One of the power supply caps in one of my Quicksilver 8417s is leaking. The caps are marked "320 MFD 450V" and "650MFD 450V" and are Mallorys. I've seen references that these were oversized for this application. I need to replace at least one (and might as well replace them all) so I have a couple of questions:

1. Does "MFD" mean microfarad, millifarad, or (highly unlikely) megafarad? I'm not an electrical type, but my understanding of prefixes on units is that a capital "M" means mega, which doesn't make sense here (I'm a chemical engineer and even I know that a megafarad would be HUGE).

2. What size replacement(s) do you recommend and where can I get them?

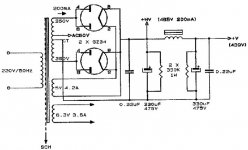

3. The circuit diagram posted elsewhere on this site doesn't agree with the configuration of the amps I have (it shows two 330 uF/475V caps in the power supply).

Again, thanks for your help and advice in advance.

Doug

1. Does "MFD" mean microfarad, millifarad, or (highly unlikely) megafarad? I'm not an electrical type, but my understanding of prefixes on units is that a capital "M" means mega, which doesn't make sense here (I'm a chemical engineer and even I know that a megafarad would be HUGE).

2. What size replacement(s) do you recommend and where can I get them?

3. The circuit diagram posted elsewhere on this site doesn't agree with the configuration of the amps I have (it shows two 330 uF/475V caps in the power supply).

Again, thanks for your help and advice in advance.

Doug

1: Microfarad.

2:a: Same as what's in there.

2:b: Dunno, sorry, I'm not in the US.

3: The different circuit could simply have been a revision. Quicksilver are a small company and can change their designs slightly, maybe because an original part is no longer available, or they found something better. Not having the two schems in front of me, it could simply be that they're using two 330u in parallel to equal the 650u. Email them and ask.

2:a: Same as what's in there.

2:b: Dunno, sorry, I'm not in the US.

3: The different circuit could simply have been a revision. Quicksilver are a small company and can change their designs slightly, maybe because an original part is no longer available, or they found something better. Not having the two schems in front of me, it could simply be that they're using two 330u in parallel to equal the 650u. Email them and ask.

All,

Thanks for your replies. I also dug deeper into one of the earlier threads (a 99 message one, ugh) and found some reference to replacing the front cap with one in the 100 uF range and running up to 750 uF cap on the back side of the choke (pi circuit). Mike Sanders also just sent me a note back that I could use 300 uF in both slots (he doesn't have the higher capacitance unit any more), so it sounds like the actual values aren't that critical (as long as I don't go higher than the 320 uF on the front side and stay above the 450V rating).

So, if I replace the front cap with anything from 100 uF to 320 uF and the back cap with anything from 300 uF to 750 uF it should work fine, right? Of course I'd prefer to just leave it like it is as they sound pretty darned good as-is.

Sorry for the basic questions, but Circuit Design was PFM to me in college.....

Thanks, Doug

Thanks for your replies. I also dug deeper into one of the earlier threads (a 99 message one, ugh) and found some reference to replacing the front cap with one in the 100 uF range and running up to 750 uF cap on the back side of the choke (pi circuit). Mike Sanders also just sent me a note back that I could use 300 uF in both slots (he doesn't have the higher capacitance unit any more), so it sounds like the actual values aren't that critical (as long as I don't go higher than the 320 uF on the front side and stay above the 450V rating).

So, if I replace the front cap with anything from 100 uF to 320 uF and the back cap with anything from 300 uF to 750 uF it should work fine, right? Of course I'd prefer to just leave it like it is as they sound pretty darned good as-is.

Sorry for the basic questions, but Circuit Design was PFM to me in college.....

Thanks, Doug

Hi All,

I've been following any posts I could find on Quicksilver 8417 Monos. Information seems to be scarce,so the posts on diyAudio Forums is most appreciated.

I have just replaced a Mallory 320mF 450v cap that leaked, taking out one of the Phillips 8417s. It can join the other saved 8417s that I will try to match up when needed (I initially biased too high. Have since been advised 80ma).

You can get the 320mF Mallory from Mouser, catalogue number: CGS321T450V3C.

However I replaced mine with a Vishay/Sprague 380mF 450 volt, as that was all I could find at the time (measures over 400mF).

After seeing this thread I phoned a fellow who repairs Quicksilvers and he asssured me that there will not be a problem with the higher value.

My Q/S are early 6volt heater models that have been professionally modded. It has an 850mf cap on the cathode side of the choke and a 320mF on the other side in // with 200mF but separated by a 33k 2w resistor. It now uses only one 5AR4.

What do you think of the following? The repairer says the GE 8417 needs a 5.5 volt heater supply or they will have a short life, and should not be used unless the supply is dropped 1volt. I have quite a few GE 8417s standing by.

Space is short for more.

Audie.

I've been following any posts I could find on Quicksilver 8417 Monos. Information seems to be scarce,so the posts on diyAudio Forums is most appreciated.

I have just replaced a Mallory 320mF 450v cap that leaked, taking out one of the Phillips 8417s. It can join the other saved 8417s that I will try to match up when needed (I initially biased too high. Have since been advised 80ma).

You can get the 320mF Mallory from Mouser, catalogue number: CGS321T450V3C.

However I replaced mine with a Vishay/Sprague 380mF 450 volt, as that was all I could find at the time (measures over 400mF).

After seeing this thread I phoned a fellow who repairs Quicksilvers and he asssured me that there will not be a problem with the higher value.

My Q/S are early 6volt heater models that have been professionally modded. It has an 850mf cap on the cathode side of the choke and a 320mF on the other side in // with 200mF but separated by a 33k 2w resistor. It now uses only one 5AR4.

What do you think of the following? The repairer says the GE 8417 needs a 5.5 volt heater supply or they will have a short life, and should not be used unless the supply is dropped 1volt. I have quite a few GE 8417s standing by.

Space is short for more.

Audie.

Hi All,

The Quicksilver repairer mentioned a few changes he has made to his own Q/S Monos, which may be of interest.

100mf 500volt Elna Cerafine for both caps. He prefers the sound to that of the larger caps.

0.22 mF coupling cap and 100k bias resistor. This gives good bass, speed and stability. He uses GE 8417 which he prefers to the Phillips/sylvania 8417.

He prefers the sound with 80mA bias. As a bonus, the tubes will last longer ( I already use 80/85mA ).

He advises a 1 amp ( 240volt ac ) main fuse for better protection.

( I will adopt this. I use a Variac to ramp the voltage up and down, so will not get the possible occasional blown fuse at startup).

Audie.

The Quicksilver repairer mentioned a few changes he has made to his own Q/S Monos, which may be of interest.

100mf 500volt Elna Cerafine for both caps. He prefers the sound to that of the larger caps.

0.22 mF coupling cap and 100k bias resistor. This gives good bass, speed and stability. He uses GE 8417 which he prefers to the Phillips/sylvania 8417.

He prefers the sound with 80mA bias. As a bonus, the tubes will last longer ( I already use 80/85mA ).

He advises a 1 amp ( 240volt ac ) main fuse for better protection.

( I will adopt this. I use a Variac to ramp the voltage up and down, so will not get the possible occasional blown fuse at startup).

Audie.

billabong said:What do you think of the following? The repairer says the GE 8417 needs a 5.5 volt heater supply or they will have a short life, and should not be used unless the supply is dropped 1volt. I have quite a few GE 8417s standing by.

The datasheets (http://tdsl.duncanamps.com/show.php?des=8417) seem to say 6.3V for the heaters, but maybe the reparer has some special knowledge of this tube?

> maybe the reparer has some special knowledge of this tube?

I never heard of that trick. Running a power tube 10% low on heater will shorten its life a little. But the 8417 is a flawed design: it has a LOT of gain, good; but they did that by putting the grid too close to cathode (or something), BAD because they short-out internally. Some more than others: apparently one factory could wind with enough precision, another really couldn't.

Reducing heat will give lower peak emission and less grid warp. That may let you get-by with the less-reliable versions of 8417. Emission will decline with thousands of hours, and the under-heated tube will punk-out sooner.

The best answer is to go back to 1970 and get some good 8417, but that's not possible.

A hack would be to convert to 6550, but that needs a lot more negative bias, gives lower gain, less NFB. It would change the amplifier, and possibly not for the better (except it will be reliable as a rock).

> I initially biased too high.

Don't do that! With good old stone-age 6V6, you can bias by looking at the glow on the plate, and turn-down until the glow is gone. Try that on the souped-up late-design tubes, particularly 8417, and you get catastrophic tube failure, occasionally leading to burning transformers.

> been advised 80ma

80mA per tube is AT the 35 Watt plate rating. (If you find a 42W rating on 8417, remember your 30-day tube warranty ran out in 1970.) These tubes should NOT be cruised that hard. 80mA per pair is half the rating, a safe value. Yes, it may sound better the higher the current, but they are not making replacement 8417s and I don't think there is a factory left alive that could wind 8417 with good reliability and affordable price.

I never heard of that trick. Running a power tube 10% low on heater will shorten its life a little. But the 8417 is a flawed design: it has a LOT of gain, good; but they did that by putting the grid too close to cathode (or something), BAD because they short-out internally. Some more than others: apparently one factory could wind with enough precision, another really couldn't.

Reducing heat will give lower peak emission and less grid warp. That may let you get-by with the less-reliable versions of 8417. Emission will decline with thousands of hours, and the under-heated tube will punk-out sooner.

The best answer is to go back to 1970 and get some good 8417, but that's not possible.

A hack would be to convert to 6550, but that needs a lot more negative bias, gives lower gain, less NFB. It would change the amplifier, and possibly not for the better (except it will be reliable as a rock).

> I initially biased too high.

Don't do that! With good old stone-age 6V6, you can bias by looking at the glow on the plate, and turn-down until the glow is gone. Try that on the souped-up late-design tubes, particularly 8417, and you get catastrophic tube failure, occasionally leading to burning transformers.

> been advised 80ma

80mA per tube is AT the 35 Watt plate rating. (If you find a 42W rating on 8417, remember your 30-day tube warranty ran out in 1970.) These tubes should NOT be cruised that hard. 80mA per pair is half the rating, a safe value. Yes, it may sound better the higher the current, but they are not making replacement 8417s and I don't think there is a factory left alive that could wind 8417 with good reliability and affordable price.

Thanks dsavitsk and PRR for your responses.

I would guess the repairman, being an elderly retired chap, would have chalked up a fair amount of experience.

Seems that there are differing opinions about running heaters at a lower voltage. I came across an earlier link on this Forum that discusses this topic:

When I got the first pair of Q/S monos I biased at 125ma since that was printed beside the biasing socket and I was not advised otherwise by the retailer. It did not take too long before I realised that it was too high and settled on 85/90 ma. This is the total bias current for the pair of 8417s as the monos do not have individual biasing.

I intend to use a dropping resistor to reduce the heater voltage to 5.5 volts as the chap suggested. I have seen references that the GE 8417 tends to have a shorter life than the Phillips/Sylvania 8417 and am hoping that this will be helpful. That is, unless I find compelling agreement that it would be detremental.

The repairman sure was convincing when he said I should not run the GE8417 at 6.3 heater voltage, and I feel it would be unwise to disregard his advice.

Audie.

I would guess the repairman, being an elderly retired chap, would have chalked up a fair amount of experience.

Seems that there are differing opinions about running heaters at a lower voltage. I came across an earlier link on this Forum that discusses this topic:

When I got the first pair of Q/S monos I biased at 125ma since that was printed beside the biasing socket and I was not advised otherwise by the retailer. It did not take too long before I realised that it was too high and settled on 85/90 ma. This is the total bias current for the pair of 8417s as the monos do not have individual biasing.

I intend to use a dropping resistor to reduce the heater voltage to 5.5 volts as the chap suggested. I have seen references that the GE 8417 tends to have a shorter life than the Phillips/Sylvania 8417 and am hoping that this will be helpful. That is, unless I find compelling agreement that it would be detremental.

The repairman sure was convincing when he said I should not run the GE8417 at 6.3 heater voltage, and I feel it would be unwise to disregard his advice.

Audie.

> Seems that there are differing opinions about running heaters at a lower voltage.

There's a lot of BS around.

The non-oxide filaments in HIGH-voltage tubes WILL be ruined if worked anywhere near rating with filament not at FULL heat.

The oxide-coated cathodes we use at 100V-800V plate supply are more tolerant.

> The repairman sure was convincing when he said I should not run the GE8417 at 6.3 heater voltage, and I feel it would be unwise to disregard his advice.

Underheating is unusual advice. For low-current duty like preamps, it is quite safe and may help noise/hum. At high current, normally you do NOT under-heat a power tube cathode: they made it that size/heat for a reason. But we can count on the fact that an oxide cathode has 3X to 10X the emission we normally need. BUT emission declines with age (and also temperature-hours). All things considered, you do NOT run power tubes at low heater voltage (but 6.0V-6.6V is perfectly OK for a "6.3V" heater).

BUT the 8417 is a special case. I was abusing them when new. They allow a much simpler 150W amp than is possible with 6L6GC, 6550, EL34, etc. But I got mine because one (of a set of three) caught fire in operation. (I'm told it was still working when the operator woke up and pulled the plug.) At the time, I used various brands of 8417 and did not correlate brand with reliability. BUt the 8417 is very powerful, very sensitive, and VERY high-strung. Under-heating is very odd advice, but I don't think it is wrong in this special case.

There's a lot of BS around.

The non-oxide filaments in HIGH-voltage tubes WILL be ruined if worked anywhere near rating with filament not at FULL heat.

The oxide-coated cathodes we use at 100V-800V plate supply are more tolerant.

> The repairman sure was convincing when he said I should not run the GE8417 at 6.3 heater voltage, and I feel it would be unwise to disregard his advice.

Underheating is unusual advice. For low-current duty like preamps, it is quite safe and may help noise/hum. At high current, normally you do NOT under-heat a power tube cathode: they made it that size/heat for a reason. But we can count on the fact that an oxide cathode has 3X to 10X the emission we normally need. BUT emission declines with age (and also temperature-hours). All things considered, you do NOT run power tubes at low heater voltage (but 6.0V-6.6V is perfectly OK for a "6.3V" heater).

BUT the 8417 is a special case. I was abusing them when new. They allow a much simpler 150W amp than is possible with 6L6GC, 6550, EL34, etc. But I got mine because one (of a set of three) caught fire in operation. (I'm told it was still working when the operator woke up and pulled the plug.) At the time, I used various brands of 8417 and did not correlate brand with reliability. BUt the 8417 is very powerful, very sensitive, and VERY high-strung. Under-heating is very odd advice, but I don't think it is wrong in this special case.

Quote:

The repairman sure was convincing when he said I should not run the GE8417 at 6.3 heater voltage, and I feel it would be unwise to disregard his advice.

I would have to disagree 100% with your repairmans advice. Since I have owned (4) sets of Quicksilver mono block amps I feel that maybe my advice may be worth listening to. The count is 3 sets of 8417's and one set of KT88's. One set of 8417's left stock and the others converted to use 6550's and KT88's.

Data sheets were made for a reason. That reason is to supply the very best operating data. This data can be relied on to be point on accurate. It specifies the operating voltage as 6.3 + or minus a tolerance. These values are to be followed. Severe loss of life will result from going lower or higher than this value.

I bias my 8417's at 100mA for the pair.

The repairman sure was convincing when he said I should not run the GE8417 at 6.3 heater voltage, and I feel it would be unwise to disregard his advice.

I would have to disagree 100% with your repairmans advice. Since I have owned (4) sets of Quicksilver mono block amps I feel that maybe my advice may be worth listening to. The count is 3 sets of 8417's and one set of KT88's. One set of 8417's left stock and the others converted to use 6550's and KT88's.

Data sheets were made for a reason. That reason is to supply the very best operating data. This data can be relied on to be point on accurate. It specifies the operating voltage as 6.3 + or minus a tolerance. These values are to be followed. Severe loss of life will result from going lower or higher than this value.

I bias my 8417's at 100mA for the pair.

Thanks for the informed posts. It's now possible to make a reasoned decision on whether I should follow the low heater voltage path.

I tend to agree with PRR that in this special case using 5.5 volts for the GE8417 heater, may not be called wrong.

The serviceman uses GE8417 from preference and is very pleased with the sound and longetivity of the tubes with 5.5v heaters and 80mA bias. Together with 0.22 mF coupling caps and 100k resistors connected to the bias pot wiper,he says the bias is rock steady. As Bill*B noted , the Ge8417 are known to not hold bias and will cause runaway. The serviceman has obviously devised a method to preserve the cherished and soon obsolete 8417 valve, yet still retain a sound he is happy with. One could even admire him for being ingenious enough to buck perceived wisdom and come up with a solution that he is satisfied with over time.

Will I follow suite ? For the present, no (never say never). I am an elderly guy with enough 8417s to see me out, so preserving my remaining 8417s should not influence my decision.

I've almost completed mods/repairs/upgrades to the four monos and am not looking for more work. I have DC heaters on the input and driver tubes, the rectifier of which is fed from the 8417 heater supply. Lowering the heater voltage to the 8417s would also lower it to the small signal valves, though as PRR says, that would be acceptible. I could however take a separate and parallel feed to supply the full 6.3 volts to the rectifier.

Thanks to your helpful input, I'm going with the majority consensus and sticking with 6.3 volt heaters, no matter what the imagined cost.

Thanks guys.

I tend to agree with PRR that in this special case using 5.5 volts for the GE8417 heater, may not be called wrong.

The serviceman uses GE8417 from preference and is very pleased with the sound and longetivity of the tubes with 5.5v heaters and 80mA bias. Together with 0.22 mF coupling caps and 100k resistors connected to the bias pot wiper,he says the bias is rock steady. As Bill*B noted , the Ge8417 are known to not hold bias and will cause runaway. The serviceman has obviously devised a method to preserve the cherished and soon obsolete 8417 valve, yet still retain a sound he is happy with. One could even admire him for being ingenious enough to buck perceived wisdom and come up with a solution that he is satisfied with over time.

Will I follow suite ? For the present, no (never say never). I am an elderly guy with enough 8417s to see me out, so preserving my remaining 8417s should not influence my decision.

I've almost completed mods/repairs/upgrades to the four monos and am not looking for more work. I have DC heaters on the input and driver tubes, the rectifier of which is fed from the 8417 heater supply. Lowering the heater voltage to the 8417s would also lower it to the small signal valves, though as PRR says, that would be acceptible. I could however take a separate and parallel feed to supply the full 6.3 volts to the rectifier.

Thanks to your helpful input, I'm going with the majority consensus and sticking with 6.3 volt heaters, no matter what the imagined cost.

Thanks guys.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Quicksilver 8417 power supply caps?