I just got a 2A3+300B Music Angel from ebay - nice sounding right out of the box  I will post a review once I get more familiar with the amp.

I will post a review once I get more familiar with the amp.

However - the power transformer makes a low snerring sound (you can also feel the vibration when touching the cover of the transformer) - it does somehow seems hum related - a low level hum is also comming from the speakers. The transformer gets fairly hot (40-45 degree C). I'll try to get the schematic from the supplier...

Is there a simple "cure" for the power transformer (apart from buying a decent sized one)?

Thanks,

Thomas

However - the power transformer makes a low snerring sound (you can also feel the vibration when touching the cover of the transformer) - it does somehow seems hum related - a low level hum is also comming from the speakers. The transformer gets fairly hot (40-45 degree C). I'll try to get the schematic from the supplier...

Is there a simple "cure" for the power transformer (apart from buying a decent sized one)?

Thanks,

Thomas

Apart from mechanically decoupling the trafo from the chassis (to prevent the chassis and other components from resonating along) there's not much you can do IMO. I wouldn't worry about it too much. A larger trafo is a costly affair and will only yield mechanical silence, you'll still have humm on the outputs.

Simon

Simon

Yes, hum on the outputs has not necessarily to do with transformer mechanical hum. The obvious: You did make sure that the clamping bolts are tight? Otherwise if it is troublesome, take off and open up, and apply mains - one could often use a finger to feel where the trouble is. (Also just to comply with forum rules: You would know to be careful NOT to feel where the voltage is!!) If you can determine the spot, applying some lacquer there or just generally often helps - in the past I was fortunate to have had that work. A little more problematic if the noise comes from the centre piece for E-I laminations; a lot more problematic if you have a C-core transformer!

Regarding electronic hum, if you have a drop-through transformer and steel chassis, you also have my sympathy. But as it is an existing amplifier one would presume that it was originally quiet. Then the "usual suspects" apply: Poor filter capacitors, corroded earth connections et al.

Good luck!

Regarding electronic hum, if you have a drop-through transformer and steel chassis, you also have my sympathy. But as it is an existing amplifier one would presume that it was originally quiet. Then the "usual suspects" apply: Poor filter capacitors, corroded earth connections et al.

Good luck!

Would you say that a drop through transformer is generally a bad thing, or only with a steel chassis?Johan Potgieter said:if you have a drop-through transformer and steel chassis, you also have my sympathy.

Especially on a steel chassis, I would not use it. Yet again, there are commercial equipment using this quite successfully. So if you have one, do not throw it away; try first. But starting from new, there are enough on-chassis models available not to choose a drop through, and it is simply less of a risk (like for me, all the gremlins usually come rushing up, so I chicken out and avoid rather than cure!).

Regards.

Regards.

Separate filament supplies might end up reducing the hum problem on the main transformer. All of those SS rectifiers dumping into big capacitors is tough on the transformer. Better filament supplies might sound better anyway. You have a lot of options: choke input, CCS, ...

To be honest, I don't know what the 3A5 heater supply is all about, but I don't like halfwave rectifiers anywhere. They are especially hard on the transformer actually putting DC through the winding. That is never good as far as I'm concerned.

-- Dave

To be honest, I don't know what the 3A5 heater supply is all about, but I don't like halfwave rectifiers anywhere. They are especially hard on the transformer actually putting DC through the winding. That is never good as far as I'm concerned.

-- Dave

I had a commercial ss amp long ago where the transformer hummed and ran very hot. I don't think it had a shorted winding or anything, it was just a cheap transformer. The amp performed fine electrically, but you could hear it in a quiet room. It seems to be common that a transformer design will start out at a high quality level, using a decent grade of steel, and then be transferred to a cheaper source. First to go is the good grade of transformer steel, followed by wire gage and construction practice. Losses go up, then you have hum and high temperature even under quiescent conditions. Grommets and careful mounting will help, but the real cure is a well made transformer. I prefer non-drop through transformers, but haven't had a bit of trouble with either type.

The 100µF input capacitor for the input/driver PS is very high (check 5z3p datasheet for max. rating); furthermore this PS could be greatly improved by redesign (PSUDII) and introduction of a choke; also allowing a reduction in capacitance which on it's turn makes the use of better sounding (but larger) caps like motor-runs a real-world option.

Simon

Simon

I'd change the half wave rectifier on the 3A5 filament supply to a full wave rectifier and adjust the resistor values to maintain the correct dc voltage at the filaments. Or use a low drop out voltage regulator.

A CLC supply for the driver stages with a reasonable value of input capacitance for the 5z3p would be a good idea.

Converting the dht filament supplies to clc using modified iron core (sidewinders or similar) x-over inductors would both reduce ripple and reduce the pk currents in the heater windings.

For all of the above PSUD II is the tool of choice to figure it all out.

40 - 45 C is not really excessive, not that we don't like cold running transformers, the concern starts when the external temperature exceeds about 60C.

One other concern might be the relay in the output stage supply, I'd install a snubber across the contacts to prevent possible contact welding or turn it into a slow start by putting a 1K 10W power resistor across the contacts. (Inrush current at contact closure will be lots of amps.)

A CLC supply for the driver stages with a reasonable value of input capacitance for the 5z3p would be a good idea.

Converting the dht filament supplies to clc using modified iron core (sidewinders or similar) x-over inductors would both reduce ripple and reduce the pk currents in the heater windings.

For all of the above PSUD II is the tool of choice to figure it all out.

40 - 45 C is not really excessive, not that we don't like cold running transformers, the concern starts when the external temperature exceeds about 60C.

One other concern might be the relay in the output stage supply, I'd install a snubber across the contacts to prevent possible contact welding or turn it into a slow start by putting a 1K 10W power resistor across the contacts. (Inrush current at contact closure will be lots of amps.)

I don't like halfwave rectifiers anywhere. They are especially hard on the transformer actually putting DC through the winding. That is never good as far as I'm concerned.

I'd have to agree. Every time I've ever used half wave it caused mechanical hum.

Do you feel that a spice simulation is any less useful than using PSUD ll?kevinkr said:For all of the above PSUD II is the tool of choice to figure it all out.

jnb said:

Do you feel that a spice simulation is any less useful than using PSUD ll?

No, not at all, but unless you are lucky enough to have good tube rectifier models or the tools to make them (Curve Captor) PSUD II will get you there a lot quicker. Personally I use spice for just about everything...

what's the mains voltage there? most chinese amps are designed for 220volts and 110volts

also, less iron in the core means the core will saturate sooner, which is probably what is happening, so it buzzes and gets hot.

so you may have a few issues...

a small transformer core area

a design that uses a high value of flux B, so that pushes it even higher

and higher voltages that its designed for

low turns will do that, too.

and the wrong mains frequency

all of those are measures to make a transformer cheap...ie not much iron, low windings.

also, less iron in the core means the core will saturate sooner, which is probably what is happening, so it buzzes and gets hot.

so you may have a few issues...

a small transformer core area

a design that uses a high value of flux B, so that pushes it even higher

and higher voltages that its designed for

low turns will do that, too.

and the wrong mains frequency

all of those are measures to make a transformer cheap...ie not much iron, low windings.

Dave Cigna said:To be honest, I don't know what the 3A5 heater supply is all about, but I don't like halfwave rectifiers anywhere. They are especially hard on the transformer actually putting DC through the winding. That is never good as far as I'm concerned.

I would also agree with this (also as said by Jeb-d), but though I do not have 3A5 data, I doubt that the heater supply would be more than 1W. This is not likely to cause enough dc saturation to limit the flux.

But really, why a half wave rectifier in this day and age .... (except for a fixed bias supply of almost zero current - and even then, what could the cost saving be?). Also, while I am in a questioning mood: dc hardly necessary for the heater of any power amplifier stage (except for directly heated stages).

But Lt cdr Data raised one important point - is the mains frequency in order, Thomas S? We have 50 Hz and that does make a notable temperature difference when I test USA equipment, especially with at-the-edge transformers.

I have made a seperate (solid) enclosure for the PSU - I'll start to put things back together tonight....

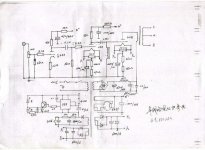

The amp seems nicely made with reasonably good parts and heavy iron (total weight >20kg) - the mains transformer is ~5kg. The amp is identical to the schematic with the exception of the caps on the output supply - they put the larger cap after the choke, which should (slightly) lower the in-rush current.

Initially I'll don't do any mods (apart from a power resistor to prevent welding on the output stage supply as suggested by Kevinkr).

Thanks for the suggestions - stay tuned

Thomas

The amp seems nicely made with reasonably good parts and heavy iron (total weight >20kg) - the mains transformer is ~5kg. The amp is identical to the schematic with the exception of the caps on the output supply - they put the larger cap after the choke, which should (slightly) lower the in-rush current.

Initially I'll don't do any mods (apart from a power resistor to prevent welding on the output stage supply as suggested by Kevinkr).

Thanks for the suggestions - stay tuned

Thomas

Hello ThomasS,

I too have recently purchased this amp. I have to return a friends 300B and I thought this would be a good alternative since I like very much the 300B. I was caught convinced for the price and available to make minor modifications. I plan to replace the valves asap because there is a hiss in the right channel after a few weeks of use. Better to buy a matching set. I have forgotten to continuosly check the bias (oops!). The seller has told me that the bias is automatic, is this true? Any advice how to do this. Have you successfully executed this?

kevinkr really knows giving good advice. He has already helped me identify a small noise from the 300Bs. Thank you for the rectifier advice but now I realise I cannot avoid major modifications to this ampli.

I will order a (maybe used) copy of the Morgan Jones book. Maybe this will explain to me the important power supply?

Whats a good way to discharge the condensors (for security)?

Thanks and cheers.

I too have recently purchased this amp. I have to return a friends 300B and I thought this would be a good alternative since I like very much the 300B. I was caught convinced for the price and available to make minor modifications. I plan to replace the valves asap because there is a hiss in the right channel after a few weeks of use. Better to buy a matching set. I have forgotten to continuosly check the bias (oops!). The seller has told me that the bias is automatic, is this true? Any advice how to do this. Have you successfully executed this?

kevinkr really knows giving good advice. He has already helped me identify a small noise from the 300Bs. Thank you for the rectifier advice but now I realise I cannot avoid major modifications to this ampli.

I will order a (maybe used) copy of the Morgan Jones book. Maybe this will explain to me the important power supply?

Whats a good way to discharge the condensors (for security)?

Thanks and cheers.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Power transformer snerring.