Advice and suggestions requested:

I am refitting my Dynakit ST-70 with Gregg V's (Geek's) driver board, and while I am at it, converting the tube rectification to solid state. Naturally that requires a re-think of the voltage dropping scheme to make the driver board happy.

The driver board expects 400v for the phase inverter (LTP using 6CG7), and 250v for the 5751 voltage amplifier. I'm guessing about the current draw from the LTP as I am not familiar with Gregg's unusual implementation. (info here)

The output section is stock ST-70 (P-P EL34 UL) and I'm using all the stock Dynaco transformers (the cloth wire ones).

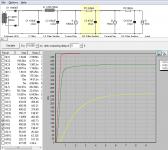

I modelled this with PSUD2, but I am new to that, so I don't know if it's done well. (see attached pic). I will use a CL150 ntc thermistor after the diodes. The first current tap in the model is for the EL34s, next is for the LTP, and last for the voltage amplifier.

..Todd

I am refitting my Dynakit ST-70 with Gregg V's (Geek's) driver board, and while I am at it, converting the tube rectification to solid state. Naturally that requires a re-think of the voltage dropping scheme to make the driver board happy.

The driver board expects 400v for the phase inverter (LTP using 6CG7), and 250v for the 5751 voltage amplifier. I'm guessing about the current draw from the LTP as I am not familiar with Gregg's unusual implementation. (info here)

The output section is stock ST-70 (P-P EL34 UL) and I'm using all the stock Dynaco transformers (the cloth wire ones).

I modelled this with PSUD2, but I am new to that, so I don't know if it's done well. (see attached pic). I will use a CL150 ntc thermistor after the diodes. The first current tap in the model is for the EL34s, next is for the LTP, and last for the voltage amplifier.

..Todd

I'm a little vague about the use of the CL-150. If this is a GE sensing part, it is 5 ohms cold, .15 ohms hot. It is small enough high voltage will short right across it when the dust gets thick enough or the humidity is high. I'm using a 47 ohm 5 watt resistor between the transfomer and the rectifier tube to protect my transformer from shorted rectifier tubes. It doesn't drop a lot of voltage at these currents. Using the CL-150 on the primary of the power transformer makes more sense.

I just copied the CL-150 usage from the Mullard KT88 project power supply. From that conversation I understood that it lessened the impact of the HT being available before the heaters get the cathodes up to temp (or maybe to ensure the bias voltage is fully operational before the HT is). Not required with a tube rectifier of course.

I've heard of folks using a different NTC thermistor (CL-90?) on the primary side. I'm too much of a non-EE to know much beyond following the example of others here, and trying to understand their reasons.

..Todd

I've heard of folks using a different NTC thermistor (CL-90?) on the primary side. I'm too much of a non-EE to know much beyond following the example of others here, and trying to understand their reasons.

..Todd

Last edited:

Generally from what I understand when going from tube to SS rectification a resistor of somewhere from 10 ohms or so is put in series from pin 8 of the tube socket. Some are actually building their own SS rectifiers inside a octal base and fitting the resistor inside the base with the diodes. Making your own SS rectifier instead of buying it is cost effective and allows for an instant swap back to the tube rectifier when you want to go back.

My personal usage on my 70...I have installed permanent diodes from pins 3 to 4 and pins 5 to 6 if my memory is correct. The diodes allow the strain to be taken off the 5AR4 but still allow for the slow B+ ramp. When I want to go to the SS mode I pull out the 5AR4 and pop in the home made rectifier with the dropping resistor and the voltage remains the same but you still are able to hear what I consider to be the difference between the tube rectifier sound and the SS sound. Hope this helps

My personal usage on my 70...I have installed permanent diodes from pins 3 to 4 and pins 5 to 6 if my memory is correct. The diodes allow the strain to be taken off the 5AR4 but still allow for the slow B+ ramp. When I want to go to the SS mode I pull out the 5AR4 and pop in the home made rectifier with the dropping resistor and the voltage remains the same but you still are able to hear what I consider to be the difference between the tube rectifier sound and the SS sound. Hope this helps

Keep an eye to the allowable peak reverse voltage of the 1N4007 diode, which is 1000V. One half of your transformer secondary gives 360V, so each diode sees 720V for parts of the mains cycle. Also, these are RMS values, so you're getting quite close to the allowable reverse voltage in the peaks - too close for my taste...

Also, mind that L-filters need a minimum current for the L to behave as an inductance. I don't remember the formula right now, but the smaller L is, the higher is the minimum current. For low values as 2.5H the minimum current might be larger than the 200mA you're drawing from it. Maybe it's ok, but should be checked.

Greetings, and have fun!

Andreas

Also, mind that L-filters need a minimum current for the L to behave as an inductance. I don't remember the formula right now, but the smaller L is, the higher is the minimum current. For low values as 2.5H the minimum current might be larger than the 200mA you're drawing from it. Maybe it's ok, but should be checked.

Greetings, and have fun!

Andreas

Yes, 1n4007 is physically too small to hold off 720 V at high humidity or in the presence of dirt. I salvaged from a Wyse terminal board a diode with plastic rings about 1/2 " along the leads with leads 1" long holding the diode up in the air. That ought to hold off high voltage. Air is good for about 1000 v/inch, dirt much less.

Taj: Your PSUD model looks fine to me.......assuming that you are close to the needed current on each stage.

I believe you are correct in using the resistance for 1/2 the secondary, ie one end to center tap.

As far as the NTC/thermister goes, look at the data sheet for a CL-140, CL-90, etc. They give a cold resistance and a hot resistance at the rated current. Problem is, with typical tube PS designs, we are not pulling very much current, especially on the secondary side, so they never get very hot. I believe that's why it's quite common to see a CL-90 on the mains side of the transformer, as you are drawing more than a couple hundred ma, and can get the device warmed up.

Is 450V the typical voltage for the ST-70 outputs? If the power transformer can handle it (probably not if it's a stock ST-70 transformer), you can reduce the 450V and increase the idle current to have a larger percentage of the available power as class A....just a thought

A larger choke (More H) would help reduce the ripple voltage and allow you to reduce B+ depending on it's resistance.

Indianajo: PSUD doesn't have lots of choices for diodes; so the 1N4007 is usually the one picked for a typical FWCT model. I'm assuming Taj will be using 1200V Fairchild FREDs or 1200V Schottky's or something similar if the budget allows.

I believe you are correct in using the resistance for 1/2 the secondary, ie one end to center tap.

As far as the NTC/thermister goes, look at the data sheet for a CL-140, CL-90, etc. They give a cold resistance and a hot resistance at the rated current. Problem is, with typical tube PS designs, we are not pulling very much current, especially on the secondary side, so they never get very hot. I believe that's why it's quite common to see a CL-90 on the mains side of the transformer, as you are drawing more than a couple hundred ma, and can get the device warmed up.

Is 450V the typical voltage for the ST-70 outputs? If the power transformer can handle it (probably not if it's a stock ST-70 transformer), you can reduce the 450V and increase the idle current to have a larger percentage of the available power as class A....just a thought

A larger choke (More H) would help reduce the ripple voltage and allow you to reduce B+ depending on it's resistance.

Indianajo: PSUD doesn't have lots of choices for diodes; so the 1N4007 is usually the one picked for a typical FWCT model. I'm assuming Taj will be using 1200V Fairchild FREDs or 1200V Schottky's or something similar if the budget allows.

Last edited:

1N4007 is great theoretically and in prototyping, but I cleaned a lot of dirt off my 50 year old ST70 last year. Better longer arc path diodes are probably available salvage in a CRT display or somewhere.Taj:

As far as the NTC/thermister goes, look at the data sheet for a CL-140, CL-90, etc. They give a cold resistance and a hot resistance at the rated current. Problem is, with typical tube PS designs, we are not pulling very much current, especially on the secondary side, so they never get very hot. I believe that's why it's quite common to see a CL-90 on the mains side of the transformer, as you are drawing more than a couple hundred ma, and can get the device warmed up.

Is 450V the typical voltage for the ST-70 outputs? If the power transformer can handle it (probably not if it's a stock ST-70 transformer), you can reduce the 450V and increase the idle current to have a larger percentage of the available power as class A....just a thought

Indianajo: PSUD doesn't have lots of choices for diodes; so the 1N4007 is usually the one picked for a typical FWCT model. I'm assuming Taj will be using 1200V Fairchild FREDs or 1200V Schottky's or something similar if the budget allows.

CL anything is too physically small to not be bridged by current at high voltage assuming dirt or humid air. Calculations are great, but 1000v/in/.3 in=300 volt standoff. I'm using a russian 5AR4 but putting a silicon diode in series couldn't hurt. CL 90 on transformer primary might solve the big "whang" noise when you turn it on.

ST70s came originally with a 525 VDC rated B+ capacitor. I removed mine in 1971 when I bought the ST70 and found it had low watts. This is probably a surge voltage rating, as modern caps are rated, instead of a steady state rating. I have used 450 VDC rated panasonic & nichicon radial lead caps in my 1961 dynakit ST70 with fabric transformer leads, so far so good. The wall voltage has increased from 110 VAC nominal in 1961 to 125 VAC nominal in 2011, with lots of people on organforum reporting 130+ V on their receptacle, So designing for high voltage with original transformers is a good plan.

Last edited:

All good points. Thanks. Some filler information...

Yes, The only reason it shows 1N4007 is because of PSUD2's choices. As boywonder says, I will use much higher rated FREDs or whatever. Maybe Vishay SF1600, as used in a popular DIY guitar amp power supply.

Regarding line voltage, the Dynaco power transformer is spec'd at 117VAC, and my line voltage is 120-122VAC typically. So not as bad as it could be, in general. On the original ST-70, the voltage at the reservoir cap is listed as 430V with the GZ34, so it will be higher with the SS diodes and higher line voltage, but not as big a difference as other rectifier tubes, or other locations, I will consider higher line voltages though.

I won't really know what I have to contend with in terms of current load and voltage supply until I get it hooked up, so I was just hoping to get a ballpark idea beforehand, hence the PSUD2 sanity check request. Thanks for the reply boywonder, I respect your answer.

Rundmaus: The new load on the old power supply parts, from the output section and driver boards will be pretty close to what it was in the original ST-70. A little more, but not much. So using the existing parts should be fine.

indianajoe: Would insulating the leads of the CL-150 reduce the chance of dusty/humid-part arcing?

..todd

Yes, The only reason it shows 1N4007 is because of PSUD2's choices. As boywonder says, I will use much higher rated FREDs or whatever. Maybe Vishay SF1600, as used in a popular DIY guitar amp power supply.

Regarding line voltage, the Dynaco power transformer is spec'd at 117VAC, and my line voltage is 120-122VAC typically. So not as bad as it could be, in general. On the original ST-70, the voltage at the reservoir cap is listed as 430V with the GZ34, so it will be higher with the SS diodes and higher line voltage, but not as big a difference as other rectifier tubes, or other locations, I will consider higher line voltages though.

I won't really know what I have to contend with in terms of current load and voltage supply until I get it hooked up, so I was just hoping to get a ballpark idea beforehand, hence the PSUD2 sanity check request. Thanks for the reply boywonder, I respect your answer.

Rundmaus: The new load on the old power supply parts, from the output section and driver boards will be pretty close to what it was in the original ST-70. A little more, but not much. So using the existing parts should be fine.

indianajoe: Would insulating the leads of the CL-150 reduce the chance of dusty/humid-part arcing?

..todd

Last edited:

Here's that diode mode. I first read about it on this form from Kevin Kennedy.

tube rectifier diode mod

UF4007 may be quieter.

More info on a really good replacement can cap if you want to keep that.

http://dynacotubeaudio.forumotion.com/t191-dynaco-st-70-pc-3-driver-board-parts-layout-photo

Lot's of ST-70 info at diytube.com

Hope everybody had a great Christmas and a Happy New Year to all!

Randy

tube rectifier diode mod

UF4007 may be quieter.

More info on a really good replacement can cap if you want to keep that.

http://dynacotubeaudio.forumotion.com/t191-dynaco-st-70-pc-3-driver-board-parts-layout-photo

Lot's of ST-70 info at diytube.com

Hope everybody had a great Christmas and a Happy New Year to all!

Randy

Last edited:

Spreading the legs of the CL-150 and a good blob of some sort of voltage specified epoxy (not black) on each lead to get the arc path out to 2 cm or 3/4" couldn't hurt. I don't think heat shrink tubing has a high enough voltage rating to help. I had replaced tubes in the preamp over the years because of popping, but when I replaced the capacitors & carbon comp resistors last year, found that I had blue arcs (in the dark) at places on the PCB I hadn't worked at (on the bottom). Simultaneous with popping sounds. My theory is the original 1961 builder (a minister) had left solder rosin on the PCB, that only acted up in high humidity. 450 VDC is rather unforgiving. Wash, wash wash wash. And nifty prototypes discussed here probably don't get used for 50 years like my dynakit equipment, or 43 years like my organs. Dead skin flakes (household dirt) make a great arc conductor.indianajoe: Would insulating the leads of the CL-150 reduce the chance of dusty/humid-part arcing?

Greetings Taj,

May I ask where you got those current tap values simulating the driver and PI?

Cheers!

Hi Gregg,

Glad to see you're hanging around here. I thought you left a while back.

Those were just approximate starting values to learn PSUD2. My question was mainly about whether I was using PSUD2 correctly. Next step was going to be figuring out the correct currents (or ask you), so I could land at approx. the right supply voltage values. The 5751 amplifier is a pretty straightforward calculation once I pull up the datasheet, but the tail on that PI is beyond my comprehension. Looks like a CCS with feedback from the anodes (or something..)

What are the current draws, if you don't mind my asking?

My plan was to use solid state rectifier (I'm not a tube rectifier fan) without resistively dropping the B+ voltage down to GZ34 level , let the EL34's run at whatever B+ resulted from the power supply (and adjust their operating point accordingly), then drop the next stage voltages in the power supply so that they land at 400V for the 6CG7 supply and 250V for the 5751 supply (as your board expects.)

I love the driver board PCB. I was raised on single-sided roll-your-own PCBs, so those plated through holes are such a pleasure to work with.

..Todd

Last edited:

Heya Todd,

Actually, I did.... a buddy directed me to this thread.

The current draw for the 5751 is ~2.2mA (both channels) and the 6CG/FQ7 you had about right - draws 15-18mA for both channels.

The PI is less forgiving... 400-415V it's OK with and the pre is more forgiving - 230-270V. The important thing for best CMFB performance is keeping 100-110V across the anode resistors on the PI

On my test bed, I've used SS and all sorts of tube rects. I've had the B+ up to 525V with a pair of MUR4100 in series on each leg or as low as 410V with a 5R4. It works.

And thanks on the board! My partner does excellent PCB work.

Cheers!

Actually, I did.... a buddy directed me to this thread.

The current draw for the 5751 is ~2.2mA (both channels) and the 6CG/FQ7 you had about right - draws 15-18mA for both channels.

The PI is less forgiving... 400-415V it's OK with and the pre is more forgiving - 230-270V. The important thing for best CMFB performance is keeping 100-110V across the anode resistors on the PI

On my test bed, I've used SS and all sorts of tube rects. I've had the B+ up to 525V with a pair of MUR4100 in series on each leg or as low as 410V with a 5R4. It works.

And thanks on the board! My partner does excellent PCB work.

Cheers!

Thanks Gregg,

If I had taken 30 seconds to look at the 5751 datasheet (or even thought about it for 30 seconds), I would have gotten much closer, and may have even nailed it without a calculator. But the 6CG7 current was fluke.

Does one need sharing resistors when using a pair of diodes in series?

..Todd

If I had taken 30 seconds to look at the 5751 datasheet (or even thought about it for 30 seconds), I would have gotten much closer, and may have even nailed it without a calculator. But the 6CG7 current was fluke.

Does one need sharing resistors when using a pair of diodes in series?

..Todd

Last edited:

And nifty prototypes discussed here probably don't get used for 50 years like my dynakit equipment, or 43 years like my organs.

Thanks indianajoe,

This won't be a prototype really, it'll end up looking good in the living room, and being bequeathed to successors eventually. So it will make sense to consider its long-term health (and safety). But I won't be filling it full of expensive boutique parts unless they make sense technically.

..Todd

Hi Todd,

With guesses like that, maybe I'll have you choose my Keno numbers

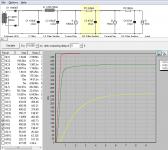

I ended up doing this. Not for the diodes, but for the longetivity of the tubes:

Cheers!

With guesses like that, maybe I'll have you choose my Keno numbers

Does one need sharing resistors when using a pair of diodes in series?

I ended up doing this. Not for the diodes, but for the longetivity of the tubes:

Cheers!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Sanity check please? ST-70(-ish) power supply