Hi,

I am using this tv toob for slow start-up after SS rectification. I see on the RCA data sheet that the max. DC Plate Current is 210 ma but the Sylvania data sheet lists it at 190 ma.

Just curious, has anyone ever attempted to measure these values? Can any sort of tester out there do this?

My thinking by using this tube in my PS I am also building in a current limiter which could prevent accidental over-biasing... not that I would rely on it entirely, but just for additional safety it is nice.

In any case the sound is very natural - still the solid bass response I experience with SS rectification - and the start-up is nice and slow....

I am using this tv toob for slow start-up after SS rectification. I see on the RCA data sheet that the max. DC Plate Current is 210 ma but the Sylvania data sheet lists it at 190 ma.

Just curious, has anyone ever attempted to measure these values? Can any sort of tester out there do this?

My thinking by using this tube in my PS I am also building in a current limiter which could prevent accidental over-biasing... not that I would rely on it entirely, but just for additional safety it is nice.

In any case the sound is very natural - still the solid bass response I experience with SS rectification - and the start-up is nice and slow....

The GE data sheet show max. continuous DC as 190 mA., design center. Design center ratings are EXTREMELEY conservative and the 210 mA. rating is the 10% more that is associated with a design maximum rating. The 210 mA. number is quite safe to rely on. AAMOF, an occasional pulse to a greater current is OK.

6AU4GTA (I presume)

The maximum average current rating of a tube rectifier can't really be measured per se, since you can often go well above it without immediate damage. It is really a rating for maximum long-term reliability. What is more important here is the peak current rating. If you are using large filter caps right after the rectifiers, you may easily exceed the peak ratings, especially during initial turn-on. The symptom is arcing inside the tube. The series tube rectifier works best with modest capacitance (100uF or less) or choke input filters.

- John Atwood

The maximum average current rating of a tube rectifier can't really be measured per se, since you can often go well above it without immediate damage. It is really a rating for maximum long-term reliability. What is more important here is the peak current rating. If you are using large filter caps right after the rectifiers, you may easily exceed the peak ratings, especially during initial turn-on. The symptom is arcing inside the tube. The series tube rectifier works best with modest capacitance (100uF or less) or choke input filters.

- John Atwood

Thanks John and Eli.

I am using this sort of set-up:

SS bridge -> 6AU4-GTA -> C1 -> Fuse -> L -> C2

The rca spec sheet lists peak plate current at max. 1300 ma and the caps are actually 200uf. The choke is 8h. I have considered using a smaller C1 value though.

I have observed no arcing in the 6AU4-GTA and it has been over a month. Just to be sure though, I built in a T500ma fuse (it hasn't blown either). The amp is grid biased the amp to (about) 185 ma.

I am using this sort of set-up:

SS bridge -> 6AU4-GTA -> C1 -> Fuse -> L -> C2

The rca spec sheet lists peak plate current at max. 1300 ma and the caps are actually 200uf. The choke is 8h. I have considered using a smaller C1 value though.

I have observed no arcing in the 6AU4-GTA and it has been over a month. Just to be sure though, I built in a T500ma fuse (it hasn't blown either). The amp is grid biased the amp to (about) 185 ma.

6AU4-GTA

Reducing your C1 capacitance will make life easier for the 6AU4GTA and not affect the amp much (except for slightly lower B+ voltage). C2 is your reservoir capacitor that supplies current surges to the amplifier.

I have been using 19AU4GT rectifiers in my main amps (push-pull 300Bs) for several years without any problems. I am using a choke-input filter, though.

- John

Reducing your C1 capacitance will make life easier for the 6AU4GTA and not affect the amp much (except for slightly lower B+ voltage). C2 is your reservoir capacitor that supplies current surges to the amplifier.

I have been using 19AU4GT rectifiers in my main amps (push-pull 300Bs) for several years without any problems. I am using a choke-input filter, though.

- John

Mr. Atwood's remarks are, of course, correct. However, there is an alternative to holding the value of the 1st filter cap. down, that will protect the damper diode. Use the arrangement that follows.

SS bridge -> C1 -> 6AU4-GTA -> L -> C2

A large cap. can now be used safely as C1, which suppresses the ripple fundamental and keeps the rail voltage up. A downside of such a large 1st cap. is a tiny conduction angle and concommitant trafo heating. TANSTAAFL. IMO, the use of CL150 inrush current limiting thermistor between the bridge and C1 is a good idea, when that 1st cap. is huge. Clanging power trafos are not amusing. Also, inserting a "hash" filter consisting of a RF choke and mica or NPO ceramic cap. makes sense, to keep high order ripple overtones from leaking through the interwinding capacitance of the main filter inductance. Per Fourier's theorem, smaller conduction angles imply more high order ripple overtone energy.

SS bridge -> C1 -> 6AU4-GTA -> L -> C2

A large cap. can now be used safely as C1, which suppresses the ripple fundamental and keeps the rail voltage up. A downside of such a large 1st cap. is a tiny conduction angle and concommitant trafo heating. TANSTAAFL. IMO, the use of CL150 inrush current limiting thermistor between the bridge and C1 is a good idea, when that 1st cap. is huge. Clanging power trafos are not amusing. Also, inserting a "hash" filter consisting of a RF choke and mica or NPO ceramic cap. makes sense, to keep high order ripple overtones from leaking through the interwinding capacitance of the main filter inductance. Per Fourier's theorem, smaller conduction angles imply more high order ripple overtone energy.

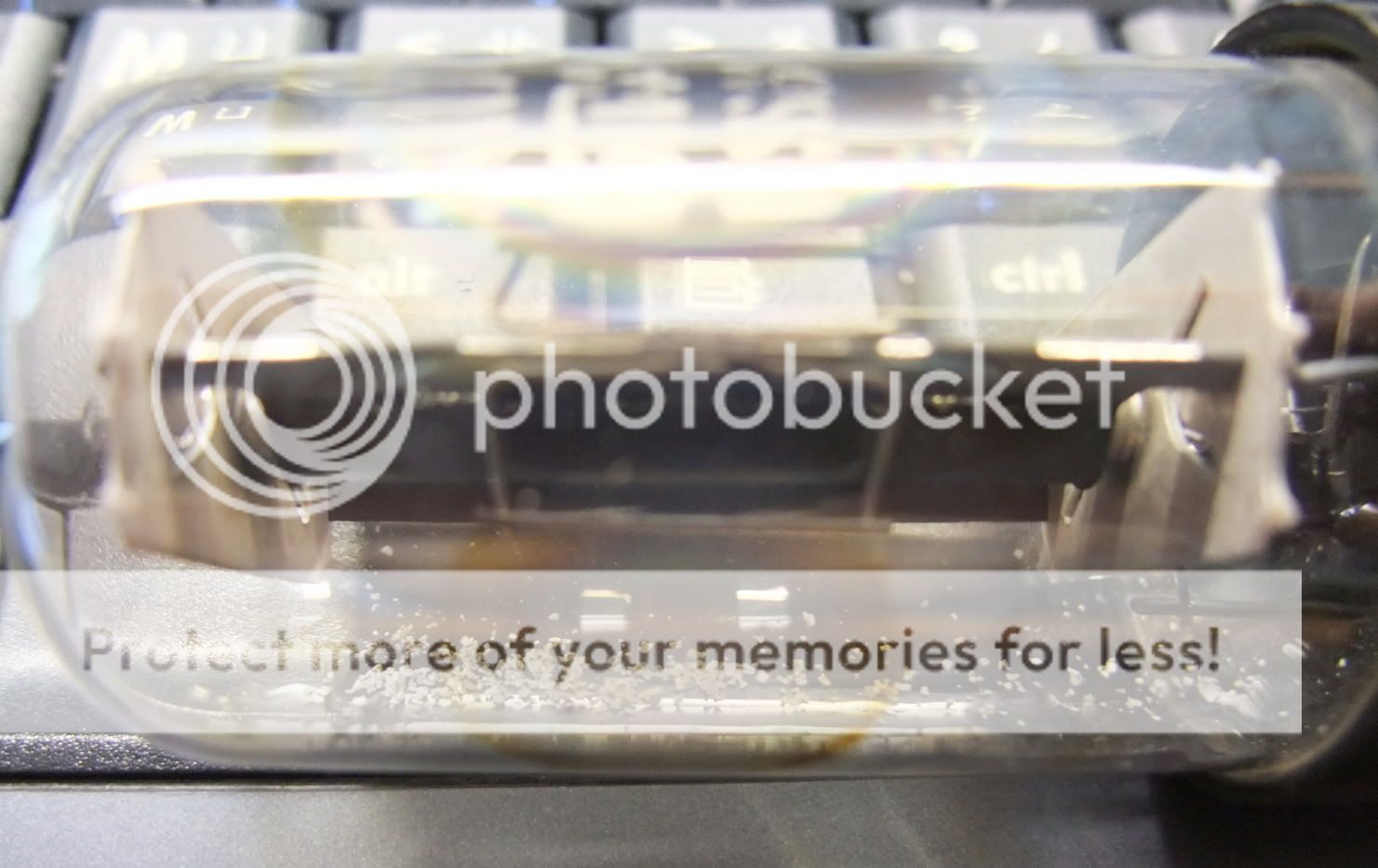

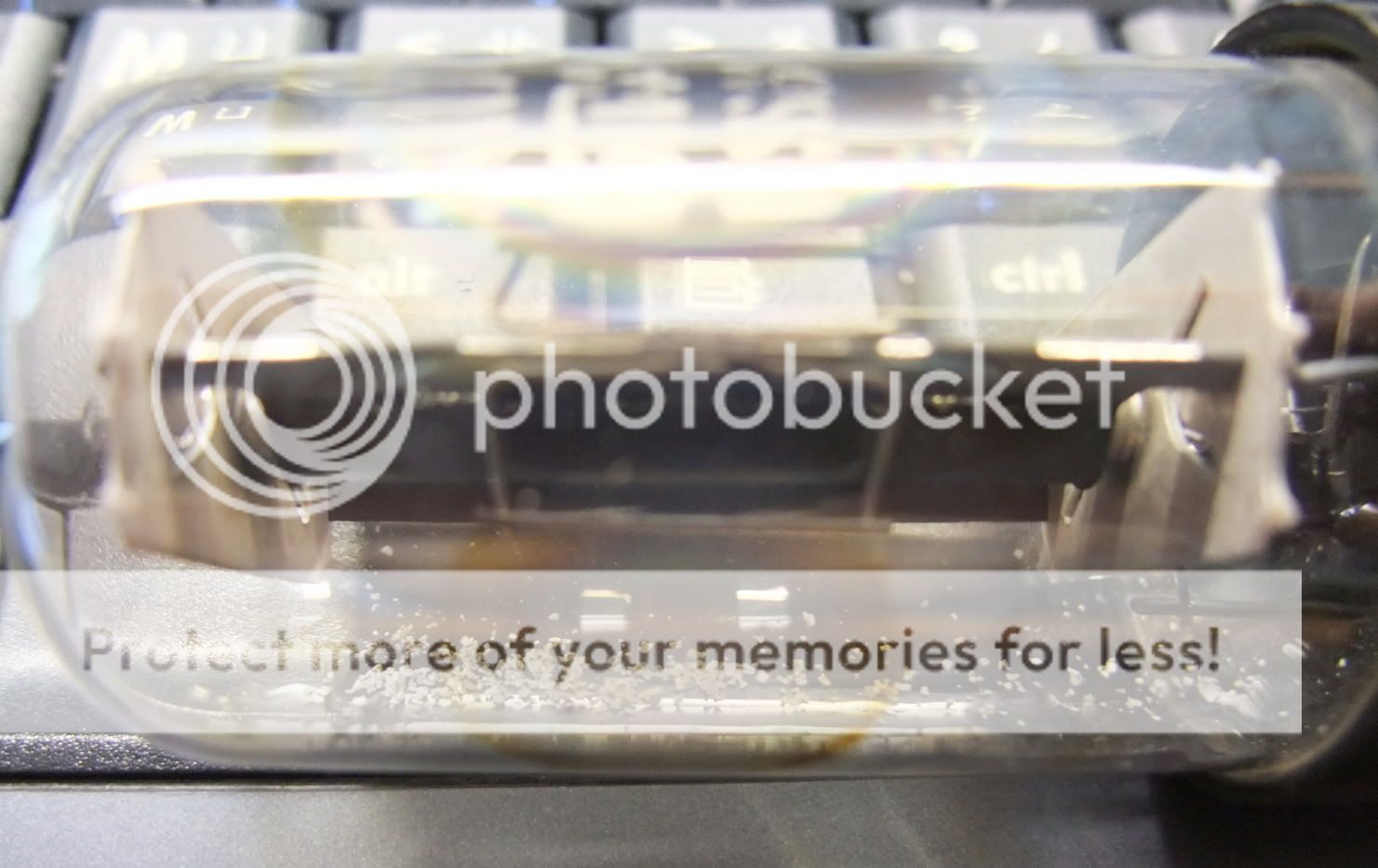

Brownish stain and white powder ?

I bought 2 6AU4 the other day, one of them comes with 2 circular brownish stains on the inner wall of glass, around the getter splashes. And some white powder in the tube, looks like cracked insulation material.

And this very tube starts up much quicker than the other - both lit-up and the raise of HV. Almost twice as quick. Is this OK? Would there be any foreseeable bad? Shorter life span or... ? Should I return it?

I see no other unusual things, though, and it seems working fine in my amp.

I bought 2 6AU4 the other day, one of them comes with 2 circular brownish stains on the inner wall of glass, around the getter splashes. And some white powder in the tube, looks like cracked insulation material.

And this very tube starts up much quicker than the other - both lit-up and the raise of HV. Almost twice as quick. Is this OK? Would there be any foreseeable bad? Shorter life span or... ? Should I return it?

I see no other unusual things, though, and it seems working fine in my amp.

Heavily-used 6AU4

This tube (the one in the photos) has seen a hard life. The brown circles seem to be the edge of where the original getter flash was. Note that there is no getter flash left at all on the left. The white particles are probably bits of the heater-cathode insulation that have broken off either due to mechanical shock or lots of on-off cycles. It may still work, but the lifetime will likely be short.

If you bought this as a used but tested good tube, you might be able to get a return, based on the very poor condition of the getter. This is actually about the worst looking damper tube I've seen (and I've seen a lot!), so you should be able to get a used one in better shape.

- John

This tube (the one in the photos) has seen a hard life. The brown circles seem to be the edge of where the original getter flash was. Note that there is no getter flash left at all on the left. The white particles are probably bits of the heater-cathode insulation that have broken off either due to mechanical shock or lots of on-off cycles. It may still work, but the lifetime will likely be short.

If you bought this as a used but tested good tube, you might be able to get a return, based on the very poor condition of the getter. This is actually about the worst looking damper tube I've seen (and I've seen a lot!), so you should be able to get a used one in better shape.

- John

Strange getters

The tube on the right doesn't look quite right, although it may be perfectly OK. Normally the getter flash should be continuous, without a "shadow". On some tubes, especially some American miniature tubes with circular getters, the getter flash has a hole in the middle, but this is OK, since the getter is close to the glass.

When a tube has been run hard, two things can happen to the getter: gasses are liberated from the metal and glass parts and the getter reacts chemically to "clean-up" the vacuum. This results in a lighter-colored getter. In the worst case when air gets into the tube, the getter will turn completely white. The other thing that can happen is that if the glass bulb gets too hot, the getter will start to evaporate and deposit getter materials (typically barium and strontium) throughout the tube. This isn't good, since electrical leakage can result. The result of evaporation is that the getter flash starts to disappear, especially around the edge where the flash is the thinnest.

Sometimes you will see black areas in the getter flash. This is caused by gasses reacting with the getter as it is actually flashed. This is just the getter doing its job. As the flashing continues, the vacuum is cleaned-up and the flash reverts to the metallic-looking color on the inside of the tube. So don't get worried about black zones in the flash. For some reason, certain brands seem to have this more than others. British Mullard tubes and some Russian tubes show this a lot, but they are perfectly fine.

- John

The tube on the right doesn't look quite right, although it may be perfectly OK. Normally the getter flash should be continuous, without a "shadow". On some tubes, especially some American miniature tubes with circular getters, the getter flash has a hole in the middle, but this is OK, since the getter is close to the glass.

When a tube has been run hard, two things can happen to the getter: gasses are liberated from the metal and glass parts and the getter reacts chemically to "clean-up" the vacuum. This results in a lighter-colored getter. In the worst case when air gets into the tube, the getter will turn completely white. The other thing that can happen is that if the glass bulb gets too hot, the getter will start to evaporate and deposit getter materials (typically barium and strontium) throughout the tube. This isn't good, since electrical leakage can result. The result of evaporation is that the getter flash starts to disappear, especially around the edge where the flash is the thinnest.

Sometimes you will see black areas in the getter flash. This is caused by gasses reacting with the getter as it is actually flashed. This is just the getter doing its job. As the flashing continues, the vacuum is cleaned-up and the flash reverts to the metallic-looking color on the inside of the tube. So don't get worried about black zones in the flash. For some reason, certain brands seem to have this more than others. British Mullard tubes and some Russian tubes show this a lot, but they are perfectly fine.

- John

Hi John,

Thanks a lot for sharing the tube knowledge. Playing with tubes for all these years, I know very few about them

Getters aside, I've seen other types of brownish "stains" - near the supporting sheet mica. Some on the top and 'reflect' the 'windows' shape' of the sheet mica. Some on the side around the mica... What are they? Marks of bombardment by those 'lost' electrons?

CLS

Thanks a lot for sharing the tube knowledge. Playing with tubes for all these years, I know very few about them

Getters aside, I've seen other types of brownish "stains" - near the supporting sheet mica. Some on the top and 'reflect' the 'windows' shape' of the sheet mica. Some on the side around the mica... What are they? Marks of bombardment by those 'lost' electrons?

CLS

pics

One is 300B with mesh plate. Brownish stain on the 'head' and 'shoulder' of the glass.

The other is GZ37, with 2 square holes in the top mica support and seem aligned with the cathodes? These 2 stains are not so brownish, grey-silver instead.

One is 300B with mesh plate. Brownish stain on the 'head' and 'shoulder' of the glass.

The other is GZ37, with 2 square holes in the top mica support and seem aligned with the cathodes? These 2 stains are not so brownish, grey-silver instead.

Attachments

tube stains

We have talked about the degradation of the getter flash. Now I will go over some of the other stains you see inside the glass bulbs of tubes.

When electrons hit glass, after a while they start to turn the glass brown. This seems to depend on the kind of glass, which explains why you see this on some tubes and not others. This is often seen near the top and bottom micas, since there is often a gap where electrons can stream out past the plate. In the dark, the places where the electrons hit often glow blue - both on the mica and glass, but again, this depends on the type of glass. This doesn't harm the tube but it is an indicator of the length of use of the tube. I've mainly seen this on Chinese and some Russian tubes, but it is also common on British Mullard tubes.

When a tube is made, an important step is "activating" the cathode. This is done by raising the temperature of the cathode much above normal and at the same time drawing current from the cathode. This is done while the tube is still on the vacuum pump (before it is sealed) so that any gasses generated are removed. As part of the activation, some of the cathode material is evaporated and can get deposited on other parts of the tube and on the glass. Particularly in some European mesh-shielded tubes, this causes a metallic film on the glass around the middle of the tube. This is normal and not harmful. For some reason, probably differences in processing or materials, I've rarely seen this on American or Russian tubes.

As a tube is used, both the cathode coating and the insulation around the heater slowly evaporates and start to get deposited on the mica and glass. On the mica, this shows up as darkening around the cathode (you can see this on the picture of the sick 6AU4GTA) and as a darkening on the glass that eventually becomes a dark metallic look. This most often is seen at the top of the tube, just around the cathode, and on on the base of miniature tubes. This coating, as well as the getter flash, is slightly conductive so can cause leakage. I think that this is why some audio tubes become noisy as they age. Steps taken to avoid this leakage include: putting slots in the mica to increase the leakage path, putting an extra mica between the getter and the rest of the tube (the so-called "triple mica" construction), and putting a white alumina coating around the leads through the glass, which reduces leakage. On a well-designed tube, this kind of darkening is not very problematic, but it is an indicator of usage. By, the way, running the heater over its rated voltage greatly accelerates this evaporation, which is another reason why you should check your heater voltage and lower it if it is too high.

- John

We have talked about the degradation of the getter flash. Now I will go over some of the other stains you see inside the glass bulbs of tubes.

When electrons hit glass, after a while they start to turn the glass brown. This seems to depend on the kind of glass, which explains why you see this on some tubes and not others. This is often seen near the top and bottom micas, since there is often a gap where electrons can stream out past the plate. In the dark, the places where the electrons hit often glow blue - both on the mica and glass, but again, this depends on the type of glass. This doesn't harm the tube but it is an indicator of the length of use of the tube. I've mainly seen this on Chinese and some Russian tubes, but it is also common on British Mullard tubes.

When a tube is made, an important step is "activating" the cathode. This is done by raising the temperature of the cathode much above normal and at the same time drawing current from the cathode. This is done while the tube is still on the vacuum pump (before it is sealed) so that any gasses generated are removed. As part of the activation, some of the cathode material is evaporated and can get deposited on other parts of the tube and on the glass. Particularly in some European mesh-shielded tubes, this causes a metallic film on the glass around the middle of the tube. This is normal and not harmful. For some reason, probably differences in processing or materials, I've rarely seen this on American or Russian tubes.

As a tube is used, both the cathode coating and the insulation around the heater slowly evaporates and start to get deposited on the mica and glass. On the mica, this shows up as darkening around the cathode (you can see this on the picture of the sick 6AU4GTA) and as a darkening on the glass that eventually becomes a dark metallic look. This most often is seen at the top of the tube, just around the cathode, and on on the base of miniature tubes. This coating, as well as the getter flash, is slightly conductive so can cause leakage. I think that this is why some audio tubes become noisy as they age. Steps taken to avoid this leakage include: putting slots in the mica to increase the leakage path, putting an extra mica between the getter and the rest of the tube (the so-called "triple mica" construction), and putting a white alumina coating around the leads through the glass, which reduces leakage. On a well-designed tube, this kind of darkening is not very problematic, but it is an indicator of usage. By, the way, running the heater over its rated voltage greatly accelerates this evaporation, which is another reason why you should check your heater voltage and lower it if it is too high.

- John

...

As a tube is used, both the cathode coating and the insulation around the heater slowly evaporates and start to get deposited on the mica and glass. On the mica, this shows up as darkening around the cathode (you can see this on the picture of the sick 6AU4GTA) and as a darkening on the glass that eventually becomes a dark metallic look. This most often is seen at the top of the tube, just around the cathode, and on on the base of miniature tubes.

...

Yes indeed. I saw another example of this on my other 6AU4. On the top of the bottle (just on top of the cathode), there is a dark metallic spot gradually forming which was not there several days ago!!

I'm wondering how so. The heater is supplied by 5.9Vac windning of the transformer, quite a bit lower than the rated 6.3V. And current draw is 140mA, also lower than the rated 190mA.

Hmmm.....

tube darkening

This can happen under almost any condition, depending on the tube. Current draw won't affect this much. Another parameter I didn't mention is the voltage difference between the heater, the cathode, and the glass envelope. In some scenarios, more material is thrown against the glass if the electrostatic conditions are right. I wouldn't worry about this, since this is common on damper tubes and the slots in the mica between the cathode and plate help avoid leakage problems.

- John

This can happen under almost any condition, depending on the tube. Current draw won't affect this much. Another parameter I didn't mention is the voltage difference between the heater, the cathode, and the glass envelope. In some scenarios, more material is thrown against the glass if the electrostatic conditions are right. I wouldn't worry about this, since this is common on damper tubes and the slots in the mica between the cathode and plate help avoid leakage problems.

- John

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- 6UA4-GTA Question