not like compromises.

I have been involved in a truly monstrous power amplifier project during the last months and there has been a quad of iron C transformer core pieces that were finally not used, so I decided to wind a pair of one-of-a-kind output transformers. I wanted to manufacture something truly unique and push the limits of what’s possible, as much as I could. These are nominally specified as 8 Watts RMS, 3.5kOhms OPTs but there is more room available to be used as 2.5kOhms or even 6kOhms OPTs without the slightest deterioration of their performance. They were designed around the idea to be used as OPTs for SET amps equipped with the most popular output tube 300B, or any other tube with similar load characteristics, like 2A3 or PX25.

Nominal power output is specified at 8 Watts but due to design considerations, this is a very controversial product. As you might already know, the main compromise related to Single Ended Tube amplification is reproduction of low frequencies. The deeper you go in low frequency reproduction, the size of iron pieces become larger. You often come in front of small-sized transformers specified as e.g. 20W OPTs (a rather big amount of SET power), but it is not possible to use such transformers in order to achieve High Fidelity sound reproduction of low frequencies. In order to reproduce the deeper registers of a grand piano or a double bass through a Single Ended Tube amplifier, you must invest a lot in large transformer cores; in real world, unfortunately it is not possible to deviate from this path!

This unique pair of OPTs is designed around the principle of using very big iron C core pieces. They are of course Double C Core transformers that could otherwise be easily specified as 20W OPTs, but for this application they are specified as 8W. The main difference is that each primary coil consists of an unusually large amount of turns, so through these OPTs you can easily achieve perfect sound reproduction at full power down to 20 Hz or even lower! The iron core pieces and the primary coils are oversized for perfect linearity down to subsonics, where other transformers are not able to provide the nominal power even at 40 Hz! The difference in sound quality, not only in lower registers but in the whole spectrum of sound is astonishing!

The coil formers are mare of carton paper, precisely cut at a CNC laser jet machine, there is no plastic piece anywhere in the former structure. Insulating material between coil layers is only natural handmade unbleached Japanese calligraphy paper, carefully selected among 5 different grades of comparable paper types, with high impact in sound quality. Even the tape connecting the hand cut paper rolls is made of paper! Everything has been intentionally left un-varnished (varnish takes something out of the magic due to dampening effects). Magnet wire has been carefully selected among at least 4 types and of course the best has been used. Banding straps are of course totally non magnetic, and do not affect the unique properties of the core pieces. Non-magnetic mounting material has intentionally been avoided; it is even non-metallic! As you see, mounting plates are made of CNC laser jet cut Baltic birch plywood for best sound and least interaction with coils and cores.

The most unique feature of these output transformers is the adjustable gap inside the magnetic circuit. The transformers are originally supplied with 0.30mm magnetic gap thickness but the user has the flexibility to fine tune the gap thickness to his specifications, needs or preferences up to 50 microns of precision! Nominal power output has been specified at 8 Watts RMS, a typical spec of 300B power tube, but there is more room available. The minimum frequency where the core is able to perform at its full power without the slightest distortion is 17.5 Hz. Although the specified magnetic core material can easily reach 16.000 – 17.000 Gauss before severe saturation starts to appear, full power output at 17.5 Hz does not drive the core beyond 13.600 Gauss at a hundred percent of linearity! That means you can drive a 300B output tube to its absolute power limits, at a frequency well below the minimum threshold of human hearing at 20 Hz, without the slightest saturation effect of the magnetic material, as on the B-H chart of the specified material, saturation starts to develop above 14.000-14.500 Gauss! I feel very doubtful whether such an OPT has ever been designed and manufactured or not… For power aficionados, this design gives the flexibility to surpass the above-mentioned specifications and always stay in full linearity on the B-H curve. For the experienced DIYer, all these can be easily identified due to the relatively large size of the cores in use! And with proper magnetic gap thickness adjustment or fine tuning, you are able to push the performance towards maximum power output at lowest frequencies or towards maximum primary coil inductance/high effective magnetic permeability for more finesse, tonal colors, and low level detail. The banding straps are secured onto the magnetic cores by means of a screw, so the user is able to take it out, completely dismantle the cores, fine tune the gap very easily and then band the cores again.

The secondary coil is extremely complicated, with 32 leads coming out of each coil former. Through proper arrangement the user is able to match every loudspeaker available. There are no output taps and under each scheme all secondary output leads must be connected in order to achieve best power transmission and linear response in high frequencies. Under specified 3.5kOhms of primary impedance, proper arrangements exist for loudspeakers having a nominal impedance of 4, 6, 8, 16, 20 and 24 ohms. Due to the large amount of primary coil turns and unusually large iron cores, the user can select a different load/loudspeaker connection scheme

Specifications:

- Core type: Double C Core

- Material: Cold Rolled Grain Oriented silicon steel cores at 0.1mm ribbon thickness

- Size: More than 10 square centimeters of cross-sectional area

- Nominal power output is rated at 8 Watts RMS at 17.5Hz and maximum peak magnetic flux density at 13.600 Gauss. Considering 25Hz of lowest undistorted frequency reproduction capability and at 14.500 Gauss of maximum peak magnetic flux density, these cores can deliver more than 18 Watts of undistorted Single Ended Triode power output at the nominal load of 3.5kOhms!

- Primary DC resistance is 105 Ohms

- Maximum suggested anode current is specified at 200mA for continuous and safe operation

- Cores are unvarnished, with adjustable magnetic gaps for ideal use under a drastically different load/power output/loudspeaker combination than the nominally specified. With the supplied paper pieces the user can fine tune the gap from 0.1 up to 0.9mm with a precision of 50 microns (0.05mm)!

- Dimensions fully assembled: 126mm(W) x 137mm(H) x 99mm(D) including supplied mounting structure

- Frequency response with the transformers fully loaded, without DC bias:

- Below 10Hz – 60kHz (-1dB)

- Below 10Hz – 95kHz (-3dB)

http://www.excelsioraudio.com/classifieds/35kopt/text.htm

Have a nice day!

Attachments

-

P0001.jpg138.2 KB · Views: 858

P0001.jpg138.2 KB · Views: 858 -

P0022_10kHz_sq.jpg167.1 KB · Views: 265

P0022_10kHz_sq.jpg167.1 KB · Views: 265 -

P0021_1kHz_sq.jpg162.2 KB · Views: 325

P0021_1kHz_sq.jpg162.2 KB · Views: 325 -

P0018.jpg160.9 KB · Views: 310

P0018.jpg160.9 KB · Views: 310 -

P0017.jpg125.7 KB · Views: 320

P0017.jpg125.7 KB · Views: 320 -

P0016.jpg167.6 KB · Views: 319

P0016.jpg167.6 KB · Views: 319 -

P0014.jpg138 KB · Views: 814

P0014.jpg138 KB · Views: 814 -

P0005.jpg96.9 KB · Views: 811

P0005.jpg96.9 KB · Views: 811 -

P0004.jpg148.1 KB · Views: 819

P0004.jpg148.1 KB · Views: 819 -

P0003.jpg141.3 KB · Views: 825

P0003.jpg141.3 KB · Views: 825

All very impressive except for the all paper insulation and lack of any vacuum impregnation to seal against moisture. Paper is quite hygroscopic regardless of what fancy name it has. How long to you think they will last in a real world atmosphere before the ever present humidity and oxygen does their dirty work on them? And you live on an island surounded by water with humid sea breezes. Hermetically sealing them in a steel box would help. Enjoy them while they last.

Last edited:

I had drawn up something similar by using a 'standard' E I core with an adjustment for gapping...A micrometer type rigging/frame. I'm glad someone decided to try such .

More than likely one would need to "re-tune" such an OPT.

_______________________________________________________Rick.........

More than likely one would need to "re-tune" such an OPT.

_______________________________________________________Rick.........

Hi!

I have wound some very high voltage OPTs. The one that currently runs on the bench lies there for more than a year. B+ is around 1450 volts, paper only insulation without any impregnation. Insulation is adequate for normal indoor use, more than enough. If you plan to use them in the garden under the rain, this is a totally different story.

Thank you for your comments.

Peter

I have wound some very high voltage OPTs. The one that currently runs on the bench lies there for more than a year. B+ is around 1450 volts, paper only insulation without any impregnation. Insulation is adequate for normal indoor use, more than enough. If you plan to use them in the garden under the rain, this is a totally different story.

Thank you for your comments.

Peter

Hi Peter,I have wound some very high voltage OPTs. The one that currently runs on the bench lies there for more than a year.

A year or two is nothing in the life of a transformer. It is still in it's infancy. Twenty or thirty years will be more telling. I know that everything one does in OPT design is a compromise having studying them and been there, even if not immediately obvious. So you have opted for (subjective) sonics over long term durability. Paper has a poor dielectric absorption figure compaired to even the most common (cheapest) plastic. And left unprotected, it will only degrade. And yea, plastic is not forever either, but it lasts longer then paper, and might even sound better. Subjectively of course. Still, yours is an interesting and noteworthy design. Hey, I've got several of those Chinese scissors too.

Last edited:

Hello there! Thanks for yourfeedback.

Those transformers have been designed towards the perspective of performance maximization AND reliability in long term, both at the same time. Not towards compromise direction. Best iron cores, best dielectrics, best coil arrangement, best performance. All this unfortunately comes at a cost, but that's what my friend requested for his amplifier.

Hollowstate, I do not know anything about your experience in coil winding for critical applications. For your information, modern magnet wires have absolutely nothing in common with wires of the 50's or 60's. Dielectric strength is magnitudes of order higher and insulation layering on the wire's surface is almost perfect nowadays. During the 50's or 60's this was the main problem and as a result the reliability was inferior.

E.g. those days it was almost impossible to wind a bifilar/multifilar transformer and have a good reliability, nowadays everybody winds multifilar transformers and there is almost 0% failure!

Your fear of reliability issues are no more relevant, at least to this degree. If you leave the trannies performing outdoors, in the garden, under the rain, it is certain that you will need extra protection. In this case the best way is to wrap them with many turns of cotton tape and apply hot wax allover. This way the transformer will be 100% protected from outside and at the same time will not suffer from high humidity. And all this without the slightest sound deterioration. By the time the varnish enters inside the coils, you can simply say bye bye to the sound those trannies deliver.

Under any case, your notice regarding reliability is interesting and noteworthy because all the people here in DIYaudio.com should get informed a little bit more for all this.

When this project started, I had evaluated may types of insulating material. Except the coil formers, the primary to secondary insulating material plays a very critical role in sound performance. As soon as a simple cap of say 0.1uF has so high impact in sound quality, could you imagine the impact that the dielectric material has on an OPT? Mylar was the worse, paper with natural fibers is miles better. There also exists waxed paper which theoretically add some more protection, but this is not needed in this special design.

If you feed doubtful, do a simple experiment. Take 2 wire bobbins of new ***modern*** magnet wire, of newest production and wind a bifilar transformer. Leave it there on the AC mains for as long as you can and you will see that insulation fears are no more an issue. Trust me! I have done it already. And for your information, the most "dangerous" transformer of all is the filament transformer for rectifiers heating. Those are exposed both in very high DC and maximum AC ripple, both at the same time. I did a test a year ago, winding such a transformer with no insulating material at all. OK, this is insane, but was done only as an experiment. The transformer lasted until I dismantled it in pieces!

Thanks for your notice.

Take care.

Regards,

Peter

Those transformers have been designed towards the perspective of performance maximization AND reliability in long term, both at the same time. Not towards compromise direction. Best iron cores, best dielectrics, best coil arrangement, best performance. All this unfortunately comes at a cost, but that's what my friend requested for his amplifier.

Hollowstate, I do not know anything about your experience in coil winding for critical applications. For your information, modern magnet wires have absolutely nothing in common with wires of the 50's or 60's. Dielectric strength is magnitudes of order higher and insulation layering on the wire's surface is almost perfect nowadays. During the 50's or 60's this was the main problem and as a result the reliability was inferior.

E.g. those days it was almost impossible to wind a bifilar/multifilar transformer and have a good reliability, nowadays everybody winds multifilar transformers and there is almost 0% failure!

Your fear of reliability issues are no more relevant, at least to this degree. If you leave the trannies performing outdoors, in the garden, under the rain, it is certain that you will need extra protection. In this case the best way is to wrap them with many turns of cotton tape and apply hot wax allover. This way the transformer will be 100% protected from outside and at the same time will not suffer from high humidity. And all this without the slightest sound deterioration. By the time the varnish enters inside the coils, you can simply say bye bye to the sound those trannies deliver.

Under any case, your notice regarding reliability is interesting and noteworthy because all the people here in DIYaudio.com should get informed a little bit more for all this.

When this project started, I had evaluated may types of insulating material. Except the coil formers, the primary to secondary insulating material plays a very critical role in sound performance. As soon as a simple cap of say 0.1uF has so high impact in sound quality, could you imagine the impact that the dielectric material has on an OPT? Mylar was the worse, paper with natural fibers is miles better. There also exists waxed paper which theoretically add some more protection, but this is not needed in this special design.

If you feed doubtful, do a simple experiment. Take 2 wire bobbins of new ***modern*** magnet wire, of newest production and wind a bifilar transformer. Leave it there on the AC mains for as long as you can and you will see that insulation fears are no more an issue. Trust me! I have done it already. And for your information, the most "dangerous" transformer of all is the filament transformer for rectifiers heating. Those are exposed both in very high DC and maximum AC ripple, both at the same time. I did a test a year ago, winding such a transformer with no insulating material at all. OK, this is insane, but was done only as an experiment. The transformer lasted until I dismantled it in pieces!

Thanks for your notice.

Take care.

Regards,

Peter

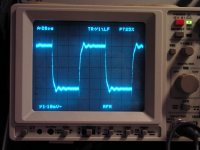

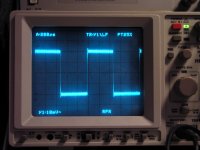

Nice response waveforms.

Can you show us a 100Hz square wave?

This is square wave response WITHOUT DC BIAS!

Keep in mind that under DC bias, the magnetic permeability is raised at a factor of 2-2.5 depending on biasing and magnetic circuit gap. So this graph is of no use. But if you are experienced in OPT graphs without DC biasing, this might tell you something.

Take care.

Peter

Attachments

Hi!Core type: Double C Core

Material: Cold Rolled Grain Oriented silicon steel cores at 0.1mm ribbon thickness

Could you tell me where an I buy such a C Core material?

Greets:

Tyimo

The difference is the oil which acts as an insulator. It has a higher breakdown voltage than the paper or air.but you can use paper in oil caps with high voltage ? whats the difference ?

A comment on bifilar magnet wire windings for mains use... CSA will not approve them for 240V use, though UL will. I tested a product for line surges (2KV) which failed repeatedly due to breakdown between the two bifilar primaries, connected in series. It proved necessary to add an MOV (Metal Oxide Varistor) to protect this transformer. Other transformers with layer insulation between the dual primaries had no problem with the 2KV surge test. Some switch-mode transformers use triple-insulated magnet wire which would be another story... but it's too expensive for use in mains transformers.

This is square wave response WITHOUT DC BIAS!

Keep in mind that under DC bias, the magnetic permeability is raised at a factor of 2-2.5 depending on biasing and magnetic circuit gap. So this graph is of no use. But if you are experienced in OPT graphs without DC biasing, this might tell you something.

Take care.

Peter

I have seen this said before but I have never been able to see it in practice except when the applied DC shrinks the physical gap.

dave

Hi Petavgeris!

I have only 0.25-0.3mm lamination.

greets:

Tyimo

Could you tell me where can I buy such a C Core material?Core type: Double C Core

Material: Cold Rolled Grain Oriented silicon steel cores at 0.1mm ribbon thickness

I have only 0.25-0.3mm lamination.

greets:

Tyimo

Hello to Hungary!

Are you living in Budapest?

If so, all I can tell you is that it's the place with the most gorgeous women I have ever seen in my life. You're really lucky living in this place

Regarding the cores, 0.1mm is not so easy to find. Ask your vendor for 0.23-0.30mm, most likely he has also 0.1mm, even in special order only.

Personally I can find even 0.05mm but it is very hard to acquire in smaller quantities. India and Chine are the best place to search.

Have a nice day.

PS: personally I buy my own ones as a special order to a factory in far east, they are willing to manufacture them for me because I have had a very good cooperation in the past and they now help me to survive because here in Greece everything dies. They do not manufacture 0.1mm cores but only as a special order 1-2 times per year.

Are you living in Budapest?

If so, all I can tell you is that it's the place with the most gorgeous women I have ever seen in my life. You're really lucky living in this place

Regarding the cores, 0.1mm is not so easy to find. Ask your vendor for 0.23-0.30mm, most likely he has also 0.1mm, even in special order only.

Personally I can find even 0.05mm but it is very hard to acquire in smaller quantities. India and Chine are the best place to search.

Have a nice day.

PS: personally I buy my own ones as a special order to a factory in far east, they are willing to manufacture them for me because I have had a very good cooperation in the past and they now help me to survive because here in Greece everything dies. They do not manufacture 0.1mm cores but only as a special order 1-2 times per year.

Could you compare the sound of these transformer to any others you have used?

Greetings to Chicago!

Thanks for your message.

I will write you in more detail and will try to be focused in details as much as I can.

These cores are practically left-overs of a huge project that is now under completion. Next week I will post some pictures for all of you. These were proposed for transformer volume control (TVC) but we decided that this will be placed externally, not inside the mono amps but at an earlier degree, like a passive preamp.

There are many aspects that contribute to the sound that these trannies are able to give. This is the angle from which they must be observed. They are not a commercial product, made by a company which makes is living out of selling transformers, it is not possible to establish a company and live by selling them, their cost would be sky-high. They are made with only one scope in mind: to give something extraordinarily good, something that is not possible to acquire even on a special order but only if paying many thousands of dollars. They are made to give out the best that can be done, without the slightest compromise that deteriorates their sound.

The structure of the secondary is incredibly complex, remember, they are 32 leads coming out of each of the formers! Manufacture is very painful and costly, so the expectations are not only high, but the absolutely highest possible.

So let's come to their sound, after this small introduction...

They do not give out this lush, lazy and uninvolving sound that many people here mistakingly seek for. They are extremely transparent, dynamic, incredibly immediate, with razor-sharp detail & focus. All things shrink to their original dimensions, with more defined focus and boundaries and at the same time ambient becomes larger, more air and depth. Both at the same time! You will notice a unique layering of things in space, never listened before and at the same time incredibly defined distances between each layer.

I have listened to practically all OPTs from commercial vendors. Needless to write that nothing comes close. Absolutely nothing. I have also listened to several DIY transformers, most of them surpass the level of performance of commercial products. These were the benchmark against which the comparisons were done. There are several things here that are met for first time. One is the incredibly high number of primary turns for such a design, this way you can lower the magnetic gap and achieve very high primary inductance, which leads to very high effective permeability of iron core, which leads to all the goods found on earth, and at the same time you can have a lot of power available, something that is not met with permalloy cores. Permalloy behaves very nicely (not necessarily better) but only in a very small margin of core excitation, outside of which sound is far worse than what those transformers provide. The second is the p-s insulation, it is so unique with so subjectively unique sound that is hard to believe. There are resons for this kind of performance but it is outside of the scope of this article.

Other aspects contribute to their level of performance as well. There are no ferromagnetic pieces around, except the corner feet, which can be replaced easily (they are far away from the core anyway...). Banding strap is of highest quality feasible, mounting brackets are made of CNC cut baltic birch plywood and last, there is intentionally no cover at all. I can manufacture two nicely looking covers out of wood or corian but any metallic material is intentionally avoided.

Apart from what described, overall, you get more tonal colors, more inner detail, more finesse and texture portrayal, complexity, dynamics and immediacy never listened before. The end result is to get closer to the performance, feeling the thrill and excitement of the recorded event like never before. All these come as expression of their specifications and not as a result of any snake oil or magic filter. I have studied mechanical engineering and have a working experience of 16 years in the field of magnetics/electronagnetism. I am not making my living out of this, although I am handling several Hi Fi projects right now.

I just wanted to show what can be made if you raise the bar of performance and characteristics as much as possible, outside of any commercial point of view. Here only absolutely highest quality matters and this is the point of view that those transformers must be observed from.

Thank you for reading through.

Regards,

Peter

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Vendor's Bazaar

- Most exotic 3.5kOhms Output Transformers