I apologize for throwing out such a rudimentary question, but my search is not getting me any definitive answers.

I have limited experience building tube amps. I have build a few projects from complete kits that include chassis and am taking the next step with building a st-70 "clone" using one of the driver board rebuild kits and sourcing the rest of the parts myself. It's been in the planning process for a year and there has yet to be any solder melted, and it will likely drag on over several more months as I find the occasional spare hour here or there to work on it.

I have everything but the chassis and I am not finding the Hammond chassis or similar offerings in the dimensions or look I want.

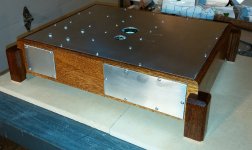

I don't have access to a metal shop and don't have a lot of skills with metal working, but I have a well-equipped woodshop and am a pretty competent amateur woodworker. What I would really like to do is buy a sheet of thick aluminum and use a step drill to cut the tube socket holes, buy a piece of steel for the bottom plate and drill some holes in it for ventilation and make the rest of the chassis out of nice figured wood, probably some pieces of curupay I have been saving for something special.

I have limited experience building tube amps. I have build a few projects from complete kits that include chassis and am taking the next step with building a st-70 "clone" using one of the driver board rebuild kits and sourcing the rest of the parts myself. It's been in the planning process for a year and there has yet to be any solder melted, and it will likely drag on over several more months as I find the occasional spare hour here or there to work on it.

I have everything but the chassis and I am not finding the Hammond chassis or similar offerings in the dimensions or look I want.

I don't have access to a metal shop and don't have a lot of skills with metal working, but I have a well-equipped woodshop and am a pretty competent amateur woodworker. What I would really like to do is buy a sheet of thick aluminum and use a step drill to cut the tube socket holes, buy a piece of steel for the bottom plate and drill some holes in it for ventilation and make the rest of the chassis out of nice figured wood, probably some pieces of curupay I have been saving for something special.

If you look through the photo thread, I think you'll find most (I'm sure at least 1/2) of the projects are built as you describe.. Wood side, aluminum plate for the top.

Don't put anything that will get extremely hot up against the wood.

Negatives, can't use the sides as heat sinks, and metal might offer a little better shielding (but probably not enough to matter).

Don't put anything that will get extremely hot up against the wood.

Negatives, can't use the sides as heat sinks, and metal might offer a little better shielding (but probably not enough to matter).

I really like wood sides and aluminum top myself. Heavy transformers mounted on top might make the top plate bow so use a heavy gauge metal. I also have never been a fan of the driver board in view on the Dynaco St-70.

Here is a link for reference to give you some build ideas:

Hammond Mfg. - Walnut Chassis with Aluminum Top Panel (HWCHAS Series)

Here is a link for reference to give you some build ideas:

Hammond Mfg. - Walnut Chassis with Aluminum Top Panel (HWCHAS Series)

Heavy transformers mounted on top might make the top plate bow so use a heavy gauge metal.

That's a good point. It took years for my first nice project to noticeably sag, but it eventually did. Now I put extra supports in the areas around the transformers. (extra mounts at the edge, or a bar across the entire chassis, under the transformers)

Here is a link for reference to give you some build ideas:

Hammond Mfg. - Walnut Chassis with Aluminum Top Panel (HWCHAS Series)

I built an amp on one of those they look great, I used Front Panel Express for the top panel and made it with 6-mm alumimum and beveled edges.

there are also these, they are 20 gage steel with wood sides, I have used these and they are nice

Hammond Mfg. - Steel Chassis & Bottom Plates with Walnut Side Panels (1441 CWW & 1431 Series)

Best to use all metal chassis if you have sensitive speakers 100db+. If you want to Jazz it up put wood on the sides. You need metal at least top and bottom. With hard to drive speakers you can get away with just about anything. The amp can even hum like hell and you get away with it.

Phil

Phil

shielding for interference is important, depending on speaker sensitivity, your circuit's sensitivity and the RF interference in your location. If you prefer a wood chassis, you ll see in the photo gallery that some people have used copper foil to electrically isolate the entire wood chassis from inside (it hs to be electrically connected to the top part). I am also thinking about painting the inside wood with graphite paint (the kind we use for treating the electric stove)

I've had no problems with noise in the phono-pre amp I build. You do need to ground (back to your star point) all metal plates. And I found it's easier to finish the aluminum with about 400 grit in your random orbital sander then trying to keep it polished. I'm like you, do a lot of wood working - but not much metal work.

Just because you don't hear any noise doesn't mean that your tubes are not oscillating at some RF frequency. You don't really know for sure unless you have a 'scope that goes up to the 100 MHz range. Many kinds of circuits have frequency response well into the radio frequency range, so using an all metal box and putting the tubes in shields is the wise thing to do.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- wood/metal vs all-metal chassis