I made the nicest little amp, with the sweetest sound. No hum in the speakers. But my power transformer hummmmmms - a lot.

Type Musical Power Supplies 190.2i

Its mounted tightly with rubber washers. I can try adding more or removing those.

The end bells are polished and the iron painted white. Everything is tightened down afterwards.

It has the following outputs, most of which are lightly loaded:

240 v in - I have 238V

190 - 0 - 55 - 190 at 120mA - I measure 80mA at 385V, 55V not used

6.3V 3Amp - I use 6.3V 2 Amp

6.3V or 5V 2 amp - I use 5V 2Amp (Right at the limit)

Do I need another transformer, or do you have any Ideas?

Type Musical Power Supplies 190.2i

Its mounted tightly with rubber washers. I can try adding more or removing those.

The end bells are polished and the iron painted white. Everything is tightened down afterwards.

It has the following outputs, most of which are lightly loaded:

240 v in - I have 238V

190 - 0 - 55 - 190 at 120mA - I measure 80mA at 385V, 55V not used

6.3V 3Amp - I use 6.3V 2 Amp

6.3V or 5V 2 amp - I use 5V 2Amp (Right at the limit)

Do I need another transformer, or do you have any Ideas?

Nice amplifier... I like the build quality. You must have real high sensitivity speakers to take advantage of so little power.

It doesn't look an overload from the secondaries loads.

But You can always check it by unplugging all the tubes, and power on the amplifier unloaded.

Being a new amplifier and new transformer, did it start humming since the first day of use?

That white paint on the transformer iron came from the manufacturer, or did You apply it afterwards?

The transformer may have excessive iron losses, sometimes caused by bad isolation between the core silicon steel sheets. This is caused by oxidation but it takes long years to happen, usually.

Or if You used a conductive paint, then it is shorting the core lamination causing abnormal iron losses on a new transformer.

If this is not the case, then the transformer winding may be loose and vibrating when loaded, so it is defective and I would return it to the manufacturer.

Cheers.

It doesn't look an overload from the secondaries loads.

But You can always check it by unplugging all the tubes, and power on the amplifier unloaded.

Being a new amplifier and new transformer, did it start humming since the first day of use?

That white paint on the transformer iron came from the manufacturer, or did You apply it afterwards?

The transformer may have excessive iron losses, sometimes caused by bad isolation between the core silicon steel sheets. This is caused by oxidation but it takes long years to happen, usually.

Or if You used a conductive paint, then it is shorting the core lamination causing abnormal iron losses on a new transformer.

If this is not the case, then the transformer winding may be loose and vibrating when loaded, so it is defective and I would return it to the manufacturer.

Cheers.

I´m happy you like it

I´m using 96db/W Visaton 200B on open baffle, and dreaming of making a back loaded horn.

Thanks for several useful ideas.

I became aware of the hum after maybe the first hour or so. but in the beginning I was focusing on voltages and bias and playing loud so I cant say if it was there at the start.

I did the painting several months ago. I cant remember whether I had the screws in when I painted. So I may have gotten some paint between the laminations. In the old days sink was used a a pigment in white paint. I have no idea what is in the one i used tho. It is an acrylic car touch-up spray. The laminations were pretty heavily coated with some glossy stuff from the factory. I roughed it up for painting but did not remove it, figuring rust and isolation was a good thing.

I´ll check no load tomorrow - its getting late here.

I´m using 96db/W Visaton 200B on open baffle, and dreaming of making a back loaded horn.

Thanks for several useful ideas.

I became aware of the hum after maybe the first hour or so. but in the beginning I was focusing on voltages and bias and playing loud so I cant say if it was there at the start.

I did the painting several months ago. I cant remember whether I had the screws in when I painted. So I may have gotten some paint between the laminations. In the old days sink was used a a pigment in white paint. I have no idea what is in the one i used tho. It is an acrylic car touch-up spray. The laminations were pretty heavily coated with some glossy stuff from the factory. I roughed it up for painting but did not remove it, figuring rust and isolation was a good thing.

I´ll check no load tomorrow - its getting late here.

Last edited:

Is it the end bells?

If you press on the end bells of the Tx does it stop or reduce?

Edcor tend to do this so I took it apart and filled the inside of each with a layer of sealant as thick as possible but not in contact with the windings..

You have to take into account how hot it gets..

Another thing is a shorted turn..ie if 2 bolts come into contact with each side of the laminations there should be insulators to stop this..

Either plastic inserts or fiber washers..test on ohms between each bolt and the laminations or between each bolt and each other bolt..there should be no connection..

One in contact is OK for earthing the laminations (only one)with no connection to any other bolt that goes through the laminations.

Regards

M. Gregg

If you press on the end bells of the Tx does it stop or reduce?

Edcor tend to do this so I took it apart and filled the inside of each with a layer of sealant as thick as possible but not in contact with the windings..

You have to take into account how hot it gets..

Another thing is a shorted turn..ie if 2 bolts come into contact with each side of the laminations there should be insulators to stop this..

Either plastic inserts or fiber washers..test on ohms between each bolt and the laminations or between each bolt and each other bolt..there should be no connection..

One in contact is OK for earthing the laminations (only one)with no connection to any other bolt that goes through the laminations.

Regards

M. Gregg

Last edited:

Ok - I tried no load - taking out the tubes. Hum was very slightly lower - could be my imagination.

Then I put in the tubes again and tried pressing the end bells firmly. A very slight difference. I could probably use the sealant trick.

I also tried pushing it from different directions relative to the chassis. Pushing it towards the front helped a bit.

So it may be a combination of several factors. I´ll try removing the rubber grommets next.

Then I put in the tubes again and tried pressing the end bells firmly. A very slight difference. I could probably use the sealant trick.

I also tried pushing it from different directions relative to the chassis. Pushing it towards the front helped a bit.

So it may be a combination of several factors. I´ll try removing the rubber grommets next.

All four screws have nylon washers, and I remember putting heat-shink on the screws before mounting them, as there was no isolation originally. I´ll open them up and check whether the heat has made them shrink and open a connection. Heat shrink may not have been a smart idea. Is there a point about having one screw connected?

Last edited:

I recall that many of the power transformers I encountered years ago had a wide copper strap that went around them covering sides of the winding area under the bells and visible going up and over the outside of the far sides of the "E"s. The strap continuous being soldered to itself. I never measured idle currents, but recall that those transformers were quiet.

Are you sure you don't have a shorted turn?

I'm not talking about the windings..

Three of the screws through the laminations should be insulated from the end bells and the laminations..

Regards

M. Gregg

This is interesting. perhaps he can take the screws out and try it. Easy enough to find out.

I´m back from work and ready to try more of your suggestions now.

First test is to loosen the transformer so its riding more freely on the rubber grommets. No noticeable effect.

I tried wriggling it around and at some positions hum was reduced. There is a resonance in the chassis involved. But the transformer is still vibrating noticeably.

I´ll post back when I have taken off the end bells and inspected the bolts.

First test is to loosen the transformer so its riding more freely on the rubber grommets. No noticeable effect.

I tried wriggling it around and at some positions hum was reduced. There is a resonance in the chassis involved. But the transformer is still vibrating noticeably.

I´ll post back when I have taken off the end bells and inspected the bolts.

I unbolted the end bells while they were still mounted to the chassis. While playing the amp in this state, I found that the transformer is dead quiet, it is one end bell that has one of its mounting lugs doubling as the star ground point that is vibrating. It is directly connected to the smoothing capacitor pcb.

So now the question is a ground loop or induction from the transformer.

I have mains power earthed at a point 3cm from the socket.

Then I have a str ground in the center of each tube, both of which are connected to a common star ground with the power supply. Finally there is a separate back wall of aluminum for inputs and outputs that are grounded at the opposite point from the power supply.

So I guess I´ll have to find another star ground point.

Guilty of the heat shrink!  For some reason I forgot it and didn't see my mistake until I was too focused on finishing the wiring. I´ll have to go back and fix it.

For some reason I forgot it and didn't see my mistake until I was too focused on finishing the wiring. I´ll have to go back and fix it.

And since I´m dismounting stuff with the hum problem it will get done in the process.

The vibration I observed now is that the transformer is almost quiet, but end bells held by hand close by vibrate. No bolts involved.

And since I´m dismounting stuff with the hum problem it will get done in the process.

The vibration I observed now is that the transformer is almost quiet, but end bells held by hand close by vibrate. No bolts involved.

That transformer has got too much magnetic radiation, perhaps due to a insufficient core quality and/or the bells are not thick enough to void vibration.

I get my E/I transformers from UK suppliers like Sowter SOWTER AUDIO TRANSFORMERS and SJS http://www.users.globalnet.co.uk/~valveamp/ and so far never had these kind of issues as they build them really well, even the bells are heavy and dead enough to void vibrations.

I get my E/I transformers from UK suppliers like Sowter SOWTER AUDIO TRANSFORMERS and SJS http://www.users.globalnet.co.uk/~valveamp/ and so far never had these kind of issues as they build them really well, even the bells are heavy and dead enough to void vibrations.

So basically I´ll have to hum along to the tune, or get another transformer...

Sowther M021 is £211.46

or Edcor XPWR186-240 at $54

SJS I could´nt find the right type

Hammond does not have all the voltages required[SIZE=+1]

[/SIZE]The simple amp will be expensive it I travel that route.[SIZE=+1]

[/SIZE]

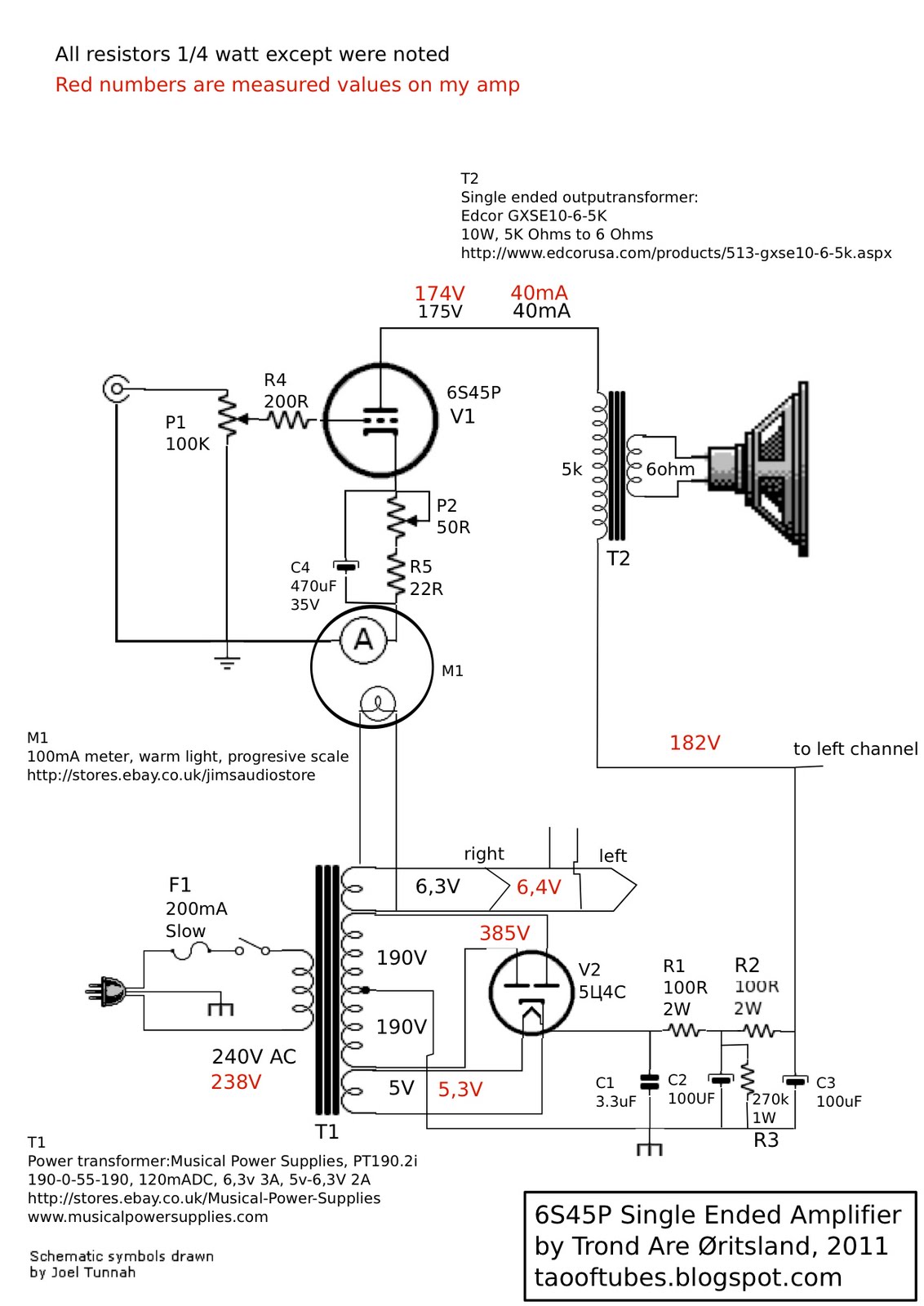

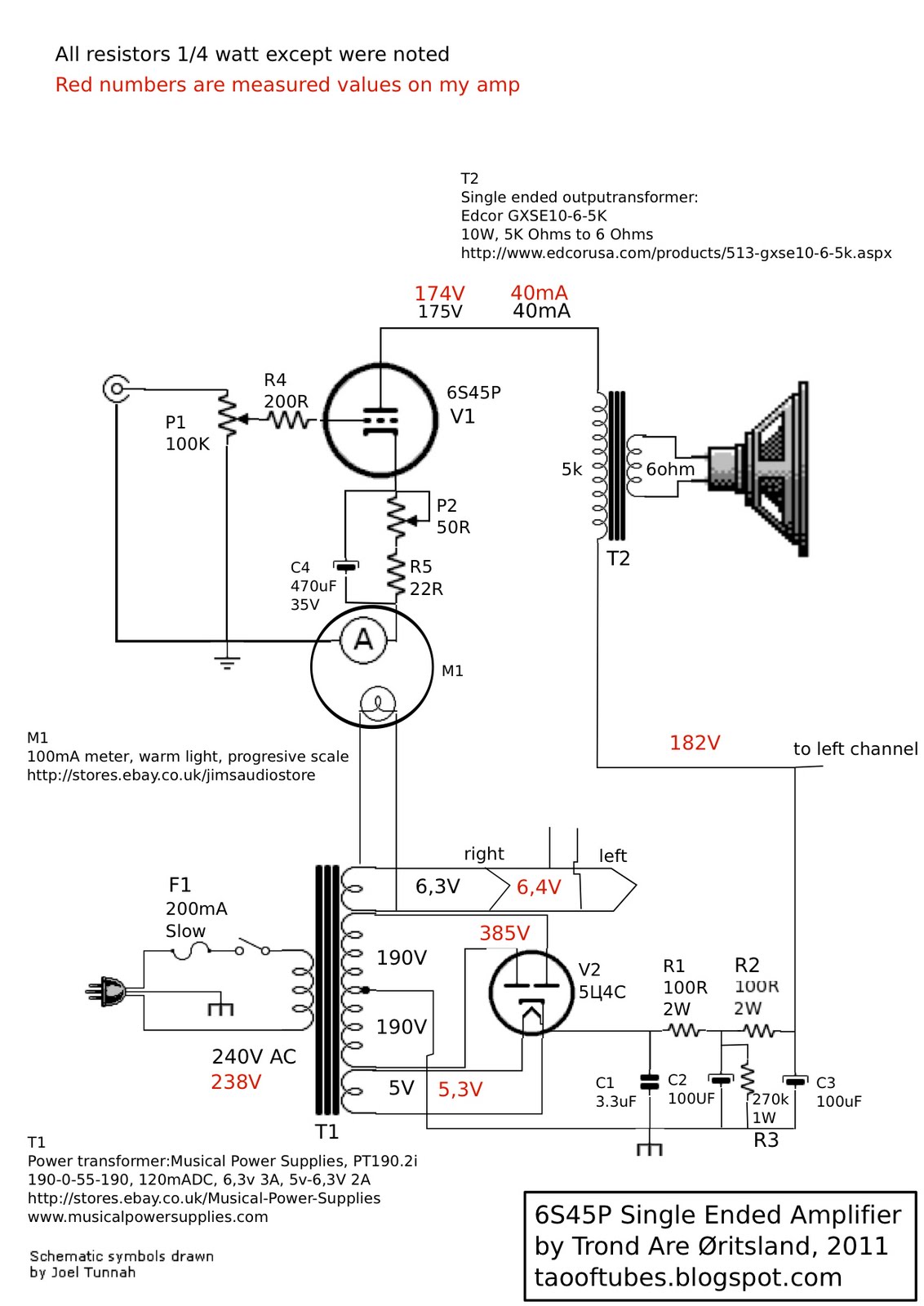

Or could It be that it actually is overpowered/ under rated. here is the schematic with measured values in red:

Sowther M021 is £211.46

or Edcor XPWR186-240 at $54

SJS I could´nt find the right type

Hammond does not have all the voltages required[SIZE=+1]

[/SIZE]The simple amp will be expensive it I travel that route.[SIZE=+1]

[/SIZE]

Or could It be that it actually is overpowered/ under rated. here is the schematic with measured values in red:

Last edited:

You may want to double check if the bell ends and the 4 bolts passing through the transformer laminations aren't still making short circuit loops somehow.

This could be a possibility. The bolts passing through the transformers should not make any contact with the laminations.

Its definitely not the bolts since I have tried taking them out and pressing the bells on by hand. The problem is the magnetic field making the end bells vibrate. So I need heavier bells or non magnetic ones, or I need to find out why the transformer has this strong field.

Next I´ll try another transformer to see if the wiring or ground loops are making trouble.

Next I´ll try another transformer to see if the wiring or ground loops are making trouble.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- I need to lose that Hummmm