Too much to absorb in any reasonable time.

Reading his documents, he tests each electrode assembly (or partially completed tube) in a soft or partial vacuum and at low filament current *in inverted triode mode* to verify the geometry and alignment before going to the trouble of pulling high vacuum and sealing off.

The T-tube with 2 discs that glow purple is his final manometer. He applies up to 4KV and observes the purple glow to determine when the air is removed. I forget the name of it.

Incredible!

Reading his documents, he tests each electrode assembly (or partially completed tube) in a soft or partial vacuum and at low filament current *in inverted triode mode* to verify the geometry and alignment before going to the trouble of pulling high vacuum and sealing off.

The T-tube with 2 discs that glow purple is his final manometer. He applies up to 4KV and observes the purple glow to determine when the air is removed. I forget the name of it.

Incredible!

abzug said:I wonder if it's possible by spending attention to get better results than in mass produced tubes. Because I would definitely pay for custom tubes

Most of the NOS tubes and new produced ones are indirect heated tubes, on the vids they make direct heated ones. Direct heated triodes can sound very natural but i have no experience with them.

They have to produce a lot of the same tubes and test/select them for I/U caracteristics.

Since tube behavior depends on geometry and not magic, it could be determined by simulation before anything is built. You cannot possibly argue that tubes are harder to simulate than jumbo jets, yet the latter are designed in simulators and their behavior is well known before any wind testing with models is ever done.

abzug said:Since tube behavior depends on geometry and not magic, it could be determined by simulation before anything is built. You cannot possibly argue that tubes are harder to simulate than jumbo jets, yet the latter are designed in simulators and their behavior is well known before any wind testing with models is ever done.

You miss the point, which is that any manual process is very susceptible to wide and varying tolerances. As such, completed assemblies would need to be checked to ensure that correct tolerances have been maintained throughout the manufacturing process.

: )

Unfortunately, plane behavior is NOT well known before a physical model is built. The industry has a good guess as to what will happen, but the science is simply not there to account for all the dynamics involved with flight. In other words, the plane could still explode. This is straight from a jet engine engineer (for lack of a better term) who visited my school a couple years ago. Worked for Airbus, I think.abzug said:jumbo jets . . . are designed in simulators and their behavior is well known before any wind testing with models is ever done.

Fascinating!

Look here to learn more about this remarkable fellow: F2FO

or for a translation in 'Franglish': Google Translate

Look here to learn more about this remarkable fellow: F2FO

or for a translation in 'Franglish': Google Translate

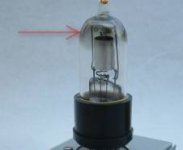

Getter

Instead, tungsten from the filament is used for this purpose. See pic.I didn't see any getter, but he did heat up the anode to drive off gases.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Too awesome for words