I completely concur with Richard Marsh on this. I worked for UL for almost a year, and I know why they spec what they do. It is not arbitrary.

Kindhornman, when it comes to amp or preamp differences, I am in serious disagreement with many here, and that is the source of the controversy.

I am expected to PROVE by every possible means, that I cannot go in a specific direction, if I decide not to, because of some potential compromise.

So, if I decide not to use an input transformer, because I can envision some potential problem with some customer, I have to PROVE IT. And this may take more extra time and trouble that I am not equipped to put forth.

For the record, I have tried for the last 50 years to REMOVE transformers from every part of an audio circuit. First, the output transformer by going to complementary transistor amps, then I EVEN tried to remove the power transformer, BUT it was too dangerous. However, I eliminated input and output transformers in ALL my multichannel studio boards successfully, and from moving coil cartridges. It is what I do, and I am pretty good at it, as well.

However, sometimes, a transformer could be useful. In my recent experience, I tried adding one to improve the input noise for a certain limited number of MC cartridges. However, the distortion at the very low frequencies, finally put me off. No big deal, there are other, equally expensive approaches to do the same thing, and I can do them.

When it comes to amp and preamp differences in general, my goal is to get enthusiastic public acceptance of any product that I design, without meeting the public, personally, myself. This I have been able to do relatively successfully, BUT not with EVERY design that I have finished, and sent out into the world. Some measured OK, but sounded 'marginal'.

So what am I to do? Ignore the subjective feedback? Tell everybody that they are deluded in some way? No. What I do it modify the design UNTIL it sounds its best. What is wrong with that?

Now, I TRY to convey my oversights (yes, I make them too) from past disappointments, here, and I get a barrage of criticism for even trying. That is the situation.

Kindhornman, when it comes to amp or preamp differences, I am in serious disagreement with many here, and that is the source of the controversy.

I am expected to PROVE by every possible means, that I cannot go in a specific direction, if I decide not to, because of some potential compromise.

So, if I decide not to use an input transformer, because I can envision some potential problem with some customer, I have to PROVE IT. And this may take more extra time and trouble that I am not equipped to put forth.

For the record, I have tried for the last 50 years to REMOVE transformers from every part of an audio circuit. First, the output transformer by going to complementary transistor amps, then I EVEN tried to remove the power transformer, BUT it was too dangerous. However, I eliminated input and output transformers in ALL my multichannel studio boards successfully, and from moving coil cartridges. It is what I do, and I am pretty good at it, as well.

However, sometimes, a transformer could be useful. In my recent experience, I tried adding one to improve the input noise for a certain limited number of MC cartridges. However, the distortion at the very low frequencies, finally put me off. No big deal, there are other, equally expensive approaches to do the same thing, and I can do them.

When it comes to amp and preamp differences in general, my goal is to get enthusiastic public acceptance of any product that I design, without meeting the public, personally, myself. This I have been able to do relatively successfully, BUT not with EVERY design that I have finished, and sent out into the world. Some measured OK, but sounded 'marginal'.

So what am I to do? Ignore the subjective feedback? Tell everybody that they are deluded in some way? No. What I do it modify the design UNTIL it sounds its best. What is wrong with that?

Now, I TRY to convey my oversights (yes, I make them too) from past disappointments, here, and I get a barrage of criticism for even trying. That is the situation.

Richard,

Is every part really marked with a UL approval stamp or is that a little beyond the requirement? Does an inductor even have a label many times or would a circuit board have to be checked before you could use it? Isn't it the product in its entirety that is tested by a licensed inspection lab to UL standards? And what about TUV or any European inspection requirements?

When a product is "tested" by a lab for safety compliance (UL) - they will look at your BOm, list of parts and your vendor/source for that part etc. they will ascertain whether it is built with 'approved' parts as well as approved construction materials and methods that meet standards. they will be stress tested and in some cases destructive testing is done.... thus the need for multiple units being sent to the testing lab.

For the DIY'er here making all sorts of things with power supplies etc. You owe it to yourselves and love ones to make them as safe as possible. Only use UL/VDE/etc approved parts. And, yes they are stamped or noted in spec sheets etc if they are approved for such use. If they dont say, assume they are not.

It all adds into the cost to the consumer and for low volume products, it adds a lot that may not be recovered until many units are sold. Some may not do the testing at all because they cant afford to for such a limited market.... buyer beware.

Thx-RNMarsh

caps which are approved for ac line voltage duty have a stamp of the agency(s) that approved it ($$). All parts if the size allows will have a code number or stamp or molded into it some way to track it and proof of compliance...... they are also better made parts... so you get what you pay for.

Last edited:

I assume one of the most prevalent reasons that input transformers are used in professional equipment is to isolate one piece of equipment from another and eliminate any ground loop problems that can happen from all the different designs of equipment out there. At least that is what I have been led to believe.

Richard,

Thank you for the clarification on that. So as long as the specification sheet has the UL rating that is what is required, not that each individual part is marked with the UL logo. I can understand your concern and desire to keep safe, I wouldn't want to subject anyone to that kind of problem, I've gotten my share of zaps over my life and they are never pleasant! I have a piece of equipment that came with only German electrical standards and believe me it was a real pain to get the machinery certified so I could use it, that was the last piece of equipment that BASF shipped into this country without a UL cert on it. Same went for the fact I would not accept the pressure vessel cert for some chemical tanks for that same machine, my friend who was a mechanical engineer clued me into that before the machine was sent and I made them produce the tanks in the US to ASME standards. Same as the electrical problem they used nothing but American made and certified tanks after I clued them into this standard.

Thank you for the clarification on that. So as long as the specification sheet has the UL rating that is what is required, not that each individual part is marked with the UL logo. I can understand your concern and desire to keep safe, I wouldn't want to subject anyone to that kind of problem, I've gotten my share of zaps over my life and they are never pleasant! I have a piece of equipment that came with only German electrical standards and believe me it was a real pain to get the machinery certified so I could use it, that was the last piece of equipment that BASF shipped into this country without a UL cert on it. Same went for the fact I would not accept the pressure vessel cert for some chemical tanks for that same machine, my friend who was a mechanical engineer clued me into that before the machine was sent and I made them produce the tanks in the US to ASME standards. Same as the electrical problem they used nothing but American made and certified tanks after I clued them into this standard.

Codd's piece (sorry couldn't resist) will misterminate a typical MM cartridge, for which the typical 47k has most of its effect at high frequencies. So you will already be well-below that resistance just due to the 22k shown.

Brad

Thank you. Comments are welcome.

From the simulations I run, this HF roll off can be compensated for. See the two lower circuits of the two attachments.

(1kOhm and 500mH are the MM cartridge. 200pF capacitor represents the capacitance of the cable).

Do you see any other issues with this HP filter there?

George

Attachments

Richard,

Thank you for the clarification on that. So as long as the specification sheet has the UL rating that is what is required, not that each individual part is marked with the UL logo.

Spec sheet is a minimum.... but with parts made all over the planet, you cant always count on the spec sheet and what distributor is selling you is same version. In most cases UL requires the labelling. And, you would want the label on your part to help explain why your competitor without the approval mark is so much cheaper than your part. And, that you are assured it will pass the required tests if you use the cap marked as such in your product.

many people on this forum are not as aware as professionals in the field are of these saefty issues and requirements of manufacturing and built home made things which wont be safe unknowingly. So just use "approved" parts and be safe and the reliablity is built in. yes, it will cost more.

-RNM

Thx-RNMarsh

Last edited:

Brad

Thank you. Comments are welcome.

From the simulations I run, this HF roll off can be compensated for. See the two lower circuits of the two attachments.

(1kOhm and 500mH are the MM cartridge. 200pF capacitor represents the capacitance of the cable).

Do you see any other issues with this HP filter there?

George

Transients? Any affect on cartridge tracking or damping?

Jacco,

You mean all the capacitor failures in the earlier Apple Imac that I have had to change for a friend, all the leaking cheap lowest cost caps leaking all over the place with puffy end caps giving it away! Sometimes I do wonder how they got away with some of that?

You mean all the capacitor failures in the earlier Apple Imac that I have had to change for a friend, all the leaking cheap lowest cost caps leaking all over the place with puffy end caps giving it away! Sometimes I do wonder how they got away with some of that?

many people on this forum are not as aware as professionals in the field are of these safety issues and requirements of manufacturing and built home made things which wont be safe unknowingly. So just use "approved" parts and be safe and the reliability is built in. yes, it will cost more.

-RNM

Thx-RNMarsh

Look for a safety approval on any of the high end audio power stuff. Only a few have any approvals. Same for fuses and other audiophile oriented protective devices. Caveat Emptor, and we will send flowers to your funeral (Sorry about the insurance claim being denied). . .

Both components and they way they are used must be checked for safety approval. Many times small details can make a big difference. For DIY use an abundance of caution and if you are not absolutely sure use Google and learn.

trust good, check better.

Better to use parts only you've got long time experience with, and/or do fatigue tests yourself, instead of checking for the stamped mark.

Aka, don't trust the label before taking a shuttle for a spin, but check the gaskets.

(must be a Euro-Pee-An thinking)

Better to use parts only you've got long time experience with, and/or do fatigue tests yourself, instead of checking for the stamped mark.

Aka, don't trust the label before taking a shuttle for a spin, but check the gaskets.

(must be a Euro-Pee-An thinking)

Jacco,

You mean all the capacitor failures in the earlier Apple Imac that I have had to change for a friend, all the leaking cheap lowest cost caps leaking all over the place with puffy end caps giving it away! Sometimes I do wonder how they got away with some of that?

Other side of the power interface, anything goes. Many computers suffered from this problem. Partly due to an abundance of counterfeit caps in China.

Let us assume I have a setup where two identical turntables with identical recordings, completely in sync, drive two different preamplifiers, that in turn drive identical amplifiers going to a single switch to a single loudspeaker in a well balanced room. The listener sit on axis and has an ABX switch. What does it prove if no listener can tell what x is? ES

Nothing

What if only one of the panel can tell? ES

That there is an audible difference

What if they all can tell?

That there is an audible difference

Now if none of the listeners can tell, but the power amplifier is changed and the results change, what does that mean?

ES

Depends on the changed results.

Does this help you to figger out the concepts, Ed?

jan

I think I've related my horror story with substandard ceramic discs, and in a situation where nothing else held a voltage down. And that was on the other side of an ostensibly-safe simple stepdown transformer wall-wart. Probing the circuit with even a 10M scope probe was enough to conceal the mechanism and eliminate the effect.Other side of the power interface, anything goes. Many computers suffered from this problem. Partly due to an abundance of counterfeit caps in China.

I would like to point out something important:

UL listing is NOT MANDATORY for making a safe piece of audio equipment.

UL listed parts are certainly recommended for ANYTHING in the high voltage above, let's say 35V, because we cannot always tell from JUST LOOKING whether a product is safe from overvoltage or overcurrent, or from some strange, unusual condition.

UL listing is EXPENSIVE, and bureaucratic, and a bit of common sense and experience keeps it from being necessary, to make a safe product. One thing that I do, is I ALWAYS attempt to cover any exposed AC with heatshrink, and not just depend on spacing to prevent arcing, etc. If you are a complete newbe, then try to get some UL regulations over the internet or even buy the appropriate UL spec manual for your product. They are expensive, but CHEAP by comparison to having your product actually LISTED by UL. Common sense, once you read the specs, will be apparent, and maybe keep you from overlooking something. You might say that UL is an accumulation of more than 100 years of experience in fire and electrical dangers, and you can learn from them.

UL listing is NOT MANDATORY for making a safe piece of audio equipment.

UL listed parts are certainly recommended for ANYTHING in the high voltage above, let's say 35V, because we cannot always tell from JUST LOOKING whether a product is safe from overvoltage or overcurrent, or from some strange, unusual condition.

UL listing is EXPENSIVE, and bureaucratic, and a bit of common sense and experience keeps it from being necessary, to make a safe product. One thing that I do, is I ALWAYS attempt to cover any exposed AC with heatshrink, and not just depend on spacing to prevent arcing, etc. If you are a complete newbe, then try to get some UL regulations over the internet or even buy the appropriate UL spec manual for your product. They are expensive, but CHEAP by comparison to having your product actually LISTED by UL. Common sense, once you read the specs, will be apparent, and maybe keep you from overlooking something. You might say that UL is an accumulation of more than 100 years of experience in fire and electrical dangers, and you can learn from them.

Nothing

That there is an audible difference

That there is an audible difference

Depends on the changed results.

Does this help you to figger out the concepts, Ed?

jan

Jan,

I think you get the point. Doing an accurate listening test is extremely difficult and the results are very specific.

As an example I used to have a box that simulated the RLC of 12 gauge cable in 3/4" conduit by 100' steps to 1000' Now if one listened to the difference between 100' and 200' most could not tell the difference. But the conclusion that the cable length didn't matter would of course be wrong because between 100' and 1000' pretty much anyone could tell the difference.

ES

Last edited:

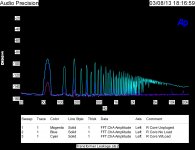

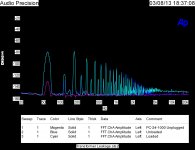

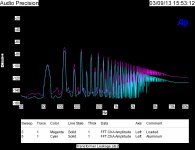

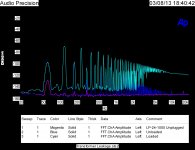

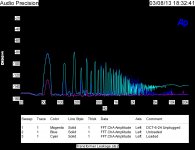

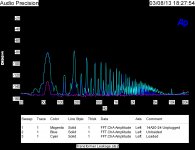

Attached are the FFT results for six different transformers of different construction but all about the same ratings. They are imposing a voltage on the chassis as shown in my test setup (Prior Post.) There is a duplicate of one transformer but using an aluminum chassis.

Four of the transformers (All Signal Brand) are mounted on PC cards. The R core came with a bracket and the Triad Torroid uses a single bolt. The ac cord is the same shielded 6' type with the safety ground connected to the chassis. The R core has a shield that is also grounded.

ES

Four of the transformers (All Signal Brand) are mounted on PC cards. The R core came with a bracket and the Triad Torroid uses a single bolt. The ac cord is the same shielded 6' type with the safety ground connected to the chassis. The R core has a shield that is also grounded.

ES

Attachments

I would like to point out something important:

UL listing is NOT MANDATORY for making a safe piece of audio equipment.

UL listed parts are certainly recommended for ANYTHING in the high voltage above, let's say 35V, because we cannot always tell from JUST LOOKING whether a product is safe from overvoltage or overcurrent, or from some strange, unusual condition.

UL listing is EXPENSIVE, and bureaucratic, and a bit of common sense and experience keeps it from being necessary, to make a safe product. One thing that I do, is I ALWAYS attempt to cover any exposed AC with heatshrink, and not just depend on spacing to prevent arcing, etc. If you are a complete newbe, then try to get some UL regulations over the internet or even buy the appropriate UL spec manual for your product. They are expensive, but CHEAP by comparison to having your product actually LISTED by UL. Common sense, once you read the specs, will be apparent, and maybe keep you from overlooking something. You might say that UL is an accumulation of more than 100 years of experience in fire and electrical dangers, and you can learn from them.

That used to be enough. But now Europe and even China now require such safety proof or they cannot be imported into their countries, legally. And distributors are more and more weary of holding the bag if anything they imported goes wrong. Its insurance.

But my point here is for the non-manfr'ers... the less knowledagable DIY builder. The short story to be safe with parts exposed to the ac line voltage is to use proven safe parts and the other would be to get informed... such as what JC pointed out.

Thx-RNMarsh

Attached are the FFT results for six different transformers of different construction but all about the same ratings. They are imposing a voltage on the chassis as shown in my test setup (Prior Post.) There is a duplicate of one transformer but using an aluminum chassis.

Four of the transformers (All Signal Brand) are mounted on PC cards. The R core came with a bracket and the Triad Torroid uses a single bolt. The ac cord is the same shielded 6' type with the safety ground connected to the chassis. The R core has a shield that is also grounded.

ES

How are you going to make them all - transformers - zero/base-line'ed?

How are you going to make them all - transformers - zero/base-line'ed?

If you have an idea how to do it I am very open for it. What I tried was to mount them all using the mounting typical for each type. All centered in the same chassis. With the exception of the R core they all have the same voltage rating and are close on current.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II