I still have a quartet of coppers in addition to several pairs I gave away with high hours.. I've come to the conclusion over time that I really prefer the graphite overall, with 7K primary Z I hear only the very slightest difference in the HF performance of graphite vs copper. I have several brands, and seem to recall that the very long in the tooth graphites (1500 hours) currently in the amp are Reflektor made, they still sound really good. I've had other pairs that sounded dead at 1000 hours.

I've had 3 pairs of coppers in my amps and the odd noises they make during warm up scare me... The graphites are pretty quiet, just a little corona crackle as they warm up.. lol (My supplies are all solid state and come up pretty quick, no reliability problems in more than 4 yrs of hard use.)

I've had 3 pairs of coppers in my amps and the odd noises they make during warm up scare me... The graphites are pretty quiet, just a little corona crackle as they warm up.. lol (My supplies are all solid state and come up pretty quick, no reliability problems in more than 4 yrs of hard use.)

What are your impressions on the Ulianov Graphite plate SQ and time life?I still have a quartet of coppers in addition to several pairs I gave away with high hours.. I've come to the conclusion over time that I really prefer the graphite overall, with 7K primary Z I hear only the very slightest difference in the HF performance of graphite vs copper. I have several brands, and seem to recall that the very long in the tooth graphites (1500 hours) currently in the amp are Reflektor made, they still sound really good. I've had other pairs that sounded dead at 1000 hours.

I've had 3 pairs of coppers in my amps and the odd noises they make during warm up scare me... The graphites are pretty quiet, just a little corona crackle as they warm up.. lol (My supplies are all solid state and come up pretty quick, no reliability problems in more than 4 yrs of hard use.)

Thanks

Filament Supply

Hi all.

I'd really like to hear your thoughts about the filament supply for this tube.

Choke or capacitor input? Choke or capacitor output?

Or current regulated?

Should the filament polarity be swapped over now and then because of the unbalanced emission across the 20V DC filament?

Should I use a resistor center-tap across the filament or ground one end?

If I've learned one thing during this whole process, it's that the power supply for this tube is much more complicated than I expected……

Hi all.

I'd really like to hear your thoughts about the filament supply for this tube.

Choke or capacitor input? Choke or capacitor output?

Or current regulated?

Should the filament polarity be swapped over now and then because of the unbalanced emission across the 20V DC filament?

Should I use a resistor center-tap across the filament or ground one end?

If I've learned one thing during this whole process, it's that the power supply for this tube is much more complicated than I expected……

All of my comments should be taken as anecdotal or conjecture; I've not taken notes or in general paid a lot of attention in recent times to GM70 variations.

I haven't met a graphite plate version I didn't like, but am no longer a fan of the coppers for a variety of reasons including I just don't like the way they sound that much. In my system the last pair sounded a bit "nasal" - how is that for subjective.. lol The behavior during warm up is frightening and is not exhibited by the graphite plate ones at all. (Squeals, pops, rustling, corona noise, etc.)

I've had at least one pair of the Ulianov GM70 graphite plate and thought they were quite good. Most of my current stash I am pretty sure are Reflektor regardless of the marking on them. (And many have no brand marking other than the type, date and inspector #) I have so far not had a single GM70 fail in service, but I generally replace them at 1200 hours or so. This last pair were still giving relatively good service at over 1500 hrs (an experiment) but replacing them did result in significantly better bottom end. Based on operating point measurements over time emission dropped substantially over those hours - something around 30% or so would be about right. (I suspect transconductance decreased somewhat and rp increased which would account for the loss of low end response)

A couple of years ago I purchased a quartet of 1960s vintage Souz made GM70 which unfortunately were destroyed in transit due to inadequate packing. The seller, a nice fellow made good upon presentation of sufficient evidence. I have never been able to find more. They were clearly not made on the same tooling as all of the ones I currently own.

I haven't met a graphite plate version I didn't like, but am no longer a fan of the coppers for a variety of reasons including I just don't like the way they sound that much. In my system the last pair sounded a bit "nasal" - how is that for subjective.. lol The behavior during warm up is frightening and is not exhibited by the graphite plate ones at all. (Squeals, pops, rustling, corona noise, etc.)

I've had at least one pair of the Ulianov GM70 graphite plate and thought they were quite good. Most of my current stash I am pretty sure are Reflektor regardless of the marking on them. (And many have no brand marking other than the type, date and inspector #) I have so far not had a single GM70 fail in service, but I generally replace them at 1200 hours or so. This last pair were still giving relatively good service at over 1500 hrs (an experiment) but replacing them did result in significantly better bottom end. Based on operating point measurements over time emission dropped substantially over those hours - something around 30% or so would be about right. (I suspect transconductance decreased somewhat and rp increased which would account for the loss of low end response)

A couple of years ago I purchased a quartet of 1960s vintage Souz made GM70 which unfortunately were destroyed in transit due to inadequate packing. The seller, a nice fellow made good upon presentation of sufficient evidence. I have never been able to find more. They were clearly not made on the same tooling as all of the ones I currently own.

Hi all.

I'd really like to hear your thoughts about the filament supply for this tube.

Choke or capacitor input? Choke or capacitor output?

Or current regulated?

Should the filament polarity be swapped over now and then because of the unbalanced emission across the 20V DC filament?

Should I use a resistor center-tap across the filament or ground one end?

If I've learned one thing during this whole process, it's that the power supply for this tube is much more complicated than I expected……

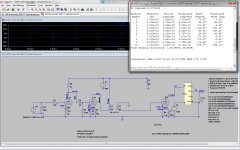

I use Schottky rectifiers, and a single 10000uF cap into an LT1084 monolithic regulator which in turn feeds a Rod Coleman filament regulator. (gyrator and ccs)

I am very pleased with the overall performance and this is also kinder to the tube filaments during warm up. There is no noise from filament heating to contend with using this approach.

Note that the LT1084 does not like to start into this sort of load so I continuously bypass about 1/3 of the filament current around it to assist in starting. Under extreme line transient conditions the LT1084 can still latch occasionally.

The tubes under the conditions I use them don't last long enough for filament polarity to be a concern. Emission drops well before anything else happens.

I ground the negative end of the filament supply. In lower voltage designs I sometimes like to create an artificial center using a pair of resistors and a small resistor from there to ground to sense current. Not all that practical at 20V I'd say due to dissipation in the resistors, and you have to compensate for the current if you are using a CCS for heating.

I've come to prefer CCS heating over AC or DC heating. DC heating has been unregulated w/wo chokes, voltage regulated with chokes between the regulator and the filament which would be my second choice - costs way more than the CCS and IMHO looses some advantages like controlled warm up, and extreme ripple suppression.

Thanks Kevin for your detailed reply.All of my comments should be taken as anecdotal or conjecture; I've not taken notes or in general paid a lot of attention in recent times to GM70 variations.

I haven't met a graphite plate version I didn't like, but am no longer a fan of the coppers for a variety of reasons including I just don't like the way they sound that much. In my system the last pair sounded a bit "nasal" - how is that for subjective.. lol The behavior during warm up is frightening and is not exhibited by the graphite plate ones at all. (Squeals, pops, rustling, corona noise, etc.)

I've had at least one pair of the Ulianov GM70 graphite plate and thought they were quite good. Most of my current stash I am pretty sure are Reflektor regardless of the marking on them. (And many have no brand marking other than the type, date and inspector #) I have so far not had a single GM70 fail in service, but I generally replace them at 1200 hours or so. This last pair were still giving relatively good service at over 1500 hrs (an experiment) but replacing them did result in significantly better bottom end. Based on operating point measurements over time emission dropped substantially over those hours - something around 30% or so would be about right. (I suspect transconductance decreased somewhat and rp increased which would account for the loss of low end response)

A couple of years ago I purchased a quartet of 1960s vintage Souz made GM70 which unfortunately were destroyed in transit due to inadequate packing. The seller, a nice fellow made good upon presentation of sufficient evidence. I have never been able to find more. They were clearly not made on the same tooling as all of the ones I currently own.

I wonder how much more hours your GM70 would last in your amp.

1200-1500 hours seems too early to change a GM70.

Do you believe they would reach 500 hours in a 25W amp??

Their rated life is just 1000 hours under the rated conditions of use which is how I run them.

I don't see why you couldn't get around 1500 hours out of a pair running in a 25Wpc amp - you won't be dissipating any more power than I am in all likelihood as I am at the design limit. (And yes you can run at 20% or more beyond their ratings without visible signs of distress at 1kV anyway)

My current amps with sufficient drive for A2 (not available) can produce about 40W output. The current driver by intent limits ouput to around 20W, other considerations like the desire to stick to a two stage design took precedence..

I don't see why you couldn't get around 1500 hours out of a pair running in a 25Wpc amp - you won't be dissipating any more power than I am in all likelihood as I am at the design limit. (And yes you can run at 20% or more beyond their ratings without visible signs of distress at 1kV anyway)

My current amps with sufficient drive for A2 (not available) can produce about 40W output. The current driver by intent limits ouput to around 20W, other considerations like the desire to stick to a two stage design took precedence..

I made a typo, sorry. I mean say 5K hours, not 500 hours.Their rated life is just 1000 hours under the rated conditions of use which is how I run them.

I don't see why you couldn't get around 1500 hours out of a pair running in a 25Wpc amp - you won't be dissipating any more power than I am in all likelihood as I am at the design limit. (And yes you can run at 20% or more beyond their ratings without visible signs of distress at 1kV anyway)

My current amps with sufficient drive for A2 (not available) can produce about 40W output. The current driver by intent limits ouput to around 20W, other considerations like the desire to stick to a two stage design took precedence..

If the GM70 can reach 5000 hours with 20-25Wpc I have interest in it.

I suppose the 1000 hours rated life is at the hard military conditions.

In the Hi-Fi conditions I think time life would be much longer than it.

I expect I dont be wrong.

With 4x gm-70 PSE is upon you and it is beyond your will to resist. Build it:

GM-70 PSE | dream of all Audiophiles | TG

GM-70 PSE | dream of all Audiophiles | TG

I made a typo, sorry. I mean say 5K hours, not 500 hours.

If the GM70 can reach 5000 hours with 20-25Wpc I have interest in it.

I suppose the 1000 hours rated life is at the hard military conditions.

In the Hi-Fi conditions I think time life would be much longer than it.

I expect I dont be wrong.

I get the same mileage as Kevin. 1500 Hours is replacement time for sure.

Putz not good news.I get the same mileage as Kevin. 1500 Hours is replacement time for sure.

I was think GM70 was much more robust than 6C33.

What plate dissipátion you run? Around 100W?

I use Schottky rectifiers, and a single 10000uF cap into an LT1084 monolithic regulator which in turn feeds a Rod Coleman filament regulator.

Thanks for the reply Kevin. I've ordered a pair of Rod Coleman regulators.

I made a typo, sorry. I mean say 5K hours, not 500 hours.

If the GM70 can reach 5000 hours with 20-25Wpc I have interest in it.

I suppose the 1000 hours rated life is at the hard military conditions.

In the Hi-Fi conditions I think time life would be much longer than it.

I expect I dont be wrong.

I think you would be wrong, very wrong.. lol It is quite justifiable based on the recommendation if you want consistent and safe performance with these tubes to replace them at the 1000 - 1500 hour mark. I've had ones that sounded terrible at 1100 hours, and the just replaced pair at 1500 hours sounds OK but was bettered in some respects by a new pair.

This tube is not a military tube as far as I know, I don't own a single one with an OTK stamp on it. These are very high quality DHTs designed primarily for fixed civilian installations; they were found in amplifiers used in large venues, stadiums and the like. (A quartet in PPP can do 1kW) Amps using these tubes I am aware of came in 500W and 1kW flavors. I also recall seeing them used in at least one plate modulator application for moderate power AM transmitters.

These tubes use very hot running pure tungsten filaments, and they wear out quite quickly. The 60W of filament power combined with 120W of plate dissipation means operating temperatures are very high. (IIRC I measured an envelope temperature of > 175 C) They are hard on the gettering as well..

They were never designed with the idea that audiophiles would use them in big SE amps. Scads of them were made to supply the commercial PA market which is why they were and are so inexpensive. I suspect because of central planning they continued to be made in very large quantities long after the demand for them had peaked.

A good 300B (JJ for example) will give you > 5000 hours if run at no more than 80% of dissipation rating but a pair would cost you about as much as 5 or 6 pairs of GM70 so it is a choice you have to make.

Thanks Kevin for taking time to post it.I think you would be wrong, very wrong.. lol It is quite justifiable based on the recommendation if you want consistent and safe performance with these tubes to replace them at the 1000 - 1500 hour mark. I've had ones that sounded terrible at 1100 hours, and the just replaced pair at 1500 hours sounds OK but was bettered in some respects by a new pair.

This tube is not a military tube as far as I know, I don't own a single one with an OTK stamp on it. These are very high quality DHTs designed primarily for fixed civilian installations; they were found in amplifiers used in large venues, stadiums and the like. (A quartet in PPP can do 1kW) Amps using these tubes I am aware of came in 500W and 1kW flavors. I also recall seeing them used in at least one plate modulator application for moderate power AM transmitters.

These tubes use very hot running pure tungsten filaments, and they wear out quite quickly. The 60W of filament power combined with 120W of plate dissipation means operating temperatures are very high. (IIRC I measured an envelope temperature of > 175 C) They are hard on the gettering as well..

They were never designed with the idea that audiophiles would use them in big SE amps. Scads of them were made to supply the commercial PA market which is why they were and are so inexpensive. I suspect because of central planning they continued to be made in very large quantities long after the demand for them had peaked.

A good 300B (JJ for example) will give you > 5000 hours if run at no more than 80% of dissipation rating but a pair would cost you about as much as 5 or 6 pairs of GM70 so it is a choice you have to make.

I appreciated it.

I think I will stick w/6C33 or maybe the small 6C41 if it have good sound quality as the 6C33.

Regards

I still have a quartet of coppers in addition to several pairs I gave away with high hours.. I've come to the conclusion over time that I really prefer the graphite overall, with 7K primary Z I hear only the very slightest difference in the HF performance of graphite vs copper. I have several brands, and seem to recall that the very long in the tooth graphites (1500 hours) currently in the amp are Reflektor made, they still sound really good. I've had other pairs that sounded dead at 1000 hours.

I've had 3 pairs of coppers in my amps and the odd noises they make during warm up scare me... The graphites are pretty quiet, just a little corona crackle as they warm up.. lol (My supplies are all solid state and come up pretty quick, no reliability problems in more than 4 yrs of hard use.)

I think I will sell my copper plates (4PC) and get the more graphite

Spend that extra money on irons or other stuff.

I wish I could read these post from you before the purchase.

Greetings

I also have several GM70 and others tubes that I will not use.I think I will sell my copper plates (4PC) and get the more graphite

Spend that extra money on irons or other stuff.

I wish I could read these post from you before the purchase.

Greetings

This is rather common among users of valve amps.

Welcome to the club!

I can only speak for myself; just because I prefer the graphites to the coppers does not mean that everyone should or will. Much of this is down to personal preferences and system design. I listen to a lot of music with deep bass and graphite do a better job in my specific amplifier design, and I find the mids and HF performance with JBL 2440/2382A mid driver and horn and Fostex T825 horn tweeter quite pleasing as well, but your experience could be different for a variety of reasons no one anticipates.

You should form your own conclusions based on your own experience rather than take my word for it. You could even reach the same conclusion I did, but you also may not. So check it out first and then decide!

You should form your own conclusions based on your own experience rather than take my word for it. You could even reach the same conclusion I did, but you also may not. So check it out first and then decide!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- GM-70 design approach