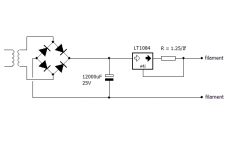

I'm trying on CCS for filament. Below is my simple schematic. I've got problem that I can hear vibration noise at quite high level in first 25-30 seconds. Filament voltage increases step by step. When Vout reaches 2-3Vdc, that noise dissapears. I guess filament string shaking a lot in early periode. Those noises are only for directed heater tubes (2E22, 6B4G, 300B are my cases), not for indirected heater tubes(ex. 6L6, 6550)

I have some questions :

What is the cause and how to treat it ?

Does that phenomenon impact in filaments quality of directed heater tube, also tube quality too ?

Thank you,

QA.

I have some questions :

What is the cause and how to treat it ?

Does that phenomenon impact in filaments quality of directed heater tube, also tube quality too ?

Thank you,

QA.

Attachments

Last edited:

(1) Are all tubes being heated by ONE constant-current source? (if YES, then this is an error. It is very unwise to do... as it can force current into tubes that heat up at different rates unequally)

(2) The direct-heated tubes are designed to have a higher inrush current, and to heat rather signficantly faster than a constant-current source will supply. This causes much slower heating, so all thermal expansion (that normally might take a couple seconds) is stretched out over 20+ seconds.

(3) After its all good and 'warmed up', is the final output voltage where the manufacturer spec wants it to be?. Reason... constant current sources are well known for either under, or over-voltage driving tubes of slightly different conduction. Tubes are specified with precise filament voltages, and no guarantees are made for amperage. j

In short, since you have a nice regulator there, why not put it in voltage-regulation mode, and let it do its job per the manufacturer spec? I think it makes a whole lot more sense. Further, you can install a small potentiometer to let it be variable voltage, between ±20% of the center-position set to "nominal".

GoatGuy

(2) The direct-heated tubes are designed to have a higher inrush current, and to heat rather signficantly faster than a constant-current source will supply. This causes much slower heating, so all thermal expansion (that normally might take a couple seconds) is stretched out over 20+ seconds.

(3) After its all good and 'warmed up', is the final output voltage where the manufacturer spec wants it to be?. Reason... constant current sources are well known for either under, or over-voltage driving tubes of slightly different conduction. Tubes are specified with precise filament voltages, and no guarantees are made for amperage. j

In short, since you have a nice regulator there, why not put it in voltage-regulation mode, and let it do its job per the manufacturer spec? I think it makes a whole lot more sense. Further, you can install a small potentiometer to let it be variable voltage, between ±20% of the center-position set to "nominal".

GoatGuy

(1) Are all tubes being heated by ONE constant-current source? (if YES, then this is an error. It is very unwise to do... as it can force current into tubes that heat up at different rates unequally)

As you see my schema, power transformer and Rconstant source was adjusted depending on kind of tube.

I'm concerning 2 issues above and waiting for the answer(2) The direct-heated tubes are designed to have a higher inrush current, and to heat rather signficantly faster than a constant-current source will supply. This causes much slower heating, so all thermal expansion (that normally might take a couple seconds) is stretched out over 20+ seconds.

I did regulator voltage plus 1 choke as current source for my 71A tube and I did regu voltage schemas for indirected tube in my phono tube preampli. This manner is so easy. But filament current source choke is very hard to power tube... cause of very big volume (high current)In short, since you have a nice regulator there, why not put it in voltage-regulation mode, and let it do its job per the manufacturer spec? I think it makes a whole lot more sense. Further, you can install a small potentiometer to let it be variable voltage, between ±20% of the center-position set to "nominal".

CCS plays isolation filaments and PSU, so you get much better sound.

Frankly I'd use Rod Coleman's regulators - much better than LM1084. The LM1084 works, and I've used it a lot, but it can have some hiss in the sound. Looking at your schematic I'm wondering if you've connected it correctly. Pin 3 is input. The resistor goes between pins 1 and 2 and the output is from pin 1 Adjust. It sounds better in current mode for filaments. But it's not in the same world as Rod's regulators.

Last edited:

If your question is about the mechanical noise then yes, many directly heated tubes (and some indirectly heated ones) will make mechanical tings and poings as the tube structure heats up and moves. Some do it not at all and others do it a lot. If the B+ is on and the circuit functioning as the filament heats then you'll hear it from the speakers. I've never considered it to be a problem except with a couple of tubes I had that went on and on . . . . . . . .and . . . . . . . . . . . . . . .on.

I've had circuit noise troubles with the LT108_ a few times but they were caused by oscillation and were taken care of by compensating the pins with capacitors as described in the data sheet.

I've had circuit noise troubles with the LT108_ a few times but they were caused by oscillation and were taken care of by compensating the pins with capacitors as described in the data sheet.

Frankly I'd use Rod Coleman's regulators - much better than LM1084. The LM1084 works, and I've used it a lot, but it can have some hiss in the sound. Looking at your schematic I'm wondering if you've connected it correctly. Pin 3 is input. The resistor goes between pins 1 and 2 and the output is from pin 1 Adjust. It sounds better in current mode for filaments. But it's not in the same world as Rod's regulators.

I'm correct on connecting LT1084 pins

I've heard noise from tube inside by using CCS above (without B+ supply) . But these noises don't exist when I use AC heater or DC heater with CRC filtering for the same tube. Noise is so loud that I can hear 2 meters away.

during heat up/cool down period metalic noises can be heard. depends on mechanical (build) quality of tube

filament changes temperature and lenght significantly

But I can not hear any noise from those tubes when they are heated by AC power

Does anyone have the same situation like me ?

I will try this one on pre DHT, like 26, 71A or 4P1L....

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Problem with CCS for filaments