Thx Wave! Interesting assessment: "In order to build it you need to have an experience, but if you have an experience, you will never build it as is." I guess I'm not too surprised. It's just that with PS iron, output iron, chassis and tubes, it seems hard to NOT try it. At the price it COULD be a decent foundation for playing around. For the moment, though, I have enough projects on my bench.

Yes, for playing around it is a decent foundation. To find and correct errors, learning on them...

The power transformer in the kit appeared to be not properly made for US voltage. After I insulated bolts, idle current dropped down, so losses and hum decreased, but voltages on secondaries are still too high. Looks like they made it for Chinese 220V, dividing the primary in half. I used 5V winding in series since I use Vishay SF1600 diodes for rectification; voltages on secondaries have dropped a bit, but not enough. So, since it is a class A amp and consumes always the same current, I will be able to improve it further burning some extra voltage on a wirewound resistor in series with the primary winding, otherwise if the voltage in US outlet gets higher that 122 that I have now, it may start saturating. The resistor also will provide some softer start decreasing inrush current.

I've noticed there are quite a few tube power amps kits on eBay. The main one which comes to mind is a 6SN7/300B kit. It comes with a PCB and then you can order from a collection of parts.

I (who have built dozens of tube power amps and preamps) wouldn't bother because I build my amps on tags strips which just cost a few dollars but for the novice a real easy way to go.

The Asian market has flooded us with these choices but I can only see it as a bonus for the DIY GUY.

I (who have built dozens of tube power amps and preamps) wouldn't bother because I build my amps on tags strips which just cost a few dollars but for the novice a real easy way to go.

The Asian market has flooded us with these choices but I can only see it as a bonus for the DIY GUY.

Yes, for playing around it is a decent foundation. To find and correct errors, learning on them...

The power transformer in the kit appeared to be not properly made for US voltage. After I insulated bolts, idle current dropped down, so losses and hum decreased, but voltages on secondaries are still too high. Looks like they made it for Chinese 220V, dividing the primary in half. I used 5V winding in series since I use Vishay SF1600 diodes for rectification; voltages on secondaries have dropped a bit, but not enough. So, since it is a class A amp and consumes always the same current, I will be able to improve it further burning some extra voltage on a wirewound resistor in series with the primary winding, otherwise if the voltage in US outlet gets higher that 122 that I have now, it may start saturating. The resistor also will provide some softer start decreasing inrush current.

At the risk of getting too off-topic... Insulated bolts dropped current significantly??? Yikes! So is the transformer grounded now? Tube rectifiers would, of course, drop voltage... I did a little reading on the kit and it seems PS transformer errors are pretty common. That seems like such a simple thing to correct, particularly since this seems to have been around for a while.

Depending on time of day, and day of week, in my neighborhood, it runs anywhere from 117 to 128, and I've even seen it as high as 140 once. On the same outlet, just at different times.China should make transformers; 120-120 then could be used in Australia on 240 volts,

I have read the average in the USA is 120 volts not 110volts.

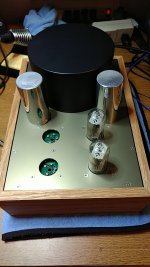

Ok, the amp is all soldered, performed the first audio test. It sounds lively, real high end, even with Chinese output transformers from Walmart. Tomorrow I will measure and fine tune the schematic, then post the results.

https://www.youtube.com/watch?v=y2hMkFTvA38&feature=youtu.be

https://www.youtube.com/watch?v=y2hMkFTvA38&feature=youtu.be

It is a pretty generic amplifier from China. Siliconray did sell the same one early on, but the market has matured and I recall seeing the "original" one being tweeked and changed through the years by various copycats in China (depending where you stand, they either made it cheaper or better via component quality and quantity in places like the transformers, polyester caps, chassis, wiring, etc...). This is why sometimes when you buy one, the component list doesn't match. Improved schematics with the proper math or measured readings can be found along with what improvements that can be made. Those ought to be treated as a case by case basis since there are so many versions of the same base amplifier out there from eBay to AliExpress and now Walmart.

There is a whole micro-industry in the small audio shops of Hong Kong who buy these and improve the base reliability and sound of these kit amplifiers via component changes and tube changes. You can buy a tube amplifier with different levels from, "nice sound and won't catch fire" to, "outstanding" in comparison. They slap on a nameplate and some customer is off to the races. But nothing to Waveboun's level of commitment though.

I would love to buy one because the price is a hard to beat for iron, some components, and a chassis, but Canada...

There is a whole micro-industry in the small audio shops of Hong Kong who buy these and improve the base reliability and sound of these kit amplifiers via component changes and tube changes. You can buy a tube amplifier with different levels from, "nice sound and won't catch fire" to, "outstanding" in comparison. They slap on a nameplate and some customer is off to the races. But nothing to Waveboun's level of commitment though.

I would love to buy one because the price is a hard to beat for iron, some components, and a chassis, but Canada...

I would love to buy one because the price is a hard to beat for iron, some components, and a chassis, but Canada...

I used the chassis and an iron. I did not measure yet how it performs with their output transformers, but the sound is gorgeous! Power transformer does not hum, does not overheat, but I had to insulate bolts and add 5V secondary in series with the primary. I highly recommend the kit as the source of chassis & an iron.

Dual Hybrid Power Supply

This is a dual hybrid power supply using 6CL3 damper diodes.

First stage filtered DC, heater supply, and chassis ground sent via umbilical cables to future planned monoblock amps.

This is a dual hybrid power supply using 6CL3 damper diodes.

First stage filtered DC, heater supply, and chassis ground sent via umbilical cables to future planned monoblock amps.

Attachments

It is off-topic here, may be Moderators move it to some appropriate thread?

I use a machine that I bought in Harborfreight store and a compressor that I also bought there. They sell a cheap stuff, enough to learn the process.

The machine contains a pulverizer and a high voltage source. High voltage attracts a special powder that then is being cured in an oven, 400F for half an hour.

The machine needs up to 30 psi, otherwise the dust will be everywhere!

It is very similar to laser printing. The adhesion is great, and the surface is pretty durable.

Hello Mr Wavebourne:

Could you talk a little about "baking a chassis". I find this concept quite intriguing. Does it help reduce scratching the finish during the final assembly of the project?

I use a machine that I bought in Harborfreight store and a compressor that I also bought there. They sell a cheap stuff, enough to learn the process.

The machine contains a pulverizer and a high voltage source. High voltage attracts a special powder that then is being cured in an oven, 400F for half an hour.

The machine needs up to 30 psi, otherwise the dust will be everywhere!

It is very similar to laser printing. The adhesion is great, and the surface is pretty durable.

My new chassis for PP EL34 audio amplifier !

Excellent design!

- Home

- Amplifiers

- Tubes / Valves

- Photo Gallery