Felipe, it makes life easier for the kind people trying to help you if you draw your circuit as built. It is better for all of us if you give more prior effort to your posts.

Also, can we request that instead of almost daily posts about very little, which make the thread impossible to follow for people wanting more general information on a 26 preamp, you wait until you have a number of questions and put them all in one weekly post. I would also suggest that you try harder to solve a lot of these problems yourself. I think we're seeing something of a psychological dependency on others in this thread.

Last edited:

Andy, sorry for my lazyness but I think I remember you said some time you were experimenting with 26 p-p as pre. If I'm right, were there any results?

Hello! I haven't used any 26 for a year. In fact I have a 26 preamp for sale since I don't use it. I use a 2 stage amp, 4P1L into LL1660/18 into PSE 4P1L (x2) with LL1620/80. Everything in filament bias. I drive it with a DAC outputting 2v and that's loud enough for my system. I would use a 26 preamp if I needed 3 stages, but I don't any more. Not sure what to do with all my 26 tubes either - maybe I'll come back to it.

I don't use PP at all. I also have some PP amps for sale including a really good one with PP 26 into PP 4P1L into PP 6B4G. O-Netics transformers. It's the best PP amp I ever built (with a friend). I just use a simple SE amp these days.

What were you thinking of doing exactly?

This link doesn't work; it points to post 3948270 which doesn't exist.

I'd prefer if you made your own copy of this schematic. The one you are using has my initials on it but it's totally incorrect - there is no grid leak resistor and it will oscillate.

It is good practice to make your own schematics and post them under your own name. It is bad practice to change other people's schematics when their names are still on them.

It would be better to simply delete your post. Could you please not use versions of my schematic again?

Last edited:

It is interesting to note that the #26 globes are preferred by some, especially the ones with brass pins. I even read remarks that a #26 linestage with ST type are inferior compared to a 6922 Aikido. I have 2 pairs of globes and 2 pairs of ST and yes, I am one of those that prefer the globes.

Since I just have a very limited tube selection, background information and measuring equipments, I would like to hear opinions on the probable cause of difference in perceived sounds from the very similarly constructed tubes. Most of us hear a difference but have very little idea about what measures differently and what factors may contribute the perceived difference.

Since I just have a very limited tube selection, background information and measuring equipments, I would like to hear opinions on the probable cause of difference in perceived sounds from the very similarly constructed tubes. Most of us hear a difference but have very little idea about what measures differently and what factors may contribute the perceived difference.

It is interesting to note that the #26 globes are preferred by some, especially the ones with brass pins. I even read remarks that a #26 linestage with ST type are inferior compared to a 6922 Aikido. I have 2 pairs of globes and 2 pairs of ST and yes, I am one of those that prefer the globes.

6922 against 26? No contest, but depends on the 26 circuit.

I generally prefer the globes - can't give any reasons though.

I measured many CX226/326 and probably only measurement I can correlate with the globe sound is the slightly higher H2 harmonic profile, even when filaments are starved. Only thing to watch out in my experience is not to use some worn out globe valves. Transconductance and emission tend to be on the low side and you can easily perceive a loss of treble as the valve will struggle to drive the capacitance load in higher frequencies.

Comparing a globe to the ST version, all other details be identical, one can surmise that the tube's envelope would have different acoustic resonance points from the difference in shape.

Since tubes are microphonic, this would cause a difference in the sonic signature.

This would probably be quite subtle, but since one can hear differences between passive cables I don't see why an active component like a tube would not also have an audiable difference.

Best wishes,

Susan.

Since tubes are microphonic, this would cause a difference in the sonic signature.

This would probably be quite subtle, but since one can hear differences between passive cables I don't see why an active component like a tube would not also have an audiable difference.

Best wishes,

Susan.

Thanks for the shared opinions. On the #26 tubes that I have, noted construction differences are :

- ST have larger mica spacer that touches the glass envelope

- Globes have wider and larger plates

- Globes have closer grid to plate distance

Can not say if noted differences between types are consistent on wider selections. However, those properties will certainly contribute to microphonic and resonance property differences as Susan mentioned.

I suspected filament wire property to be one of dominant contributing factor, but still have not found a definite method on what to observe or measure.

- ST have larger mica spacer that touches the glass envelope

- Globes have wider and larger plates

- Globes have closer grid to plate distance

Can not say if noted differences between types are consistent on wider selections. However, those properties will certainly contribute to microphonic and resonance property differences as Susan mentioned.

I suspected filament wire property to be one of dominant contributing factor, but still have not found a definite method on what to observe or measure.

I suspected filament wire property to be one of dominant contributing factor, but still have not found a definite method on what to observe or measure.

Try simple FFT measurement.

Good signal generator (I use Victor's), or sound card output - preamp-attenuator-sound card input-FFT capable program (for example Visual Analyzer).

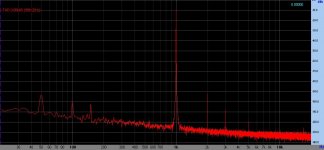

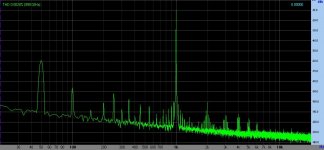

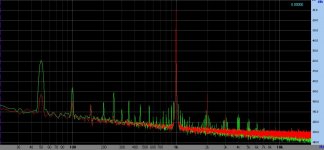

This is my #26 preamp, with different (same manufacturer, same product) tubes.

As you can see, the THD is nearly the same, but the tubes filament sensitivity of hum is significantly differ.

This difference (25dB at 50Hz) is audible. The green curve has sidebands around the 1kHz base, and harmonics (+/- n*50Hz).

Attachments

...

This is my #26 preamp, with different (same manufacturer, same product) tubes.

As you can see, the THD is nearly the same, but the tubes filament sensitivity of hum is significantly differ.

This difference (25dB at 50Hz) is audible. The green curve has sidebands around the 1kHz base, and harmonics (+/- n*50Hz).

That is a HUGE difference, and simple to set up and measure too.

I assume that this is mechanical pick-up from a chassis mounted power transformer?

It would be interesting to set up an isolated test platform with a voice coil actuator (old bass speaker?) to do vibration testing with spot and sweeps.

Anyway, great post. many thanks.

It's the two box system, 2m umbilical between us.

PSU box is about 8-10kg (large HT transformer, AZ1 mesh, CLCLC + SSHV2 for both channels, separated heater transformers and raw supplys).

Within the preamp each tube socket is on the suspended sub-chassis.

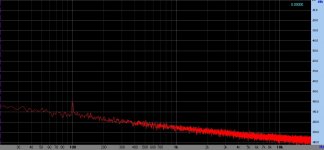

This is the self noise of the preamp (with the least hum sensitive tube).

#26 heater wire -mostly the globe versions- is very sensitive to (induced or radiated) hum, even though I use Rod Coleman regulators.

I have about two dozens of different #26 tubes, after the selection ("best" working points, hum, THD) I have two or three -mostly- identical pairs.

PSU box is about 8-10kg (large HT transformer, AZ1 mesh, CLCLC + SSHV2 for both channels, separated heater transformers and raw supplys).

Within the preamp each tube socket is on the suspended sub-chassis.

This is the self noise of the preamp (with the least hum sensitive tube).

#26 heater wire -mostly the globe versions- is very sensitive to (induced or radiated) hum, even though I use Rod Coleman regulators.

I have about two dozens of different #26 tubes, after the selection ("best" working points, hum, THD) I have two or three -mostly- identical pairs.

Attachments

Last edited:

Mechanical noise sources would be unexpected - with vibration from a mains transformer, I would expect to see only a little 50Hz, and much more 100Hz (the core's magnetostriction-driven expansion-contraction cycles occur twice for every mains-driven flux cycle).

When 50Hz dominates like this example, I think that EM coupling is more likely. Different valve designs present varying amounts of loop area (grid-filament loop or filament's own loop), and maybe this is enough to show the difference.

When 50Hz dominates like this example, I think that EM coupling is more likely. Different valve designs present varying amounts of loop area (grid-filament loop or filament's own loop), and maybe this is enough to show the difference.

I've found shielding the tubes in my 26/12 based transformer coupled line stage to be mandatory in my system due to electro-static coupling to the plates of the DHTs to surrounding electronics.

I also have a slight problem with magnetic coupling between the power transformer and the left channel output transformer. Pre-amp output hum and noise is <100uVrms, but it is still slightly audible with my 100dB+ Onken based speaker system. I have a lot of magnetic shielding between the power transformer, and the outputs, works well but does not quite get it all. (Giron from EMF Safety Superstore - Electromagnetic Field Detection and Protection)

A small change in orientation or area of the plate from sample to sample can have a significant impact on external pick up. In my case the shield cans eliminated this as an issue, I don't hear or measure a significant variation in hum pick up with the shields in place from tube sample to tube sample.

I've stopped using globes as they seem in general to be even more microphonic than the STs, and I have found some ST types to be better than others, and it seems to relate to the design of the top mica, those with only two contact points to the envelope seem to ring somewhat less than those with 4, and much less than those where the entire mica contacts the glass.

When I pause loud music abruptly I generally hear a loud ping which is from the dhts. I'm going to try a little loose fitting acoustical batting between the shields (WE can style) and the tubes. I'll report back on whether or not this helps at all.

I also have a slight problem with magnetic coupling between the power transformer and the left channel output transformer. Pre-amp output hum and noise is <100uVrms, but it is still slightly audible with my 100dB+ Onken based speaker system. I have a lot of magnetic shielding between the power transformer, and the outputs, works well but does not quite get it all. (Giron from EMF Safety Superstore - Electromagnetic Field Detection and Protection)

A small change in orientation or area of the plate from sample to sample can have a significant impact on external pick up. In my case the shield cans eliminated this as an issue, I don't hear or measure a significant variation in hum pick up with the shields in place from tube sample to tube sample.

I've stopped using globes as they seem in general to be even more microphonic than the STs, and I have found some ST types to be better than others, and it seems to relate to the design of the top mica, those with only two contact points to the envelope seem to ring somewhat less than those with 4, and much less than those where the entire mica contacts the glass.

When I pause loud music abruptly I generally hear a loud ping which is from the dhts. I'm going to try a little loose fitting acoustical batting between the shields (WE can style) and the tubes. I'll report back on whether or not this helps at all.

- Home

- Amplifiers

- Tubes / Valves

- #26 pre amp