As Andy said, heat is not a problem. Picking hum it could well be. So layout is more critical when you are thinking on having power supplies and pre on same chassis, something I'd strongly not recommend. 26 are prone to pick hum from chokes, etc.

Something I noticed looking at the spectrum of the valve whilst testing THD of the 40 one samples is that on some old ones, you could see the 50/100 Hz byproducts that when you shielded the tube disappeared. I remember that someone did this with aluminium foil. I take it's a workaround for those 26 which are defective (for whatever reason that would be great for anyone to explain here) they are very sensitive to picking hum? Testing setup and conditions didn't change. Is important to clarify that I only found this on a couple of samples which remind me clearly to the workaround suggested here by someone...

All very good points, I use shield cans on my 26 transformer coupled pre-amp. Very quiet. All, and I mean all 26 electro-statically couple to surrounding objects because of the large plate surface area, rp is high enough that this is a significant problem - most tubes with a similar rp have much less plate surface area. My speaker system is highly efficient (>100dB) and reproduces down to 35Hz so any source of hum pick up is a problem - no 26 tube I've tried so far is totally immune. (Dozens)

Thomas Mayer kindly send me a pair of Lundahl LL2745/8mA to test on my 26 and CX301a preamps. These OTs look very promising to provide low output impedance in an DHT pre-amp configuration whilst driving them in their best conditions.

http://www.bartola.co.uk/valves/wp-content/uploads/2012/07/26-preamp-based-on-LL2745.png

I played a bit with spice to try different operating points based on previous tests and what Andy also tried. Found an interesting point that I'd like to try this setup which is Va=114V, Ia=5ma, Filament bias at around 7V with Rod filament boards. Gain is about 3.3dB when configured in 5.6:1 and distortion figures seems really promising. Much better that what I had with the LL1660 and previous op point.

Has anyone been using the LL2745 OT and share his/her experience?

Been also looking at similar circuit for the CX301a as am currently using it in my setup and want to do a side by side comparison to the 26...

http://www.bartola.co.uk/valves/2012/07/14/a-preamp-design-with-the-ll2745/

Ale

http://www.bartola.co.uk/valves/wp-content/uploads/2012/07/26-preamp-based-on-LL2745.png

I played a bit with spice to try different operating points based on previous tests and what Andy also tried. Found an interesting point that I'd like to try this setup which is Va=114V, Ia=5ma, Filament bias at around 7V with Rod filament boards. Gain is about 3.3dB when configured in 5.6:1 and distortion figures seems really promising. Much better that what I had with the LL1660 and previous op point.

Has anyone been using the LL2745 OT and share his/her experience?

Been also looking at similar circuit for the CX301a as am currently using it in my setup and want to do a side by side comparison to the 26...

http://www.bartola.co.uk/valves/2012/07/14/a-preamp-design-with-the-ll2745/

Ale

Last edited:

Hi Ale,

All your work is much appreciated. This is all getting the 26 down to a fine art, so not surprising you are freshening the air with other DHTs. Have to keep the creative challenges going!

I've gone over to push-pull. Loving my amp which is 26PP, plate choke Hammond 124b direct coupled to 4P1L, pentode sink, into LL1660 into 6C4C, O-netics OPTs. I'm using PP because I prefer PP2a3 types to SETs with 300b. And my RAKK DAC is differential out so goes directly into the 26s. No caps in signal path, no cathode resistors or bypasses except the output stage. I'm a bit in awe of it - best amp I've ever built.

I didn't think I'd end up all PP but I have! No more filament bias! There's a place for a PP 26 preamp, which is something we haven't discussed yet. Pretty likely it would be transformer OPT, so discussion would probably be around what kind of current sink to use under the 26s.

Andy

All your work is much appreciated. This is all getting the 26 down to a fine art, so not surprising you are freshening the air with other DHTs. Have to keep the creative challenges going!

I've gone over to push-pull. Loving my amp which is 26PP, plate choke Hammond 124b direct coupled to 4P1L, pentode sink, into LL1660 into 6C4C, O-netics OPTs. I'm using PP because I prefer PP2a3 types to SETs with 300b. And my RAKK DAC is differential out so goes directly into the 26s. No caps in signal path, no cathode resistors or bypasses except the output stage. I'm a bit in awe of it - best amp I've ever built.

I didn't think I'd end up all PP but I have! No more filament bias! There's a place for a PP 26 preamp, which is something we haven't discussed yet. Pretty likely it would be transformer OPT, so discussion would probably be around what kind of current sink to use under the 26s.

Andy

Andy,

Will have to pop over to listen to that amp at some point! Very interesting design!

Thought about 26 preamp in PP, perhaps worth trying it. As I don't have a differential source was not that encouraged at this point. But I think it may be a good thing to try...

pS: Finally replaced the 6j5 driver in my 45SE with the 7193s. They sound better in my opinion and look really cool as well with the top caps

Cheers,

Ale

Will have to pop over to listen to that amp at some point! Very interesting design!

Thought about 26 preamp in PP, perhaps worth trying it. As I don't have a differential source was not that encouraged at this point. But I think it may be a good thing to try...

pS: Finally replaced the 6j5 driver in my 45SE with the 7193s. They sound better in my opinion and look really cool as well with the top caps

Cheers,

Ale

Still working on my 26 preamp - the holdup is getting the custom boxes made at a reasonable cost. Still working on that; plan is black aluminum with chrome top plates.

Also still testing out various output scenarios as I await the boxes. Since I have the Bent TAP remote-control slagleformers I'm running through various possibilities:

1) 26 cap coupled directly from plate (8k Zo) to slagleformers, restacked for max inductance (190H according to Intact audio website). This uses the autoformers as combined stepdown "transformers" and volume controls, eliminating the need for an additional output transformer in the path. Nominal 16V into slagleformers may be pushing it, however.

2) 26 plate through Lundahl LL1676 (2:1 or 4:1 parafeed) into slagleformers. Easier job for the slagleformers but probable loss of transparency and bandwidth.

3) 26 mu output (1.5k Zo) of CCS cap coupled into slagleformers. Lower Z to drive the autoformers but how does the mu output sound relative to the plate output when using a MOSFET CCS? MOSFET mist???

4) Slagleformers on the input, Lundahls on the output in 4:1 parafeed. Doesn't take full advantage of the impedance transformation at lower volume offered by the slagleformers, and doesn't improve the circuit signal/noise when VC is on the input.

Also need to consider the max input voltage of the slagleformers, perhaps I'll put the Lundahls on the input 2:1 to drop the voltage before the 26.

Of course I'll most likely try every combination before I'm done...

.

Also still testing out various output scenarios as I await the boxes. Since I have the Bent TAP remote-control slagleformers I'm running through various possibilities:

1) 26 cap coupled directly from plate (8k Zo) to slagleformers, restacked for max inductance (190H according to Intact audio website). This uses the autoformers as combined stepdown "transformers" and volume controls, eliminating the need for an additional output transformer in the path. Nominal 16V into slagleformers may be pushing it, however.

2) 26 plate through Lundahl LL1676 (2:1 or 4:1 parafeed) into slagleformers. Easier job for the slagleformers but probable loss of transparency and bandwidth.

3) 26 mu output (1.5k Zo) of CCS cap coupled into slagleformers. Lower Z to drive the autoformers but how does the mu output sound relative to the plate output when using a MOSFET CCS? MOSFET mist???

4) Slagleformers on the input, Lundahls on the output in 4:1 parafeed. Doesn't take full advantage of the impedance transformation at lower volume offered by the slagleformers, and doesn't improve the circuit signal/noise when VC is on the input.

Also need to consider the max input voltage of the slagleformers, perhaps I'll put the Lundahls on the input 2:1 to drop the voltage before the 26.

Of course I'll most likely try every combination before I'm done...

.

Last edited:

Choices indeed!

I have a caveman approach to all this - use my Mac Mini as a source for everything (don't use vinyl) and use the volume control in the software. I'm using Audirvana+ beta direct drive version which I STRONGLY recommend - I've done extensive A-B comparisons with Amarra and PureMusic and Audirvana right now is the one, besides being the cheapest. Mind, situation changes every month so one can leapfrog the other. Amarra is always in development as well as Audirvana, and has some of its own virtues. This setup via USB is better than feeding my RAKK DAC from Rega transport.

I also only use exactly the gain in my system I need, so mostly the input doesn't need much attenuation.

Andy

I have a caveman approach to all this - use my Mac Mini as a source for everything (don't use vinyl) and use the volume control in the software. I'm using Audirvana+ beta direct drive version which I STRONGLY recommend - I've done extensive A-B comparisons with Amarra and PureMusic and Audirvana right now is the one, besides being the cheapest. Mind, situation changes every month so one can leapfrog the other. Amarra is always in development as well as Audirvana, and has some of its own virtues. This setup via USB is better than feeding my RAKK DAC from Rega transport.

I also only use exactly the gain in my system I need, so mostly the input doesn't need much attenuation.

Andy

I'm leaning toward my option #1, as my main source (Zero One Mercury CD/HD player) has selectable output voltage of 2V or 1.5V. The 1.5V should be low enough - that would give 12V max into the slagleformers, which they should handle fine (unless it's a straight 10Hz sinewave!). Almost no content is mastered right to max output anyway, so I'll undoubtedly be well below 12V most of the time.

I want to avoid any unneccessary stuff in the chain if at all possible. I suppose I could add a switch to cut the Lundahls in and out if I get a particularly loud source, but that's still more stuff in the chain!

I want to avoid any unneccessary stuff in the chain if at all possible. I suppose I could add a switch to cut the Lundahls in and out if I get a particularly loud source, but that's still more stuff in the chain!

Hmmm...seems the Lundahl input transformers do more than step up and down...

I was reading some of Gary Pimms work on a 47 amp he built and he found that inserting a Lundahl 1676 at the input of his amp improved the sound considerably - he attributed it to the electrostatic shield and bandwidth limiting of the Lundahl removing high frequency garbage from the input (still had a bandwidth of 100kHz, though, so no music was filtered out!). Perhaps putting the Lundahl at the input is the better idea after all - I'll get my 2:1 stepdown, and filter out HF garbage before the 26 sees it.

Quote: This makes me think that the main improvement in sound quality is from the ground isolation or bandpass filtering of the transfomer. In talking about bandpass filtering I'm referring to blocking high frequency garbage that is well outside of the desired frequency range we want the amplifier to amplify, not having a system with limited frequency response in the audio band. Even with the transformer in series with the amplifier, the high frequency response extends out past 100Khz.

Gary Pimm's DIY audio pages

I was reading some of Gary Pimms work on a 47 amp he built and he found that inserting a Lundahl 1676 at the input of his amp improved the sound considerably - he attributed it to the electrostatic shield and bandwidth limiting of the Lundahl removing high frequency garbage from the input (still had a bandwidth of 100kHz, though, so no music was filtered out!). Perhaps putting the Lundahl at the input is the better idea after all - I'll get my 2:1 stepdown, and filter out HF garbage before the 26 sees it.

Quote: This makes me think that the main improvement in sound quality is from the ground isolation or bandpass filtering of the transfomer. In talking about bandpass filtering I'm referring to blocking high frequency garbage that is well outside of the desired frequency range we want the amplifier to amplify, not having a system with limited frequency response in the audio band. Even with the transformer in series with the amplifier, the high frequency response extends out past 100Khz.

Gary Pimm's DIY audio pages

2 156c

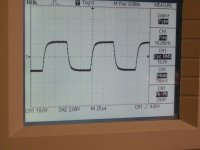

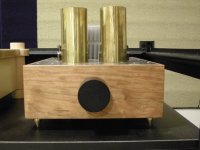

I lately tried 2 156c route with Andy's inspiration. The result is more than what I expect. It sounds better and measures better to my former configuration with 1660 10mA.

I have Sala's SSHV2 in 40mA to 2 156c, a FT-3 0.22 with 1M to ground, filament bias with Rod's reg. My power amp is with 100k input - 6C33C OTL. Soundstage is open, wide and deep. Sounds very good indeed and not congest with complex music. I know there is still lots of good tubes for preamp out there, but this is the best preamp to my ear to date. Will up some pics later.

Thanks guys

Albert

I lately tried 2 156c route with Andy's inspiration. The result is more than what I expect. It sounds better and measures better to my former configuration with 1660 10mA.

I have Sala's SSHV2 in 40mA to 2 156c, a FT-3 0.22 with 1M to ground, filament bias with Rod's reg. My power amp is with 100k input - 6C33C OTL. Soundstage is open, wide and deep. Sounds very good indeed and not congest with complex music. I know there is still lots of good tubes for preamp out there, but this is the best preamp to my ear to date. Will up some pics later.

Thanks guys

Albert

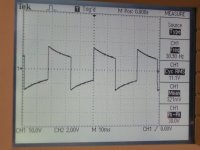

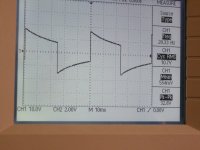

Measure with cyc.RMS

I fixed 10v input from my signal generator to 1K and I have the following numbers.

20 9.65

30 9.95

40 10.1

50 10.2

80 10.3

100 10.3

300 10.3

500 10.3

700 10.2

1k 10

2k 9.92

3k 9.77

4k 9.69

5k 9.60

6k 9.52

7k 9.45

8k 9.36

9k 9.30

10k 9.13

11k 9.07

12k 8.98

It shows the higher the frequencies, the more it drops. Is there anything I could do to improve this ??

I added 3 4.7uf Solen on the signal box before the Sala's reg. and it improve the noise floor.

A friend with good ears came over last night and he gave very good comment to this pre. We really enjoyed listening to Cello & Piano kinds of music with this preamp. The saxophone sounds so real that we almost can touch it.

It had a very light hum at first. I have the 2 156c wrapped with plumber tape and topped with tin foil, and it works perfect. They are under the hood, you don't see them anyway. Ah...........

I fixed 10v input from my signal generator to 1K and I have the following numbers.

20 9.65

30 9.95

40 10.1

50 10.2

80 10.3

100 10.3

300 10.3

500 10.3

700 10.2

1k 10

2k 9.92

3k 9.77

4k 9.69

5k 9.60

6k 9.52

7k 9.45

8k 9.36

9k 9.30

10k 9.13

11k 9.07

12k 8.98

It shows the higher the frequencies, the more it drops. Is there anything I could do to improve this ??

I added 3 4.7uf Solen on the signal box before the Sala's reg. and it improve the noise floor.

A friend with good ears came over last night and he gave very good comment to this pre. We really enjoyed listening to Cello & Piano kinds of music with this preamp. The saxophone sounds so real that we almost can touch it.

It had a very light hum at first. I have the 2 156c wrapped with plumber tape and topped with tin foil, and it works perfect. They are under the hood, you don't see them anyway. Ah...........

Attachments

- Was an power amp connected?

- Did you take measurements at the output socket of the pre or at the input socket of the power amp?

- What happens when you feed the pre-amplifier 2Vpp?

No power amp was connected.

Yes, I took the measurement from the output socket with the signal generator injects 10v @1k to the preamp.

I've been looking at 2" aluminium tube to put around the 26s, 1.5mm wall thickness. The 26 is 45mm diameter, both ST and globe, so may help. Haven't bought any yet.

Wondering if the hum comes from the tubes or the 156C chokes

Andy

I cut them out of the legs of the coffee table which people trashed at the yard.

I've been looking at 2" aluminium tube to put around the 26s, 1.5mm wall thickness. The 26 is 45mm diameter, both ST and globe, so may help. Haven't bought any yet.

Wondering if the hum comes from the tubes or the 156C chokes

Andy

When I built my 26 preamp first time I've documented (earlier in the thread) that the 156C chokes pick up hum like crazy. No problem whatsoever with gyrator/ccs. In your case I don't think it is the 26s that pick up the hum, but the chokes.

Hi Andy,

- orientation: if you are lucky, rotating the choke will help, since the electromagnetic fields are oriented.

other methods to try:

- all power transformers located on a remote chassis.

- wiring between power transformer secondary and rectifier - and from rectifier to caps must be kept to an absolute minimum length. This is especially true with filament supplies, where the peak currents in the rectifier are 3A or more. The bandwidth of the rectifier pulses is very high (may be hundreds of MHz) and long wiring "transmits" these pulses to sensitive nodes of your audio circuit.

If you have a remote power chassis, and wire the rectifiers short, and locate it 1.5m away or further, and there are no large filter capacitors on your signal chassis, AND all filaments/heaters are well filtered or regulated dc, the hum-generating sources should be very small.

Screening with thin Alu or steel sheet will work if electrostatic fields are the problem (presence of voltages nearby that swing rapidly from one value to another (eg anode signals). This is much less effective against magnetic fields (proximity of rapidly changing current, eg power supply capacitor/rectifier node). In case of magnetic field, distance (from the generating source) is your only practical friend.

- orientation: if you are lucky, rotating the choke will help, since the electromagnetic fields are oriented.

other methods to try:

- all power transformers located on a remote chassis.

- wiring between power transformer secondary and rectifier - and from rectifier to caps must be kept to an absolute minimum length. This is especially true with filament supplies, where the peak currents in the rectifier are 3A or more. The bandwidth of the rectifier pulses is very high (may be hundreds of MHz) and long wiring "transmits" these pulses to sensitive nodes of your audio circuit.

If you have a remote power chassis, and wire the rectifiers short, and locate it 1.5m away or further, and there are no large filter capacitors on your signal chassis, AND all filaments/heaters are well filtered or regulated dc, the hum-generating sources should be very small.

Screening with thin Alu or steel sheet will work if electrostatic fields are the problem (presence of voltages nearby that swing rapidly from one value to another (eg anode signals). This is much less effective against magnetic fields (proximity of rapidly changing current, eg power supply capacitor/rectifier node). In case of magnetic field, distance (from the generating source) is your only practical friend.

Hi!

It's probably the winding capacitance of those chokes which impacts the high frequencies.

Best regards

Thomas

It shows the higher the frequencies, the more it drops. Is there anything I could do to improve this ??

It's probably the winding capacitance of those chokes which impacts the high frequencies.

Best regards

Thomas

Hi!

Mu metal is very effective in screening magnetic fields. Rather expensive though

Thomas

What extra measures can I take to screen chokes? Steel, alu, cages? Never tried mu-metal.

Mu metal is very effective in screening magnetic fields. Rather expensive though

Thomas

- Home

- Amplifiers

- Tubes / Valves

- #26 pre amp