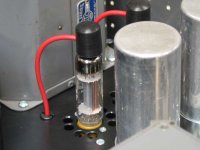

Anyone got a line on tube caps that actually fit? I'm tired of the ceramic caps that "fit" 1/4 skirted pins (like on the 6KG6 and countless others). Electrically they fit just fine but they end up looking like they're floating above the tube. I've given up on caps like the one here (kinda small pic..):

http://www.geocities.com/bobdanielak/technoteNo33.html

..just impossible to find.

Searched around a lot on the net to no avail. What would be really nice is something that doesn't consume so much real estate on the top of the tube - attaching typically supplied caps to tubes with twin 1/4" pins can be a frustrating exercise. What would be cool is something like these "butt splice connectors"..

http://airic.manufacturer.globalsou...e-gland/1003946441/Butt-Splice-Connectors.htm

Problem with most of these is they aren't large enough to handle a 1/4" pin. I'm not talking a skinny 829B pin here - lots of examples of those on this forum. It's the bigger pins that are the pain. Any ideas/sources?

http://www.geocities.com/bobdanielak/technoteNo33.html

..just impossible to find.

Searched around a lot on the net to no avail. What would be really nice is something that doesn't consume so much real estate on the top of the tube - attaching typically supplied caps to tubes with twin 1/4" pins can be a frustrating exercise. What would be cool is something like these "butt splice connectors"..

http://airic.manufacturer.globalsou...e-gland/1003946441/Butt-Splice-Connectors.htm

Problem with most of these is they aren't large enough to handle a 1/4" pin. I'm not talking a skinny 829B pin here - lots of examples of those on this forum. It's the bigger pins that are the pain. Any ideas/sources?

I thought about making my own 1/4" plate caps because they seem to be the most expensive for some reason. AES wants almost 7 bucks each for one! Too bad I don't own a lathe or I would consider making a small run and selling them. The tricky part is coming up with a simple type of spring or contact to keep pressure on the cap

I recently bought and used these -

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&rd=1&item=120189983581

very very tight phospor contacts... so tight that it ripped the cap off of an EL38... so make sure to loosen them up a little bit. You will have to solder your leads right on to the contact, run the wire through the side hole and screw them the contact into the plastic holder...

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&rd=1&item=120189983581

very very tight phospor contacts... so tight that it ripped the cap off of an EL38... so make sure to loosen them up a little bit. You will have to solder your leads right on to the contact, run the wire through the side hole and screw them the contact into the plastic holder...

I am in the same boat. I am looking for .25" anode caps for 7193s. I finally stumbled across these:

http://thetubestore.com/anodecap.html

they say they work...I have been looking for a while, found some out of china but dont want to pay $20 for 8 of these.

Has anyone used them?

http://thetubestore.com/anodecap.html

they say they work...I have been looking for a while, found some out of china but dont want to pay $20 for 8 of these.

Has anyone used them?

check out this site:

www.thetubecenter.com

Jack (?) made me a deal of 7 small anode caps for $10.00. I asked for a price on 10 of these, I should have a message later today. Pretty much the best price I've found.

www.thetubecenter.com

Jack (?) made me a deal of 7 small anode caps for $10.00. I asked for a price on 10 of these, I should have a message later today. Pretty much the best price I've found.

I think these are the british ones kstagger mentions. The contact is stamped out of phosphor bronze and needs some tweaking after assembly, usually to reduce the contact pressure. They don't come with instructions and require a little trial and error to solder the lead in the right place. I found an inside corner where the contact is bent into a U shape the best place.

They're great for DIY but I'm looking for something more engineered and consistent for future projects. I do like the caps though.

Another thing that works is one end of a 1/4 inch fuse holder. These usually have good contacts. I like the chassis mount kind with the gray twist-in plug that makes the removable contact. The gray end can be cut down, the wire soldered to it, and shrink tubed. It's not really pretty but not a clown nose either ;-)

Michael

PS a lot of old TVs and such used a simple piece of spring wire with 2-3 loops a bit smaller in ID than the cap. The free ends stuck out at 90 degree angles so you could pinch them between your fingers and expand the spring thus allowing it to slip over the cap. The free ends had little loops on the ends you could solder to. Not fancy but it works.

They're great for DIY but I'm looking for something more engineered and consistent for future projects. I do like the caps though.

Another thing that works is one end of a 1/4 inch fuse holder. These usually have good contacts. I like the chassis mount kind with the gray twist-in plug that makes the removable contact. The gray end can be cut down, the wire soldered to it, and shrink tubed. It's not really pretty but not a clown nose either ;-)

Michael

PS a lot of old TVs and such used a simple piece of spring wire with 2-3 loops a bit smaller in ID than the cap. The free ends stuck out at 90 degree angles so you could pinch them between your fingers and expand the spring thus allowing it to slip over the cap. The free ends had little loops on the ends you could solder to. Not fancy but it works.

Attachments

I have some of the old wire loop plate cap connectors from an ebay purchae a few years ago. They appear to be made of nickel plated steel. My only concern with them would be safety. When I was much, much younger, I remember seeing phenolic push-on plate caps for sweep tubes like the 6BQ6. I haven't seen any lately, though, even as NOS stock.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- tube caps that fit.. anyone?