I'm not sure if this is the right forum, so Mods feel free to move this thread.

I know nothing about tubes, so bear with me

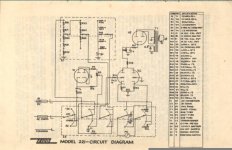

I have an Eico 221 VTVM. The transformer runs hot after only a few minutes on as well as giving off a strong odor. The 6x5 tube glows at the top and gets warm fast. Looking at the schematic, the tube is directly after the transformer winding. I'm not sure if the transformer or the tube is at fault.

The 6x5 tube glows at the top and gets warm fast. Looking at the schematic, the tube is directly after the transformer winding. I'm not sure if the transformer or the tube is at fault.

Any suggestions.

Is it possible to check the tube without a tube tester?

I can post the schematic if it helps.

Thanks for looking.

I know nothing about tubes, so bear with me

I have an Eico 221 VTVM. The transformer runs hot after only a few minutes on as well as giving off a strong odor.

Any suggestions.

Is it possible to check the tube without a tube tester?

I can post the schematic if it helps.

Thanks for looking.

Thanks, DF96. Should I pull the tubes one by one and power up to start eliminating components in the circuit or start checking components in the circuit?

Is it normal for the 6x5 tube to light up on the top (apex) and heat up fast after a minute on or is this an indication that it's drawing too much current?

How can I check if the tube has an internal short w/o a tube tester? (if possible)

Shows how much (nothing) I know about tubes. I'll spend the evening Goggling tubes and how they work.

Is it normal for the 6x5 tube to light up on the top (apex) and heat up fast after a minute on or is this an indication that it's drawing too much current?

How can I check if the tube has an internal short w/o a tube tester? (if possible)

Shows how much (nothing) I know about tubes. I'll spend the evening Goggling tubes and how they work.

I pulled the 6x5 tube with the same results. The transformer heats up and makes a boiling sound as well as giving off a terrible odor. I'm beginning to think the transformer insulation has boiled off causing the windings to short. I may remove the transformer and check DCR as well as ac voltages.

Before doing anything else, disconnect all the transformer's secondary leads from the sockets. Then wire up a standard 40 watt incandescent lamp in series with the transformer's primary. Upon power, the lamp should not light. If it does, the tranny is bad. If you still hear a smoldering sound, it's bad. DC resistance measurments may not tell you much unless you have previous numbers to compare to plus a special ohmmeter capable of making accurate very low resistance measurments. But a boiling & pungent smelling transformer is never a good sign.

While the diagnosis of power trafo failure is probably correct, that may be a manifestation of an underlying problem. Electrolytic caps. in the PSU filter go bad, with age. It is inevitable. Old 'lytics may have taken the rectifier and power trafo down.

If the instrument is to be restored, make certain to replace ALL electrolytic caps., in addition to correcting the flaws detected. Don't send good money after bad.

If the instrument is to be restored, make certain to replace ALL electrolytic caps., in addition to correcting the flaws detected. Don't send good money after bad.

I bought a silver face Eico 221 (newer version) off EBay. Mine was the blue face (original version). If the silver works and is calibrated (I'll calibrate it if needed after a recap), I'll use it as a voltage/resistance reference to repair the blue 221 as the blue was spot on/on all Functions. If it needs a new transformer a fellow AK member made a generous offer for a replacement. Interesting to see what transformer will be in the new set.

If the 6x5 tube is also defective, I'll replace it with the diode mod on both sets. No need to have another transformer go down if a workable modification is looking back at me.

I plan to have 2 fully functional VTVM.

There are some different Functions on the newer silver 221, so the end result won't be 2 of the same, rather 2 working VTVMs with different functions. I think there is a good possibility of success.

If the 6x5 tube is also defective, I'll replace it with the diode mod on both sets. No need to have another transformer go down if a workable modification is looking back at me.

I plan to have 2 fully functional VTVM.

There are some different Functions on the newer silver 221, so the end result won't be 2 of the same, rather 2 working VTVMs with different functions. I think there is a good possibility of success.

Last edited:

Hi jblmar, All

I know this is an old thread but for clarity I'll add this for those that may find them selfs in a similar predicament.

First off, anything this old and being from the Day of Tubes/Valves

Resist all temptation to "plug it in and see if it works" chances are it wont and even if it does it wont work well, more so your liable to cause more damage

Follow the procedures as would be the case with Tube/valve Radio restoration

Check the transformer, replace all electrolytic Caps along with replacing any Wax paper capacitors , depending even silver mica caps can and do fail

Replace any mains Caps with suitable Safety Caps (X & Y or universal)

Check all resistors are within spec and replace any out of spec along with anyone that you feel have been subjected to a lot of heat stress or damage.

On the infamous 6X5 Rectifier tube there are known issues with them as pointed out H~K (heater cathode) being one well known problem.

Just if you must use one use it within the designed parameters, but also remember some circuits did somewhat abuse it even then

If you replace with Silicon Diodes you probably should be using a dropping resistor to bring the B+ down to the original list rail voltage (research that)

(also states side be aware that the mains there it seems has climbed a bit over the years from the original 110 VAC, this can and does cause problems)

With Tube rectifiers dont whack in big Electro Caps, more generally your just asking for trouble in the longer term if not in the shorter term, use what was originally listed is probably the safest idea.

(unless you know how the circuit functions and how far you can deviate from that.)

Your transformer was probably smoked before you got it and possibly due to a shorted tube, thought it may not have been the orginal fault in its self,

Not much help to you jblmar, but it may help others and that why I posted it

Hope you got them both working

I know this is an old thread but for clarity I'll add this for those that may find them selfs in a similar predicament.

First off, anything this old and being from the Day of Tubes/Valves

Resist all temptation to "plug it in and see if it works" chances are it wont and even if it does it wont work well, more so your liable to cause more damage

Follow the procedures as would be the case with Tube/valve Radio restoration

Check the transformer, replace all electrolytic Caps along with replacing any Wax paper capacitors , depending even silver mica caps can and do fail

Replace any mains Caps with suitable Safety Caps (X & Y or universal)

Check all resistors are within spec and replace any out of spec along with anyone that you feel have been subjected to a lot of heat stress or damage.

On the infamous 6X5 Rectifier tube there are known issues with them as pointed out H~K (heater cathode) being one well known problem.

Just if you must use one use it within the designed parameters, but also remember some circuits did somewhat abuse it even then

If you replace with Silicon Diodes you probably should be using a dropping resistor to bring the B+ down to the original list rail voltage (research that)

(also states side be aware that the mains there it seems has climbed a bit over the years from the original 110 VAC, this can and does cause problems)

With Tube rectifiers dont whack in big Electro Caps, more generally your just asking for trouble in the longer term if not in the shorter term, use what was originally listed is probably the safest idea.

(unless you know how the circuit functions and how far you can deviate from that.)

Your transformer was probably smoked before you got it and possibly due to a shorted tube, thought it may not have been the orginal fault in its self,

Not much help to you jblmar, but it may help others and that why I posted it

Hope you got them both working

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- 6x5 tube