As I look at you amplifier pictures, running a high voltage wire should not be your main concern. That's the easy part if you use the proper high voltage wire. Belden 8899 5KV test probe wire is a good one I like to use. And there are others like Marcal silicone HV wire. The possible problem I see is the tube socket itself and the metal chassis in close proximity.I run 1386volts to the front of my amp to the 6D22S rec tubes, but then I have to run the B+ from there back to the tall set of caps. I am concerned that I will run a wire with more than 1000 volts along the chassis and the volts can "jump" or arc to a ground. So how do I run the wire back to the caps without it arcing? How much space do I have to provide? Thanks.

I'm unfamiliar with the 6D22S, but it doesn't look like a high voltage rectifier I would use just based on it's size. But if it really is like an EY500, and not an exaggeration, then I suppose it will serve. You'll need a good porcelain socket that's rated for several thousand volts. Same for the filament transformer insulation.

Last edited:

Too funny Mel. I didn't think I'd like the E140 but it sounds fairly good.JBL E140's you say!

I used 1500v rated wire. Then on the chokes and transformers which only had 600v rated wire I bought a roll of shrink tubing (600v rating) and added an extra layer of protection over all the wires. My chokes were all hi-pot tested to 2500v so I'm feeling pretty good about it all. Oh and rubber grommets for anything through the chassis.

Thanks Mel. I just got a handful of grommets just for that reason.

As I look at you amplifier pictures, running a high voltage wire should not be your main concern. That's the easy part if you use the proper high voltage wire. Belden 8899 5KV test probe wire is a good one I like to use. And there are others like Marcal silicone HV wire. The possible problem I see is the tube socket itself and the metal chassis in close proximity.

I'm unfamiliar with the 6D22S, but it doesn't look like a high voltage rectifier I would use just based on it's size. But if it really is like an EY500, and not an exaggeration, then I suppose it will serve. You'll need a good porcelain socket that's rated for several thousand volts. Same for the filament transformer insulation.

Thanks Hollow. after I read your post last night I look for anywhere around here that sold the 8899 to no avail. I need some other parts from Mouser so I'll add that to the order.

The 6D22S is well up to the job. For all the tubes in this amp I have heavy duty ceramic sockets. I was most worried about the corona effect of running such high B+ around the chassis.

I used high voltage wire and in some instances added an additional layer of heatshrink tubing to bolster the insulation. I also covered the plate connection and wiring to the OPT.

I have had problems with Corona discharge in this amplifier, new GM70 tubes seem to need to bake the base to eliminate internal paths, and I have had various other high voltage induced issues. My previous designs operated with raw supplies in the 600 - 700V range, going to just over 1kV seems to have opened a whole new world of issues.

I would run the filaments for about 30 minutes before applying B+ the first time just to bake out the tube bases and prevent internal tracking. (Strange sizzling noises during warm up will otherwise result)

Without a doubt though this is the best sounding (and probably measuring) SE amplifier I have yet designed. Worth the quirks..

I have had problems with Corona discharge in this amplifier, new GM70 tubes seem to need to bake the base to eliminate internal paths, and I have had various other high voltage induced issues. My previous designs operated with raw supplies in the 600 - 700V range, going to just over 1kV seems to have opened a whole new world of issues.

I would run the filaments for about 30 minutes before applying B+ the first time just to bake out the tube bases and prevent internal tracking. (Strange sizzling noises during warm up will otherwise result)

Without a doubt though this is the best sounding (and probably measuring) SE amplifier I have yet designed. Worth the quirks..

Thanks K. Will do on the burn in of the filliments. I've ordered a roll of Belden 8899 and have many feet of shrink tube. I am also thinking about epoxying blocks of white nylon with holes drilled through it here and there to make sure that I route all the hv wiring away from the signal path. I thought there was more room in the chassis but as I continue to add parts, it is starting to get tighter than I like for a high voltage amp.

I used high voltage wire and in some instances added an additional layer of heatshrink tubing to bolster the insulation. I also covered the plate connection and wiring to the OPT.

I have had problems with Corona discharge in this amplifier, new GM70 tubes seem to need to bake the base to eliminate internal paths, and I have had various other high voltage induced issues. My previous designs operated with raw supplies in the 600 - 700V range, going to just over 1kV seems to have opened a whole new world of issues.

I would run the filaments for about 30 minutes before applying B+ the first time just to bake out the tube bases and prevent internal tracking. (Strange sizzling noises during warm up will otherwise result)

Without a doubt though this is the best sounding (and probably measuring) SE amplifier I have yet designed. Worth the quirks..

Boy I am with you on that last comment. My GM70 amp just sounds fantastic! And with a $25.00 tube! It is after all a "High-Power Low-Frequency Triode" and then some.

well my project got pushed back a week or so.....actually I did it to myself. As you know, being an artist, how things look are as important to me as any other aspect of a build. I kept looking at the color I painted the power transformer, choke, and OPTs and they just don't work well with the over all color of the chassis. So, I am taking them to Ron's to paint them a more better color. He is a tester for House of Kolor so be assured, they will look better when we get done. Because of the color difference, it looks like an amp with a top side and a base......not one amp. If I have to look at this thing for the next 30 years (or more I hope), I'd rather take the time to do it right.

Hi All, well its been months since I posted. I put the GM70 aside to do a lot of other things one of which was to lay in bed for three months suffering horrible depression after quitting smoking 2 packs a day. The doc gave me some funny little pills that put me right back on track.

My new room does not have the built in audio rack my old room did so I have been building an audio rack. I hope to have it done in a week. Then the GM70 is on the bench.

Merry Christmas!!!

My new room does not have the built in audio rack my old room did so I have been building an audio rack. I hope to have it done in a week. Then the GM70 is on the bench.

Merry Christmas!!!

Hi All, well its been months since I posted. I put the GM70 aside to do a lot of other things one of which was to lay in bed for three months suffering horrible depression after quitting smoking 2 packs a day. The doc gave me some funny little pills that put me right back on track.

My new room does not have the built in audio rack my old room did so I have been building an audio rack. I hope to have it done in a week. Then the GM70 is on the bench.

Merry Christmas!!!

Djn,

Occupational therapy is one of the best things to get well quickly from depression. So start the AMP asap.

Merry Christmas

Pawel

I agree Pawel. I only took the meds for one month and it snapped me out of it. The doc said it is normal. Here is a link to my rack build. Cheers, Dennis.

http://www.diyaudio.com/forums/ever...shing-my-audio-rack-many-pix.html#post3298241

.

http://www.diyaudio.com/forums/ever...shing-my-audio-rack-many-pix.html#post3298241

.

Not true – (in fact, I've never even heard that), but it is true that the ΓM-70 likes a high impedance primary (6-7K is good, 9-12K is better) and carries a good amount of current in higher wattage applications (>100mA often) resulting in a larger OPT core, the two of which add up to extra inductance which could roll off highs if not carefully done. My bet is that anyone who complains of the '70 not giving great highs has their OPT to blame, not the tube itself (which is capable of well beyond 40KHz).That is what I am hoping Mel. The only down side I've ever heard about the ΓM70 is there, in some cases, can be a lack of highs.

I just used Pomona 6733 (rated 10Kv) and no matter where I ran it, it didn't arc. That being said, the most direct path you can take from the recs – (I used the 6Д22C as well) – to the filter bank and from the final caps to the OPT is advisable.I need a little advice. Because I like my junk to look cool it sometimes gets me in trouble. Here is a case in point. I run 1386volts to the front of my amp to the 6D22S rec tubes, but then I have to run the B+ from there back to the tall set of caps. I am concerned that I (geez I can't remember the term) will run a wire with more than 1000volts along the chassis and the volts can "jump" or arc to a ground. So how do I run the wire back to the caps without it arcing? How much space do I have to provide? Thanks.

Really??I'm unfamiliar with the 6D22S, but it doesn't look like a high voltage rectifier I would use just based on it's size.

The 6Д22C is not small. It's an 1¼" in diameter and about 4" tall with a separate cathode cap – pretty good sized for a half-wave rectifier.

They're rated 6000V and will take current peaks up to 1000mA (300 continuous) – and those are conservative ratings. I've used them with everything from 6С33C, 813, 845, to (yes) ΓM-70 (running at 1250V) and they're tough as nails – in fact, I'm hard pressed to find a more durable, hearty rectifier. The only drawback is that you need about 4A of 6.3V (for heaters) for a full-wave rectifier.

I have a seperate PTX for the filliments of the 6D22S and the 12GN7A. It is 6.3-0-6.3 with (I think) 15amps. I have to make sure of that but I know it was enough to light the 4 tubes without heating up.

My OPTs are 8K and are HUGE. If you look at the pix, you can see how big they are compared to the GM70 standing right in front of them. They are really heavy as well.

My OPTs are 8K and are HUGE. If you look at the pix, you can see how big they are compared to the GM70 standing right in front of them. They are really heavy as well.

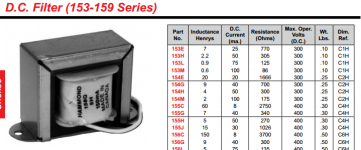

Here are the chokes a friend gave me (thanks Sean) for loading the 12GN7As. I don't know much about choke loading so I am asking if you all think they will work. I am running 350vdc through them.

Opps. They are the 156Cs down near the bottom of the clip

Opps. They are the 156Cs down near the bottom of the clip

Attachments

Check some theory and/or parafeed calculator at Voltsecond's website

Effects of Parafeed Part Values

Effects of Parafeed Part Values

+1Check some theory and/or parafeed calculator at Voltsecond's website

Effects of Parafeed Part Values

This may help as well:

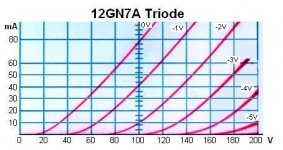

Looks like (@8mA), you could run at a Vg of about -3.5V (≈148V) and get 240VPk-Pk swing @ 2½VRMS input.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- FINALLY I can start building my GM70