sorenj07 said:Hey, how much did the XPWR035 cost? It looks about right for a small project I'm planning using Z565 output transformers and some 6V6 type tubes.

$66.01

rknize said:

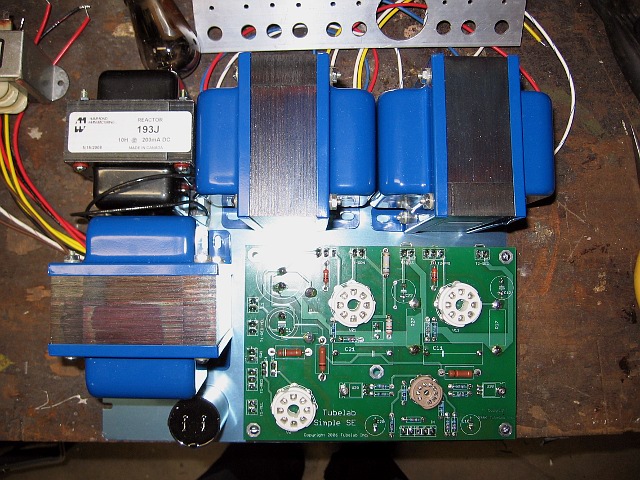

OK, so even though I knew the rough dimensions of these Edcors, I didn't quite come to terms with their size until they arrived. Man, these things are huge...and heavy. You definately get your money's worth with these guys. There is no way I am going to fit these on the 12x10 chassis I have on hand, so I am going to have to rethink that.

Isn't the mounting footprint of the Edcors 3.625" x 3.625"?

Attached is a shot of a Tubelab SE I built on a 10" x 12" chassis with the small Trancendars. They have a footprint of 3.875" x 3.0", so I think the Edcors will fit.

I like the 12" x 10" chassis because Hammond makes a cage for it.

If you put the Simple SE board (IIRC, the Tubelab SE and Simple SE are the same size), under the chassis, it would be even easier.

Win W5JAG

Attachments

My bad.

I just looked at the dimensions for the mounting centers, and not the bells.

I think the next size up for the Hammond chassis is like 13" x 17", at least that offers a cage.

LMB has some 11" x 13" chassis that I built my Simple SE on - that might be another possibility.

Win W5JAG

I just looked at the dimensions for the mounting centers, and not the bells.

I think the next size up for the Hammond chassis is like 13" x 17", at least that offers a cage.

LMB has some 11" x 13" chassis that I built my Simple SE on - that might be another possibility.

Win W5JAG

The custom Tubelab SE transformer specs are posted:

http://www.diyaudio.com/forums/showthread.php?postid=1783762#post1783762

http://www.diyaudio.com/forums/showthread.php?postid=1783762#post1783762

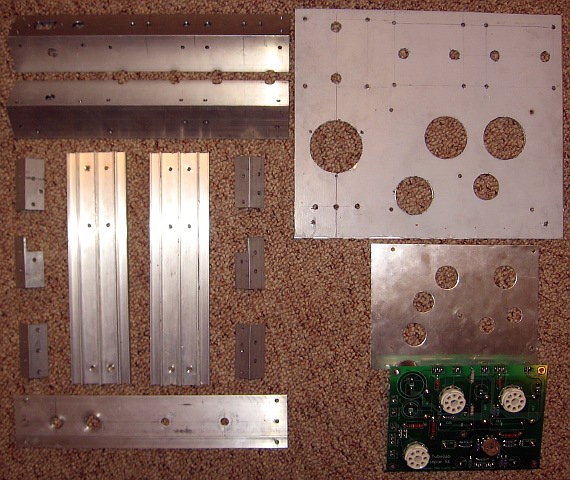

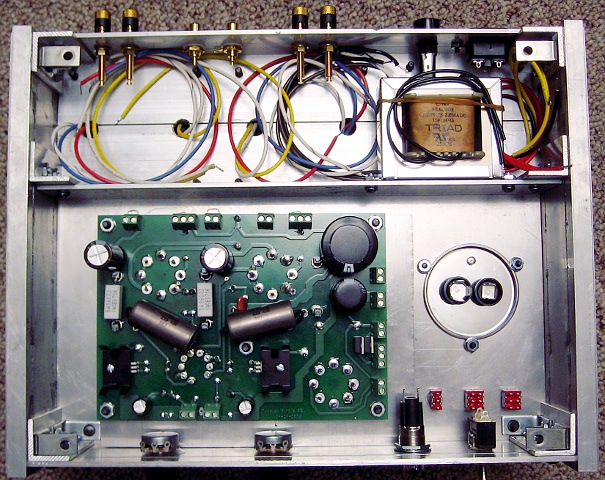

Pics of the test fitting of everything. Still rough from machining and so forth, but I wanted to make sure everything fit nicely before i started thinking about cleanup and paint. I very specifically did NOT wire anything up. If I did that it would look like this forever.

It's not exactly the look I was going for, but I think it will look pretty good with paint. Sort of Morgan-Jones-meets-a-heatsink.

The reason why the tube holes in the top plate are so large:

One one snafu with the fuse holder nearly bumping the choke:

It's not exactly the look I was going for, but I think it will look pretty good with paint. Sort of Morgan-Jones-meets-a-heatsink.

The reason why the tube holes in the top plate are so large:

One one snafu with the fuse holder nearly bumping the choke:

Dang! That's one glorious looking hunk of glass and iron! I like the K40 caps you used in the coupling position. I had some myself I wanted to try on mine, but I was scared to try to fit them in. Looks like you did a pretty good job...

edit: I just noticed the FREDs installed on the right edge. Keep an eye on those - if one of them shorts, it'll start blowing fuses. It doesn't matter whether or not SW1 is closed. Did you use the IXYS parts for your FREDs?

edit: I just noticed the FREDs installed on the right edge. Keep an eye on those - if one of them shorts, it'll start blowing fuses. It doesn't matter whether or not SW1 is closed. Did you use the IXYS parts for your FREDs?

Ty_Bower said:Dang! That's one glorious looking hunk of glass and iron! I like the K40 caps you used in the coupling position. I had some myself I wanted to try on mine, but I was scared to try to fit them in. Looks like you did a pretty good job...

Thanks! Yeah, the K40s are tight in there, but I managed to form the leads in such a way that I could twist the cap to avoid terminals for the cathode resistors. I actually put them in there for testing the board because they were the only decent caps I had that had high enough voltage rating. I bought a bunch from Dimitry on eBay just for the heck of it. Nice guy and really can't complain about the price. My first experience with them was on the VTA board for the Dynaco. I didn't like the sound at all at first, but after a few hours they "broke-in" I guess. I've always thought that electronic "break in" is for the most part nonsense, but I have to eat my words for these caps anyway. I've since picked-up some 600V Auricaps, which is generally what I use, but I'll leave the PIOs in there for now.

Ty_Bower said:edit: I just noticed the FREDs installed on the right edge. Keep an eye on those - if one of them shorts, it'll start blowing fuses. It doesn't matter whether or not SW1 is closed. Did you use the IXYS parts for your FREDs?

I have been using Fairchild "Stealth" diodes instead of HexFREDs for a while now because they are so much cheaper and seem to perform just as well. I forget who turned me on to them...might have been my dad. That is what I used in that spot because I had a stash on hand. From what I have read in this forum, it sounds like that is what George recommends anyway because of their avalanche current rating. I don't remember what the part number is that I used, but the specs were close enough to the part number George mentions.

I used "regular" FREDs in my preamp project, but they have held up OK there.

Lingwendil said:You should use a piece of wood for the front plate, that would make it really come together! Very nice!

Hmm...that is a thought. I'll try the panel I have for now, but wood would give it a different kind of look that might work better.

Thanks!

The chassis is all made of various scrap aluminum left over from house and car projects. I have one of those Chinese "universal" milling/drilling machines that does OK as an end mill on aluminum. The sides are a bunch of U-channel JB-welded (high temp epoxy) together! Everything was cut with a sawzall and them straightened/squared up on the mill.

Everything was cut with a sawzall and them straightened/squared up on the mill.

The top and bottom plate are cut of a piece I got from a surplus store. It still has the white plastic protective film in those pics. It was cheap because it had defects/blemishes. Bottom line is that it will all have to be painted.

I prepped everything last night and will prime it today. The primer is a very dark flat grey (almost black), so I will see how that looks. In my mind I have the sides and back all satin black and the top plate and front plate in a black/grey "hammered" finish. That should look good with the blue Edcors. If I like how it looks in primer, I will go that route. I'm going for an industrial/gig look with this amp.

Russ

The chassis is all made of various scrap aluminum left over from house and car projects. I have one of those Chinese "universal" milling/drilling machines that does OK as an end mill on aluminum. The sides are a bunch of U-channel JB-welded (high temp epoxy) together!

The top and bottom plate are cut of a piece I got from a surplus store. It still has the white plastic protective film in those pics. It was cheap because it had defects/blemishes. Bottom line is that it will all have to be painted.

I prepped everything last night and will prime it today. The primer is a very dark flat grey (almost black), so I will see how that looks. In my mind I have the sides and back all satin black and the top plate and front plate in a black/grey "hammered" finish. That should look good with the blue Edcors. If I like how it looks in primer, I will go that route. I'm going for an industrial/gig look with this amp.

Russ

Your build seriously has inspired me to pick up some aluminum. I know menards has a rack of small pieces and I have some ideas now on how I could put something pretty cool together. Out of curiosity, any info on your milling machine or something similar I could just check out. I am sure it is expensive but wouldn't mind looking into it. I have a class d amp set up that an industrial type looking box really would fit in great with what I have envisioned.

My dad bought it back in the 80s. He inherited a better one and gave this one to me after we bought our home. Its not a precision machine by any standards, but it works well once you get to know it. You can get machines like this from importers of sketchy Chinese equipment like Harbor Freight and Eastwood.

Attachments

I built two tubelab Simple SE amp.

One with Tango U-808(OPT) and the other (Simple SE 2) with the James JS-6123HS (OPT). I prefer the sound with the James, it has more bass. Not a lot but just enough to make the difference.

Album here: http://picasaweb.google.ca/TigrineAudio

Tigrine

One with Tango U-808(OPT) and the other (Simple SE 2) with the James JS-6123HS (OPT). I prefer the sound with the James, it has more bass. Not a lot but just enough to make the difference.

Album here: http://picasaweb.google.ca/TigrineAudio

Tigrine

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- More Vendors...

- Tubelab

- Tubelab Simple SE with big honkin' Edcors?