I was wondering if anyone has used a 100v transformer backwards as a driver stage for a 811.

This is an idea I have been tossing around. there are many cheap Lm7886? Kits around and running one at low levels should not produce to much distortion.

There could be problems with grid current in the 100V transformer and finding the right transformer ratio any sugestions would be appreciated, if this idea sounds crazy I will go back to plan A, all valve design.

Thanks

This is an idea I have been tossing around. there are many cheap Lm7886? Kits around and running one at low levels should not produce to much distortion.

There could be problems with grid current in the 100V transformer and finding the right transformer ratio any sugestions would be appreciated, if this idea sounds crazy I will go back to plan A, all valve design.

Thanks

Not tried Tx drive to an 811A, but have done it with a MOSFET....

Works pretty well....You'll need around 20 odd volts positive on the grid to get around 60mA through the 811A with a +B of 450V.......

The 811A does need quite some hefty drive....I guess if you choose Transformer, it would have to be chosen carefully, as it would 'see' the bias current as well as the drive...

Works pretty well....You'll need around 20 odd volts positive on the grid to get around 60mA through the 811A with a +B of 450V.......

The 811A does need quite some hefty drive....I guess if you choose Transformer, it would have to be chosen carefully, as it would 'see' the bias current as well as the drive...

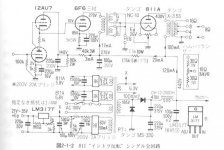

Looks like I will stick with an all tube amplifier and avoid transformer coupling the 811. I have found a couple of circuits that use a 6V6 or a 6L6 wired in triode mode as a current source? ( i think this is what you call it) to drive the 811a.

The 6V6 appeals to me as a driver but will it be too stressed providing the 30-60ma of grid current?

The 6V6 appeals to me as a driver but will it be too stressed providing the 30-60ma of grid current?

To me it seems like the bias voltage is more important than the grid current. Surely 30ma would be enough to overcome any miller effect.

I built an 811 amp like the one you describe with direct coupled 6V6 driver stage. My mistake was misreading the datasheet and running the tubes at 65 watt Pd. Thats 45 watts continuous or 65 intermittent. Oh well they were chinese 811s anyhow so no big loss. One issue I had was extremely loud hum even with a balance pot. The only solution was a very clean DC supply. Worrying about two linear regulators with 4 amps on each was a pain so I modified two 5v switching supplies to output 6.3v. On another thread someone said they had no hum issues so maybe its related to tube manufacture.

I built an 811 amp like the one you describe with direct coupled 6V6 driver stage. My mistake was misreading the datasheet and running the tubes at 65 watt Pd. Thats 45 watts continuous or 65 intermittent. Oh well they were chinese 811s anyhow so no big loss. One issue I had was extremely loud hum even with a balance pot. The only solution was a very clean DC supply. Worrying about two linear regulators with 4 amps on each was a pain so I modified two 5v switching supplies to output 6.3v. On another thread someone said they had no hum issues so maybe its related to tube manufacture.

Cool,

I have dug up every schematic i could find for A2 on the Diy forums and yes it looks like i will go with a 6V6 as a driver.

By running the tubes at 45w do you mean grid dissipation or plate dissipation.

How do I keep this down lower the plate voltage or the grid current.

How much power did your amp put out?

I am aiming to achieve approx 10w or more.

Thanks.

I have dug up every schematic i could find for A2 on the Diy forums and yes it looks like i will go with a 6V6 as a driver.

By running the tubes at 45w do you mean grid dissipation or plate dissipation.

How do I keep this down lower the plate voltage or the grid current.

How much power did your amp put out?

I am aiming to achieve approx 10w or more.

Thanks.

It seems too obvious to even bother saying, but with deep A2 grid current is the major obstacle, and I don't think there's any way to run a 811A other than deep A2. The grid sucks a lot of current, but more importantly, the current depends on grid voltage; it goes way up at positive peaks exponentially. Grid current is not proportional to grid voltage.

One way to think of it is that the grid presents a load to the driver that varies over the signal cycle. At negative peaks it might present a relatively high impedance - effectively just Miller C - while at positive peaks the impedance might drop to as low as a 100 ohms or less depending on operating conditions and how positive you drive the grid.

So this varying load is THE problem to be dealt with. Miller capacitance is insignificant by comparison. Obviously, you want a driver with very low output impedance to deal with the *varying* load that it sees.

Direct coupling or transformer coupling are the only options. In the case of transformer coupling you need to allow for the grid current which has a large DC component. Ungapped transformers might saturate. I wouldn't even think about a toroidal power transformer in this application even if they do work well when there is no grid current.

One way to think of it is that the grid presents a load to the driver that varies over the signal cycle. At negative peaks it might present a relatively high impedance - effectively just Miller C - while at positive peaks the impedance might drop to as low as a 100 ohms or less depending on operating conditions and how positive you drive the grid.

So this varying load is THE problem to be dealt with. Miller capacitance is insignificant by comparison. Obviously, you want a driver with very low output impedance to deal with the *varying* load that it sees.

Direct coupling or transformer coupling are the only options. In the case of transformer coupling you need to allow for the grid current which has a large DC component. Ungapped transformers might saturate. I wouldn't even think about a toroidal power transformer in this application even if they do work well when there is no grid current.

OK every ones advice has confirmed what ideas I have been toying around with so I will go with the simple direct coupled circuits.

interstage transformers appear to be more of a hassle and a huge cost.

As this is the largest SE amp I have ever planed to build ill keep it simple and realitively cheap.

I think my last questions would be; who has had any major problems with a 811a in se class a2?

I believe it would be safer and more economical than pure class A.

What do you think?

Cheers

interstage transformers appear to be more of a hassle and a huge cost.

As this is the largest SE amp I have ever planed to build ill keep it simple and realitively cheap.

I think my last questions would be; who has had any major problems with a 811a in se class a2?

I believe it would be safer and more economical than pure class A.

What do you think?

Cheers

You don't seem to have religious objections to ss devices. How bout a mosfet follower to supply current for A2: http://www.tubelab.com/powerdrive.htm

very interesting, and after a few mods the "Tube Labs Solid State Driver" circuit Can Deliver positive bias. But this looks complicated; more voltages and even heatsinks. two tubes and two mosfets= more parts. I wanted to replace the tube front end completely

Which would then mean i have a simple SS imput/ buffer and then a single tube output which should remove two tubes and half of the power supply required.

Which would then mean i have a simple SS imput/ buffer and then a single tube output which should remove two tubes and half of the power supply required.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- 811A se amp using a solid state driver