Hi,

Suppose you have a valve preamplifier driving a solid-state main amplifier. Normally the solid-state main amplifier will power up much faster than the valve preamplifier, so any power-on plop on the preamp output will be amplified by the main amp. Because of the high DC bias voltages, the power-on plop of the preamp can be really big, especially when the time constant of the output DC blocking circuit is large.

How do you normally handle this? By simply shorting the output with a relay until all valves are heated up? Or are there more elegant methods?

Regards,

Marcel

Suppose you have a valve preamplifier driving a solid-state main amplifier. Normally the solid-state main amplifier will power up much faster than the valve preamplifier, so any power-on plop on the preamp output will be amplified by the main amp. Because of the high DC bias voltages, the power-on plop of the preamp can be really big, especially when the time constant of the output DC blocking circuit is large.

How do you normally handle this? By simply shorting the output with a relay until all valves are heated up? Or are there more elegant methods?

Regards,

Marcel

There are many ways for doing this. One, as you said, is to use a mute relay. If the sand power amp can handle being on without a source connected, you could just have the mute relay in series with the preamp output.

A more elegant (IMO) solution would be to delay turn-on of the power amp until the valve preamp is up. If the valve amp uses a valve rectifier, you could just monitor the B+ voltage and turn on the power amp when the B+ in the preamp reaches, say, 75 % of the final B+ voltage.

Or better yet, if the sand amp has a mute input (such as the LM3886, LME49810, etc) one could power up the sand amp but leave it muted until the preamp comes online.

Or one could go simple and just have a time delay that that turns the power amp on 30 seconds after the preamp has been turned on...

Options, options...

~Tom

A more elegant (IMO) solution would be to delay turn-on of the power amp until the valve preamp is up. If the valve amp uses a valve rectifier, you could just monitor the B+ voltage and turn on the power amp when the B+ in the preamp reaches, say, 75 % of the final B+ voltage.

Or better yet, if the sand amp has a mute input (such as the LM3886, LME49810, etc) one could power up the sand amp but leave it muted until the preamp comes online.

Or one could go simple and just have a time delay that that turns the power amp on 30 seconds after the preamp has been turned on...

Options, options...

~Tom

Hi Tom,

In all alternatives you mention except those with a relay, the main amp needs to have some knowledge of the preamp and the state it is in. So if you want to make a preamp that you can simply connect to any main amp, a mute relay is basically the only choice, right?

Regards,

Marcel

In all alternatives you mention except those with a relay, the main amp needs to have some knowledge of the preamp and the state it is in. So if you want to make a preamp that you can simply connect to any main amp, a mute relay is basically the only choice, right?

Regards,

Marcel

Marcel,

Some power amps support remote turn-on via a small cable strung between the preamp and the power amp. Others support turn-on when music is applied, though, due to the time delay of the turn-on circuitry this option can be kinda annoying.

If the two amps are to be completely separate, you have two options:

1) Mute relay

2) Timed turn-on of mains power to power amp.

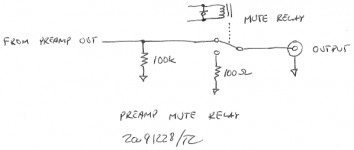

If you chose option 1), I would suggest using attached circuit. In this circuit, the preamp output tube is 'seeing' a load of 100 kOhm while the amp is muted.

Option 2) can be realized by using something like X10 control or by building an intelligent power strip.

~Tom

Some power amps support remote turn-on via a small cable strung between the preamp and the power amp. Others support turn-on when music is applied, though, due to the time delay of the turn-on circuitry this option can be kinda annoying.

If the two amps are to be completely separate, you have two options:

1) Mute relay

2) Timed turn-on of mains power to power amp.

If you chose option 1), I would suggest using attached circuit. In this circuit, the preamp output tube is 'seeing' a load of 100 kOhm while the amp is muted.

Option 2) can be realized by using something like X10 control or by building an intelligent power strip.

~Tom

Attachments

Thanks for all your suggestions!

Allen, why do you expect the valves to last longer when the preamp is switched on continuously? I would expect the emission of the cathodes to drop much faster when they are used continuously than when they are only used when needed.

The idea of having the preamp switch the mains power of the main amp sounds interesting. If the preamp needs to have some sort of relay control anyway, it might as well be a relay that only switches the mains.

The concept of using ones brain sounds too risky to me. One can easily get distracted and accidentally switch stuff on and off in the wrong order. Besides, the equipment needs to be user-friendly; people who are not very technical will also use it.

Allen, why do you expect the valves to last longer when the preamp is switched on continuously? I would expect the emission of the cathodes to drop much faster when they are used continuously than when they are only used when needed.

The idea of having the preamp switch the mains power of the main amp sounds interesting. If the preamp needs to have some sort of relay control anyway, it might as well be a relay that only switches the mains.

The concept of using ones brain sounds too risky to me. One can easily get distracted and accidentally switch stuff on and off in the wrong order. Besides, the equipment needs to be user-friendly; people who are not very technical will also use it.

I don't like the idea of leaving the preamp on all the time. Both from an environmental stand point, but also for the cathode emissions reasons you mention.

Most filaments fail due to the thermal stress of the turn-on transient. Remember that the resistance of the filament when cold is somewhere around one tenth that of a hot filament (which is small-ish anyway). So if a filament draws 300 mA under normal operation, figure it'll draw 3 A at turn-on. This imposes stress on the filament materials and this stress causes them to fail eventually. That's why some people recommend leaving the filaments on all the time. However, that does reduce the lifespan of the cathode emission. So a happy medium is to have a stand-by mode where the filaments are operated at a lower voltage, thereby, keeping them warm (but not hot) and minimizing the turn-on transient.

You can read more in Robert Tomer's book, Getting the Most Out of Vacuum Tubes and in Morgan Jones' Valve Amplifiers book.

~Tom

Most filaments fail due to the thermal stress of the turn-on transient. Remember that the resistance of the filament when cold is somewhere around one tenth that of a hot filament (which is small-ish anyway). So if a filament draws 300 mA under normal operation, figure it'll draw 3 A at turn-on. This imposes stress on the filament materials and this stress causes them to fail eventually. That's why some people recommend leaving the filaments on all the time. However, that does reduce the lifespan of the cathode emission. So a happy medium is to have a stand-by mode where the filaments are operated at a lower voltage, thereby, keeping them warm (but not hot) and minimizing the turn-on transient.

You can read more in Robert Tomer's book, Getting the Most Out of Vacuum Tubes and in Morgan Jones' Valve Amplifiers book.

~Tom

The traditional way of reducing the thermal shock is making a slow-start circuit by connecting an NTC in series with the filament (or, when NTC's were not invented yet, just using some fixed series resistor to reduce the resistance ratio between hot and cold). The cheapest solution was using a heating transformer with a relatively high wire resistance.

I forgot to explain why I prefer to have the preamp loaded by 100 kOhm while it's being muted.

Shorting the preamp output to ground works well until somebody turns on the source feeding the preamp. Then who knows what will happen.

Many outputs of valve preamps are cap coupled. Leaving the cap floating will likely cause a huge pop when the mute relay switches as the cap will be floating at some voltage. By using a resistor to ground, the charge on the cap is allowed to stabilize before the relay switches, thus, minimizing the pop...

You can probably ground the input to the power amp without using a resistor. But I like using a resistor there just in case the input to the power amp is DC coupled. If the 2-cent resistor causes financial instability for you then just leave it out.

~Tom

Shorting the preamp output to ground works well until somebody turns on the source feeding the preamp. Then who knows what will happen.

Many outputs of valve preamps are cap coupled. Leaving the cap floating will likely cause a huge pop when the mute relay switches as the cap will be floating at some voltage. By using a resistor to ground, the charge on the cap is allowed to stabilize before the relay switches, thus, minimizing the pop...

You can probably ground the input to the power amp without using a resistor. But I like using a resistor there just in case the input to the power amp is DC coupled. If the 2-cent resistor causes financial instability for you then just leave it out.

~Tom

Shorting the preamp output to ground works well until somebody turns on the source feeding the preamp. Then who knows what will happen.

Valve (Tube) amps (at pre-amp sorts of power level) are very forgiving of shorted outputs.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Are there elegant ways to prevent huge power-on plops?