I have just swapped out my Welwyns for Mills. Can't really tell if they are better, too many other changes, but as they are non-inductive I thought it wouldn't do any harm.I would certainly go for vitreous enamel on the basis of my own listening tests.

Maybe vitreous enamels are best but I really don't want resistors protruding on top of my preamp, and it seems difficult to get enough cooling when placing them inside. Some thought on different types of chassismounted types? Are some alus better than others or is there some ingenious way of cooling the enamels inside a cabinet?

An externally hosted image should be here but it was not working when we last tested it.

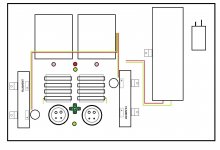

My resistors are inside, between those 2 white teflon plates. There are holes on the top plate for ventilation, and they don't get too hot, especially as I have used four 10 ohm resistors in a series/parallel configuration. I suppose it depends how small you want to make it all, mine is in two boxes.

Maybe vitreous enamels are best but I really don't want resistors protruding on top of my preamp, and it seems difficult to get enough cooling when placing them inside. Some thought on different types of chassismounted types? Are some alus better than others or is there some ingenious way of cooling the enamels inside a cabinet?

Looks like there are choices here. I wouldn't let any kind of layout stop me from using the parts that sound the best. But that's just me. For a 26 preamp resistors on top are cooler, but inside the chassis isn't impossible as you can see from awkward's photos. When it comes to 2 x 4P1L, the cathode resistors are definitely on top and they get hot - that's 15 ohms at 1.25A each channel. The heat discolours PVC wire coating and destroys hexagonal nylon spacers in the end, so they need to be attached with some kind of heat resistant pillar with metal inserts or the equivalent like a tag strip. Parts get brittle with this kind of heat, so wires need to be securely wrapped before soldering etc. etc. But I haven't found it necessary to abandon vitreous enamel yet. If I go up to 3 x 4P1L I may have to re-consider but I'd probably parallel up more resistors so each passes less current.

Last edited:

Encouraging that the resistors in "awkwards" amp doesn't get too hot. Maybe there's hope afterall. By the way - is that Cardas unisolated RCA sockets I see in the pictures? Unusual and interesting grounding in your amp methinks (Sorry. I'm starting to sound like Shakespeare).

By George you have convinced me Mr. Evans. I will go with vitreous enamels.

By George you have convinced me Mr. Evans. I will go with vitreous enamels.

By George you have convinced me Mr. Evans. I will go with vitreous enamels.

Alt i orden....

My RCA sockets are these - Valab Rhodium Plated Tellurium Copper RCA Socket 2 pairs/4 pcs | eBay All insulated, star grounding is used throughout, only the black 4mm socket is connected to the chassis. And I use a ground lift connection to mains earth.

BTW, my name is Richard, if it helps.

BTW, my name is Richard, if it helps.

Here is an attachment with an unfinished sketch of a layout that seems to have some potential. With the filament resistors close to rectangular holes in the bottom one should think that there would be some sorely needed cooling from outside of the chassis. But I've seen that almost everybody (not really. Just Andy and Ale) uses vertical stacked resistors. Is there any advantages in going vertical vs. horisontal?

Attachments

Space saving. But the disadvantage is worse cooling. BTW, my pre has no bottom plate, which actually doesn't help with screening. I lined the wooden sides with aly foil, covered the shelf with earthed copper foil, and made bronze cages for the valves, which all helped. These are seriously hum sensitive valves!Is there any advantages in going vertical vs. horisontal?

Yes, I'm going to prepare some space for cages if necessary. The challenge is finding a material that is effective on magnetic fields without using Mu-metal. Maybe some kind of steel is better than aluminium. I read somewhere that DHT's are most sensitive on top of the tube, I think it was Thorsten Loesch who wrote it in the old Tram2 thread, so maybe it's worthwhile to try out different "roofing" as well.

I made a steel plate to fit under the shelf above, and connected that to the pre-amp's ground post. It made a difference. I don't know if the bronze mesh did, but that also holds the sorbothane damping ring on the top and sides of the type 26. But it creates a Faraday cage of sorts, so there may be RF shielding benefits.I read somewhere that DHT's are most sensitive on top of the tube, I think it was Thorsten Loesch who wrote it in the old Tram2 thread, so maybe it's worthwhile to try out different "roofing" as well.

An externally hosted image should be here but it was not working when we last tested it.

Surprisingly, earthing the wire support cradle, visible here, reduced hum. And there is no conductive connection between that and anything else! Weird, but it inspired me to try the other shielding options.It's very interesting, and as you say surprising, that earthing a wire connected to nothing still reduces hum. Is that really necessary when you use your mesh shields directly on the tubes? If so, have you tried grounded aluminum foil wrapped around the tubes? Not aesthetically pleasing I know but just as an experiment?

The wire cradle earthing was the first thing I did, the mesh shields followed. And no, I haven't taken them off to see if they are needed or not. And no foil, as you say not pretty. I wonder if the wire was acting as an aerial, but it is a puzzle.

I have been very fortunate with this build, my first attempt at a DHT pre. I had great help, and it worked first time, no breadboarding, but then I did pretty much copy Rui's layout.

I have been very fortunate with this build, my first attempt at a DHT pre. I had great help, and it worked first time, no breadboarding, but then I did pretty much copy Rui's layout.

There must be some science somewhere that can explain why the 26 is so sensitive to hum pickup. Where does it happen? Is it the filament that acts like a noise sniffer/receiver or is it the plate? I wish someone could lead me to the theory behind it all. I read and experienced myself that there is a difference between different 26 valves regarding hum pickup levels, which again obviously must mean that there are differences inside the tubes. By the way, my ramblings is the planning stage of my second amp. With a single shunt regulator and filament bias this time.

I have few dozens of #26 tube, from different manufacturers (Cunningham, Fada, Majestic, Philco, Radiotron etc.). Most of them is -older- globe type.

My #26 preamp (two box type, PSU away from tubes -about 1m-) has wood frame and 3mm aluminium plate (open in bottom).

No extra shields, and no hum .... with appropriate (selected) tubes.

Some tube sensitive to radiated hum, some almost insensitive.

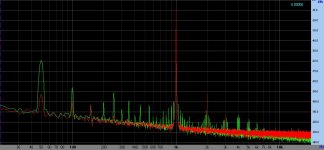

As you can see (measured in my preamp), within same products the (50Hz) hum sensitivity difference would be over 20 dB!

My #26 preamp (two box type, PSU away from tubes -about 1m-) has wood frame and 3mm aluminium plate (open in bottom).

No extra shields, and no hum .... with appropriate (selected) tubes.

Some tube sensitive to radiated hum, some almost insensitive.

As you can see (measured in my preamp), within same products the (50Hz) hum sensitivity difference would be over 20 dB!

Attachments

Sorry, I have no idea.

These tubes are made from -about- 80-90 years, so anything could happen (mechanically?).

The tubes made by the same manufacturer (Majestic), -I bought these as matched pair, gm is almost equal- , the position in the preamp (location, heater supply -incidentally I use Rod Coleman regulators- etc.) is indifferent.

BTW the globe Majestic #26 tubes are the very best in tonality... after the F.A.D.A tubes.

The Radiotron globe #26 tubes are also very good tonality tubes.

The mostly hyped Cunningham tubes (I have few pairs, some of them a little distortion generator :-( ) are far from these types.

These tubes are made from -about- 80-90 years, so anything could happen (mechanically?).

The tubes made by the same manufacturer (Majestic), -I bought these as matched pair, gm is almost equal- , the position in the preamp (location, heater supply -incidentally I use Rod Coleman regulators- etc.) is indifferent.

BTW the globe Majestic #26 tubes are the very best in tonality... after the F.A.D.A tubes.

The Radiotron globe #26 tubes are also very good tonality tubes.

The mostly hyped Cunningham tubes (I have few pairs, some of them a little distortion generator :-( ) are far from these types.

- Home

- Amplifiers

- Tubes / Valves

- #26 pre amp