Hello All,

Well, after a month of working and clear coating copper plate I have learned a valuable lesson. Boy, oh boy! sure looks great but aluminium is a lot easier to work. Anyway the wood bases are next. Then I hope all you wonderful folks at diyAudio will help me with all the questions about hooking all the wires together. I attached a pic of the plates because, I need a slap on the back. (back of the head is more like it and feel free)

Well, after a month of working and clear coating copper plate I have learned a valuable lesson. Boy, oh boy! sure looks great but aluminium is a lot easier to work. Anyway the wood bases are next. Then I hope all you wonderful folks at diyAudio will help me with all the questions about hooking all the wires together. I attached a pic of the plates because, I need a slap on the back. (back of the head is more like it and feel free)

Attachments

Brett, Tomatito,

Thanks guys

Milzie,

I cannot testify as to how they sound, yet. Others have built this amp and say it's real good.

They are monoblocks needing a preamp and efficient speakers.

As far as cost, you get what you pay for, it's a "do it yourself" amp and the only limit is how deep are ones pockets? Transformers and chokes were my biggest purchase and the cost goes up from there.

Making mistakes (learning) will add to the cost as I go along, but then it's suppose to be a hobby (obsession?)

Thanks guys

Milzie,

I cannot testify as to how they sound, yet. Others have built this amp and say it's real good.

They are monoblocks needing a preamp and efficient speakers.

As far as cost, you get what you pay for, it's a "do it yourself" amp and the only limit is how deep are ones pockets? Transformers and chokes were my biggest purchase and the cost goes up from there.

Making mistakes (learning) will add to the cost as I go along, but then it's suppose to be a hobby (obsession?)

Thomas

It looks like you are trying to plug a product here. It could be considered to be in bad taste.

maybeim

I for one have to applaud your workmanship on your plates and your amp. Copper is hard to work with but it does show your love and enthusiasm for your project. You could have taken the easy way out and saved time with the T6 6061 Aluminum alloy but you choose the better and your project proves this. There are no free rides and no free lunches. Why settle for fast food take out when with a little more effort a gourmet feast is at hand?

If an award was given based on craftsmanship you would have my vote as your project is stunning.

Joe

It looks like you are trying to plug a product here. It could be considered to be in bad taste.

maybeim

I for one have to applaud your workmanship on your plates and your amp. Copper is hard to work with but it does show your love and enthusiasm for your project. You could have taken the easy way out and saved time with the T6 6061 Aluminum alloy but you choose the better and your project proves this. There are no free rides and no free lunches. Why settle for fast food take out when with a little more effort a gourmet feast is at hand?

If an award was given based on craftsmanship you would have my vote as your project is stunning.

Joe

Thanks for the compliments.

Thomas, I love the looks of your amps. I wish I could afford all the oriental transformers but here in the states they are expensive. I would love to hear your project also, but I do not think that will be anytime soon.

Here is a pic of the finished monoblocks and a matching preamp, speaker project is next.

Thomas, I love the looks of your amps. I wish I could afford all the oriental transformers but here in the states they are expensive. I would love to hear your project also, but I do not think that will be anytime soon.

Here is a pic of the finished monoblocks and a matching preamp, speaker project is next.

An externally hosted image should be here but it was not working when we last tested it.

hi maybeim,

pls trust me that I post this photos & my site is not mainly to earn money.

They were not the kits, they were me & my friends amp.

see more photos for my another friends transformer couple 300b amps.

I was very surprise that why in europe the tamura, tango & james sell too expensive.

I had some friends in L.A. They told me to help them to by outputs & post to them. For example the said the angelX instruXXXX sell xe20s & F5002 is over USD 500 & USD1500.

I was very surprise why they earn too much money.

So I call the MJ magazine from japan. (one of the writer was my friend) to help me to dirtectly open account from japan factory.

So I can get the ex-factory price.

Pls trust me My website was not earn money on the first point.

I had a vert stable job & steady income.

Any questions pls email to me.

If I can help more diyer in the world that thewy can cost less money to enjoy quality products. I was glad to see theis view.

thaks

Thomas

www.diyaudiocraft.com

pls trust me that I post this photos & my site is not mainly to earn money.

They were not the kits, they were me & my friends amp.

see more photos for my another friends transformer couple 300b amps.

I was very surprise that why in europe the tamura, tango & james sell too expensive.

I had some friends in L.A. They told me to help them to by outputs & post to them. For example the said the angelX instruXXXX sell xe20s & F5002 is over USD 500 & USD1500.

I was very surprise why they earn too much money.

So I call the MJ magazine from japan. (one of the writer was my friend) to help me to dirtectly open account from japan factory.

So I can get the ex-factory price.

Pls trust me My website was not earn money on the first point.

I had a vert stable job & steady income.

Any questions pls email to me.

If I can help more diyer in the world that thewy can cost less money to enjoy quality products. I was glad to see theis view.

thaks

Thomas

www.diyaudiocraft.com

Attachments

hello maybeim ,

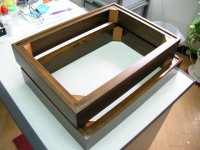

this is recently I made.

I use vintage eastern wood craft with piano finish to make the wood chassis already.

Do U feel good. Pls give me some advise.

I hope I use diyer's heart to make diy goods will fit to all diyer.

P.S. This is not promotion!!!!! I want to collect diyers advise to improve.

thanks

Thomas

www.diyaudiocraft.com

this is recently I made.

I use vintage eastern wood craft with piano finish to make the wood chassis already.

Do U feel good. Pls give me some advise.

I hope I use diyer's heart to make diy goods will fit to all diyer.

P.S. This is not promotion!!!!! I want to collect diyers advise to improve.

thanks

Thomas

www.diyaudiocraft.com

Attachments

Hello Thomas,

First, the wood bases look, well, like wood bases. I believe that the joinery (corners) is run of the mill 45 degree butted joints, which are the easiest joints to make and the least for structural strength. If you were to use dovetail joints or some other joinery the aesthetics (looks) would be greatly improved.

Choice of woods is not as important as the choice of the figure (grain) of the wood. The wood needs to be beautiful on it's own, before sanding and finishing. I do not care for straight grains and look more for a quilt and mottled look. Burl figured wood is the most beautiful and the most expensive wood one can buy. Finding burl large enough to produce a chassis is next to impossible and very, very expensive.

Aluminium plate is cheap and easy to work, very forgiving on finishing. Copper is the champagne of metals when it comes to making amp chassis and it shows. Very beautiful when the chassis come together.

All in all, you get what you pay for and planning and effort shows in ones work. I think more like an artist than an engineer, because I am not an engineer.

You do have a commercial website and are selling components to the diy community, even offering a service for custom-built chassis, I believe.

I wish you luck in you business adventure and there is room for improvement in your artistic tastes for chassis building, which also goes for me, as everyone learns as we go through life.

First, the wood bases look, well, like wood bases. I believe that the joinery (corners) is run of the mill 45 degree butted joints, which are the easiest joints to make and the least for structural strength. If you were to use dovetail joints or some other joinery the aesthetics (looks) would be greatly improved.

Choice of woods is not as important as the choice of the figure (grain) of the wood. The wood needs to be beautiful on it's own, before sanding and finishing. I do not care for straight grains and look more for a quilt and mottled look. Burl figured wood is the most beautiful and the most expensive wood one can buy. Finding burl large enough to produce a chassis is next to impossible and very, very expensive.

Aluminium plate is cheap and easy to work, very forgiving on finishing. Copper is the champagne of metals when it comes to making amp chassis and it shows. Very beautiful when the chassis come together.

All in all, you get what you pay for and planning and effort shows in ones work. I think more like an artist than an engineer, because I am not an engineer.

You do have a commercial website and are selling components to the diy community, even offering a service for custom-built chassis, I believe.

I wish you luck in you business adventure and there is room for improvement in your artistic tastes for chassis building, which also goes for me, as everyone learns as we go through life.

hi maybeim,

thanks for your complient.

actually I use the tail with all the join already to increase the strength.

The wood I choose was hard wood 1 inch thick & raw the 4 mm depth for the plate.

I still thinking the copper plate. Can u told me that how much cost for the surface craft for the copper plate??

Is it really very expensive??

The best now I can find in hong kong was the USA made 6061 or 7075 aluminium alloy. The company told me that was 6061 use in 747plane & 7075 was the f117 plane use.

I don't know the journey that i walk was right or not. I only want to prepare a reasonable chassis but good strength & good look for the diyer.

Good & cheap is my wills.

The website acually wasa not a commecical website.

U check the price with other diy company U will know that.

I hope I got item's discount can be same for everyone.

NOT ONLY I CAN ENJOY.

thanks

Thomas

thanks for your complient.

actually I use the tail with all the join already to increase the strength.

The wood I choose was hard wood 1 inch thick & raw the 4 mm depth for the plate.

I still thinking the copper plate. Can u told me that how much cost for the surface craft for the copper plate??

Is it really very expensive??

The best now I can find in hong kong was the USA made 6061 or 7075 aluminium alloy. The company told me that was 6061 use in 747plane & 7075 was the f117 plane use.

I don't know the journey that i walk was right or not. I only want to prepare a reasonable chassis but good strength & good look for the diyer.

Good & cheap is my wills.

The website acually wasa not a commecical website.

U check the price with other diy company U will know that.

I hope I got item's discount can be same for everyone.

NOT ONLY I CAN ENJOY.

thanks

Thomas

Attachments

Hi,

Copper costs more than aluminium. If you can use a plate thickness that is thinner than the aluminium you now use, the cost will go down. The problem with thinner plate is structural in nature, it could buckle if it is to thin, when you load it with heavy transfomers. It could be possible to add braces to add strength or go with thicker plate.

I sprayed a polyurethane ( plastic ) coating over the finished plates. Just the tops that show, not the bottoms that no one sees. Since the amps will never be outdoors, the finish I used is fine for indoor use.

DO NOT BUY COPPER WITH BERILIYUM, very toxic.

http://www.diyaudio.com/forums/showthread.php?s=&threadid=8877

Copper costs more than aluminium. If you can use a plate thickness that is thinner than the aluminium you now use, the cost will go down. The problem with thinner plate is structural in nature, it could buckle if it is to thin, when you load it with heavy transfomers. It could be possible to add braces to add strength or go with thicker plate.

I sprayed a polyurethane ( plastic ) coating over the finished plates. Just the tops that show, not the bottoms that no one sees. Since the amps will never be outdoors, the finish I used is fine for indoor use.

DO NOT BUY COPPER WITH BERILIYUM, very toxic.

http://www.diyaudio.com/forums/showthread.php?s=&threadid=8877

Thomas,

I think that what you are doing is great. Even if he does make a profit, if it benefits the DIY community what is wrong with it? He is taking the time out of his day to bring discounted products to us. For those of us that don't have the tools or skill to make our own plates / bases, he is providing a great asset to the community.

On a side note, your website doesn't seem to work for me... what's the ip address? thanks!

Mark

I think that what you are doing is great. Even if he does make a profit, if it benefits the DIY community what is wrong with it? He is taking the time out of his day to bring discounted products to us. For those of us that don't have the tools or skill to make our own plates / bases, he is providing a great asset to the community.

On a side note, your website doesn't seem to work for me... what's the ip address? thanks!

Mark

hi maybeim,

do u try to use the magnesium-alum inium alloy to makde the chassis experience.

In hong kong, some people said that the vintage console mCHINE WAS USE THIS MATERIAL TO MAKE THE CHASSIS.

This several days I go to one meeting to diyers in hong kong & they use yellow colour, Red copper & this alloy to make the chassis. The different of the sound was red copper still had a high er density, but the alloy we use same method to ground in same point can get more slient background.

We use 104db horn speaker to test.

Do U feel good. In hong kong cannot use your suggest method to handle the surface of the copper because the high humidity.

any advise.

thanks

thomas

do u try to use the magnesium-alum inium alloy to makde the chassis experience.

In hong kong, some people said that the vintage console mCHINE WAS USE THIS MATERIAL TO MAKE THE CHASSIS.

This several days I go to one meeting to diyers in hong kong & they use yellow colour, Red copper & this alloy to make the chassis. The different of the sound was red copper still had a high er density, but the alloy we use same method to ground in same point can get more slient background.

We use 104db horn speaker to test.

Do U feel good. In hong kong cannot use your suggest method to handle the surface of the copper because the high humidity.

any advise.

thanks

thomas

Hi Thomas,

In order to paint the copper plate effectively, build a mini-paint booth. All you need is a very large cardboard box and hang a light bulb inside. Be ware that fumes from paint could ignite from heat of light bulb, so use the right bulb. Make a flap to cover the opening of the box that is used to put your parts in ( a lid so to speak ). You can put a cheap thermometer inside the box to check how hot it gets inside the box. Good luck!

In order to paint the copper plate effectively, build a mini-paint booth. All you need is a very large cardboard box and hang a light bulb inside. Be ware that fumes from paint could ignite from heat of light bulb, so use the right bulb. Make a flap to cover the opening of the box that is used to put your parts in ( a lid so to speak ). You can put a cheap thermometer inside the box to check how hot it gets inside the box. Good luck!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- JE Labs 300b round 2 1/2 Copper Plates