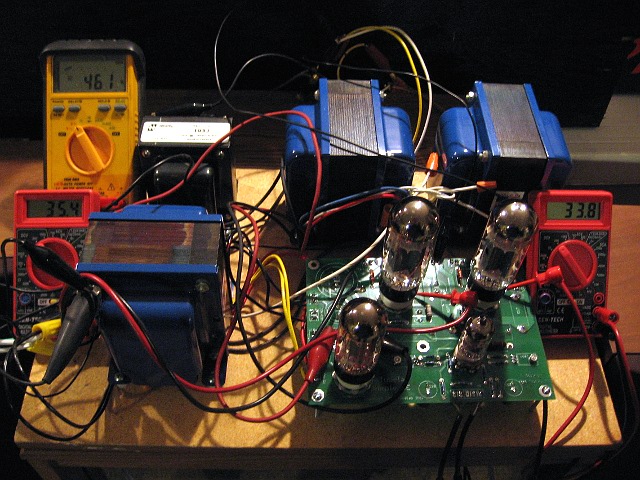

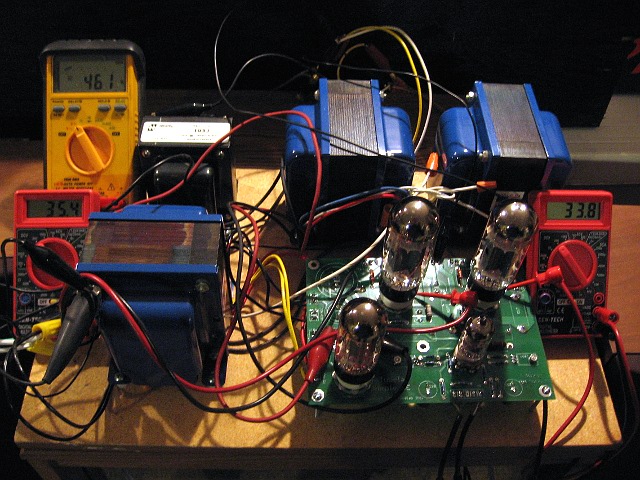

Sorry I am flooding the forum with Tubelab builds. I guess this would be YATSSE?

OK, so even though I knew the rough dimensions of these Edcors, I didn't quite come to terms with their size until they arrived. Man, these things are huge...and heavy. You definately get your money's worth with these guys. There is no way I am going to fit these on the 12x10 chassis I have on hand, so I am going to have to rethink that. I knew they were overkill for this amp, but did I take it a bit too far? They are:

XPWR035

CXSE25-8-5K x 2

After testing with cheap Chinese tubes, I ran this amp for several hours on two evenings with the JJ 6L6GCs. The power transformer barely got warm. So nice have properly-implemented iron again in that respect.

I read a lot about going with oversize output iron to get better low-end frequency response, but there is the other extreme as well. Seems like most builders are going with the smaller Edcors. Has anyone build Simple SE with these guys?

I listened to this amp with the new speakers and was happy with the results (triode, no feedback), but I decided to tear it down and bring the Tubelab SE back to life instead. Guess 2W is enough after all. Never thought I would utter those words....

OK, so even though I knew the rough dimensions of these Edcors, I didn't quite come to terms with their size until they arrived. Man, these things are huge...and heavy. You definately get your money's worth with these guys. There is no way I am going to fit these on the 12x10 chassis I have on hand, so I am going to have to rethink that. I knew they were overkill for this amp, but did I take it a bit too far? They are:

XPWR035

CXSE25-8-5K x 2

After testing with cheap Chinese tubes, I ran this amp for several hours on two evenings with the JJ 6L6GCs. The power transformer barely got warm. So nice have properly-implemented iron again in that respect.

I read a lot about going with oversize output iron to get better low-end frequency response, but there is the other extreme as well. Seems like most builders are going with the smaller Edcors. Has anyone build Simple SE with these guys?

I listened to this amp with the new speakers and was happy with the results (triode, no feedback), but I decided to tear it down and bring the Tubelab SE back to life instead. Guess 2W is enough after all. Never thought I would utter those words....

Isn't it sweet to have everything come together so well?

No there is no overkill there as long as you stay within your output Z parameters. Did you notice the One-Electron high end OPTs??? They have a dimensionally different looking core? Recall that core size vs. winding turns vs. wire diameter vs. power they are all balanced together..change one and the other three must be changed.... a percarious balancing act.

I think the use of the "basic" Edcors is driven by the cost differences.

Its a great thing that your mains TX got "barely warm"....that way you will not have any heat related problems.

Now that your project 'Won't fit' you are free to explore your artistic side. Tube amps are a real artform I believe, both electrically and visually.....let your mind create a real work-of-art........

________________________________________Rick..........

No there is no overkill there as long as you stay within your output Z parameters. Did you notice the One-Electron high end OPTs??? They have a dimensionally different looking core? Recall that core size vs. winding turns vs. wire diameter vs. power they are all balanced together..change one and the other three must be changed.... a percarious balancing act.

I think the use of the "basic" Edcors is driven by the cost differences.

Its a great thing that your mains TX got "barely warm"....that way you will not have any heat related problems.

Now that your project 'Won't fit' you are free to explore your artistic side. Tube amps are a real artform I believe, both electrically and visually.....let your mind create a real work-of-art........

________________________________________Rick..........

Evenharmonics said:I'm not familiar with XPWR035. What are the voltages and are you going to use it on Tubelab SE?

It's one of their designs from the PDF posted in their forums.

370-0-370 @ 200mA

6.3 VCT @ 5A

5V @ 2A

Richard Ellis said:Isn't it sweet to have everything come together so well?

No there is no overkill there as long as you stay within your output Z parameters. Did you notice the One-Electron high end OPTs??? They have a dimensionally different looking core? Recall that core size vs. winding turns vs. wire diameter vs. power they are all balanced together..change one and the other three must be changed.... a percarious balancing act.

Yes...I have noticed lots of different combinations. I assume it's up to the designers to make use of what bobbins and laminations they have on-hand. I do have the UBT-2s and they are smaller...but have a LOT more laminations than I was expecting. Very nice transformers, but they lack an UL tap so I used them for the Tubelab SE amp

Now that your project 'Won't fit' you are free to explore your artistic side. Tube amps are a real artform I believe, both electrically and visually.....let your mind create a real work-of-art........[/B]

Yeah, I will probably do something interesting with this amp...probably out of some hardware store metal stock or something. Maybe time to try my hand at welding aluminum with the MIG...been looking for a paintable project to try that on. 😉

Evenharmonics said:...and are you going to use it on Tubelab SE?

Sorry...didn't see the other half of your question. This transformer is not the best for Tubelab SE. Even 300Bs aren't going to like 460V on the plates. Instead I am likely going to have Edcor make a special transformer for me that will allow both 400V and 300V operation for 300Bs and 45s. The specs are:

330-260-0-260-330 @ 175mA

6.3V CT @ 3A

5V @ 3A

I'll use the 520VCT taps for 45s, since I now have a few decent pairs of these on hand. I haven't bitten the bullet on 300Bs yet, but I probably will at some point to get a bit more oomph. This way I can switch over to the 660VCT taps when I switch the heater config and run the tubes closer to where they like it.

300B needs 6.3V @ 4A min per Tubelab description.rknize said:

330-260-0-260-330 @ 175mA

6.3V CT @ 3A

5V @ 3A

Has anyone build Simple SE with these guys?

YES, I did. It ROCKED!

but I decided to tear it down and bring the Tubelab SE back to life instead.

That's where my big Edcors are now, but my amp still looks like yours. I never had the time to finish the chassis.

300B needs 6.3V @ 4A min per Tubelab description.

If it is not too late 4 amps or more would be a good idea. Generic 300B's draw 1.2 amps, the 5842's draw .3 amps. That adds up to 3 amps of DC out of the regulator so you need more than 3 amps of AC out of the transformer. Some of the "super 300B" variants draw 2+ amps each. They cost far too much for me to even think about them.

Have you ordered one of these universal transformers yet?

rknize said:Yeah, I will probably do something interesting with this amp...probably out of some hardware store metal stock or something. Maybe time to try my hand at welding aluminum with the MIG...been looking for a paintable project to try that on. 😉

Try some nice wood for the frame and a piece of aluminum plate for the top panel, or at least a nice wood front panel. Glowing tubes and nicely figured wood belong together.

tubelab.com said:That's where my big Edcors are now, but my amp still looks like yours. I never had the time to finish the chassis.

My ears really like the Tubelab SE with the KLF-10s, but I am hopeful that I stay motivated enough to finish both amps before summer really gets here and the itch to be out in the garage returns. Tubes are my winter hobby. 😛

If it is not too late 4 amps or more would be a good idea. Generic 300B's draw 1.2 amps, the 5842's draw .3 amps. That adds up to 3 amps of DC out of the regulator so you need more than 3 amps of AC out of the transformer. Some of the "super 300B" variants draw 2+ amps each. They cost far too much for me to even think about them.

Have you ordered one of these universal transformers yet?

No, but I was about to. I should be able to add another amp to the 6.3 winding. I'll have to see how much this affects the cost. Going up to 5A for mega 300Bs are not the cards for me. If/when I do get a set of them, they'll be Shaugang or some other cheap variant. No mesh plate globe tubes for me unless I run into someone very generous.

Thanks Even and George for the heads-up.

kuroguy said:

Try some nice wood for the frame and a piece of aluminum plate for the top panel, or at least a nice wood front panel. Glowing tubes and nicely figured wood belong together.

I intend to go with a very clean and classic look for the Tubelab SE in my other thread. Probably mahogany frame with a SS top plate. That will look nice with the ST-shaped tubes. I will probably not use the on-board 4 pin sockets in order to spread-out the tubes a bit.

The layout of the SSE PCB puts the tubes in an asymmetric orientation, so I am probably going to run with that and put the PSU to the side. So I'm thinking of doing a more industrial design. Probably not Morgan-Jones-meets-treadplate like George's, but something more along the lines of a big finned heatsink, like a giant car amp with tubes and transformers on top. I can't find an extrusion with enough real estate, but I can make something out of channel and bar stock to give a similar affect.

Just want to do something a little different.

Regarding the tubelab SE, consider that stainless is much harder to machine than aluminum (and much harder on your cutting tools). I have been able to polish aluminum to a mirror finish with 120 grit through 1200 grit and then metal polish - not too much work.

kuroguy said:Regarding the tubelab SE, consider that stainless is much harder to machine than aluminum (and much harder on your cutting tools). I have been able to polish aluminum to a mirror finish with 120 grit through 1200 grit and then metal polish - not too much work.

You bring up a good question i was going to ask. Not in this thread, but who cares...

Have folks successfully punched SS with Greenlee punches? I have a few that would work. I have some SS plate on hand already, so that is why i was going to use it.

Russ

Weren't you the guy I told they would be overkill unless your building a Pentode or UL mode 6550/KT88? Now you know what I'm talking about 😀

I made the mistake of getting the chassis first (a really nice $160 chassis I may add) for my project that uses Edcors. Once they arrived, I realized that a larger chassis is needed. It was an expensive mistake.

On the bright side, in my 15Wrms SE (6c33c) the frequency response is only down .2dB@20Hz running full power.Though distortion is 1-2% higher at 20Hz than 1kHz measurement. It cleans up around 40Hz.

The power transformer transformer I got from them are the first I've seen that doesn't display a flat-topped waveform when rectified and ran close to the VA rating. It still looks like a sine wave

I made the mistake of getting the chassis first (a really nice $160 chassis I may add) for my project that uses Edcors. Once they arrived, I realized that a larger chassis is needed. It was an expensive mistake.

On the bright side, in my 15Wrms SE (6c33c) the frequency response is only down .2dB@20Hz running full power.Though distortion is 1-2% higher at 20Hz than 1kHz measurement. It cleans up around 40Hz.

The power transformer transformer I got from them are the first I've seen that doesn't display a flat-topped waveform when rectified and ran close to the VA rating. It still looks like a sine wave

Try some nice wood for the frame and a piece of aluminum plate for the top panel, or at least a nice wood front panel.

I am planning a wood surround with a clear Lexan top plate. The tube sockets will be up on stilts so the PC board can sit on the lower deck.

I am hopeful that I stay motivated enough to finish both amps before summer really gets here and the itch to be out in the garage returns.

The situation here is a bit different the garage is a storage shed. The table saw must be used outside. In the summer it is just too hot, so my woodworking is usually done in the winter. I cut and routed the wood and Lexan for this amp a year ago. I haven't had the time to work on it, or any amp since then. It won't happen any time soon either.

Still off topic (sorry for the hijack). aluminum can be worked with wood cutting tools as long as you keep the cutting edge well oiled and use low speed tools. I've used hole saws, drill bits and even circular saw blades that were made for wood on aluminum. You gotta go really slow and keep things lubricated. wood tools are way less expensive than metal cutting tools. I can't say that I'd ever consider stainless with the way that aluminum polishes up and machines.

Yeah, as I mentioned in the other SSE thread, you can do nice work with aluminum in a drill press with otherwise crude tools as long as you mount the piece firmly and go slow with oil. I've used flat wood bits and cheap hole saws with good results, as long as you are aware that the holes will be slightly larger due to the way these tool clear their teeth.

I have a really big SS door kicker plate in the basement that I never used. It has a nice brushed finish and will look good. I'm just not quite sure if the Greenlee punches are hard enough.

I have a really big SS door kicker plate in the basement that I never used. It has a nice brushed finish and will look good. I'm just not quite sure if the Greenlee punches are hard enough.

Jeb-D. said:Weren't you the guy I told they would be overkill unless your building a Pentode or UL mode 6550/KT88? Now you know what I'm talking about 😀

Yep, that's me and my answer was "yes". 🙂 I have 6550s, KT88s, and KT90s to try. Since then I have finally upgraded my speakers, so the picture has changed slightly.

I made the mistake of getting the chassis first (a really nice $160 chassis I may add) for my project that uses Edcors. Once they arrived, I realized that a larger chassis is needed. It was an expensive mistake.

On the bright side, in my 15Wrms SE (6c33c) the frequency response is only down .2dB@20Hz running full power.Though distortion is 1-2% higher at 20Hz than 1kHz measurement. It cleans up around 40Hz.

The power transformer transformer I got from them are the first I've seen that doesn't display a flat-topped waveform when rectified and ran close to the VA rating. It still looks like a sine wave[/B]

So far I've been happy with them, but I only have one power transformer and it's fairly over-rated. As to the chassis, it's just a Hammond 12x10 aluminum one that I already had. I'll find some other use for it, I'm sure.

tubelab.com said:I am planning a wood surround with a clear Lexan top plate. The tube sockets will be up on stilts so the PC board can sit on the lower deck.

I wanted to raise the 5842s so I could drop the board a bit more and recess the other tubes. Those little triodes are so short. I didn't do it because I was concerned about increasing the distance between the tube and the grid stopper. I did spring for carbon comp for those two, but I would think adding another 1/2 inch wouldn't be good for oscillation. My only thought was to put the grid stopper "into" the leg of the socket between the base and the PCB.

Russ

- Status

- Not open for further replies.

- Home

- More Vendors...

- Tubelab

- Tubelab Simple SE with big honkin' Edcors?