I've used Sikaflex a lot on boats. It sticks really well to clean surfaces and will be hard to remove. It also will not run/spread into gaps, it only goes where it is forced to go by gun application.

These comments apply to genuine Sikaflex. There are many similar products which may have different characteristics. Genuine Sikaflex is also relatively expensive.

These comments apply to genuine Sikaflex. There are many similar products which may have different characteristics. Genuine Sikaflex is also relatively expensive.

@TonyTecson, what a HUGE beast!

What EI size is that? EI-171?

I can get EI-150 and EI-180, and I think EI-174 (5,8 cm center length, which is a little bit bigger) but that one I need to ask. Is this one OK for you?

For EI-180 there're bobbins for up to 12 cm stacking height, so probably there will be bobbins the height you need. Just tell me if EI-174 is good for you, or not, let me ask, and I'll come back with some news in several days time.

as long as it is scrapless EI-174 seems good, thanks...

A couple of hours later, I rewinded the primary to lower the magnetization to 1.1 Tesla.

I also replaced the stiff wire with two more flexible wires, and this way the filaments winding came out much nicer!

The measured magnetic field is so much reduced (more than I expected). Less than half the original values.

Now the bad news: there's still some buzzing. In fact, it just reduced a little bit.

@TonyTecson, how do you wedge a wooden shim between the center leg cores and the bobbin?? There's absolutely no space!

And, could I use cardboard somehow, if the transformer is already buzzing without bells? Isn't cardboard supposed to be used between core and bells? Or has it more uses?

I also replaced the stiff wire with two more flexible wires, and this way the filaments winding came out much nicer!

The measured magnetic field is so much reduced (more than I expected). Less than half the original values.

Now the bad news: there's still some buzzing. In fact, it just reduced a little bit.

@TonyTecson, how do you wedge a wooden shim between the center leg cores and the bobbin?? There's absolutely no space!

And, could I use cardboard somehow, if the transformer is already buzzing without bells? Isn't cardboard supposed to be used between core and bells? Or has it more uses?

I replaced the bolts, to make sure there's not conduction through them.

No improvement.

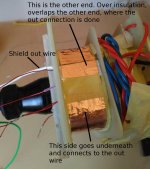

The other addition to my previous (quiet) power transformer is the electrostatic shield (well, the other one is much smaller).

I attached a picture of how I made it. Hope it is OK.

Both use split bobbin. But this one needs the shield (the small one didn't), because I cannot fit the three secondaries into a single bobbin section.

So, filament winding is on top of the shield, and on top of the primary.

Any advice?

@ Alan4411, the laminations are interleaved E, filled with I,... the standard way. With the same kind of side facing the same direction.

No improvement.

The other addition to my previous (quiet) power transformer is the electrostatic shield (well, the other one is much smaller).

I attached a picture of how I made it. Hope it is OK.

Both use split bobbin. But this one needs the shield (the small one didn't), because I cannot fit the three secondaries into a single bobbin section.

So, filament winding is on top of the shield, and on top of the primary.

Any advice?

@ Alan4411, the laminations are interleaved E, filled with I,... the standard way. With the same kind of side facing the same direction.

Just to summarize.

- I started this thread, to ask if gluing the laminations together was a good idea.

- Alan4411 didn't recommended gluing them.

- So, I increased the primary inductance, to lower magnetization, and replaced a very stiff wire, to aim to reduce the vibration.

- This was a partial success.

I've come across many people varnishing "to avoid 50/60 Hz buzz/hum".

The question now is: is it realistic to expect a transformer to be silent if not varnishing/gluing?

TonyTecson just mention varnish again

And that takes me to the first post, and Alan4411 recommending me to not glue the laminations. Gluing and varnishing is more or less the same: keeps laminations together so as to prevent them vibrating, and makes unwinding the transformer almost impossible. Do we all agree on this?

As a final step, I'll rewind one last time, to try to get as much turns as I can into the bobbin.

- I started this thread, to ask if gluing the laminations together was a good idea.

- Alan4411 didn't recommended gluing them.

- So, I increased the primary inductance, to lower magnetization, and replaced a very stiff wire, to aim to reduce the vibration.

- This was a partial success.

I've come across many people varnishing "to avoid 50/60 Hz buzz/hum".

The question now is: is it realistic to expect a transformer to be silent if not varnishing/gluing?

TonyTecson just mention varnish again

And that takes me to the first post, and Alan4411 recommending me to not glue the laminations. Gluing and varnishing is more or less the same: keeps laminations together so as to prevent them vibrating, and makes unwinding the transformer almost impossible. Do we all agree on this?

As a final step, I'll rewind one last time, to try to get as much turns as I can into the bobbin.

Hi Elerion,

Just to clarify my first answer way back in post 2. I initially thought you were talking about the 'end bells' buzzing. Hence my recommendation not to glue them on, but to use soft packing between them and the core. I misunderstood your problem.

I think you have given this every effort to stop the hum, but maybe you will eventually have to use a transformer varnish or wax to eliminate it. As Tony says dip the whole thing...

Just to clarify my first answer way back in post 2. I initially thought you were talking about the 'end bells' buzzing. Hence my recommendation not to glue them on, but to use soft packing between them and the core. I misunderstood your problem.

I think you have given this every effort to stop the hum, but maybe you will eventually have to use a transformer varnish or wax to eliminate it. As Tony says dip the whole thing...

Yes, it seems so.

This is why I asked for two component epoxy glue.

It is much nicer to use at home in small spaces than electrical varnish,...

Maybe not as effective, but just a small amount; apply on the laminations using a brush, and hold tightly together for a while with some tool like a vise.

This is why I asked for two component epoxy glue.

It is much nicer to use at home in small spaces than electrical varnish,...

Maybe not as effective, but just a small amount; apply on the laminations using a brush, and hold tightly together for a while with some tool like a vise.

Good news

After three rewinding processes, I achieved 1 Tesla, and,... guess what.

No buzz or noise whatsoever.

No shim, and of course no gluing.

Even without bolts!

I need my multimeter or magnetic field meter to know weather the transformer is powered or not. If I touch the laminations, I do feel a very soft vibration.

Unfortunately, the copper loses have increased, and I wouldn't ask this trannie for more than 220 mA B+ current. As I built it for a KT88 SE amplifier biased at 80 mA (each), I assume it will be OK.

Filament winding is 6.65 V unloaded. I hope it stays over 6V when loaded.

After three rewinding processes, I achieved 1 Tesla, and,... guess what.

No buzz or noise whatsoever.

No shim, and of course no gluing.

Even without bolts!

I need my multimeter or magnetic field meter to know weather the transformer is powered or not. If I touch the laminations, I do feel a very soft vibration.

Unfortunately, the copper loses have increased, and I wouldn't ask this trannie for more than 220 mA B+ current. As I built it for a KT88 SE amplifier biased at 80 mA (each), I assume it will be OK.

Filament winding is 6.65 V unloaded. I hope it stays over 6V when loaded.

congratulations!!!

now you know how mr. Tesla influences things...

regulation is of course the trade off....

but you are as far away from core saturation as you need be..

what i do in my build is to design the unloaded voltages a bit higher than wanted

so that when under load, your target is met...

anyway starting from higher voltage it is easy to lose some voltage,

i will choose it over than when you do not have enough of it...

now you know how mr. Tesla influences things...

regulation is of course the trade off....

but you are as far away from core saturation as you need be..

what i do in my build is to design the unloaded voltages a bit higher than wanted

so that when under load, your target is met...

anyway starting from higher voltage it is easy to lose some voltage,

i will choose it over than when you do not have enough of it...

Just one more question.

When adding bells, which are grounded via chassis, the core becomes grounded.

Using four isolated bolts (also using nylon spacers, so they don't touch the bells) would be enough, isn't it?

Core should be grounded (for safety) and no eddy currents coming from the bolts.

Is there any other better approach?

When adding bells, which are grounded via chassis, the core becomes grounded.

Using four isolated bolts (also using nylon spacers, so they don't touch the bells) would be enough, isn't it?

Core should be grounded (for safety) and no eddy currents coming from the bolts.

Is there any other better approach?

the nylon shoulder washers are used to help in the eddy current to minimise,

using plastic bobbins, there is little chance that the copper winding touch the core,

if the endbells have electrical contact with your metal chassis, then so does your core..

nothing much to worry about...

using plastic bobbins, there is little chance that the copper winding touch the core,

if the endbells have electrical contact with your metal chassis, then so does your core..

nothing much to worry about...

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- DIY transformer and two-component epoxy adhesive