I got most of the stuff to populate the board from Digikey. I got the power transformer, choke, coupling capacitors, tubes and Hammond chassis from Antique Electronics http://www.tubesandmore.com/ and the output transformers from Edcor http://www.edcorusa.com/products/transformers/xse/xse15-8-5k.html

The chassis I used was a standard Hammond 10"*12"*2" aluminum with the 10"*12" aluminum base plate. Worked well. Used a set of cheap chassis punches from Harbour Freight to punch the holes for the tubes. If you do happen to have a chassis that is only 2" deep, the tall thin 1500uF Panasonic caps will only just fit with an under the chassis build. You would probably be better mounting the caps horizontal rather than vertical.

Others may have some good tube recommendations as well, but I am very happy with the JJ ECC81 (12AT7) and E34Ls.

The chassis I used was a standard Hammond 10"*12"*2" aluminum with the 10"*12" aluminum base plate. Worked well. Used a set of cheap chassis punches from Harbour Freight to punch the holes for the tubes. If you do happen to have a chassis that is only 2" deep, the tall thin 1500uF Panasonic caps will only just fit with an under the chassis build. You would probably be better mounting the caps horizontal rather than vertical.

Others may have some good tube recommendations as well, but I am very happy with the JJ ECC81 (12AT7) and E34Ls.

The Tubedepot sockets will work. The AES part number is P-ST8-193G (gold) or P-ST8-193 (tin). I believe that they all come from the same Chinese source. I have used both of the AES parts, and now get them from another source.I could not find it on AES but found this:

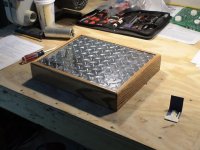

I still don't have a decent photo of it, but here it is:

Looks good to me. Let me know if you want me to add it to the "users amps" page on my web site. I found some stainless steel baking pans at Sams Club, but haven't built anything with them yet. Stainless is harder to deal with than aluminum.

Does anyone know of a 1-stop shopping website for these parts? I still have to order the power trans, output trans, volume pot, etc. (All the stuff not on the PCB.)

If there is, I haven't found it yet. I usually get all of the parts that go on the board from DigiKey or Mouser. There are so many possible choices for all of the other parts that it would be impossible for one firm to stock them all.

I use Allied power transformers in most of my projects. They are Hammonds for less than Hammond prices. My OPT choices are often dictated by what the customer wants (if I am building an amp for someone else), or whatever deal that I can get (for my own amps).

I use Lowes and Home Depot for hardware. I have searched out new and unique chassis, often beginning with an Ebay purchase. The motor run caps are also from Ebay. Again Transcendar OPT's beat the usual cost/performance curve, from Ebay. Search for seller ggaet.

Thanks guys for all the info. I'm getting there. I'm gonna order up the rest of the stuff today. I used Mouser, Digikey, and Tubedepot.

What is a 'Motor run cap?' Is that the large cap used to get rid of the ripple in the power supply?

Hey George, Is that a picture of you with the electric guitar?

What is a 'Motor run cap?' Is that the large cap used to get rid of the ripple in the power supply?

Hey George, Is that a picture of you with the electric guitar?

A motor RUN cap is a capacitor designed for shifting the phase in one winding of an AC motor. They are designed for continuous duty operation at high temperatures and high ripple currents. These characteristics make them useful for filter caps in power supplies. Since they are not associated with high end audio, they are reasonably priced. These are usually rated for AC voltage. They can be used on a higher DC voltage, although there is disagreement as to how much extra voltage they can handle. Conventional wisdom says 1.41 times as much. I use 370 volt AC caps in my tube amps at voltages up to 520 volts without issue. These are usually polypropelyne film caps housed in an aluminum can. See the picture of lousymusicians amp. The motor run cap is the large can behind the power transformer. Look for something in the 50 to 100uF range at least 370 VAC.

Avoid motor START caps. These are made for short term intermittent duty during the start up of an AC motor. They are usually a non polarized electrolytic often in a plastic case.

There is a vendor on Ebay that sells these capacitors. Ebay is not available here at work, so I can't look it up right now. Their name was midori craft and capacitor farm. Or something like that.

Yes that would be me terrorizing my neighbors with a 200 watt SE guitar amp. When I actually could play guitar (a long time ago) our motto was "If you can't be good, be loud".

The board will go out tomorrow or Friday morning.

Avoid motor START caps. These are made for short term intermittent duty during the start up of an AC motor. They are usually a non polarized electrolytic often in a plastic case.

There is a vendor on Ebay that sells these capacitors. Ebay is not available here at work, so I can't look it up right now. Their name was midori craft and capacitor farm. Or something like that.

Yes that would be me terrorizing my neighbors with a 200 watt SE guitar amp. When I actually could play guitar (a long time ago) our motto was "If you can't be good, be loud".

The board will go out tomorrow or Friday morning.

I finally ordered everything I need. Sourced the motor run cap from ebay.

Below is the choke I ordered for the power supply. I'm going with the 5AR4 rectifier. The description of the choke mentioned it was good for power supply filtering on AES. Does this look ok?

P-T159ZC FILTER CHOKE, OPEN BRACKET, HAMMOND, 60 MH, 2 A

Thanks to everyone for helping!

Below is the choke I ordered for the power supply. I'm going with the 5AR4 rectifier. The description of the choke mentioned it was good for power supply filtering on AES. Does this look ok?

P-T159ZC FILTER CHOKE, OPEN BRACKET, HAMMOND, 60 MH, 2 A

Thanks to everyone for helping!

You want a choke that has at least 1 or 2 HENRIES of inductance. More is better in this application. I usually use 6 or 8 Hy. The current rating should be at least 175 mA. For cheap but UGLY I use these:

http://www.alliedelec.com/Search/Pr...4X&DESC=C-14X&R=967-1006&sid=46DF43005757617F

For a nicer looking choke, use the Hammond 193L.

http://www.alliedelec.com/Search/Pr...4X&DESC=C-14X&R=967-1006&sid=46DF43005757617F

For a nicer looking choke, use the Hammond 193L.

George, Chris, or Lousymusician,

I have most of my parts scattered across the US right now and hopefully they will all converge at my residence. (Opposite of "blowing" an amp up so that is a good thing.) While I am waiting I was going to start on building the chassis. I am going to make it out of wood and have a steel or aluminum deck. Can any of you suggest the dimensions that would be best to fit all the components?

Thanks,

Andy

I have most of my parts scattered across the US right now and hopefully they will all converge at my residence. (Opposite of "blowing" an amp up so that is a good thing.) While I am waiting I was going to start on building the chassis. I am going to make it out of wood and have a steel or aluminum deck. Can any of you suggest the dimensions that would be best to fit all the components?

Thanks,

Andy

The usable area inside the chassis of the industrial amp is 8" X 10" X 2". It is extremely cramped, and gets pretty hot inside. The Triad choke wouldn't fit underneath (too tall) so I was forced to usa a smaller choke.

A 10" X 12" top surface should be adequate for most applications, but this really depends on the size of your OPT's. The big Hammond OPT's are huge and weigh 11 pounds each. They would require a larger surface. The small Edcors may work OK on an 8" X 10" chassis. Too big is a lot easier to deal with than too small.

I would suggest planning out the top surface using the actual components, or paper cutouts. If you are good with a computer a drawing program is useful. I use Visio, but I have even mapped out a chassis in Powerpoint for someone at work. You need accurate dimensions of your large parts. Beware that the dimensions for some Hammond transformers on their web site are WRONG! I found this out the hard way when the transformers showed up and didn't fit the chassis.

Aluminum is far eaiser to work with than steel.

Look at the photos of Chris's amp it is very well laid out and uses a Hammond 12" X 10" X 2" chassis. A taller chassis may be needed to hide the choke underneath.

http://www.tubelab.com/UsersAmps.htm

A 10" X 12" top surface should be adequate for most applications, but this really depends on the size of your OPT's. The big Hammond OPT's are huge and weigh 11 pounds each. They would require a larger surface. The small Edcors may work OK on an 8" X 10" chassis. Too big is a lot easier to deal with than too small.

I would suggest planning out the top surface using the actual components, or paper cutouts. If you are good with a computer a drawing program is useful. I use Visio, but I have even mapped out a chassis in Powerpoint for someone at work. You need accurate dimensions of your large parts. Beware that the dimensions for some Hammond transformers on their web site are WRONG! I found this out the hard way when the transformers showed up and didn't fit the chassis.

Aluminum is far eaiser to work with than steel.

Look at the photos of Chris's amp it is very well laid out and uses a Hammond 12" X 10" X 2" chassis. A taller chassis may be needed to hide the choke underneath.

http://www.tubelab.com/UsersAmps.htm

Just waiting on the choke and the transformers. Finished populating the PCB today with inverted caps, SS components, terminal blocks. Sorry for all the questions. How did you drill the holes in the top deck for the tube sockets? I have a drill press but will I need special drills for metal? I have only used my drills for wood. Would there be a problem making the deck out of 1/4 inch red oak ply?

The problem that I can see is that you will probably want to have the top of the tube sockets flush with the top surface, this is because some tubes have a much larger base than the size of the socket (eg KT88s). This might make it too tight a fit for the components mounted to the top of the pc board. The other option might be to make the holes for the tube sockets large enough to take the larger tube bases, this would also allow for some cooling air flow for the tube and for the components inside the chassis. I found the Hammond aluminum chassis quite easy to work on. Small holes can be drilled with regular drill bits. I made the cutouts for the tube sockets with a set of cheap chassis punches that I purchased from Harbour Freight for about $16-$17. As a suggestion on layout, with those Edcor transformers, there is potentially a risk of touching B+ voltage on the solder tabs of the transformer if they are mounted on the top of the chassis. Since you probably want to hide the choke, you should also look for a chassis that will accommodate the output transformers under the chassis as well.

Good luck with the build!

Chris

Good luck with the build!

Chris

awhite1159 said:Just waiting on the choke and the transformers. Finished populating the PCB today with inverted caps, SS components, terminal blocks. Sorry for all the questions. How did you drill the holes in the top deck for the tube sockets? I have a drill press but will I need special drills for metal? I have only used my drills for wood. Would there be a problem making the deck out of 1/4 inch red oak ply?

My chassis is roughly 1/8" thick aluminum. 1" and 1-1/2" bimetallic hole saws and a drill press made quick work of the tube holes. As Chrish noted, I made oversized holes to assure that there would be a little air flow for cooling. A step drill is nice for the smaller holes, they don't 'grab' the way twist drills can when they punch through the metal.

I used 3/4" standoffs that set the tube sockets a bit below the deck level. I didn't want the white sockets to show below the tubes. All components except the sockets are bottom-mounted, so clearance is not an issue.

Bill

I used 1/8" aluminum for my panel too (see my avatar). you can source a piece from your local metal supply. I got 2 pieces cut to 9.5/13 for $23. A bit of advice, pay the metal supplier $3 to cut it to the right size. unless you have a shear you'll spend days trying to cut it and it still won't look as good as they can do. I also used regualr hole saws (the cheap ones for wood only). Use a drill press and set it to as slow as it will go and make sure to apply lots of oil while cutting. a nice slurry of metal chips and oil will keep the saw nice and sharp. It will also make a huge mess, but this is in the name of cool audio equipment so make a mess and get your kids to clean it when you are done.

Don't worry about small scratches on the panel while you are machining it. when you are done machining it use an orbital sander with 120, 220, 320, 450, 600, and 1000 grit sandpaper. when you have sanded it to 1000 use polishing compound on it with a buffing wheel on the drill press at high speed. I used a 3m product made for gelcoat, but your auto parts store will have something that will work. look for something that is around an equivalent of 8000 grit. when that is done you can hand polish it with Cape Cod Metal Polishing Cloths (Ace Hardware). The entire polishing process takes about 45 minutes and you will have a mirror finish when done.

Also, for a great selection of fasteners, Ace Hardware is the place. Rather than using standard pan head screws I like the look of socket head screws. They really make the chassis panel look nice.

BTW tubelab, I saw that picture of you with your guitar in front of that 212 watt tube amp. it reminded me of Christopher Lloyd in Back to the future with Michael J Fox and the 6' speaker scene where he was ejected as the speaker exploded. good for a laugh.

Don't worry about small scratches on the panel while you are machining it. when you are done machining it use an orbital sander with 120, 220, 320, 450, 600, and 1000 grit sandpaper. when you have sanded it to 1000 use polishing compound on it with a buffing wheel on the drill press at high speed. I used a 3m product made for gelcoat, but your auto parts store will have something that will work. look for something that is around an equivalent of 8000 grit. when that is done you can hand polish it with Cape Cod Metal Polishing Cloths (Ace Hardware). The entire polishing process takes about 45 minutes and you will have a mirror finish when done.

Also, for a great selection of fasteners, Ace Hardware is the place. Rather than using standard pan head screws I like the look of socket head screws. They really make the chassis panel look nice.

BTW tubelab, I saw that picture of you with your guitar in front of that 212 watt tube amp. it reminded me of Christopher Lloyd in Back to the future with Michael J Fox and the 6' speaker scene where he was ejected as the speaker exploded. good for a laugh.

Thanks to all for the responses. Well, I'm still waiting on parts so I started on the enclosure. I liked the diamond-plate that George has on one of his amps so I cut a piece to size. (3 hours with a hacksaw.) So now I have to drill holes and cutouts for tubes. I'm using EL34's so I can probably have the tube sockets slightly below the deck. Chris, do you think I can use the chassis punch method for the socket holes? I attached a pic of what it looks like so far.

Andy

Andy

Attachments

Originally posted by awhite1159 ...so I cut a piece to size. (3 hours with a hacksaw.)

$3 sounds like a bargain now, doesn't it?

Looking good so far!

I don't have any experience cutting holes in that diamond plate, but as you have seen here http://www.tubelab.com/Industrial1.htm George at Tubelab used chassis punches on his industrial amp. I would strongly suggest that you space the board so that the top of the tube sockets sit just proud of the top plate (including diamond pattern). At the moment you are planning on using EL34s, but you will get curious and want to try other tubes at some stage. You won't even notice the top of the tube sockets sitting a mm or so above the top plate when the tubes are in and the music is playing! Also not sure how deep your chassis is, but if it is 2" the 1500uF panasonic capacitors won't fit if you have not laid them over and you space the board too far away from the top plate - "measure twice, cut once". I know from experience here, mine only just fit!

I don't have any experience cutting holes in that diamond plate, but as you have seen here http://www.tubelab.com/Industrial1.htm George at Tubelab used chassis punches on his industrial amp. I would strongly suggest that you space the board so that the top of the tube sockets sit just proud of the top plate (including diamond pattern). At the moment you are planning on using EL34s, but you will get curious and want to try other tubes at some stage. You won't even notice the top of the tube sockets sitting a mm or so above the top plate when the tubes are in and the music is playing! Also not sure how deep your chassis is, but if it is 2" the 1500uF panasonic capacitors won't fit if you have not laid them over and you space the board too far away from the top plate - "measure twice, cut once". I know from experience here, mine only just fit!

Thanks Chris. I am planning on putting feet on it so I should be ok with the cap clearance. I will take your advice with the sockets since I would be interested in hearing how other tubes sound. I'm not deadset on the diamond plate soif it is going to be too difficult to cut holes in, I'll takea different route. I would still prefer wood but am concerned about heat disapation (Spelled that wrong I think.) Should I be?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- NEWBIE question SET vs. Solid State