I don´t know for the moment if it is overkill. I am balancing the different solutions. The first prototyp should offer the possibility to test all the possible solutions for heather supply:

- only AC,

- simple AC/DC regulation (LT1085),

- AC/DC regulation and capacitor multiplier and current sink,

- battery (SLA, LiFePO4?) supplying with current sink.

A lot to do... I think I will ask a friend (radio amateur and power supplies developper) for help!

I will post tomorrow the schematics for the HV supply (extremly low ripple if LM431 reference battery powered, with 7,2V pack for example; softstart; BUZ80, IRF710, 2SK30, 2N3439).

I hope the modified amplifier also...

Find the right guys at the right moment and you can do miracles! or so...

- only AC,

- simple AC/DC regulation (LT1085),

- AC/DC regulation and capacitor multiplier and current sink,

- battery (SLA, LiFePO4?) supplying with current sink.

A lot to do... I think I will ask a friend (radio amateur and power supplies developper) for help!

I will post tomorrow the schematics for the HV supply (extremly low ripple if LM431 reference battery powered, with 7,2V pack for example; softstart; BUZ80, IRF710, 2SK30, 2N3439).

I hope the modified amplifier also...

Find the right guys at the right moment and you can do miracles! or so...

The first prototyp should offer the possibility to test all the possible solutions for heather supply:

- only AC,

- simple AC/DC regulation (LT1085),

- AC/DC regulation and capacitor multiplier and current sink,

- battery (SLA, LiFePO4?) supplying with current sink.

There is even more....

My advice is to visit Thomas Mayer's blog. He has a lot of experience, particularly if you choose to go the SE way.

And you could start with another output tube for instance (Thomas has a "poor mans" 300B amp).

Last question today: what do you think about rectifier tube instead rectifier diode?

It will reduce the value of the big supply capacitor and allowed the use of a film capacitor.

It makes more sense to compare capacitor input with choke input power supplies.

Once more see Thomas on this subject.

Graag gedaan!

Hi jps64,

Before you proceed full speed with your 300B project I think

you should be aware or the design philosophies of Thomas Mayer and

Lynn Olsen and that is with regards to heater power.Thomas prefers

DC whereas Lynn Olsen prefers AC.Sound quality is very subjective.

In Lynn Olsen's article about Karna amplifier his experience with his earlier

amps that when he tried DC he noticed what some others have commented

that it sucked the life out of the sound.Now this is for the power tube and you can use DC for input and driver like Sakuma's design.Of course you are designing for yourself so you are the best judge.Thought this is important

for people to know.

With regards to tube rectifier vs silicon diodes Lynn olsen said based on his finding that silicon diodes had the most noise

versus tube diodes but if you are going for subjective sound quality then it is quite obvious what to choose unless you

don't care about this aspect and want to do it cheap and easy. All the best.

Before you proceed full speed with your 300B project I think

you should be aware or the design philosophies of Thomas Mayer and

Lynn Olsen and that is with regards to heater power.Thomas prefers

DC whereas Lynn Olsen prefers AC.Sound quality is very subjective.

In Lynn Olsen's article about Karna amplifier his experience with his earlier

amps that when he tried DC he noticed what some others have commented

that it sucked the life out of the sound.Now this is for the power tube and you can use DC for input and driver like Sakuma's design.Of course you are designing for yourself so you are the best judge.Thought this is important

for people to know.

With regards to tube rectifier vs silicon diodes Lynn olsen said based on his finding that silicon diodes had the most noise

versus tube diodes but if you are going for subjective sound quality then it is quite obvious what to choose unless you

don't care about this aspect and want to do it cheap and easy. All the best.

Last edited:

Thanks Singa,

all this gurus have they own opinion, while audio development is not a exact science! A lot of guys will do a big business whit this. The listening will confirm the own right way or solution.

I am right if I say that battery heating is the cleanest power. Involved this in a design is very constraining then battery management is not easy and will be done properly.

I will go this way...

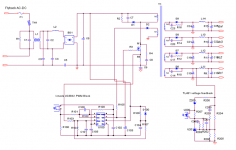

In the attachment my first scratch of the HV supply.

Today I will define the batteries: LiFePO4 (2<Ubatt<3.6V) with BMS (ATMEL Tiny µC) and CC/CV µC based charger.

all this gurus have they own opinion, while audio development is not a exact science! A lot of guys will do a big business whit this. The listening will confirm the own right way or solution.

I am right if I say that battery heating is the cleanest power. Involved this in a design is very constraining then battery management is not easy and will be done properly.

I will go this way...

In the attachment my first scratch of the HV supply.

Today I will define the batteries: LiFePO4 (2<Ubatt<3.6V) with BMS (ATMEL Tiny µC) and CC/CV µC based charger.

Attachments

Here the bloc diagram for the mono 300B SE amplifier.

Tom: the heathers needs not more then 3A. The LiFePO4 3.3V@40Ah are garantee for 2000 cycle of charge, and discharge at 0.3C, and are developped in the USA for automotive usage!

I will calculate and simulate the HV SMPS, more to come...

Tom: the heathers needs not more then 3A. The LiFePO4 3.3V@40Ah are garantee for 2000 cycle of charge, and discharge at 0.3C, and are developped in the USA for automotive usage!

I will calculate and simulate the HV SMPS, more to come...

Attachments

I suggest grounding one side of the 300B filament and taking the inter-stage tranny off of ground. Feed -85 (ish) volt to the interstage trafo, thus, biasing the 300B. This would allow you to skip the cathode cap.

If you insist on having the cathode cap, I suggest running it from the cathode to the B+ supply a la Loftin-White as it shortens up the signal path considerably on the primary side of the OPT. You'll get measurably better performance.

Generating the bias tap would be trivial on your flyback trafo.

I don't see a point of battery powering the filaments. You can get very clean power with one of National's LMZ12xxx SimpleSwitchers. Been there, done that, have the T-shirt (and the good results). The thermal mass of the filaments is more than enough to ensure that any minute variation in the output voltage are averaged out.

~Tom

If you insist on having the cathode cap, I suggest running it from the cathode to the B+ supply a la Loftin-White as it shortens up the signal path considerably on the primary side of the OPT. You'll get measurably better performance.

Generating the bias tap would be trivial on your flyback trafo.

I don't see a point of battery powering the filaments. You can get very clean power with one of National's LMZ12xxx SimpleSwitchers. Been there, done that, have the T-shirt (and the good results). The thermal mass of the filaments is more than enough to ensure that any minute variation in the output voltage are averaged out.

~Tom

Last edited:

I am reading a lot of articles, good and bad ones. No preference today. I found a nice design from Elektra, but really objective? Was very interesting before I read the detailled analysis from a experienced developper. It is like monopoly, return to the beginning.

I will draw a new design for the 300B amplifier. I am waiting for comments and I will start this way.

I need a cheap but good design to test the battery powered heather idea. Anyone an idea?

Universal SE SMPS: one possible solution!

A 400W PFC board is available from Fairchild and the transformers and chokes are very easy to built.

The Flyback for the heathers and the bias supply is calculated (for up to 4 driver tubes and up to 2 end tube with LMX regulators, thanks Tom, and up to 211 or 845, badly there is no LMX regulators for that supply current; also the 0 to -300VDC max. 7.5W adjustable bias supply); transformer is a little bit difficult, but with practice; 92% effectiveness.

The half-bridge DC/DC converter needs more attention, then it will deliver up to 1300VDC. Four windings on EE42 core for a pair of 2A3 or 300B, 45, AD1, 211, 1605, 845... 92% effectiveness.

the conventionel driver and en tube tube rectifier and mosfet supply is finish designed this weekend.

I will draw a new design for the 300B amplifier. I am waiting for comments and I will start this way.

I need a cheap but good design to test the battery powered heather idea. Anyone an idea?

Universal SE SMPS: one possible solution!

A 400W PFC board is available from Fairchild and the transformers and chokes are very easy to built.

The Flyback for the heathers and the bias supply is calculated (for up to 4 driver tubes and up to 2 end tube with LMX regulators, thanks Tom, and up to 211 or 845, badly there is no LMX regulators for that supply current; also the 0 to -300VDC max. 7.5W adjustable bias supply); transformer is a little bit difficult, but with practice; 92% effectiveness.

The half-bridge DC/DC converter needs more attention, then it will deliver up to 1300VDC. Four windings on EE42 core for a pair of 2A3 or 300B, 45, AD1, 211, 1605, 845... 92% effectiveness.

the conventionel driver and en tube tube rectifier and mosfet supply is finish designed this weekend.

As you're focusing on a DC heater supply, here's an idea for testing one:

I propose that you build a basic SE using a 45 triode. A good 45 will yield very low output noise with AC driving the filament, which is usually preferred. You can get better than 80dB s/n referenced to 1-watt output with a good 45 and proper circuit. Once you have an idea on how it sounds, you can switch over to your proposed DC heater supply and do some testing to see if you hear any difference (and then determine if the difference is good or bad).

The (WE)300B requires a DC supply as it uses a center-tapped filament and is pretty much impossible to obtain output noise at an acceptable level with AC. The fact that it is a center-tapped filament, you should (as noted earlier) think about using one end of the filament as the cathode connection and letting the other end float. For biasing points, you may want to consult the original Western Electric documentation here:

Western Electric

For driving the 300B, consider an interstage transformer topology as I think you will get the best results with a properly designed circuit. You can also take a look at these links for numerous SE amplifiers including many 300B designs:

Valves' World ƒMƒƒƒ‰ƒŠ[

Valves' World ƒMƒƒƒ‰ƒŠ[

Valves' World ƒMƒƒƒ‰ƒŠ[‚Q‚O‚O‚V

Valves' World ƒMƒƒƒ‰ƒŠ[‚Q‚O‚O‚U

Valves' World ƒMƒƒƒ‰ƒŠ[‚Q‚O‚O‚T

Valves' World ƒMƒƒƒ‰ƒŠ[‚Q‚O‚O‚S

Regards, KM

I propose that you build a basic SE using a 45 triode. A good 45 will yield very low output noise with AC driving the filament, which is usually preferred. You can get better than 80dB s/n referenced to 1-watt output with a good 45 and proper circuit. Once you have an idea on how it sounds, you can switch over to your proposed DC heater supply and do some testing to see if you hear any difference (and then determine if the difference is good or bad).

The (WE)300B requires a DC supply as it uses a center-tapped filament and is pretty much impossible to obtain output noise at an acceptable level with AC. The fact that it is a center-tapped filament, you should (as noted earlier) think about using one end of the filament as the cathode connection and letting the other end float. For biasing points, you may want to consult the original Western Electric documentation here:

Western Electric

For driving the 300B, consider an interstage transformer topology as I think you will get the best results with a properly designed circuit. You can also take a look at these links for numerous SE amplifiers including many 300B designs:

Valves' World ƒMƒƒƒ‰ƒŠ[

Valves' World ƒMƒƒƒ‰ƒŠ[

Valves' World ƒMƒƒƒ‰ƒŠ[‚Q‚O‚O‚V

Valves' World ƒMƒƒƒ‰ƒŠ[‚Q‚O‚O‚U

Valves' World ƒMƒƒƒ‰ƒŠ[‚Q‚O‚O‚T

Valves' World ƒMƒƒƒ‰ƒŠ[‚Q‚O‚O‚S

Regards, KM

Here's another approach: Loftin White: ECC83 300B Darius Loftin White Fortsetzung

No coupling caps, no electrolytics anywhere. It will burn some extra power in the output cathode resistor. Note that with DC filaments, the basic schematic is sufficient (no filament harmonic cancellation required).

No coupling caps, no electrolytics anywhere. It will burn some extra power in the output cathode resistor. Note that with DC filaments, the basic schematic is sufficient (no filament harmonic cancellation required).

As you're focusing on a DC heater supply, here's an idea for testing one:

I propose that you build a basic SE using a 45 triode. A good 45 will yield very low output noise with AC driving the filament, which is usually preferred. You can get better than 80dB s/n referenced to 1-watt output with a good 45 and proper circuit. Once you have an idea on how it sounds, you can switch over to your proposed DC heater supply and do some testing to see if you hear any difference (and then determine if the difference is good or bad).

I agree, this is exactly the right thing to do. The (only) advantage of ac heating is that it is very easy to implement. You can get started straight away, and get the bugs out of the driver stage, and B+ supply, without worrying about the complexity of the filament supply.

However, you will find straight away, that the sound changes if you use a different filament transformer. It will sound better if you use a separate transformer - instead of using a winding on the B+ transformer. A toroidal trafo sounds different, usually worse.

This effect is partly because some of the anode current will circulate right around the filament wiring, and through the transformer winding - ie capacitively coupled to the mains supply via bad quality dielectrics. Remember, this has the same effect as coupling the noise to the grid of your DHT, since the filament is like a grounded-grid stage's input. The filament transformer, and its wiring, can also act like a search coil, picking up emissions from your B+ supply (rectifier pulses) and CD player emissions (which are not small). This effect is heightened with toroidals, where the core is floating.

Actually, you can do this ac to dc test on the 300B, you can use the cheap EH300B Gold, which is quite a good 300B - when optimally heated. With 92dB/W speakers, the hum is tolerable.

When you change to a properly implemented dc current-driven supply, everything improves, better than any expectation - and this is how you know it is working properly! If it doesn't give an all-round, massive uplift to the sound, then the filament regulator design is not good enough.

Sad to say, using 3 terminal regulators, even the better ones like LT108x will not take you anywhere near what can be achieved with discrete-circuit design.

Don't take my word for it:

http://www.diyaudio.com/forums/tubes-valves/38248-new-dht-heater-5.html#post2368003

Batteries seem like a really good solution, at first blush. Provided you totally disconnect the charging at run-time, you solve the hardest problems with filament supplies: breakthough of very wideband mains noise, and breakthrough of very wideband 3A+ rectifier recovery pulses - current pulses, looking for somewhere to dissipate.

Before designing-in a battery supply though, please search the forums here for battery noise. The usual candidates for battery chemistry, especially Lead-Acid, have been characterised by a number of DIYers here, and shown to have really severe noise problems. The noise gets worse when you draw current. I have not seen measurements for Lithium chemistries, but before using them I would certainly measure the noise levels under load, and see whether they are really usable.

Thanks a lot for this informations.

I will say, that an amplifier per definition amplifie: this energy is to supply by the power supply. I suppose that I am right when I say that the power supplies needs to be free of noise and be able to supply rapidely the needed energy. I have build for years ago the Jean Hiraga Monster with big batteries supplied (SLA and external COTS battery charger). I very good pair with my Ebay SABA Greencones. Only a few very clean watts!

I will see the amplifier as my house and I don´t want to let come in person with dirty shoes. If they ignore this rule, I have a big job with cleaning, independantly the house architecture (selected amplifier design).

The only compromise from my part is the tube rectifier high voltage B+ supplies. I don´t want to stack batteries then to dangerous to handle safety (high voltage and much higher charging currents). I am thinking that SMPS are not fast enough: I have some practice with SPMS supplies in audio applications but I am not very happy with this solutions (ok, they save place); ok for rapid prototyping.

In the attachment the high voltage supplies: the right values coming if I have selected my design, but I think don´t exceed B+ 500VDC.

I am very happy in real application (military) with unbreakable LiFePO4 batteries. I will build the Bias voltage supply, the heather supplies with this one. The first sketch on paper is ready and the challenge is only the mangament of the costly battery energy.

... I forgot, the management is doing by a micro...

The LiFePO4 batteries, see at...

LiNANO 40 Ah 3,2V LiFepo4-Zelle SL-FSE, 64,00 € - Lipopower Der Akkuspezialist, Lipo, LiFepo, LiFePO4, FePo, Balancer, PCB, Lithium, Akkus, Adapter, Steckverbinder

I will say, that an amplifier per definition amplifie: this energy is to supply by the power supply. I suppose that I am right when I say that the power supplies needs to be free of noise and be able to supply rapidely the needed energy. I have build for years ago the Jean Hiraga Monster with big batteries supplied (SLA and external COTS battery charger). I very good pair with my Ebay SABA Greencones. Only a few very clean watts!

I will see the amplifier as my house and I don´t want to let come in person with dirty shoes. If they ignore this rule, I have a big job with cleaning, independantly the house architecture (selected amplifier design).

The only compromise from my part is the tube rectifier high voltage B+ supplies. I don´t want to stack batteries then to dangerous to handle safety (high voltage and much higher charging currents). I am thinking that SMPS are not fast enough: I have some practice with SPMS supplies in audio applications but I am not very happy with this solutions (ok, they save place); ok for rapid prototyping.

In the attachment the high voltage supplies: the right values coming if I have selected my design, but I think don´t exceed B+ 500VDC.

I am very happy in real application (military) with unbreakable LiFePO4 batteries. I will build the Bias voltage supply, the heather supplies with this one. The first sketch on paper is ready and the challenge is only the mangament of the costly battery energy.

... I forgot, the management is doing by a micro...

The LiFePO4 batteries, see at...

LiNANO 40 Ah 3,2V LiFepo4-Zelle SL-FSE, 64,00 € - Lipopower Der Akkuspezialist, Lipo, LiFepo, LiFePO4, FePo, Balancer, PCB, Lithium, Akkus, Adapter, Steckverbinder

Attachments

Vinnie Rossi at RedwineAudio uses LiFePo4 precisely for that reason, it is an extremely quiet battery when discharging, and has extremely low source DC and AC impedance..... I have not seen measurements for Lithium chemistries, but before using them I would certainly measure the noise levels under load, and see whether they are really usable.

As an example of one of the better offerings, Ping Battery has 3.2V/5AH cells with under 10miliOhm AC source impedance, 6miliOhm typical, at various discharge rates up to the max continuous current.

Vinnie's battery powered systems are stunningly good, and the LiFePo4 is a HUGE improvement over the best SLA batteries I've heard.

He's using battery supply for the main amp section, but of particular interest for this thread is his battery power for the tube buffer part of it.

In the comparisons i did on my Virtue amps, I could hear the SLA making very low level "burbling and gurgling" noises... the LFP pack from redWine is dead quiet and (to use a term that I'm not very fond of) the background is way "blacker" than any other supply, linear or SMPS that I have heard, and the dynamics macro and micro just seem to "instantly" arise without any warning. The overall effect is stunning.

I would sure be interested in knowing how the LiFePo4's perform in the application discussed in this thread!

TJ Full Music 300BSE/6SN7 expensive amp

This amp has taken nine months to build. It was design by Suncalc on the diyaudioprojects forum from the ground up based on three criteria I stipulated: 1-two stage 0NF, 2-6SN7 and 300B tubes with tube rectification and 3-Single ended. Most of the main components were selected by the customer I built it for: TJ Full Music 300BSE(RRP $1200), 50 year Treasure 6SN7, Audio Note Silver foil caps, Mundorf M-Tube poly filter caps, silver wire in the audio path. Other components were my selection. The bass is extended, full rich mids and treble bright and extended. Very expensive to build and a long time in the making but really worth it. retro-thermionic

This amp has taken nine months to build. It was design by Suncalc on the diyaudioprojects forum from the ground up based on three criteria I stipulated: 1-two stage 0NF, 2-6SN7 and 300B tubes with tube rectification and 3-Single ended. Most of the main components were selected by the customer I built it for: TJ Full Music 300BSE(RRP $1200), 50 year Treasure 6SN7, Audio Note Silver foil caps, Mundorf M-Tube poly filter caps, silver wire in the audio path. Other components were my selection. The bass is extended, full rich mids and treble bright and extended. Very expensive to build and a long time in the making but really worth it. retro-thermionic

Attachments

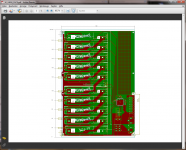

The skills for the High Voltage Supply:

- 6U 19 inch rack,

- 10 to 15 LiFePO4 boards with 10 18650 batteries and µC management,

- 600W PFC SMPS CC/CV charger,

- µC-Mainboard with management and TFT-Touch visualisation.

- and interconnaction backpanel.

Attached, the first printed circuit board for the battery board...

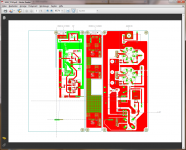

... and the 300B testboards avancement.

- 6U 19 inch rack,

- 10 to 15 LiFePO4 boards with 10 18650 batteries and µC management,

- 600W PFC SMPS CC/CV charger,

- µC-Mainboard with management and TFT-Touch visualisation.

- and interconnaction backpanel.

Attached, the first printed circuit board for the battery board...

... and the 300B testboards avancement.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Mono 300B SE Amplifier