833C Details

Hi Tubeman,

nice glowing !

50 us$ for the chokes......that's incredibly cheap for such quality. Cherrish those goodies and put them to good use. And yes....i told you....it will be big and heavy. But see the bright side of it: once the amps are finished they are almost theft-proof !

I see your running now on Hytron's (thank you....another brand to collect....). I really like those older types; they have a good sound.

But if you're able to score some 833C's do not hesitate. They are very good also. And their plate really looks like it's going to survive the Third World War. Tjeeezz...that's not a graphite-anode...it's an oven.

Already any ideas about the chassis / box / topplates / looks / etc of the amplifier. Keep in mind that the transformers and chokes are seriously heavy and the topplate will be quite large. A simple 2 mm plate will NOT do unless supported.

I've used 4 mm stainless steel (for the looks) and even then i placed 3 "pillars" in the amp in order to distribute the weight of the topplate + build-on-items.

Keep the thread alive,

Reinout

Hi Tubeman,

nice glowing !

50 us$ for the chokes......that's incredibly cheap for such quality. Cherrish those goodies and put them to good use. And yes....i told you....it will be big and heavy. But see the bright side of it: once the amps are finished they are almost theft-proof !

I see your running now on Hytron's (thank you....another brand to collect....). I really like those older types; they have a good sound.

But if you're able to score some 833C's do not hesitate. They are very good also. And their plate really looks like it's going to survive the Third World War. Tjeeezz...that's not a graphite-anode...it's an oven.

Already any ideas about the chassis / box / topplates / looks / etc of the amplifier. Keep in mind that the transformers and chokes are seriously heavy and the topplate will be quite large. A simple 2 mm plate will NOT do unless supported.

I've used 4 mm stainless steel (for the looks) and even then i placed 3 "pillars" in the amp in order to distribute the weight of the topplate + build-on-items.

Keep the thread alive,

Reinout

Attachments

Military connectors

Hi Protos,

what do you mean:"only an 300B-amp". I think that is great, i personally like that tube very much. In my last amp as the output tube and now as a driver. Nowadays there are so many choices/flavours 300B to chose from.

The connectors: that was another great find on Ebay !

I needed high voltage connectors with enough pins for all the different voltages.

On Ebay i've found Bendix military connectors. The MIL-C-5015 (the MS3016 is another nice standard) is a good standard used by the military. There are several suppliers of this standard: Bendix, Amphenol, Array to name a few. Just follow Ebay and you'll be amazed what you can find. The trouble is to find connectors WITH their plugs. Search words: (military)(mil-spec) connectors / amphenol.

I found really nice titanium stuff.

The 6SN7 and the 300b have their own "umbillical chord" for there filaments / bias / high voltage.

The 833 has also it's own "umbillical chord" since that is or very high amperage or very high voltage. I simply did not want to mix that with the 6SN7/300B-stuff.

Anyway: forget the flimsy Hirschmann's. Nice for lower voltages, NOT for 1000 VDC.

For my phonostage i've used Neutrik 4-pin XLR's with good result. But feeding 300B-voltages through them ? I would hesitate to do that.

Hope this answers your question ?

Since i manage to add only 1 picture at the time i first will attach a picture of the actual connectors and in another mail i will continue the connector-umbillical-line story.

With regards,

Reinout

Hi Protos,

what do you mean:"only an 300B-amp". I think that is great, i personally like that tube very much. In my last amp as the output tube and now as a driver. Nowadays there are so many choices/flavours 300B to chose from.

The connectors: that was another great find on Ebay !

I needed high voltage connectors with enough pins for all the different voltages.

On Ebay i've found Bendix military connectors. The MIL-C-5015 (the MS3016 is another nice standard) is a good standard used by the military. There are several suppliers of this standard: Bendix, Amphenol, Array to name a few. Just follow Ebay and you'll be amazed what you can find. The trouble is to find connectors WITH their plugs. Search words: (military)(mil-spec) connectors / amphenol.

I found really nice titanium stuff.

The 6SN7 and the 300b have their own "umbillical chord" for there filaments / bias / high voltage.

The 833 has also it's own "umbillical chord" since that is or very high amperage or very high voltage. I simply did not want to mix that with the 6SN7/300B-stuff.

Anyway: forget the flimsy Hirschmann's. Nice for lower voltages, NOT for 1000 VDC.

For my phonostage i've used Neutrik 4-pin XLR's with good result. But feeding 300B-voltages through them ? I would hesitate to do that.

Hope this answers your question ?

Since i manage to add only 1 picture at the time i first will attach a picture of the actual connectors and in another mail i will continue the connector-umbillical-line story.

With regards,

Reinout

Attachments

umbillical chord

Hi Protos,

as promised the continuation.

In the picture you can see the umbillical chords in the making. for wire i used teflon-insulated wire.

Again military stuff with exotic names like MIL-W-16878 or MIL-W-22759.

The types i used was a 600V-variety for the filaments 6SN7/300B/833 and a 1000V-variety for the high voltages 6SN7/300B. I know, i know......that was not really needed but i like a safety margin. The material itself is silver plated copper which is very nice soldering with !

And teflon.....it's forgiving if you accidentally touches the insulation wtih your soldering iron. Try that with PVC.....funny smell....molten insulation. You notice that already if you see the specifications of the mil-standards of the wire i used: 200 C. Now THAT is a safety margin.

For the high voltage of the 833 i used really different wire. It's also a teflon insulated wire but a special high voltage one: Sumitomo TV-20. This has a voltage rating of 20.000 volts...... And still AWG14-size (as were the earlier mentioned types) so they fitted the Bendix connectors good.

The result of using the teflon wires and the connectors is a rather stiff, but still flexible umbillical chord.

Does this answer suffice ?

Reinout

Hi Protos,

as promised the continuation.

In the picture you can see the umbillical chords in the making. for wire i used teflon-insulated wire.

Again military stuff with exotic names like MIL-W-16878 or MIL-W-22759.

The types i used was a 600V-variety for the filaments 6SN7/300B/833 and a 1000V-variety for the high voltages 6SN7/300B. I know, i know......that was not really needed but i like a safety margin. The material itself is silver plated copper which is very nice soldering with !

And teflon.....it's forgiving if you accidentally touches the insulation wtih your soldering iron. Try that with PVC.....funny smell....molten insulation. You notice that already if you see the specifications of the mil-standards of the wire i used: 200 C. Now THAT is a safety margin.

For the high voltage of the 833 i used really different wire. It's also a teflon insulated wire but a special high voltage one: Sumitomo TV-20. This has a voltage rating of 20.000 volts...... And still AWG14-size (as were the earlier mentioned types) so they fitted the Bendix connectors good.

The result of using the teflon wires and the connectors is a rather stiff, but still flexible umbillical chord.

Does this answer suffice ?

Reinout

Attachments

Thanks Reinout, it is very informative.I am glad you photo-diarize everything you do - amazing!Your posts are a master class.

I was looking at connectors like that at the rs catalogue but their price is a bit off putting - around 30 euro each.

I also saw that high quality computer type connectors are rated at 700V and are much cheaper.

Do you keep B+ and filaments separate?What about shielding?I can't see any in your umbilicals.Did you have any hum problems?

I was looking at connectors like that at the rs catalogue but their price is a bit off putting - around 30 euro each.

I also saw that high quality computer type connectors are rated at 700V and are much cheaper.

Do you keep B+ and filaments separate?What about shielding?I can't see any in your umbilicals.Did you have any hum problems?

Hi Protos,

i made all these pictures for several reasons:

- i'll don't make a 833-amp everyday and i've made a picture album to take with me when going to an audio-show, etc.

- my insurance company had some funny questions: "what is that, proof please ?!".

I don't have any humm-problems. All my voltages are DC. Yes, also the filaments of the 6SN7/300B/833. Of course there will be some puritans who will declare me "unwise", but now i was able to get all the wires together inside 2 umbillicals without any shielding, chance on humm, etc. And it works just fine. Besides that: the 6SN7 and 300B are possible to get humm-silent on their filaments, but the 10V of the 833 will be a hard nut to crack to ge silent on AC.

The wires are soldered inside the soldercups of the connectingpins. And i've slided some heat-shrink teflon on the soldering afterwards. Nice, stable, durable, trustworthy and it looks good too !

First connector/umbillical: 6SN7 (filament / B+), 300B (filament / bias / B+).

Second connector: 833-lines

And as said: everything on DC.

You're working with the RS cataloque, i had the Farnell one. Same thing: funny pricing for the connectors. But with the 1000-1500 VDC i had no other option than to go for the milspec stuff. Only i used Ebay as a source. I believe that i had to pay 100 euro for 8 plugs/sockets (ex postage); i sourced them from Germany. Sorry, they are all used. Looking back i understand that was an incredible low price and i had to buy everything that was possible then.....

How is the your parts-gathering going on ? Tubes ? Caps ? Iron ?

With regards,

Reinout

i made all these pictures for several reasons:

- i'll don't make a 833-amp everyday and i've made a picture album to take with me when going to an audio-show, etc.

- my insurance company had some funny questions: "what is that, proof please ?!".

I don't have any humm-problems. All my voltages are DC. Yes, also the filaments of the 6SN7/300B/833. Of course there will be some puritans who will declare me "unwise", but now i was able to get all the wires together inside 2 umbillicals without any shielding, chance on humm, etc. And it works just fine. Besides that: the 6SN7 and 300B are possible to get humm-silent on their filaments, but the 10V of the 833 will be a hard nut to crack to ge silent on AC.

The wires are soldered inside the soldercups of the connectingpins. And i've slided some heat-shrink teflon on the soldering afterwards. Nice, stable, durable, trustworthy and it looks good too !

First connector/umbillical: 6SN7 (filament / B+), 300B (filament / bias / B+).

Second connector: 833-lines

And as said: everything on DC.

You're working with the RS cataloque, i had the Farnell one. Same thing: funny pricing for the connectors. But with the 1000-1500 VDC i had no other option than to go for the milspec stuff. Only i used Ebay as a source. I believe that i had to pay 100 euro for 8 plugs/sockets (ex postage); i sourced them from Germany. Sorry, they are all used. Looking back i understand that was an incredible low price and i had to buy everything that was possible then.....

How is the your parts-gathering going on ? Tubes ? Caps ? Iron ?

With regards,

Reinout

Attachments

Things are going well with sourcing.300b EML at 14W , 6sn7, Plitron PTX&OTX,CLCLCRC PS.I have to thank Derek Walton for his help :http://indigo.ie/~walton/300bmk2.html

chassis

Hi fellow-audioholics ?!,

i received some mail about how i came up with the chassis of the amps + PS.

Peter: you've collected most of the expensive parts: iron and tubes (nice tube, the EML. I have seen and had them in my hand.....but never was able to listen to them. They looked very promising !) . But how about the "frame".

So here's my supplier: ITEM Systems

On the web under www.item-international.com

Although this is a German-based manufacturor, they have offices / service points in a lot of countries. They were very nice to deal with. Normally they make the frameworks, workbenches, conveyor-belts, etc.

They have a lot of standardised parts (called profiles) and everything fits beautifull together. I've used Profile 8 80x40 2N. Very handy: besides the possibility to bolt the plates onto it, they have more possibilities to fixate items onto it.

I made a rough drawing and they came up with a suggestion/quatation. After some weeks a package arrived with the goodies. All was pre-drilled and tapped. It was just like working with Meccano or Fischer Technik.

ITEM-profiles: a good combination of possibilities + lightweight + encredibly sturdy.

Reinout

(and will post another message with a picture of the audio-rack)

Hi fellow-audioholics ?!,

i received some mail about how i came up with the chassis of the amps + PS.

Peter: you've collected most of the expensive parts: iron and tubes (nice tube, the EML. I have seen and had them in my hand.....but never was able to listen to them. They looked very promising !) . But how about the "frame".

So here's my supplier: ITEM Systems

On the web under www.item-international.com

Although this is a German-based manufacturor, they have offices / service points in a lot of countries. They were very nice to deal with. Normally they make the frameworks, workbenches, conveyor-belts, etc.

They have a lot of standardised parts (called profiles) and everything fits beautifull together. I've used Profile 8 80x40 2N. Very handy: besides the possibility to bolt the plates onto it, they have more possibilities to fixate items onto it.

I made a rough drawing and they came up with a suggestion/quatation. After some weeks a package arrived with the goodies. All was pre-drilled and tapped. It was just like working with Meccano or Fischer Technik.

ITEM-profiles: a good combination of possibilities + lightweight + encredibly sturdy.

Reinout

(and will post another message with a picture of the audio-rack)

Attachments

rack in parts I

Hi,

my 833-amps are quite large: 52 x 75 cm. And they weigh in at 280 kg. So a lot of audio-rack suppliers were simply not capable of offering something usable.

For ITEM i was only a very small custumor. But it was the first time they saw their products used in audio !

Same procedure as the frames: my drawing which led to their suggestion + quotation.

Reinout

Picture of the "parts" of the audiorack:

Hi,

my 833-amps are quite large: 52 x 75 cm. And they weigh in at 280 kg. So a lot of audio-rack suppliers were simply not capable of offering something usable.

For ITEM i was only a very small custumor. But it was the first time they saw their products used in audio !

Same procedure as the frames: my drawing which led to their suggestion + quotation.

Reinout

Picture of the "parts" of the audiorack:

Attachments

audio-rack in parts II

And the next picture:

Here you can see the almost completely assembled rack. And you can see the amp-frame + protective cage.

Why the cage ? If there are visitors in my house with children (poking fingers......) i have the cages in place.

The frame is again made by ITEM (this time Profile 5) and i've fixed punched stainless steel plates inside the frame. The holes are large enough to let the heat out and small enough to stop children's attempts to touch the tubes.

It will never get a CE-qualification, but it will do.

Reinout

And the next picture:

Here you can see the almost completely assembled rack. And you can see the amp-frame + protective cage.

Why the cage ? If there are visitors in my house with children (poking fingers......) i have the cages in place.

The frame is again made by ITEM (this time Profile 5) and i've fixed punched stainless steel plates inside the frame. The holes are large enough to let the heat out and small enough to stop children's attempts to touch the tubes.

It will never get a CE-qualification, but it will do.

Reinout

Attachments

Hello Reinout,

I have just went through all the posts here with a great enthusiasm. Currently I 'm using DIY GM70 amp and the idea of going further into even bigger triodes fires me up.

Can you help me with a few issues?

1. Step-down IT should handle probably huge grid current. Let's get the popular lundahl stuff like LL1660. It can be configured as 4.5:1 ratio. It has a several versions with a different air gaps like for 18ma, 25mA, 30ma etc. 18ma version in 1:1.125 ratio can handle 18ma thru primary. When you configure it for 4.5:1 ratio the primary can handle 16mA DC current. Now if you want to use it for grid current hungry application, you should probably add the DC primary current of the driver + grid current of the power tube. Can you estimate what is the max grid current of 833 at full power at your op point?

2. 833 is a high mu tube so it doesn't need a lot of voltage to drive it. I assume you have the zero bias point. Can you tell me what is the needed driver/IT output voltage for 833 full power?

3. My current amp has the B+ at 870V. I can supply up to 150mA current. From a 833 curves I noticed that I can have a zero bias at 870V and about 130mA current - perfect! Do you think that 7k OPT would be fine at this op point and what power I can get from a tube?

So many questions...

thanks

Maciej

I have just went through all the posts here with a great enthusiasm. Currently I 'm using DIY GM70 amp and the idea of going further into even bigger triodes fires me up.

Can you help me with a few issues?

1. Step-down IT should handle probably huge grid current. Let's get the popular lundahl stuff like LL1660. It can be configured as 4.5:1 ratio. It has a several versions with a different air gaps like for 18ma, 25mA, 30ma etc. 18ma version in 1:1.125 ratio can handle 18ma thru primary. When you configure it for 4.5:1 ratio the primary can handle 16mA DC current. Now if you want to use it for grid current hungry application, you should probably add the DC primary current of the driver + grid current of the power tube. Can you estimate what is the max grid current of 833 at full power at your op point?

2. 833 is a high mu tube so it doesn't need a lot of voltage to drive it. I assume you have the zero bias point. Can you tell me what is the needed driver/IT output voltage for 833 full power?

3. My current amp has the B+ at 870V. I can supply up to 150mA current. From a 833 curves I noticed that I can have a zero bias at 870V and about 130mA current - perfect! Do you think that 7k OPT would be fine at this op point and what power I can get from a tube?

So many questions...

thanks

Maciej

Wow Reinout..you have a lot of patience I think.....and very good planning...That really is the best thing to have when building a valve amp or anything else really  . Gathering parts cheaply via Ebay over a period of years. But then again transformers are often the most expensive parts...How about your casing...was that expensive?

. Gathering parts cheaply via Ebay over a period of years. But then again transformers are often the most expensive parts...How about your casing...was that expensive?

Congratulations on a very very impressive project!!!

Are you bringing your amp to the Dutch DIY day? Mmmbpphrrhabaaawwhaaaahaa..

Congratulations on a very very impressive project!!!

Are you bringing your amp to the Dutch DIY day? Mmmbpphrrhabaaawwhaaaahaa..

Banned

Joined 2002

Re: 833 amp does work

WOW.. that looks great.. I'm just getting into Tubes now.. and wow i was so impressed with your amps.. WOAH..

GOOD JOB>.

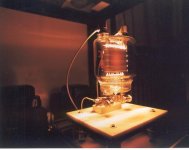

ReinoutdV said:Just finished my 833-amp. After a serious breaking-in and listening time i am pretty pleased with the result (personal opinion of course). Trying to describe the sound is not easy, but "effortless" is a nice start.

Funny: a huge tube, a massive power supply, half a truckload of components.......and the sound is ...."light" "airy". Don't get me wrong, there is seriious grunt.

The amp is in two monoblocks with their own powersupply. And yes: you need a substantial amount of transformers. I'm using 135 kg of transformers and of course that explains why not a lot of people are going for the nice tube.

Pricewise it is a nice tube as well. NOS is still available and new is nowadays produced (even a new carbon based anode).

The amp is in A2 and currently i've set the B+ at 1000 V. In the future i can switch to higher voltages in trying to find the sweetspot.

I'll attach a picture of the amp, remember there is another unit just as large which is the power supply.

Lots of luck with building and please be carefull with the high voltages (the other reason why there are not as many 833-builders around).

Reinout

WOW.. that looks great.. I'm just getting into Tubes now.. and wow i was so impressed with your amps.. WOAH..

GOOD JOB>.

top plates / Dutch DIY-audio day

Hi Bas,

thanks for the compliment. It was indeed a 2 1/2 year-project. 1 year theory. 1 year parts gathering. Last 6 months actual building. But i think worth it; they sound good. And i've received very nice comment on the amps on this forum.

I'll try to join the Dutch DIY Audio Day on 17th April, but i will NOT bring the 833-amps (spine-breaker). Maybe my 6C45-based phonostage or the 6SN7-based headphone-amplifier. If i can come.......other obligations as well.

I posted an internet-adress of ITEM systems where i sourced the casing and frame. To be honest: it was cheaper than the stuff i formerly used. Those were solid aluminium slabs bolted together. But the ITEM Systems parts are lighter, more versatile, cheaper, etc etc. And VERY important: they do all the drilling and tapping of all needed holes. You only have to bold it together.

If you contact them: they are used to work with firms, not with individual persons. But they are very friendly and visiting them in Maassluis (adress Zwarte Zee 40-42, tel: 010-5937260) is advisable. They have good coffee and than you can see the actual parts.

I hope i can join the DIY-day.....i've got lots of their "profile-samples" which i can show you.

Besides the transformers (obvious the most expensive parts) the top- and bottomplates were not cheap either. They are made out of 4 mm stainless steel. For the bottomplate standard (dull) stuff, for the topplate polished. I've contacted several firms who were able to get the material AND cutting it according to my drawings. They were all asking very "funny" prices. In the end i've found a manufacturor of agricultural devices who had a laser-cutting table and was willing and able to do the job during periods of less activity. Again.....patience.....but the result is very nice (for a good price).

I hope to see you on the 17th. With regards,

Reinout

Hi Bas,

thanks for the compliment. It was indeed a 2 1/2 year-project. 1 year theory. 1 year parts gathering. Last 6 months actual building. But i think worth it; they sound good. And i've received very nice comment on the amps on this forum.

I'll try to join the Dutch DIY Audio Day on 17th April, but i will NOT bring the 833-amps (spine-breaker). Maybe my 6C45-based phonostage or the 6SN7-based headphone-amplifier. If i can come.......other obligations as well.

I posted an internet-adress of ITEM systems where i sourced the casing and frame. To be honest: it was cheaper than the stuff i formerly used. Those were solid aluminium slabs bolted together. But the ITEM Systems parts are lighter, more versatile, cheaper, etc etc. And VERY important: they do all the drilling and tapping of all needed holes. You only have to bold it together.

If you contact them: they are used to work with firms, not with individual persons. But they are very friendly and visiting them in Maassluis (adress Zwarte Zee 40-42, tel: 010-5937260) is advisable. They have good coffee and than you can see the actual parts.

I hope i can join the DIY-day.....i've got lots of their "profile-samples" which i can show you.

Besides the transformers (obvious the most expensive parts) the top- and bottomplates were not cheap either. They are made out of 4 mm stainless steel. For the bottomplate standard (dull) stuff, for the topplate polished. I've contacted several firms who were able to get the material AND cutting it according to my drawings. They were all asking very "funny" prices. In the end i've found a manufacturor of agricultural devices who had a laser-cutting table and was willing and able to do the job during periods of less activity. Again.....patience.....but the result is very nice (for a good price).

I hope to see you on the 17th. With regards,

Reinout

Attachments

interstage

Hi Maciek,

the GM70.....very promising tube. I believe the sockets are somewhat difficult to source (although you can by high quality ones in the USA with prices to match). Sorry, never heard them. There are so many tubes around. The last tube that really impressed me was a 813 (in triode). GOOD !!!!!!

Now your questions:

- i'm using a step-down interstage between the 300B and the 833. The 300B does deliver tens of mA's (i can change that between between 0 and 75 mA ....for my panel meters stops at 75 ma....which is more than enough). So if you use say 50 mA (my current setting) than the Lundahl has to be configured to a lower ratio. And my ratio is 4:1 !!!! Which is exactly why my interstage is not a small tiny item, but a serious transformer (E96-size ! See the attached picture: the interstage is right of the 300B). I had this interstage winded as a normal (large) outputtransformer; but just a different secondary instead of the standard 4/8 ohm tabs.

- from the internet: A driver for a tube running in class A2 must have an internal impedance ten times lower than this value. Let us take the example of the 833A, a directly heated triode with 300W plate dissipation and an amplification factor mu of 35. Since mu is high, the useful operating rang in class A1 will be very narrow unless high voltage plate are applied (2500V to 3000V will be required). Class A2 biasing is much more appealing : with 1250V and Vg=0 , optimal load resistance is 5 kOmega and output power Po = 100 Watt . Maximum positive grid voltage will be Vg = +50 V , with an associated grid current Ig = 30 mA as indicated on the datasheet. The dynamic resistance computes as 1.6 k . The driver tube must have an internal impedance in the 100 ohm range or lower. Very few triodes can have such a low value; some tubes used in serie regulation will match this requirement (for example the well known 6C33C). Other options are possible, like using a step down interstage transformer so that grid impedance appears higher. In the previous example a 2:1 transformer will give 4.4 kohm resistance and a driver P near 400 ohm . An no-compromise approach will use a higher ratio, like 4:1 or 6:1 in order to allow directly heated triodes as drivers (300B for the first ratio and 845 for the second). It worth note that interstage transformers are more difficult to build when ratio is above 10:1.

- the voltages you apply are completely dependend on what driver you're going to chose and the type of schematic. I know a Belgian tube-addict who wants a 833 driven by an E55L in a mu-stage. How can i ever compare the voltages ?

- Bob Danielak did built a 833 on 650 Volts and used a 5 kOhm opt. 7 K seems somewhat high and more apllicable when using higher voltages say 1500 ~ 2000 Volts.

Hope this answers your questions ?

Looking forward to your pictures ! Please post them.

Reinout

Hi Maciek,

the GM70.....very promising tube. I believe the sockets are somewhat difficult to source (although you can by high quality ones in the USA with prices to match). Sorry, never heard them. There are so many tubes around. The last tube that really impressed me was a 813 (in triode). GOOD !!!!!!

Now your questions:

- i'm using a step-down interstage between the 300B and the 833. The 300B does deliver tens of mA's (i can change that between between 0 and 75 mA ....for my panel meters stops at 75 ma....which is more than enough). So if you use say 50 mA (my current setting) than the Lundahl has to be configured to a lower ratio. And my ratio is 4:1 !!!! Which is exactly why my interstage is not a small tiny item, but a serious transformer (E96-size ! See the attached picture: the interstage is right of the 300B). I had this interstage winded as a normal (large) outputtransformer; but just a different secondary instead of the standard 4/8 ohm tabs.

- from the internet: A driver for a tube running in class A2 must have an internal impedance ten times lower than this value. Let us take the example of the 833A, a directly heated triode with 300W plate dissipation and an amplification factor mu of 35. Since mu is high, the useful operating rang in class A1 will be very narrow unless high voltage plate are applied (2500V to 3000V will be required). Class A2 biasing is much more appealing : with 1250V and Vg=0 , optimal load resistance is 5 kOmega and output power Po = 100 Watt . Maximum positive grid voltage will be Vg = +50 V , with an associated grid current Ig = 30 mA as indicated on the datasheet. The dynamic resistance computes as 1.6 k . The driver tube must have an internal impedance in the 100 ohm range or lower. Very few triodes can have such a low value; some tubes used in serie regulation will match this requirement (for example the well known 6C33C). Other options are possible, like using a step down interstage transformer so that grid impedance appears higher. In the previous example a 2:1 transformer will give 4.4 kohm resistance and a driver P near 400 ohm . An no-compromise approach will use a higher ratio, like 4:1 or 6:1 in order to allow directly heated triodes as drivers (300B for the first ratio and 845 for the second). It worth note that interstage transformers are more difficult to build when ratio is above 10:1.

- the voltages you apply are completely dependend on what driver you're going to chose and the type of schematic. I know a Belgian tube-addict who wants a 833 driven by an E55L in a mu-stage. How can i ever compare the voltages ?

- Bob Danielak did built a 833 on 650 Volts and used a 5 kOhm opt. 7 K seems somewhat high and more apllicable when using higher voltages say 1500 ~ 2000 Volts.

Hope this answers your questions ?

Looking forward to your pictures ! Please post them.

Reinout

Attachments

Hope to see you too.hope to see you on the 17th. With regards,

Unreal..the stuff dreams are made of!They are made out of 4 mm stainless steel.

Cheers,

Bas

thanks for the answers Reinout!

Here you have the picture of my amp and GM70 copper /premium/ version.

Amp uses Tribute signal iron and lundahl PSU chokes.

It is AVVT AV8 /choke loaded/-AV8-IT 1:1-GM70 setup with separate PSU for driver and power tube section. I measured 48W output power and 3mV hum (0.3mV when the first tube was 6H6P). With my 92dB Tannoy drivers the level of hum is acceptable.

This is one monoblock picture

Maciej

Here you have the picture of my amp and GM70 copper /premium/ version.

Amp uses Tribute signal iron and lundahl PSU chokes.

It is AVVT AV8 /choke loaded/-AV8-IT 1:1-GM70 setup with separate PSU for driver and power tube section. I measured 48W output power and 3mV hum (0.3mV when the first tube was 6H6P). With my 92dB Tannoy drivers the level of hum is acceptable.

This is one monoblock picture

Maciej

Attachments

Amperex by Night 1

Hi,

Maciej....that's looking very nice. Say what you want: you simply can not buy those in the shop ! Congratulations with the result. I bet it sounds good and i'm happy that you have paying attention to "the looks" as well. Remember: the eye is listening also (and that is no misprint). For breadboarding your perfectly free for an open structure were you can change everything without any hassle. But there comes a time when it must be placed in a nice box/chassis/structure. Reasons:

- touch proof;

- your proud of your sonic achievement.....show it. A bewildering stack of funny parts will simply not do;

- you have to stop somewhere otherwise you'll never pass your very first project. Of course there will be room for minor changes;

A couple of weeks ago there was a hamfest by the NVHR (= Nederlandese Vereniging van historisch Radiomateriaal = Dutch Society of Historical Radio Equipment). Sometimes there is really nothing worth to see, but this time i hit the jackpot. I spotted a new-in-the-box Amperex 833A from February 1952. And a couple of weeks ago a found also an Amperex at Halfin in Brussels, Belgium (http://tubes.halfin.com). When i closely examined them at home they were only 7 numbers apart !! Now that is a serious pair from the same year/month/day. Even the handwriting of the assembly was the same. Now there un my set and beginning to awake after 52 years of rest.

The 17th of April there will be the very first Dutch DIY Audio Happening. looking forward to the event (Bas....i signed up....see you there ?!) and maybe there will be more 833's lying around.

Keep up the good works,

Reinout

Hi,

Maciej....that's looking very nice. Say what you want: you simply can not buy those in the shop ! Congratulations with the result. I bet it sounds good and i'm happy that you have paying attention to "the looks" as well. Remember: the eye is listening also (and that is no misprint). For breadboarding your perfectly free for an open structure were you can change everything without any hassle. But there comes a time when it must be placed in a nice box/chassis/structure. Reasons:

- touch proof;

- your proud of your sonic achievement.....show it. A bewildering stack of funny parts will simply not do;

- you have to stop somewhere otherwise you'll never pass your very first project. Of course there will be room for minor changes;

A couple of weeks ago there was a hamfest by the NVHR (= Nederlandese Vereniging van historisch Radiomateriaal = Dutch Society of Historical Radio Equipment). Sometimes there is really nothing worth to see, but this time i hit the jackpot. I spotted a new-in-the-box Amperex 833A from February 1952. And a couple of weeks ago a found also an Amperex at Halfin in Brussels, Belgium (http://tubes.halfin.com). When i closely examined them at home they were only 7 numbers apart !! Now that is a serious pair from the same year/month/day. Even the handwriting of the assembly was the same. Now there un my set and beginning to awake after 52 years of rest.

The 17th of April there will be the very first Dutch DIY Audio Happening. looking forward to the event (Bas....i signed up....see you there ?!) and maybe there will be more 833's lying around.

Keep up the good works,

Reinout

Attachments

- Home

- Amplifiers

- Tubes / Valves

- Where are the 833 amps?