Hi Folks,

This topic has come up quite a few times. Yesterday and today a few of your folks brought it up again anew.

Some people like the idea of using the miniature coaxial RF connectors such as for board to board signal connections - especially for very high speed signals such as master clocks etc. I don't necessarily see any reason to disagree with them.

For example: IPX, UMCC, U.FL and a few others that are for the most part compatible are popular choices.

These shielded coaxial connectors/cables are designed for very high bandwidth applications and (importantly) 50-ohm termination. One typical use is for WiFi connections from modules to antennae in notebook computers etc. This makes perfect sense, but the 50-Ohm termination is pretty critical in achieving this kind of bandwidth. Without that 50-ohm termination you will not achieve anything like the maximum bandwidth. The intended use is definitely not TTL level signals from all that I have read, but I could be wrong here so if someone knows where a manufacturer says otherwise I would really appreciate a link.

Still - I truly think it quite likely that even with TTL level signals and higher impedance loads those connectors will definitely still work just fine. It is just you will get the typical coax reflections common with impedance mismatches. I personally have tried them a couple of years back, but I found that there were some practical DIY considerations for not relying on them solely for module connectivity. I also personally did not see any improvement at the time. The DAC already measured so well I was not interested in changing anything that could negatively impact that. That said - I also was weighing other factors more related to builder experience and "DIYability".

A couple of those factors:

So I see that some people still want to use them, which quite honestly I think could definitely be worthwhile. In fact I have learned at least one user created a small adapter board for the Buffalo III. This is something I wholeheartedly encourage. This is why it is a DIY module.

So when I checked my email again this morning and had about a half dozen requests that I think about a way to support these connectors ourselves for modules that we produce. Not just for B-III either, but other modules as well.

I am open to the idea, but I want to get a feel for how you folks as users feel about the idea, and try to come up with a good strategy for supporting this style of connection.

My thinking is that modules should be flexible. If a builder wants to use mini coax I would like to support it, but not at the expense of other forms of connection. In other words I don't want that to be the only choice.

With that in mind - I have a few potential lines of action I would like to discuss.

I would really like to get some community feedback on how to proceed and if you all even think it worthwhile to consider at this point.

I personally think it is a good idea to support it - as long as it is completely optional. In some cases the shielding factor alone could improve build results. Especially when you need to be creative with module location.

I am listening.

Let the public discussion begin! Please respond with your thoughts and opinions on my proposals.

Cheers!

Russ

This topic has come up quite a few times. Yesterday and today a few of your folks brought it up again anew.

Some people like the idea of using the miniature coaxial RF connectors such as for board to board signal connections - especially for very high speed signals such as master clocks etc. I don't necessarily see any reason to disagree with them.

For example: IPX, UMCC, U.FL and a few others that are for the most part compatible are popular choices.

These shielded coaxial connectors/cables are designed for very high bandwidth applications and (importantly) 50-ohm termination. One typical use is for WiFi connections from modules to antennae in notebook computers etc. This makes perfect sense, but the 50-Ohm termination is pretty critical in achieving this kind of bandwidth. Without that 50-ohm termination you will not achieve anything like the maximum bandwidth. The intended use is definitely not TTL level signals from all that I have read, but I could be wrong here so if someone knows where a manufacturer says otherwise I would really appreciate a link.

Still - I truly think it quite likely that even with TTL level signals and higher impedance loads those connectors will definitely still work just fine. It is just you will get the typical coax reflections common with impedance mismatches. I personally have tried them a couple of years back, but I found that there were some practical DIY considerations for not relying on them solely for module connectivity. I also personally did not see any improvement at the time. The DAC already measured so well I was not interested in changing anything that could negatively impact that. That said - I also was weighing other factors more related to builder experience and "DIYability".

A couple of those factors:

- First there is a lot less flexibility in wiring options - with the coax you must use predefined length female cables, or make them yourself which is not trivial.

- Higher cost, for something that not every builder may even want. This can be a very real barrier for people.

- Reliability - the female connectors are not designed for repeated installation and removal which is something DIY folks can do a lot of. They soon (maybe a half dozen cycles) must be replaced if not left in place.

So I see that some people still want to use them, which quite honestly I think could definitely be worthwhile. In fact I have learned at least one user created a small adapter board for the Buffalo III. This is something I wholeheartedly encourage. This is why it is a DIY module.

So when I checked my email again this morning and had about a half dozen requests that I think about a way to support these connectors ourselves for modules that we produce. Not just for B-III either, but other modules as well.

I am open to the idea, but I want to get a feel for how you folks as users feel about the idea, and try to come up with a good strategy for supporting this style of connection.

My thinking is that modules should be flexible. If a builder wants to use mini coax I would like to support it, but not at the expense of other forms of connection. In other words I don't want that to be the only choice.

With that in mind - I have a few potential lines of action I would like to discuss.

- Would you folks be interested in a adapters for various modules? B-II, B-III,Opus, COD, SPDIF MUX, etc... If so we could offer boards very cheaply. Just what it takes to cover costs.

- Would you also like to see optional male connectors on new modules? For example I am thinking of adding them to the USB module and possibly others.

I would really like to get some community feedback on how to proceed and if you all even think it worthwhile to consider at this point.

I personally think it is a good idea to support it - as long as it is completely optional. In some cases the shielding factor alone could improve build results. Especially when you need to be creative with module location.

I am listening.

Let the public discussion begin! Please respond with your thoughts and opinions on my proposals.

Cheers!

Russ

Last edited:

I would use an adapter on my Opus, if you offered one I would buy it.

To be honest I would still prefer to have these connectors onboard as the default option. The expense of the cables is small relative to the rest of the system in the majority of cases and provides sufficient improvement to justify it.

To be honest I would still prefer to have these connectors onboard as the default option. The expense of the cables is small relative to the rest of the system in the majority of cases and provides sufficient improvement to justify it.

Last edited:

u.fl

Russ: I added a u.fl jack to my B-II board for masterclock connection, and ran a 5 cm u.fl cable from my USB interface to the B-II. I prefer the sound with synchronous clocking this way, have had no problems with the u.fl scheme, and conceptually "think" it is a good way to go. I do not have the ability to make any measurements though.

I know diyaudio member "Lorien" made some measurements of standard pin headers carrying high speed clock signals, and did not like what he saw in comparison to u.fl.

I do not suspect that adapters from pin header to u.fl is the answer though, as that just combines two contacts, and will still have the distortions inferent in the pin headers.

I would prefer to see u.fl micro BNCs right on the boards, adapters seem to compromised to me as they just add another connection on each end.

As to the reliability of connection cycles with u.fl, this does not concern me, as replacing the micro BNCs is not too difficult with an iron and a steady hand. Additionally, the expense it is not an issue, as the cables and jacks are just not really expensive in the big picture of putting together a really good DAC based on TPA kits.

So my preference would be for micro BNCs right on the boards (B-III, USB receiver, etc). The u.fls are pretty easy to purchase from Mouser/Digikey, and in many different lengths. For TPA, is would be nice if the micro BNC jacks were positioned (on the boards) such that a good layout would allow for 5 cm u.fl cables.

addendum: actually, maybe adapters could be a good idea as well, if they were designed such that they could (optionally) be soldered in place via very short pins (or bits of solid core wire) instead of plug in via pin headers (or IDC, etc).

Russ: I added a u.fl jack to my B-II board for masterclock connection, and ran a 5 cm u.fl cable from my USB interface to the B-II. I prefer the sound with synchronous clocking this way, have had no problems with the u.fl scheme, and conceptually "think" it is a good way to go. I do not have the ability to make any measurements though.

I know diyaudio member "Lorien" made some measurements of standard pin headers carrying high speed clock signals, and did not like what he saw in comparison to u.fl.

I do not suspect that adapters from pin header to u.fl is the answer though, as that just combines two contacts, and will still have the distortions inferent in the pin headers.

I would prefer to see u.fl micro BNCs right on the boards, adapters seem to compromised to me as they just add another connection on each end.

As to the reliability of connection cycles with u.fl, this does not concern me, as replacing the micro BNCs is not too difficult with an iron and a steady hand. Additionally, the expense it is not an issue, as the cables and jacks are just not really expensive in the big picture of putting together a really good DAC based on TPA kits.

So my preference would be for micro BNCs right on the boards (B-III, USB receiver, etc). The u.fls are pretty easy to purchase from Mouser/Digikey, and in many different lengths. For TPA, is would be nice if the micro BNC jacks were positioned (on the boards) such that a good layout would allow for 5 cm u.fl cables.

addendum: actually, maybe adapters could be a good idea as well, if they were designed such that they could (optionally) be soldered in place via very short pins (or bits of solid core wire) instead of plug in via pin headers (or IDC, etc).

Last edited:

I do not suspect that adapters from pin header to u.fl is the answer though, as that just combines two contacts, and will still have the distortions inferent in the pin headers.

I would prefer to see u.fl micro BNCs right on the boards, adapters seem to compromised to me as they just add another connection on each end.

As to the reliability of connection cycles with u.fl, this does not concern me, as replacing the micro BNCs is not too difficult with an iron and a steady hand. Additionally, the expense it is not an issue, as the cables and jacks are just not really expensive in the big picture of putting together a really good DAC based on TPA kits.

So my preference would be for micro BNCs right on the boards (B-III, USB receiver, etc). The u.fls are pretty easy to purchase from Mouser/Digikey, and in many different lengths. For TPA, is would be nice if the micro BNC jacks were positioned (on the boards) such that a good layout would allow for 5 cm u.fl cables.

Actually adapters need not be any real compromise at all, because you can directly solder them to the board and very solidly connect the signal just as if it were a trace. There is no interface other than the solder and copper necessary.

This would very effectively mate the adapter the board and the ground plane.

This would be very much equivalent to having it on the board. For those with existing modules it would work very nicely indeed.

Last edited:

Yeah...

Russ, right on! I had just added an addendum to my post as you were posting this. Agreed, I woud love to this for the B-II as well, thanks, looks great to me.

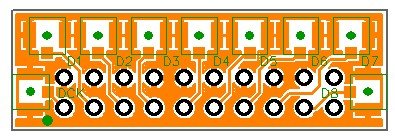

Here is an example I worked up this morning. One could directly solder this to a B3. No header needed at all. It effectively becomes integral to the circuit.

Russ, right on! I had just added an addendum to my post as you were posting this. Agreed, I woud love to this for the B-II as well, thanks, looks great to me.

Those connectors are crap. As you says they are not intended to be used. Once maybe twice - and no more.

As one of my customers who produces cables for a living once said - "it the worst connector ever invented".

That was just my opinion.

I value that opinion.

One user who is also a motherboard engineer for Asus (name omitted to protect the innocent) echoed that thought.

He also stressed that it is important to adhere to the pattern footprint and not have *any* copper directly under the pin section of the male header. Not even the ground plane. In looking at some layouts can see a few designers may have missed that point.

The question would be:

In comparison to what? As mentioned, "Lucien" looked at clock signals I found that u.fl had better signal integrity than a standard pin header, maybe there is something else which would be better than u.fl, but it does appear thta u.fl outperforms standard pin headers for high speed signals...

I value that opinion.

One user who is also a motherboard engineer for Asus (name omitted to protect the innocent) echoed that thought.

He also stressed that it is important to adhere to the pattern footprint and not have *any* copper directly under the pin section of the male header. Not even the ground plane. In looking at some layouts can see a few designers may have missed that point.

In comparison to what? As mentioned, "Lucien" looked at clock signals I found that u.fl had better signal integrity than a standard pin header, maybe there is something else which would be better than u.fl, but it does appear thta u.fl outperforms standard pin headers for high speed signals...

In comparison to what?

barrows, what we are saying is that mechanically it is just not designed to last. So while it is great for what it is designed for its not exactly designed with DIY in mind.

barrows, what we are saying is that mechanically it is just not designed to last. So while it is great for what it is designed for its not exactly designed with DIY in mind.That's all. Still if people are willing to overlook that it is still viable even if it stinks in the mechanical sense.

Understood, and I agree with that. I am willing to replace the jacks, personally, if I end up connecting them a few times, in order to maintain the best possible signal integrity.

Understood, and I agree with that. I am willing to replace the jacks, personally, if I end up connecting them a few times, in order to maintain the best possible signal integrity.

From experience I can say for TTL level signals, its tough to beat a nice short wire directly soldered to a pad.

What impedance the boards were designed with? You can't switch between impedances, you need to stick to whichever impedance you choose.

Could your circuits drive 50ohm transmission line?

I am well aware.

We are talking TTL levels. That is why other than the shielding I see no advantage at all for the coax when terminated for TTL. In fact it *could* (actually this is not in doubt, it is just the degree that I don't know) cause unwanted reflections. It would be cool if someone took a network analyzer and tested such a setup. Unfortunately I don't own one. Maybe one of you folks could do it?

Driving it should not be an issue as far as I know as long as you don't actually terminate the far end at 50ohms, but the reflections are not exactly desirable.

Last edited:

Hey Russ,

Have SMA connectors been suggested? Personally I think these connectors are a bit overkill for TTL, but SMA is only slightly larger and far more robust.

Thanks for mentioning them.

I have looked them over, they do look doable, but more bulky then I would like. I think after you leave room for a wrench you have probably taken up a lot of space.

yup...

This is where the analysis gets interesting, and where someone who has made the relevant measurements could really help out. On reflections, wouldn't these also be apparent on a ribbon cable terminated with an IDC, as TPA presently uses? Consider a 7 cm ribbin cable run terminated into IDC connectors, versus a 7 cm cable run terminated in u.fl (w,fl) at either end, wouldn't reflections present the same problem either way if we have the same source impedance and load impedance in both cases?

I am well aware.This is one reason I was not really excited about the idea originally.

We are talking TTL levels. That is why other than the shielding I see no advantage at all for the coax when terminated for TTL. In fact it *could* (actually this is not in doubt, it is just the degree that I don't know) cause unwanted reflections. It would be cool if someone took a network analyzer and tested such a setup. Unfortunately I don't own one. Maybe one of you folks do?

Driving it should not be an issue as far as I know as long as you don't actually terminate the far end at 50ohms, but the reflections are not exactly desirable.

This is where the analysis gets interesting, and where someone who has made the relevant measurements could really help out. On reflections, wouldn't these also be apparent on a ribbon cable terminated with an IDC, as TPA presently uses? Consider a 7 cm ribbin cable run terminated into IDC connectors, versus a 7 cm cable run terminated in u.fl (w,fl) at either end, wouldn't reflections present the same problem either way if we have the same source impedance and load impedance in both cases?

IDC? As long as your PCB is 100ohm, everything is fine. The connectors themselves are a bit buggy, but they work.

TP's IDCs are sometimes less than transmission lines. For proper impedance control, on which the IDC cable relies, you need to put a GND wire along each signal wire.

Then you get 100ohm impedance. If you boards are at 100ohm impedance and termination is for 110ohm, then everything should be fine from signal integrity standpoint.

Flat cables are poor on EMC thing which is important inside the DAC's case.

TP's IDCs are sometimes less than transmission lines. For proper impedance control, on which the IDC cable relies, you need to put a GND wire along each signal wire.

Then you get 100ohm impedance. If you boards are at 100ohm impedance and termination is for 110ohm, then everything should be fine from signal integrity standpoint.

Flat cables are poor on EMC thing which is important inside the DAC's case.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- More Vendors...

- Twisted Pear

- My thoughts on miniature coaxial RF connectors