Which is better steel or aluminium, and why?

Or maybe it is a question of what are the advantages / dissadvantages of each.

Al is easier to work with and does not rust, however the only tube guitar amps I've seen used steel for the chassis, as did all the tube receivers and amps I've seen.

tks.

Or maybe it is a question of what are the advantages / dissadvantages of each.

Al is easier to work with and does not rust, however the only tube guitar amps I've seen used steel for the chassis, as did all the tube receivers and amps I've seen.

tks.

Which is better steel or aluminium, and why?

Aluminum is MUCH easier to drill and cut. Ever try to cut a large square opening in steel? Aluminum can be cut with woodworking tools.

As for sound quality, some people can claim a theory where one is better. In in real life there is none

For some people it is easier to paint steel. To do a first class paint job on aluminum requires more care and good primer paint. But aluminum will not rust so it may not need paint.

There are other materials. Stainless steel and galvanized steel.

If you are building a hifi amp then you can assume it will be treated gently. Guitar amps are different. They get moved around, hauled up and down stairs on dollys and so on. Even so strength of the chassis is not an issue because the chassis is typically put inside a wood enclosure. Even if you had to mount 11 pound transformers on the chassis strength is not an issue because you can add reinforcement to the under side or (better) mount the transformer "laydown" style.

If yu are doing the cutiing and drilling buy aluminum

Last edited:

Which is better steel or aluminium, and why?

Or maybe it is a question of what are the advantages / dissadvantages of each.

Al is easier to work with and does not rust, however the only tube guitar amps I've seen used steel for the chassis, as did all the tube receivers and amps I've seen.

tks.

As has been said, aluminum is so much easier for the hobbyist to machine than steel. Powder coating is a cost effect and very durable finish for aluminum too.

As for sound quality, some people can claim a theory where one is better. In in real life there is none

Curious how you came to that conclusion. Steel, with inherently lower internal damping, is much more prone to ringing from mechanical excitation. Tubes span the range of microphonics. It makes no sense to flatly claim there's no difference between steel and aluminum in this application.

Curious how you came to that conclusion. Steel, with inherently lower internal damping, is much more prone to ringing from mechanical excitation. Tubes span the range of microphonics. It makes no sense to flatly claim there's no difference between steel and aluminum in this application.

Steel is much stiffer though and will have a higher frequency resonance than aluminum, which will be much lower in frequency. Low frequencies are going to be more problematic than higher frequencies. Aluminum will also store more energy than steel due to its compliance and release said energy at a slower rate. If I had the money, i would use a heavy gauge steel for my chassis, but I don't so 1/4" aluminum is what I intend to use.

Why aren't bells made of aluminum? My suggestion comes from experimenting with both steel and aluminum speaker cabinets. The former (1/4" wall EMT rectangular tube) was impossible to damp. 3/16" aluminum bonded to linoleum floor tile and glued to the interior walls barely made a dent. In contrast two face-to-face 1/8" aluminum sheets makes for a highly damped 1/4" plate prior to the application of any constrained layer techniques. It's not a subtle difference.Aluminum will also store more energy than steel due to its compliance and release said energy at a slower rate.

If you haven't purchased the material yet I recommend trying the experiment above at the metal supplier.

Curious how you came to that conclusion. Steel, with inherently lower internal damping, is much more prone to ringing from mechanical excitation. Tubes span the range of microphonics. It makes no sense to flatly claim there's no difference between steel and aluminum in this application.

He is talking about buying a ready made Hammon style chassis. Not making a speaking enclosure.

Look at the worst possible case. A guitar combo amp. These amps will mount the chassis and tubes inside the speaker cabinet inches away from the driver. If you could hear steel chassis vibrations it would certainly show up in that application. For over 50 years now musicians who likely have some very good ears have not complained even when the steel chassis is mounted inside a speaker cabinet.

Hammon made many, many organs this way too. Steel chassis mounted directly inside the tone cabinet along with a number of 12 and 15 drivers. Again no reported problems with chassis vibrations in over 50 years of use. But they did use very heavy steel.

I do agree that in theory there could be a difference but audible differences are not widely reported

All that said. I'd go with aluminum simply because of how much easier it is to cut and drill.

Last edited:

One is a music producer, the other a reproducer. The impact and desirability of microphonic bleed through are hardly equivalent. In most cases the primary source of chassis excitation in a hifi amp is the power supply transformer, a noise completely uncorrelated with the audio amplified.Look at the worst possible case. A guitar combo amp. These amps will mount the chassis and tubes inside the speaker cabinet inches away from the driver.

Hi Gimp,

There is a very big thread on this topic here -

http://www.diyaudio.com/forums/showthread.php?t=103815&highlight=aluminium

Rob

There is a very big thread on this topic here -

http://www.diyaudio.com/forums/showthread.php?t=103815&highlight=aluminium

Rob

If worried about power supply microphonic bleed through why not build the power supply seperate from the amp,Ala heathkit w-3am, apperently they were worried about it back then and built the kits this way and the steel in the chassis is very very thin ,I know it was allso to reduce magnetic coupling between power supply and output transformer.

These are great sounding amps, I am listening to one at this moment. Wonderfuly silent under no signal, and such sweet clear sound throughout. Something I couldn't find in a solid state amp.

These are great sounding amps, I am listening to one at this moment. Wonderfuly silent under no signal, and such sweet clear sound throughout. Something I couldn't find in a solid state amp.

Rdf,

You asked about bells. Bells or any metal thats used to ring ( chimes string bells) are all made metal that has a twinned structure.

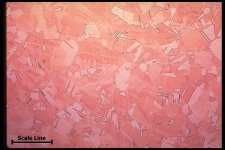

The first picture is of brass. You see the semi parallel lines going through the grian, those are twin's. Metals that have these in the grains ring very well.

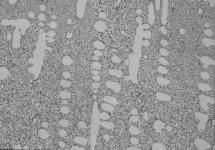

Also below it is aluminum, no twins. Steel also does not have a twinned structure so it doesn't ring well.

And the idea that a thicker piece rings less, well thats not true.

Take 2 pieces of steel, lets say bar. 1 piece is half an inch in diameter and ones 3 inch,s in diameter. And if you hit both with a hammer, with the same force the heavier piece will ring louder and longer.

Just for clarification steel as we use it in out hobby is completely different then any of the other metals we use, unless someone is using titanium. Steel is allotropic which means it can have 2 different structure but are the same phase of iron.

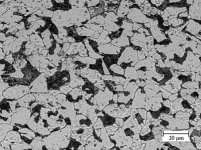

Normal steel is whats called ferritic perlite. and thats the last picture.

Hope this doesn't add to the confusion, just trying to show you there's a little science behind this discussion.

So in actuality both steel and aluminum are on about the same playing field as far as resonance. Just make sure the pieces you make aren't any fractional wave lengths.

Nick

You asked about bells. Bells or any metal thats used to ring ( chimes string bells) are all made metal that has a twinned structure.

The first picture is of brass. You see the semi parallel lines going through the grian, those are twin's. Metals that have these in the grains ring very well.

Also below it is aluminum, no twins. Steel also does not have a twinned structure so it doesn't ring well.

And the idea that a thicker piece rings less, well thats not true.

Take 2 pieces of steel, lets say bar. 1 piece is half an inch in diameter and ones 3 inch,s in diameter. And if you hit both with a hammer, with the same force the heavier piece will ring louder and longer.

Just for clarification steel as we use it in out hobby is completely different then any of the other metals we use, unless someone is using titanium. Steel is allotropic which means it can have 2 different structure but are the same phase of iron.

Normal steel is whats called ferritic perlite. and thats the last picture.

Hope this doesn't add to the confusion, just trying to show you there's a little science behind this discussion.

So in actuality both steel and aluminum are on about the same playing field as far as resonance. Just make sure the pieces you make aren't any fractional wave lengths.

Nick

Attachments

So in actuality both steel and aluminum are on about the same playing field as far as resonance.

You probably mean damping capacity, rather than resonance. The resonance of a material is related to its mass. Whether it rings or not is related to its damping capacity. Damping capacity also determines its ability to transmit vibration. If you want a metal chassis that doesn't ring or transmit vibration then the obvious choice is magnesium. But it has its own set of problems....

John

Last edited:

No ringing, no overheating. Just a rugged frame made of aluminium angles, and perforated aluminium chassis.

http://wavebourn.com/forum/download.php?id=112&f=7

http://wavebourn.com/forum/download.php?id=112&f=7

I generally use aluminum, and I prefer non-magnetic materials in general for audio electronics.

Magnetic coupling from power transformers into the chassis and hence to surrounding components is a non issue with non magnetic materials.

In applications where low signal levels are present I suspect that magnetic fields around wiring interact with the chassis and result in audible colorations in the sound. I have not done any scientific experiments to prove or disprove this notion - it is anecdotal, but it is one of the reasons I avoid steel.

Truthfully I love copper for both the appearance and its non-magnetic properties, but it is hard to work and expensive.

Magnetic coupling from power transformers into the chassis and hence to surrounding components is a non issue with non magnetic materials.

In applications where low signal levels are present I suspect that magnetic fields around wiring interact with the chassis and result in audible colorations in the sound. I have not done any scientific experiments to prove or disprove this notion - it is anecdotal, but it is one of the reasons I avoid steel.

Truthfully I love copper for both the appearance and its non-magnetic properties, but it is hard to work and expensive.

No ringing, no overheating. Just a rugged frame made of aluminium angles, and perforated aluminium chassis.

http://wavebourn.com/forum/download.php?id=112&f=7

Looks great. Where do you source the perf aluminum?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Chassis material