If you have a non inductive resistor for anode load, you have the chance to create a layout that will certainly not need a grid stopper.Question:-

What value grid stopper should you use with a type 26 tube?

What have you been using?

There is no grid stopper on Ale Moglia's schematics, but a 1K on Bela's schematics.

For example:

Mount the resistor on some tag strip, so that the anode wire is very short (but don't mount the R directly to the valve socket, or it will couple in some mechanical noise).

Next, mount a (DC link or high quality MKP) film capacitor 1 .. 10uF on the tag strip, to decouple the anode supply voltage + with a short link to the supply end of the resistor.

Mount the filament bias resistors so that a short wire can reach the supply decoupling capacitor -ve.

Mount the grid leak resistor on the tag strip Close to the capacitor -ve, with a short wire to grid.

If you can lay out any DHT stage like this, there is no reasonable risk of a grid stopper being needed, and noise pickup will also be minimised. For these reasons, it will probably be the best sounding layout too.

I do not use grid stoppers on any of my DHTs, and check them in full power operation with a sniffer-loop connected to a 1GHz spectrum analyser, so there is no real chance that they are self oscillating.

Thanks Rod. I don't have your measuring equipment or skills, so I probably wouldn't know if anything was oscillating. So I tend to put something on the grid just in case. My anode resistors are wirewound so I don't know how inductive they are. I have an inductance meter - do I measure from one end to the other, and what kind of reading means what? I may also use a wirewound grid stopper if it sounds better.

I do mount the anode resistors on tag strip or equivalent. Sometimes near the socket, sometimes on top of the coupling caps further away. I'll have to revise that and bring the resistors closer. The DC link cap you describe is presumably the last cap in the PSU chain. I use something like a DC Link 12uF or 15uF as the last cap.

<<Mount the filament bias resistors so that a short wire can reach the supply decoupling capacitor -ve.>>

In filament bias my resistors are above the top plate because they get hot, so maybe 10-15cm to ground. By "supply decoupling capacitor -ve" you mean ground?

I do mount the anode resistors on tag strip or equivalent. Sometimes near the socket, sometimes on top of the coupling caps further away. I'll have to revise that and bring the resistors closer. The DC link cap you describe is presumably the last cap in the PSU chain. I use something like a DC Link 12uF or 15uF as the last cap.

<<Mount the filament bias resistors so that a short wire can reach the supply decoupling capacitor -ve.>>

In filament bias my resistors are above the top plate because they get hot, so maybe 10-15cm to ground. By "supply decoupling capacitor -ve" you mean ground?

Andy!

Don't worry about checking the inductance - you need more advanced tools for that.

Instead, You can check for oscillation with a portable AM radio.

- Play a sine wave WAV track through your DAC at full amplitude. (Generate such tones using Audacity: example: Generate > Tone: 440Hz; amplitude 1.0; 60s duration).

- tune the radio to a weak station.

- bring the radio up slowly to the valve. Move it around and listen for strange noises.

If it doesn't interfere with the radio, it is unlikely to be unstable.

15cm is rather long for a cathode ground wire. Can the ground point be located to minimise anode and cathode wiring? This can improve noise pickup too.

Don't worry about checking the inductance - you need more advanced tools for that.

Instead, You can check for oscillation with a portable AM radio.

- Play a sine wave WAV track through your DAC at full amplitude. (Generate such tones using Audacity: example: Generate > Tone: 440Hz; amplitude 1.0; 60s duration).

- tune the radio to a weak station.

- bring the radio up slowly to the valve. Move it around and listen for strange noises.

If it doesn't interfere with the radio, it is unlikely to be unstable.

15cm is rather long for a cathode ground wire. Can the ground point be located to minimise anode and cathode wiring? This can improve noise pickup too.

Aaaah yes, sometimes back to basics can bring good sound too, I recall a DHT guru that I knew, though hum is present on high sensitivity speakers, he always argued that AC filament feed sounded better. To each his own I guess.

Yes - I'm now using anode resistors. If you use a really, really good quality resistor you can get excellent sound. It's worth choosing the resistor very carefully. As said, in needs to be at least 39K.

I do have some amorphous anode chokes but I haven't used them in a while, mainly because I'm happy with the resistors. Not to say that choke loading isn't good. I just can't remember what it sounded like now.

Aaaah yes, sometimes back to basics can bring good sound too, I recall a DHT guru that I knew, though hum is present on high sensitivity speakers, he always argued that AC filament feed sounded better. To each his own I guess.

I use AC heaters for DHT in my amplifiers and have zero hum into 109dB/w/m horn, so it can be done with good layout.

However, I use CCS for the DHT's in the preamplifier.

@andyjevans Yes a CCS in the filament supply, cmr choke loaded with a large electro right at the socket.

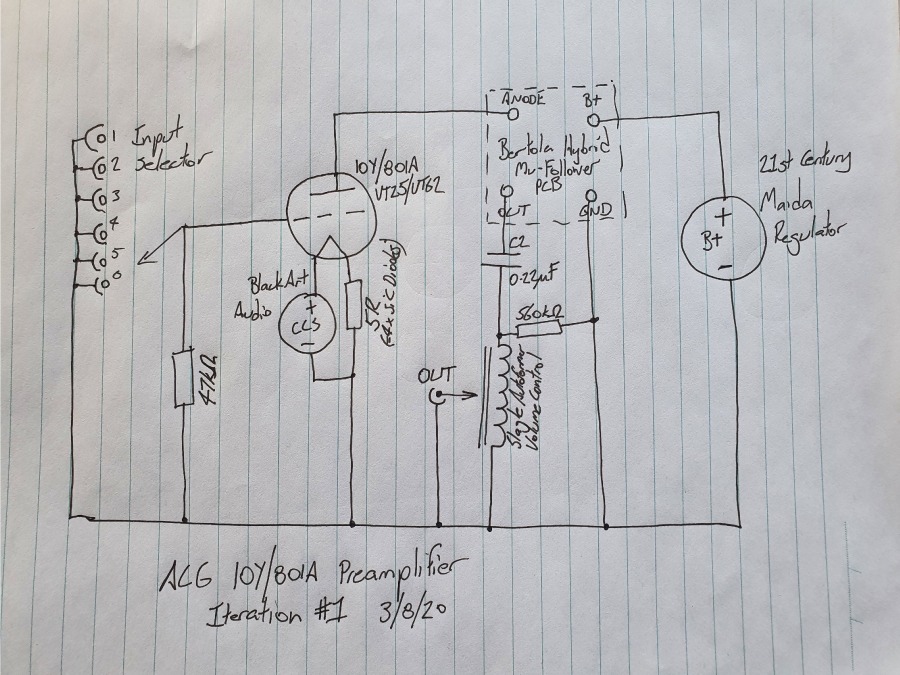

This was the simplified version of the first iteration of the preamp, using silver Slagle autoformer at the output, Ales gyrator and a regulated B+.

I've since moved the autoformer to the input of the amplifier because my sources are both high voltage and low voltage and I was getting some distortion at the input due to shallow bias of the 10Y. Have since increased the bias a little.

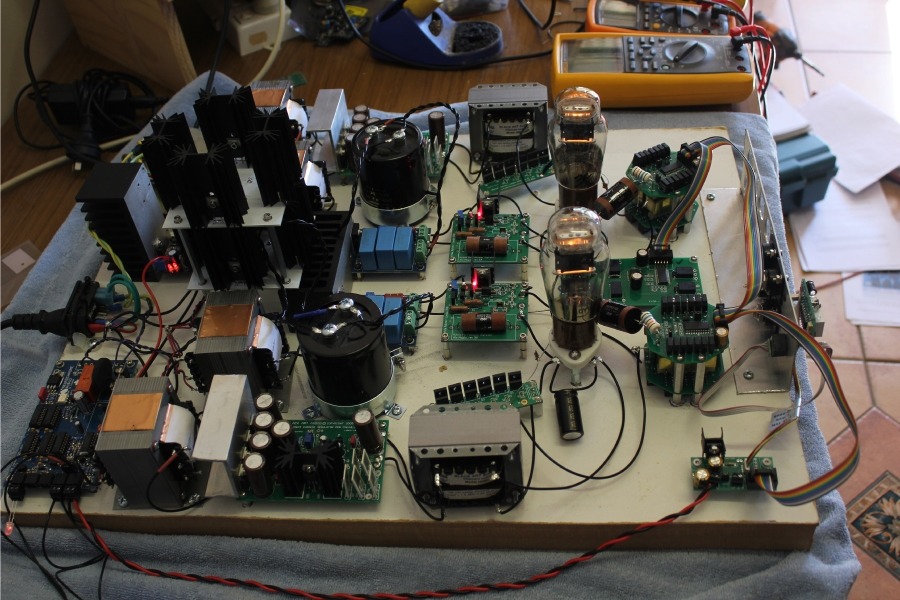

You can see here the layout in the chassis I built: filament CCS, chokes, cap in their own compartments, the B+ supply with a lot of vacant space around it, the two silver Slage autoformers in their own corners and the B+ filter caps and Ales gyrators in the middle. I have the parts here for an unregulated choke input supply for B+ but have yet to trial it as the 21st Century Maida Regulator actually sounds excellent...no defisiency in sound although I will experiment when I have time.

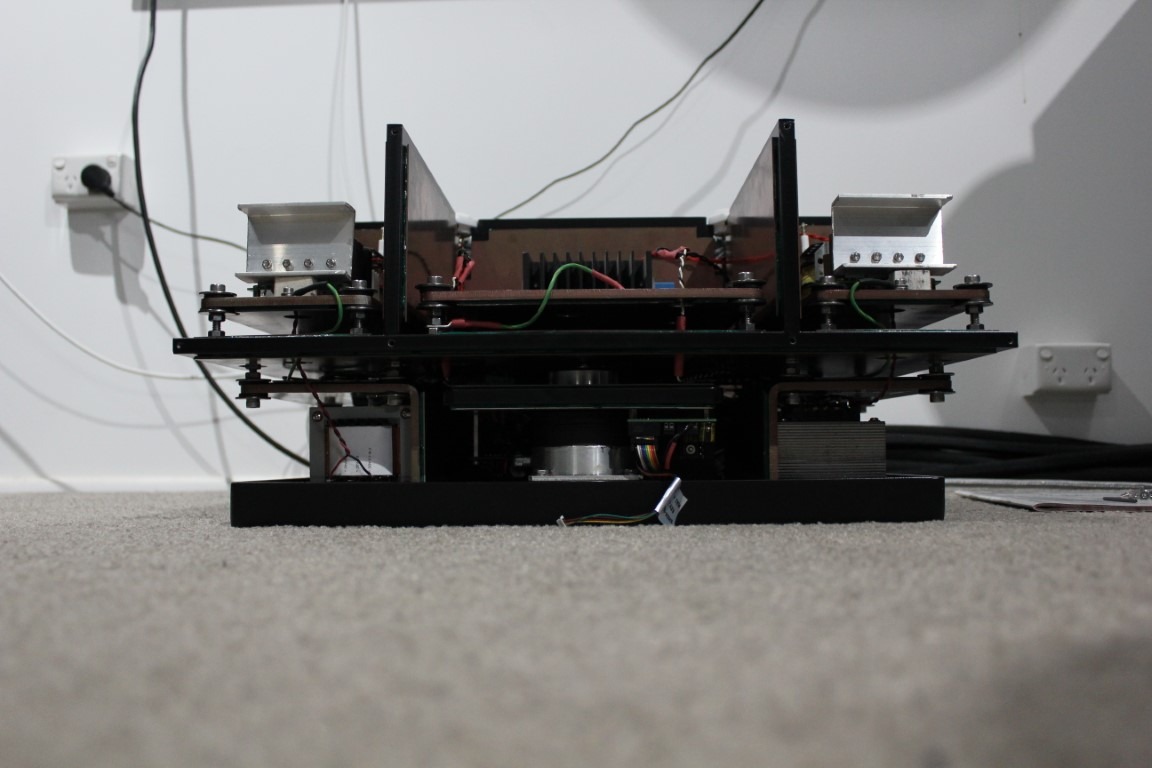

The chassis has been designed and constructed by me from dampened steel. It is very heavy and sits on the floor. To beat floor vibrations I use pneumatic isolators and some rollerblocks I made...the whole top portion of the preamp floats like it is on water....this is the base...

The power transformers are suspended beneath the main platform, also isolated from floor and other vibrations.

Here it is when first turned on in the new chassis...

...and here is was during breadboarding...

Initially, I was going to try 71a, 45, 10, 26 and maybe one or more type of DHT with Ales gyrator, but I started with the 10 and it immediately gave the results I wanted so I've not looked further. I experimented with SiC diode and resistor filament bias and settled on the diodes. Also trialled different caps in and after the gyrator and settled on the most expensive Duelund Cast silver. Experimented with the Slage autoformer at output and input and could not tell the difference. Technically, it is better at the output but practically I need it at the front as one of my dacs has 10VRMS output. Tried the filament chokes in CMR and non-cancelling wiring and preferred CMR. Also tried a couple of different filament electo caps at the DHT socket and found one that I preferred.

The 10 is a great tube. But this is a 26 thread...sorry!

This was the simplified version of the first iteration of the preamp, using silver Slagle autoformer at the output, Ales gyrator and a regulated B+.

I've since moved the autoformer to the input of the amplifier because my sources are both high voltage and low voltage and I was getting some distortion at the input due to shallow bias of the 10Y. Have since increased the bias a little.

You can see here the layout in the chassis I built: filament CCS, chokes, cap in their own compartments, the B+ supply with a lot of vacant space around it, the two silver Slage autoformers in their own corners and the B+ filter caps and Ales gyrators in the middle. I have the parts here for an unregulated choke input supply for B+ but have yet to trial it as the 21st Century Maida Regulator actually sounds excellent...no defisiency in sound although I will experiment when I have time.

The chassis has been designed and constructed by me from dampened steel. It is very heavy and sits on the floor. To beat floor vibrations I use pneumatic isolators and some rollerblocks I made...the whole top portion of the preamp floats like it is on water....this is the base...

The power transformers are suspended beneath the main platform, also isolated from floor and other vibrations.

Here it is when first turned on in the new chassis...

...and here is was during breadboarding...

Initially, I was going to try 71a, 45, 10, 26 and maybe one or more type of DHT with Ales gyrator, but I started with the 10 and it immediately gave the results I wanted so I've not looked further. I experimented with SiC diode and resistor filament bias and settled on the diodes. Also trialled different caps in and after the gyrator and settled on the most expensive Duelund Cast silver. Experimented with the Slage autoformer at output and input and could not tell the difference. Technically, it is better at the output but practically I need it at the front as one of my dacs has 10VRMS output. Tried the filament chokes in CMR and non-cancelling wiring and preferred CMR. Also tried a couple of different filament electo caps at the DHT socket and found one that I preferred.

The 10 is a great tube. But this is a 26 thread...sorry!

Fantastic build....!!!

The 10 is the king of small signal tubes. I have a small number but they're so expensive that I've been using 26 instead.

To my great pleasure I'm now not missing the 10. Been working a lot on the 26 and it has all paid off.

But I'm a resistor guy - with the right resistors. No SIC diodes or gyrators.

The 10 is the king of small signal tubes. I have a small number but they're so expensive that I've been using 26 instead.

To my great pleasure I'm now not missing the 10. Been working a lot on the 26 and it has all paid off.

But I'm a resistor guy - with the right resistors. No SIC diodes or gyrators.

Question about hum with these old 26 tubes. Users have found that wrapping the tubes in aluminium foil and grounding that cuts down on the hum, sometimes substantially.

What are your experiences with this, and any helpful hints and photos of shielding in action?

My hunch is to use a jubilee clip to secure the aluminium foil to the base, and run a wire from that to ground....

What are your experiences with this, and any helpful hints and photos of shielding in action?

My hunch is to use a jubilee clip to secure the aluminium foil to the base, and run a wire from that to ground....

I used something similar to these. Mine were threaded at the base rather than press on. You can find these on eBay typically from Japan or Taiwan sellers.

Search for tube shield covers western electric and similar to find them. There are some on eBay at the time I posted this.

Photograph is from the listing linked to below. I have no affiliation with the seller.

https://www.ebay.com/itm/125780036065?hash=item1d491309e1

Search for tube shield covers western electric and similar to find them. There are some on eBay at the time I posted this.

Photograph is from the listing linked to below. I have no affiliation with the seller.

https://www.ebay.com/itm/125780036065?hash=item1d491309e1

There's various kinds of tubing available...

https://exhaustpartsuk.com/product-...forated-tube/stainless-steel-perforated-tube/

https://www.perforated-tube.com/perforatedtube/perforated-aluminum-tubes.html

https://www.perforatedandstampedproducts.co.uk/

https://www.perforated-metal.net/perforatedmetal/slotted-tube.html

https://www.perforated-pipe.com/perforatedpipe/aluminum-perforated-tube.html

https://www.etsy.com/uk/listing/1232012869/steel-tea-infuser-universal-basket-for?ga_order=most_relevant&ga_search_type=all&ga_view_type=gallery&ga_search_query=tea+infuser&ref=sc_gallery-1-4&sts=1&plkey=f5b3f1f216cb43e4699faf8bd11363ff3014cb7d:1232012869 herbal infusers

https://www.amazon.co.uk/dp/B072XP4...4200|B072XP4FKR&linkCode=gs2&tag=dotdash21-21

https://exhaustpartsuk.com/product-...forated-tube/stainless-steel-perforated-tube/

https://www.perforated-tube.com/perforatedtube/perforated-aluminum-tubes.html

https://www.perforatedandstampedproducts.co.uk/

https://www.perforated-metal.net/perforatedmetal/slotted-tube.html

https://www.perforated-pipe.com/perforatedpipe/aluminum-perforated-tube.html

https://www.etsy.com/uk/listing/1232012869/steel-tea-infuser-universal-basket-for?ga_order=most_relevant&ga_search_type=all&ga_view_type=gallery&ga_search_query=tea+infuser&ref=sc_gallery-1-4&sts=1&plkey=f5b3f1f216cb43e4699faf8bd11363ff3014cb7d:1232012869 herbal infusers

https://www.amazon.co.uk/dp/B072XP4...4200|B072XP4FKR&linkCode=gs2&tag=dotdash21-21

Last edited:

This was my solution for a small run of EML20B based line stages I designed and built back in 2016 for me and a couple of friends.

Cold rolled aluminum perforated sheet stock welded on the back side where not visible.

Sad thing is this line stage is largely a device without purpose in my current system, I use it only to convert unbalanced analog sources to balanced for my RME ADI-2Pro when I want to play analog sources (which is hardly ever) The signal chain is now digital until the power amps. The tape machines have balanced I/O and don't need it.

Cold rolled aluminum perforated sheet stock welded on the back side where not visible.

Sad thing is this line stage is largely a device without purpose in my current system, I use it only to convert unbalanced analog sources to balanced for my RME ADI-2Pro when I want to play analog sources (which is hardly ever) The signal chain is now digital until the power amps. The tape machines have balanced I/O and don't need it.

So where do we buy transparent metal? Would be nice......... I do like the warm glow of a thermionic vacuum tube where electrons are actually working for a living, so personally would like screens that still enables their visual aspect to be seen.

Probably not resistive enough, but...So where do we buy transparent metal? Would be nice......

https://thepihut.com/products/ito-indium-tin-oxide-coated-pet-plastic-100mm-x-200mm

- Home

- Amplifiers

- Tubes / Valves

- #26 pre amp