Hi guys,

Just to raise a question on this topic again.

I want to use a 6V SLA to supply heaters on the demanding 6080's.

Well just one tube at 2.5 Amps.

I'm planning to buy a 4 Amp SLA.

Now coming to charging this thing.

I understand I can charge it slowly when the amp is switched off at 1.1 times the rated voltage.

I have a small power supply rated at 7.5 volts (other voltage selections available) at 500mA.

Will this be suitable to charge it?

Just to raise a question on this topic again.

I want to use a 6V SLA to supply heaters on the demanding 6080's.

Well just one tube at 2.5 Amps.

I'm planning to buy a 4 Amp SLA.

Now coming to charging this thing.

I understand I can charge it slowly when the amp is switched off at 1.1 times the rated voltage.

I have a small power supply rated at 7.5 volts (other voltage selections available) at 500mA.

Will this be suitable to charge it?

Brit01 said:Well just one tube at 2.5 Amps.

I'm planning to buy a 4 Amp SLA.

Do you mean a 4 Amp-hours SLA? As in 1 hour 36 minutes worth of 2.5 Amps?

I recommend you look at the real life implications of this scheme.

Find a discharge curve for a real SLA battery and look at the voltage

drop over time at the current you plan to run.

I think you will be looking at a C/10 discharge (2.5 amps from a 25 AH

battery) or less, and still may not like the resulting voltage curve.

To fully charge SLA batteries requires at least a 2 stage charger where

the final charge is at a lower rate than the bulk charge. This is needed

to fully charge the battery in any reasonable time.

Then, you may only discharge SLA batteries down to about 50% of

their AH capacity on a regular basis. Deeper discharge will shorten

the lifetime. At 50% under discharge, the voltage will be quite a bit

lower than at full charge.

Is it worth it?

Michael

Find a discharge curve for a real SLA battery and look at the voltage

drop over time at the current you plan to run.

I think you will be looking at a C/10 discharge (2.5 amps from a 25 AH

battery) or less, and still may not like the resulting voltage curve.

To fully charge SLA batteries requires at least a 2 stage charger where

the final charge is at a lower rate than the bulk charge. This is needed

to fully charge the battery in any reasonable time.

Then, you may only discharge SLA batteries down to about 50% of

their AH capacity on a regular basis. Deeper discharge will shorten

the lifetime. At 50% under discharge, the voltage will be quite a bit

lower than at full charge.

Is it worth it?

Michael

I'd still be inclined to give it a go

SERIES connect hte heaters so you are running at 12V. THat halves your current requirement immediately and gets you a better discharge curve to boot.

Yeah, two stage charging would be great, but hte reality is your amp will spend maybe 4 hours on, then 4 days off. A slow flat charge curve is entirely reasonable in this setting.

Cost and speed to impliment would be significantly less than getting the "right" transformer, and you have the holy grail - no heater hum.

SERIES connect hte heaters so you are running at 12V. THat halves your current requirement immediately and gets you a better discharge curve to boot.

Yeah, two stage charging would be great, but hte reality is your amp will spend maybe 4 hours on, then 4 days off. A slow flat charge curve is entirely reasonable in this setting.

Cost and speed to impliment would be significantly less than getting the "right" transformer, and you have the holy grail - no heater hum.

Guidelines for lead acid batteries are never to, or rarely discharge past 50% of its AH capacity. Also being it's not too practical to get past charging up to or over 90% of the AH capacity (time, eff & heating factors). So what you have to work with, on a repeat charge/discharge cycling basis, is only around 40% of a batteries AH capacity ie if you want to live up to a reasonable life expectancy of the battery.

SERIES connect hte heaters so you are running at 12V. THat halves your current requirement immediately and gets you a better discharge curve to boot.

I was planning to use only one 6080 for a headphone amp. Yes series would have been possible with 2 tubes but not in this case unfortunately.

kinda depends...

"those batteries" is a pretty broad ranging qualification. Batteries built for fire alarm or security system use are pretty damn reliable in my experience. One has been running my mountainbike lighting (50W @ 12v) for six years now including numerous complete discharges, several epic crashes, and a low tech charging system (panasonic cordless phone wall wart).

Hell, I've talked myself into it - I'm going to battery heat the PC900's in my phono pre and get back to you on the performance!

Cheers

"those batteries" is a pretty broad ranging qualification. Batteries built for fire alarm or security system use are pretty damn reliable in my experience. One has been running my mountainbike lighting (50W @ 12v) for six years now including numerous complete discharges, several epic crashes, and a low tech charging system (panasonic cordless phone wall wart).

Hell, I've talked myself into it - I'm going to battery heat the PC900's in my phono pre and get back to you on the performance!

Cheers

I have a Union Battery model MX12072 SLA battery 12v@7.2Ah that came out of a parted out security system backup power.

Years ago I came across an old WW2 naval battle lantern that was said to have come from the USS Missouri (No documentation)......It was tattered & rusted..I spent $125 restoring it with a car quality stripping & paint job, the reflector I had redone with a new silver coating.....but the 3V original bulb & switch was upgraded to a 50W 12V halogen bulb and the SLA battery. It is a PERFECT fit. The thing wound up melting the 1/4" plastic replacement lense I had made for it.

The thing is down now......awaiting me to have a glass lense cut for it. It is a remarkable lantern as it will "light up your life" when you turn it on!

(The same lantern can be seen in the movie with Humpfrey Bogart as "Captain Queeg"..in the storm scene...one of these is hanging on the wall of the bridge)

_____________________________________________________Rick........

Years ago I came across an old WW2 naval battle lantern that was said to have come from the USS Missouri (No documentation)......It was tattered & rusted..I spent $125 restoring it with a car quality stripping & paint job, the reflector I had redone with a new silver coating.....but the 3V original bulb & switch was upgraded to a 50W 12V halogen bulb and the SLA battery. It is a PERFECT fit. The thing wound up melting the 1/4" plastic replacement lense I had made for it.

The thing is down now......awaiting me to have a glass lense cut for it. It is a remarkable lantern as it will "light up your life" when you turn it on!

(The same lantern can be seen in the movie with Humpfrey Bogart as "Captain Queeg"..in the storm scene...one of these is hanging on the wall of the bridge)

_____________________________________________________Rick........

Michael Koster said:To fully charge SLA batteries requires at least a 2 stage charger where the final charge is at a lower rate than the bulk charge. This is needed to fully charge the battery in any reasonable time.

Then, you may only discharge SLA batteries down to about 50% of their AH capacity on a regular basis. Deeper discharge will shorten the lifetime. At 50% under discharge, the voltage will be quite a bit lower than at full charge.

The first part can be ignored if charging time (i.e. overnight) is not a big concern. The difference in final charge level between single stage float charging (2.25v/cell) and 2 stage charging (>2.30v/cell) is not that signfigant. The main difference is charging time.

The 50% discharge point is very true. The life curves fall off rapidly if you regularly go deeper.

It's also worth pointing out environmental surcharges on lead have nearly tripled the price of SLA batteries from 5 years ago. They're very environmentally unfriendly and have relatively low power density (power to weight ratio)--especially if you follow the 50% discharge guideline. The surcharges were designed to get companies to stop using them and cover some of the recycling cost.

NiMh is a relatively easy alternative to SLA. For the same usable capacity it used to be more expensive but, if you know where to shop, it can actually be cheaper these days. You can also get exactly the voltage you want (in 1.2v increments) instead of being stuck with increments of 6 volts.

Lithium Ion/Polymer is more expensive and it's also more dangerous to work with and requires a smart charger. Even the big manufactures (i.e. Sony, Dell, HP) have had products burst into flames from battery problems and were forced to do massive safety recalls.

But, all things considered, I'd just use a good DC power supply unless you really need to operate away from AC power.

RocketScientist said:

The 50% discharge point is very true. The life curves fall off rapidly if you regularly go deeper.

Right, and maybe even less if you want to keep it longer

Also, it should only be charged with a special pulse charger

There are much better ones for your purpos

Brit01 said:Hi guys,

Just to raise a question on this topic again.

I want to use a 6V SLA to supply heaters on the demanding 6080's.

Well just one tube at 2.5 Amps.

I'm planning to buy a 4 Amp SLA.

Now coming to charging this thing.

I understand I can charge it slowly when the amp is switched off at 1.1 times the rated voltage.

I have a small power supply rated at 7.5 volts (other voltage selections available) at 500mA.

Will this be suitable to charge it?

You plan is OK except for the size of the battery. For best long term economy and long life first decide hown many hours per day you will run the amp. let's say 1 hour per day.

Size the battery so that it was two days of energy. Also figure you can only use the first 50% of the rated amp hours as draining it more will kill it in short order. Then add some "margin" so that these specs are still met after the battery has aged a couple years. About a 50% margin is fine

You will need an 18 AH battery. You can expect about 200 charge/recharge cycles, one cycle per two days so you should get a minimum of 400 days usage from the battery before performance degrades and twice that long before it stops working. If you like to run the amp longer then 1 hour per day then scale the 18AH value by by by the number of hours per day. so for 4 hours per day just round it off to 100AH. Even a 100AH SLA battery is cheap compared to the cost of the equipment you are connecting it to. Buy them at your local marine hardware store (Google "West Marine") The same store will sell yu a very nice, computerized automatic charger that.

BTW. With a 100AH battery treat the wiring as if it were high voltage. Use a fuse inside the battery wire, heat scrink all exposed metal. You can literally vaporize a tool it it falls across the terminals. They sell platic battry boxes at the same store. These can supply over a killoamps (no kidding) if shorted. the voltage can't kill you but the flying hot metal can do serious damage.

With an SLA 20 to 25 times later you will find that charging is so much easier. A cheap trickle charger may be all you need if you play the amp 4 hours and re-charge the battery for 12 the charger only has to supply one amp. (No don't plan on a 20 hour re-charge, leave some margin for ageing.)

If SLA means sealed lead acid you have to use a special pulse charger with charge monitor control

They dont cost much though

Its also my understanding that a discharged battery in the curcuit could lead to amp failure of some kind

You may need a meter on amp to monitor battery

With a higher amp battery and a CCS you should have longer battery time

They dont cost much though

Its also my understanding that a discharged battery in the curcuit could lead to amp failure of some kind

You may need a meter on amp to monitor battery

With a higher amp battery and a CCS you should have longer battery time

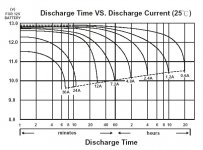

This is a curve for a typical 12 AH SLA battery. You see at the 10 hour

rate (1.2A discharge current) you can play for 5 hours and the filament

voltage is still in spec (for a new battery with nice low ESR). So scaling

up to 2.4A load, a 24AH battery would give you 5 hours playing time.

If you decided to use this 12AH battery for a 2.4A filament you might

be able to get 1-2 hours playing time.

Also, the 50% discharge spec is a maximum for deep-cycle batteries.

It will not result in good battery life in most cases. 25% is a better

number for daily or frequent use, for deep-cycle batteries. For emergency

lighting batteries, starting batteries, etc. I think 25% might be a reasonable

maximum, and even less for best life.

The manufacturers data will have the discharge curve for your battery

and DOD (depth of discharge) recommendations.

Michael

PS I would agree that a simple charger is OK if you charge overnight.

Some SLA batteries can be charged with continuous current, i.e. don't

necessarily need a pulse charger for everyday use.

rate (1.2A discharge current) you can play for 5 hours and the filament

voltage is still in spec (for a new battery with nice low ESR). So scaling

up to 2.4A load, a 24AH battery would give you 5 hours playing time.

If you decided to use this 12AH battery for a 2.4A filament you might

be able to get 1-2 hours playing time.

Also, the 50% discharge spec is a maximum for deep-cycle batteries.

It will not result in good battery life in most cases. 25% is a better

number for daily or frequent use, for deep-cycle batteries. For emergency

lighting batteries, starting batteries, etc. I think 25% might be a reasonable

maximum, and even less for best life.

The manufacturers data will have the discharge curve for your battery

and DOD (depth of discharge) recommendations.

Michael

PS I would agree that a simple charger is OK if you charge overnight.

Some SLA batteries can be charged with continuous current, i.e. don't

necessarily need a pulse charger for everyday use.

Attachments

One thing I forgot to say. If the goal is to reduce the total lifetime cost of the system. The number to look at is "lifetime amp hours of power". This is simply the number of amp hours drained from the battery per listening session times the number of listening session before you have to replace the battery. A large high quality battery might get over 1,000 charge/recharge cycles. A cheap one could do 50. If the 1000 cycle battery costs only 10 times more then the 50 cycle battery you have cut the total cost in half if you consider the cost of battery replacement over a lifetime.

For a system this small (a 2.4 amp load) this hardly matters. The theory is best applied to houses powered with solar energy. These systems can have several thousand dollars invested in batteries

There was a day when most home sound systems where battery powered. We still call the high voltage power supply "B+" after the "B battery" that was used People owned home radios years before utility power was universal and batteries were the only source of electric power.

But today why not simply buy a good clean 6.3 V power supply. I don't understand the need for a battery. If you can justify a battery then why not ru the B+ off battery power as well?

Years ago I had a radio transmitter that used a car battery as a kind of power supply input cap. We could not afford a high powered transformer for the supply so we used a one amp transformer which powered the receiver section just fine. But keying the mic pulled 15 amps. it worked well because in typical use you listen much more than you talk.

For a system this small (a 2.4 amp load) this hardly matters. The theory is best applied to houses powered with solar energy. These systems can have several thousand dollars invested in batteries

There was a day when most home sound systems where battery powered. We still call the high voltage power supply "B+" after the "B battery" that was used People owned home radios years before utility power was universal and batteries were the only source of electric power.

But today why not simply buy a good clean 6.3 V power supply. I don't understand the need for a battery. If you can justify a battery then why not ru the B+ off battery power as well?

Years ago I had a radio transmitter that used a car battery as a kind of power supply input cap. We could not afford a high powered transformer for the supply so we used a one amp transformer which powered the receiver section just fine. But keying the mic pulled 15 amps. it worked well because in typical use you listen much more than you talk.

If you charge a battery with say 1A its enough to make it "cook" when fully charged

That must NEVER happen with a SLA

And you wont know with a sealed battery

Another problem is that if charging with less than 1A it will take forever

Thats why a pulse charger is a must with SLA

Another problem is that putting load on such a battery not fully charged it will be hurt bit by bit, and may not last half as long as expected

Its build to be fully loaded always

Me and my friends have had lots of motorcyles, and thats one issue we know to take seriously

That must NEVER happen with a SLA

And you wont know with a sealed battery

Another problem is that if charging with less than 1A it will take forever

Thats why a pulse charger is a must with SLA

Another problem is that putting load on such a battery not fully charged it will be hurt bit by bit, and may not last half as long as expected

Its build to be fully loaded always

Me and my friends have had lots of motorcyles, and thats one issue we know to take seriously

Some are making this more complex than it need be. The manufacture's data, and many real world devices, demonstrate you can float charge an SLA with DC and it will last many years (typically 4 or 5 years at 20 degrees C or less) with light discharge. You don't need a pulse charger, 2 stage charger, or otherwise fancy or complex charger.

All you need to do is use a voltage regulator with current limiting to limit both the maximum voltage to 2.15v/cell and the maximum current to 10% of the battery's AH capacity.

For example, an LM317T current limits at around 1.5 amps and can be set, with 2 resistors, to give 6.8 volts. This circuit can be used with a 15 AH battery (or two 7 AH batteries in parallel) and you're done. The LM317 will limit the maximum charge current to ~1.5 amps when the battery is low and the regulated voltage will let the charger stay connected 24/7 with no fear of overcharging.

Inexpensive commercial pulse chargers are rarely available for 6 volt batteries (as specified here). And the pulse waveform creates noise that would likely find its way into the audio if you tried to use the device while it was charging.

But the issue still remains of how much run time you will get versus how big of battery you need. And how many pounds of lead waste you'll be creating over the years. And if a battery will make one bit of difference in the sound versus a clean DC power supply.

All you need to do is use a voltage regulator with current limiting to limit both the maximum voltage to 2.15v/cell and the maximum current to 10% of the battery's AH capacity.

For example, an LM317T current limits at around 1.5 amps and can be set, with 2 resistors, to give 6.8 volts. This circuit can be used with a 15 AH battery (or two 7 AH batteries in parallel) and you're done. The LM317 will limit the maximum charge current to ~1.5 amps when the battery is low and the regulated voltage will let the charger stay connected 24/7 with no fear of overcharging.

Inexpensive commercial pulse chargers are rarely available for 6 volt batteries (as specified here). And the pulse waveform creates noise that would likely find its way into the audio if you tried to use the device while it was charging.

But the issue still remains of how much run time you will get versus how big of battery you need. And how many pounds of lead waste you'll be creating over the years. And if a battery will make one bit of difference in the sound versus a clean DC power supply.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Sealed Lead Acid Batteries