I promised some time ago to post a final finished picture and also a shot of the undercarriage. I am a bit nervous showing the underside of my amp, kind of like dropping my pants on stage.

But I can take positive criticism. This is my version of Michael's KT-88 single ended circuit. I got a lot of help from people on this forum, and I thank them from my heart.

And now on to the next project........

But I can take positive criticism. This is my version of Michael's KT-88 single ended circuit. I got a lot of help from people on this forum, and I thank them from my heart.

And now on to the next project........

Attachments

Thanks for the responses, my head is sufficiently swollen.

It sounds great. It only puts out a few watts, but I have two-way bookshelves that it pushes very nicely. Plenty of power for a bedroom, office, etc. I now understand the leanings toward single-ended sound.

The base is bubinga, 45 degree miters on the ends, with about a 15 degree compound angle to get the sloped sides. That took a bit of tweaking, and I set up a jig on my disk sander to get it just right. After a few dry runs on pine, I finally did it in the expensive bubinga.

I have tried a lot of fancy finishes. But in the end I really like Deft's spray on polyurethane. You have to have a clean place to spray, you can't rub out any imperfections. But it goes on nice and you are done.

It doesn't show on the pic, but there is a perforated aluminum sheet inset into the bottom to keep fingers away from 400 volts DC.

It sounds great. It only puts out a few watts, but I have two-way bookshelves that it pushes very nicely. Plenty of power for a bedroom, office, etc. I now understand the leanings toward single-ended sound.

The base is bubinga, 45 degree miters on the ends, with about a 15 degree compound angle to get the sloped sides. That took a bit of tweaking, and I set up a jig on my disk sander to get it just right. After a few dry runs on pine, I finally did it in the expensive bubinga.

I have tried a lot of fancy finishes. But in the end I really like Deft's spray on polyurethane. You have to have a clean place to spray, you can't rub out any imperfections. But it goes on nice and you are done.

It doesn't show on the pic, but there is a perforated aluminum sheet inset into the bottom to keep fingers away from 400 volts DC.

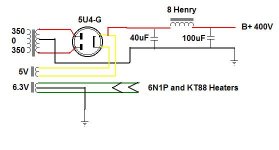

cryo said:................ This is my version of Michael's KT-88 single ended circuit. .............

Beautiful.................

pardon my ignorance, but please supply a diagram or link.

Thanks

Andy

Nice job.

How did you get such nice neat holes for the caps, especially the oval cross section one? I see you appear to have used some little clips to hold them in (requiring precision holes so the lip holds them in?). Did you make these yourself? looks like a better solution than can clamps.

Chris

How did you get such nice neat holes for the caps, especially the oval cross section one? I see you appear to have used some little clips to hold them in (requiring precision holes so the lip holds them in?). Did you make these yourself? looks like a better solution than can clamps.

Chris

I will try and answer a few questions. Rodmunch asked how much this cost to build. Probably about $500 is my guess. The biggest expense being the James transformers and power supply. Lots of little stuff.

Chrish asked about the capacitor holes. The round ones were made with hole saws, drill very slow with a drill press and use lubricant. Now I must say that my technique worked, but I could not get the exact size hole I wanted. So I have a small mill that I used to clean up a smaller diameter hole and enlarge it to the exact size I wanted. I know a milling machine is a big expense, but a used bench top model is not much compared to what we drop in parts for these guys.

The oval hole was made with two holes that were then connected, I at first filed them. But I ended up now cleaning up the holes with the mill, and then connecting them on the milling machine. Hole saws can work very nicely, you just have to be very patient, and they would be tough to control without a drill press. I just had the small milling machine, and with 1/4" aluminum plate it machines like butter.

The hold downs for the caps are actually small cable clamps. I flattened them just a bit. After the caps were fitted into the holes, I placed the clamps where I wanted them. Holes were marked, then drilled on the drill press, and things work great.

I used countersunk flat-head bolts with a hex drive throughout. They just look nice and work great. I was going to use chrome, but they are really expensive. I found stainless was a lot cheaper, and a quick polish with a rag wheel and some polishing compound makes them look just like chrome.

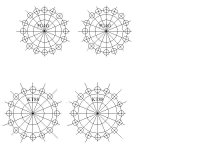

Last thing was for the output tube vent holes. I tried to lay them out by hand and it was next to impossible. So I used a simple CAD program and laid them out precisely. Then I printed off the template, used a spray adhesive to attatch it to the plate in the exact position. Then I just drilled through the template and all of my holes were dead on.

Chrish asked about the capacitor holes. The round ones were made with hole saws, drill very slow with a drill press and use lubricant. Now I must say that my technique worked, but I could not get the exact size hole I wanted. So I have a small mill that I used to clean up a smaller diameter hole and enlarge it to the exact size I wanted. I know a milling machine is a big expense, but a used bench top model is not much compared to what we drop in parts for these guys.

The oval hole was made with two holes that were then connected, I at first filed them. But I ended up now cleaning up the holes with the mill, and then connecting them on the milling machine. Hole saws can work very nicely, you just have to be very patient, and they would be tough to control without a drill press. I just had the small milling machine, and with 1/4" aluminum plate it machines like butter.

The hold downs for the caps are actually small cable clamps. I flattened them just a bit. After the caps were fitted into the holes, I placed the clamps where I wanted them. Holes were marked, then drilled on the drill press, and things work great.

I used countersunk flat-head bolts with a hex drive throughout. They just look nice and work great. I was going to use chrome, but they are really expensive. I found stainless was a lot cheaper, and a quick polish with a rag wheel and some polishing compound makes them look just like chrome.

Last thing was for the output tube vent holes. I tried to lay them out by hand and it was next to impossible. So I used a simple CAD program and laid them out precisely. Then I printed off the template, used a spray adhesive to attatch it to the plate in the exact position. Then I just drilled through the template and all of my holes were dead on.

Attachments

cryo said:John:

I'm sorry, I don't know what mistake you are referring to. Did Alex have something amiss in his own KT-88 build? I would be happy to help if possible, but am a bit confused as to the problem.

Someone mentioned this on one of the KT88 threads. It's not this one, but another. I can't remember who made it, but I think I heard it somewhere else. Maybe Porkchop, but I'm not certain. I'll try to go through and find it, ok?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Another KT-88