Am well underway to getting this amp built now and am hoping to have it finished within the next few weeks.

I decided on a hammond 260m power transformer which is capable of 250mA to the B+ so should be more than ample for stereo kt88's For the output transformers i decided on james 6123hs and bought a matching james choke. Unfortunately the hammond was part of the "ugly" range of power tx's but hopefully wont look too bad come the end.

For the output transformers i decided on james 6123hs and bought a matching james choke. Unfortunately the hammond was part of the "ugly" range of power tx's but hopefully wont look too bad come the end.

I can thouroughly recommend thlaudio for ordering components, its a bit of a pain ordering but prices, delivery and communication were very good.

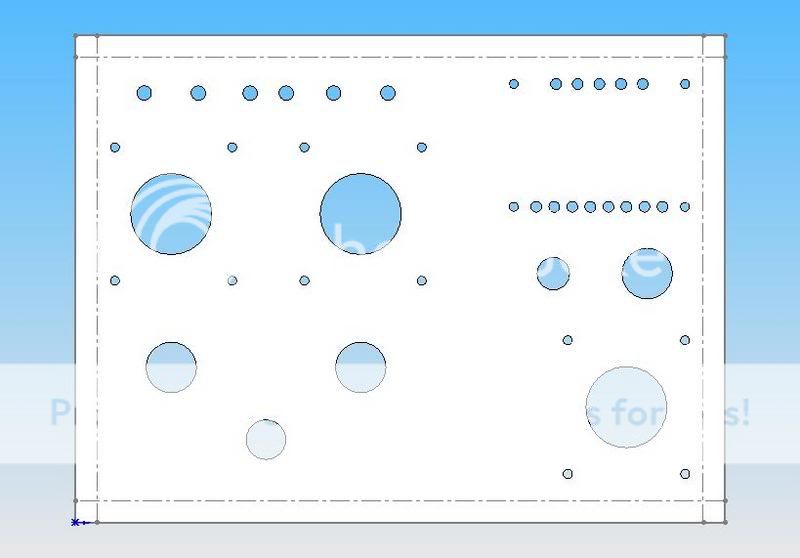

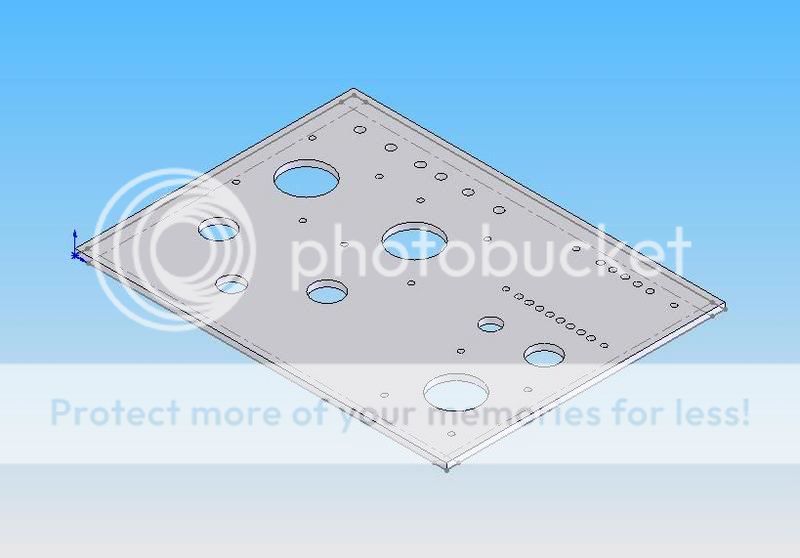

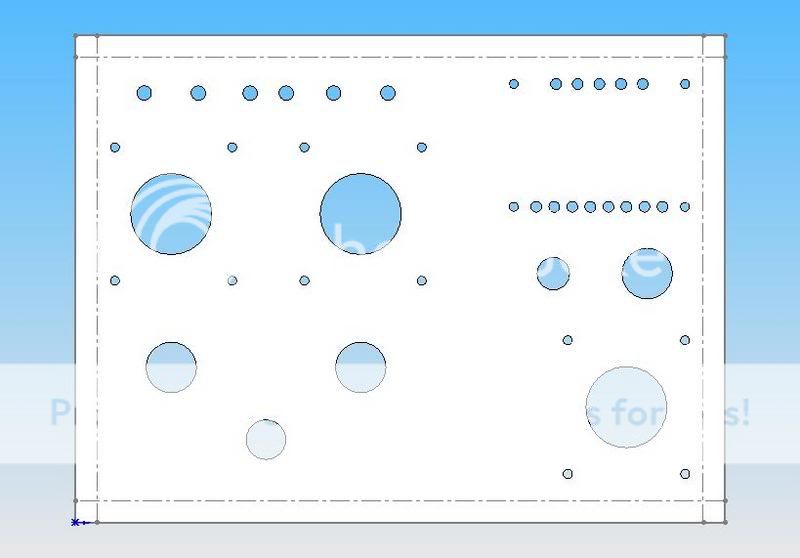

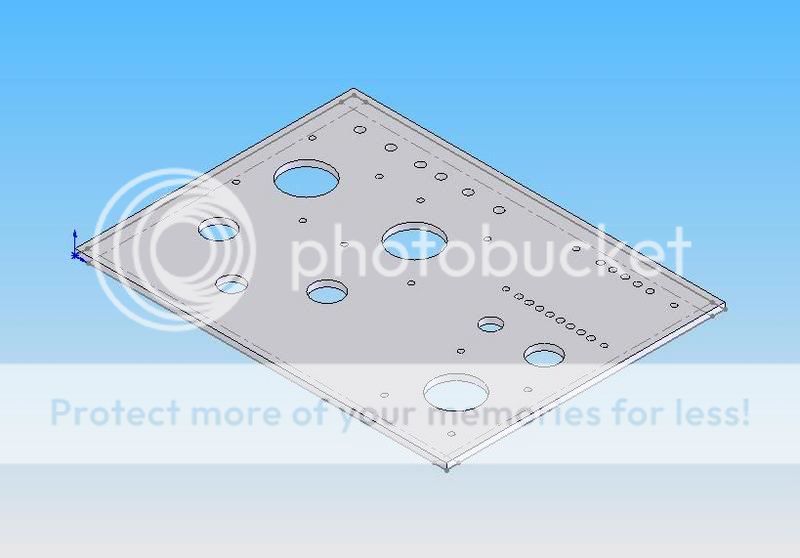

I wanted the top mounting plate made from polished stainless, but i have little patience when it comes to cutting holes into 6mm steel so decided to get the thing laser cut

I drew the plate up in solidworks and then sent it off to be cut, now its back im very happy with the finish, the reflection is absolutely 100% and the reflection of the components can be seen perfectly.

For the base I am going to use a product called avonite, its a kind of fake granity looking resin. With the stainless resting on top of this the look is incredible - will try and find a camera later on today

Now going to start the electronics and get the mounting plate finished off and start assembling

I decided on a hammond 260m power transformer which is capable of 250mA to the B+ so should be more than ample for stereo kt88's

I can thouroughly recommend thlaudio for ordering components, its a bit of a pain ordering but prices, delivery and communication were very good.

I wanted the top mounting plate made from polished stainless, but i have little patience when it comes to cutting holes into 6mm steel so decided to get the thing laser cut

I drew the plate up in solidworks and then sent it off to be cut, now its back im very happy with the finish, the reflection is absolutely 100% and the reflection of the components can be seen perfectly.

For the base I am going to use a product called avonite, its a kind of fake granity looking resin. With the stainless resting on top of this the look is incredible - will try and find a camera later on today

Now going to start the electronics and get the mounting plate finished off and start assembling

Great looking project so far! I heartily approve of your choice of the James OPTs. They are what I used on my monoblocks and they sound great (they look great also).

You should definitely have enough current capability with your PTX as well. I have my KT88s biased at 82mA and the 6N1Ps draw about 8mA (each triode, though I'm using two separate tubes of course due to the monoblock configuration).

I used 1/8" 6061 aluminum for my top plates and found it relatively easy to drill the holes. Stainless is a whole other animal!

I'm looking forward to seeing the finished amp!

You should definitely have enough current capability with your PTX as well. I have my KT88s biased at 82mA and the 6N1Ps draw about 8mA (each triode, though I'm using two separate tubes of course due to the monoblock configuration).

I used 1/8" 6061 aluminum for my top plates and found it relatively easy to drill the holes. Stainless is a whole other animal!

I'm looking forward to seeing the finished amp!

Have just taken some pics, excuse the quality i cant find my proper camera!

Gives you some idea of how it will look, the base isnt made yet but will surround the stainless by about 12mm with the top being flush with it.

The 6n1p looks a little low, thats just cause i couldnt find a box big enough to rest it on

Gives you some idea of how it will look, the base isnt made yet but will surround the stainless by about 12mm with the top being flush with it.

The 6n1p looks a little low, thats just cause i couldnt find a box big enough to rest it on

I like the base! I have a big piece of Corian laying around that I've thought of using as a base. After seeing your mockup I may pull it out and have a go.

For my amps I built a wooden base from maple and walnut dovetailed together. Also with a rebate around the top so the top plate sits flush.

I see you are also going with tube rectification, looks like a 5U4-G? If so be careful of the input cap in the filter, 40uF max in that position. (You may already be aware of this but I had to buy new caps, I had not paid enough attention to the datasheet and originally purchased 60uF for that position. )

)

Also my cheap Chinese 5U4-G tubes arced a bit on power up. No adverse affects that I could see but it was disconcerting so I changed them for Sovteks and the problem went away. I used the Chinese tubes in a lower current, lower voltage, lower value input cap EL84 amp and they have performed well for almost 2 years. Recently I put one in one of the KT88 monoblocks and it worked perfectly, no arcing, just a nice even warmup. Maybe they needed a break-in period?

For my amps I built a wooden base from maple and walnut dovetailed together. Also with a rebate around the top so the top plate sits flush.

I see you are also going with tube rectification, looks like a 5U4-G? If so be careful of the input cap in the filter, 40uF max in that position. (You may already be aware of this but I had to buy new caps, I had not paid enough attention to the datasheet and originally purchased 60uF for that position.

)

)Also my cheap Chinese 5U4-G tubes arced a bit on power up. No adverse affects that I could see but it was disconcerting so I changed them for Sovteks and the problem went away. I used the Chinese tubes in a lower current, lower voltage, lower value input cap EL84 amp and they have performed well for almost 2 years. Recently I put one in one of the KT88 monoblocks and it worked perfectly, no arcing, just a nice even warmup. Maybe they needed a break-in period?

mr.duck said:That mirror finish looks flawless! Where did you have it laser cut and was it expensive?

Im happy with it

Its a shame i cant find the camera, but if you look in the pics it looks equally as bad in the reflection as the real thing

My dad had somebody cut the stainless, i would have though in the region of £100 to have it cut and polished. Much much more if you didnt do the drawings yourself

Finished!

Got my finger out and finished it this afternoon and it worked perfectly first time, didnt blow any fuses!.

Very very happy with both the finish and the sound

Got my finger out and finished it this afternoon and it worked perfectly first time, didnt blow any fuses!.

Very very happy with both the finish and the sound

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Stereo Build - Mikaels KT88