mach1 said:AuroraB

And anyone interested in aquiring a cheap and effective PTFE wire stripper - check out this link

http://www.logwell.com/tech/shdwe/teflon_wire.html

The 'stripping woes' section gives a heads up on a really cheap stripper that works very well on PTFE insulated wire.

the IE-180

http://www.imperial-tools.com/tools/electrical_datatools/stripper_05.html

The tool is sold under several brand names, and I can personally attest to its effectiveness. At around US$10 - 12 it's a real no-brainer.

pm

I am using nail clipper on my teflon hook-up wires. works all the time! dual purpose too

I'll have to do some archeology to gig them out, but Allen Wright sent me a small set of weller (IIRC) wire strippers that work really well for teflon and for very thin wire. I've not seen it in any catalog, and may only be available in Europe.

It looks sort of like a metal Karlson slot on a handle with blades at the base of the slot... the width of the 2 blades can be adjusted to the exact diameter of the wire... you slide the wire down the slot until the insulation is cut bythe blade and then you pull the wire out leaving the unwanted insulation behind. Works a charm.

dave

It looks sort of like a metal Karlson slot on a handle with blades at the base of the slot... the width of the 2 blades can be adjusted to the exact diameter of the wire... you slide the wire down the slot until the insulation is cut bythe blade and then you pull the wire out leaving the unwanted insulation behind. Works a charm.

dave

Originally posted by planet10 In an ideal world the signal actually travels in the field around the wire -- not in the wire...

Well, not quite, although I don't know what you mean by "ideal world". The skin depth in copper at 20kHz is about 0.5mm. This means that current density at 0.5mm deep has dropped to 36.8% of the value at the surface. This depth is about the full diameter of 24 AWG wire. I believe that skin depth does indeed matter in audio cable design, but to say that the signal travels only in the field around the wire and not in the wire may be exaggerating a bit, even at 20kHz.

Here’s an excerpt on CAT 6:

“Category 6 standard. Four-pair 100. UTP and ScTP cables are recognized for use in Category 6 backbone cabling systems. The cable shall consist of 22 AWG to 24 AWG thermoplastic insulated solid conductors that are formed into four individually twisted-pairs and enclosed by a thermoplastic jacket. The cable shall meet all of the mechanical requirements of ANSI/ICEA S-80-576 applicable to four-pair inside wiring cable for plenum or general cabling within a building. In addition to the applicable requirements of ANSI/ICEA S-90-661-1994, the physical design of backbone cables shall meet the requirements of clauses 4.4.3.1 to 4.4.3.6 of ANSI/TIA/EIA -568-B.2. NOTE: Additional requirements for 100 ScTP cables are located in annex K of ANSI/TIA/EIA-568-B.2.”

So it can be 22 AWG (backbone runs), 23 AWG or 24 AWG (patch cables), about right for many audio uses. Note that Teflon insulation is not forced.

the problem with multi-strand is that there is another wire right there interfering with the field.

Yes, quite right. Multi-strand will behave somewhere in between the individual strand gauge and the composite gauge as far as skin effect is concerned (usually closer to the latter). Analysis can become quite complex and it all depends on wire lay and whether individual strands are insulated or not (Litz, etc.).

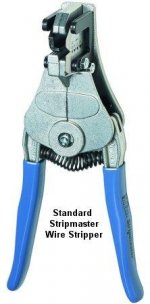

I've had great success stripping Teflon wires with the Ideal stripper shown below. I've used this kind of stripper almost exclusively for years. The dies are precision cut and nicking is minimized. The gripping action of this automated, compound tool makes stripping fast and easy. In the US, they are about $35. I’ve also used a thermal stripper, but new ones are expensive (I got mine surplus) and I don't appreciate the burnt Teflon fumes.

Attachments

Analysis can become quite complex and it all depends on wire lay and whether individual strands are insulated or not (Litz, etc.).

However, it's apparently sufficient to get high speed signals efficiently from one place to another using runs an order of magnitude or two longer than in a stereo system.

SY said:However, it's apparently sufficient to get high speed signals efficiently from one place to another using runs an order of magnitude or two longer than in a stereo system.

Yeah, it's strange that we can pipe several hundred megahertz through hundreds of feet with this stuff, but we worry about 20kHz skin effects.

Brian Beck said:

Yeah, it's strange that we can pipe several hundred megahertz through hundreds of feet with this stuff, but we worry about 20kHz skin effects.

What's that "we" stuff?

AuroraB said:Brian..

Does the standard version of the " Stripmaster" you show, work for teflon??

If so, that's interesting, 'cause the "Stripmaster PTFE" is priced around 200-250$ at this side of the pond, - even a set of new blades is close to 200!

Wow. I'm not familiar with that PTFE model. You made me look at mine again. I have two ancient Ideal Stripmasters that I got surplus (as usual). They both have the 16AWG - 26AWG knife set, which is ideal (ha!) for most uses. I don't believe mine have any special PTFE knife set (the numbers are hard to read under the patina of years of use). I use them for everything from stripping lamp cords to stripping skinny Teflon wires. Probably these would not be approved for US military and aerospace work with Teflon because of the small risk of nicking. In years past, only thermal strippers were used for Teflon for those applications. I don't know what is used today.

I can only tell you that for me, they’ve worked very well with Teflon. I suppose if you put the wire in funny, or it’s kinked a bit, you might nick or lose a strand or two, whether it’s Teflon or PVC. But the die set is oversized so that, if anything, there may be a little bit of Teflon that doesn’t get cut nearest the outer strands, and it sometimes pulls away leaving a little thread of Teflon that you can simply snip away. Usually even that doesn’t happen. This is fine for audio use. My dies are probably worn and more oversized than usual. A new stripper might make cleaner cuts of the Teflon, although I have no complaints about my antique strippers, and I haven’t been motivated to change the replaceable knife sets.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- would twisted pair from a network cable be suitable as hook-up wires inside an amp?