Someone here mentioned using a tuner (things scroll so fast its easy to lose the details).

You are welcome.

During this interlude, I would like to discuss the state of jfet technology today, at least what little that I know about.

For the last 33 years, we have gotten access to AMAZING jfets from Japan. They were not the FIRST quality jfets, but they were certainly the most consistent in noise and specification. We have had examples of very quiet jfets from around 1970, that were apparently made for the military, rather than for consumer use. These were very expensive and variable in noise. I still have a few samples. However, a GOOD one was about as good as anything made today.

However, by 1978, Toshiba, Hitachi, Sony, NEC and many other Japanese companies each made their own version of a low noise jfet, apparently in competition with each other at some level. This gave us a chance to make truly low noise, and ultimately, low noise complementary jfet input stages. Each company made a slightly different design with different advantages. For example, Hitachi made low noise 40V rated P channel jfets, compared to the slightly quieter Toshiba with only a 25V rating.

However, over the years, Toshiba came to dominate the audio scene, making excellent matched pairs like the 2SK389 and 2SJ109 at a price that virtually turned off other competitors from competing, either American or Japanese. At the same time, they showed a tendency to 'turn off' production of their earlier quality jfets, starting with the 2SK146, 2SJ73 super low noise matched jfet differential pair, originally used in the Vendetta Research phono stage to achieve a 10 ohm equivalent noise.

Then, they stopped producing the 2SK147, 2SJ72 single devices, then the 2SK240, 2SJ75 differential pairs.

For some years now, they kept the 2SK170, 2SJ74 single devices and added the 2SK389, 2SJ109 differential pairs that were truly exceptional in a number of ways, and sold them for perhaps $1 each to consumers, even cheaper OEM. Now, Toshiba has chosen (I am told) to cease production of virtually all audio jfets.

As you have been told here in the past, the Blowtorch preamp is made with very high current versions of the 2SK389, 2SJ109, parts at the top 20% of the production of these devices. When these devices were cheap and plentiful, this was possible, but today it is almost impossible to do in limited production, except for the most exotic designs demanded by hi end audio.

What about today? Well, the future is uncertain. We WILL be able to buy something that will replace the Toshiba parts, but not at a low price or necessarily as low in noise.

It IS like what happened with tubes, where a good tube is hard to find today, and it will be expensive, and an inexpensive replacement may not be really cheap, yet problematic enough to be useless in many applications.

I do not see any real solution to this, except to go to IC's as they further develop, perhaps augmenting them with some discrete parts to make them perform better.

For the last 33 years, we have gotten access to AMAZING jfets from Japan. They were not the FIRST quality jfets, but they were certainly the most consistent in noise and specification. We have had examples of very quiet jfets from around 1970, that were apparently made for the military, rather than for consumer use. These were very expensive and variable in noise. I still have a few samples. However, a GOOD one was about as good as anything made today.

However, by 1978, Toshiba, Hitachi, Sony, NEC and many other Japanese companies each made their own version of a low noise jfet, apparently in competition with each other at some level. This gave us a chance to make truly low noise, and ultimately, low noise complementary jfet input stages. Each company made a slightly different design with different advantages. For example, Hitachi made low noise 40V rated P channel jfets, compared to the slightly quieter Toshiba with only a 25V rating.

However, over the years, Toshiba came to dominate the audio scene, making excellent matched pairs like the 2SK389 and 2SJ109 at a price that virtually turned off other competitors from competing, either American or Japanese. At the same time, they showed a tendency to 'turn off' production of their earlier quality jfets, starting with the 2SK146, 2SJ73 super low noise matched jfet differential pair, originally used in the Vendetta Research phono stage to achieve a 10 ohm equivalent noise.

Then, they stopped producing the 2SK147, 2SJ72 single devices, then the 2SK240, 2SJ75 differential pairs.

For some years now, they kept the 2SK170, 2SJ74 single devices and added the 2SK389, 2SJ109 differential pairs that were truly exceptional in a number of ways, and sold them for perhaps $1 each to consumers, even cheaper OEM. Now, Toshiba has chosen (I am told) to cease production of virtually all audio jfets.

As you have been told here in the past, the Blowtorch preamp is made with very high current versions of the 2SK389, 2SJ109, parts at the top 20% of the production of these devices. When these devices were cheap and plentiful, this was possible, but today it is almost impossible to do in limited production, except for the most exotic designs demanded by hi end audio.

What about today? Well, the future is uncertain. We WILL be able to buy something that will replace the Toshiba parts, but not at a low price or necessarily as low in noise.

It IS like what happened with tubes, where a good tube is hard to find today, and it will be expensive, and an inexpensive replacement may not be really cheap, yet problematic enough to be useless in many applications.

I do not see any real solution to this, except to go to IC's as they further develop, perhaps augmenting them with some discrete parts to make them perform better.

During this interlude, I would like to discuss the state of jfet technology today, at least what little that I know about.

For the last 33 years, we have gotten access to AMAZING jfets from Japan. They were not the FIRST quality jfets, but they were certainly the most consistent in noise and specification. We have had examples of very quiet jfets from around 1970, that were apparently made for the military, rather than for consumer use. These were very expensive and variable in noise. I still have a few samples. However, a GOOD one was about as good as anything made today.

However, by 1978, Toshiba, Hitachi, Sony, NEC and many other Japanese companies each made their own version of a low noise jfet, apparently in competition with each other at some level. This gave us a chance to make truly low noise, and ultimately, low noise complementary jfet input stages. Each company made a slightly different design with different advantages. For example, Hitachi made low noise 40V rated P channel jfets, compared to the slightly quieter Toshiba with only a 25V rating.

However, over the years, Toshiba came to dominate the audio scene, making excellent matched pairs like the 2SK389 and 2SJ109 at a price that virtually turned off other competitors from competing, either American or Japanese. At the same time, they showed a tendency to 'turn off' production of their earlier quality jfets, starting with the 2SK146, 2SJ73 super low noise matched jfet differential pair, originally used in the Vendetta Research phono stage to achieve a 10 ohm equivalent noise.

Then, they stopped producing the 2SK147, 2SJ72 single devices, then the 2SK240, 2SJ75 differential pairs.

For some years now, they kept the 2SK170, 2SJ74 single devices and added the 2SK389, 2SJ109 differential pairs that were truly exceptional in a number of ways, and sold them for perhaps $1 each to consumers, even cheaper OEM. Now, Toshiba has chosen (I am told) to cease production of virtually all audio jfets.

As you have been told here in the past, the Blowtorch preamp is made with very high current versions of the 2SK389, 2SJ109, parts at the top 20% of the production of these devices. When these devices were cheap and plentiful, this was possible, but today it is almost impossible to do in limited production, except for the most exotic designs demanded by hi end audio.

What about today? Well, the future is uncertain. We WILL be able to buy something that will replace the Toshiba parts, but not at a low price or necessarily as low in noise.

It IS like what happened with tubes, where a good tube is hard to find today, and it will be expensive, and an inexpensive replacement may not be really cheap, yet problematic enough to be useless in many applications.

I do not see any real solution to this, except to go to IC's as they further develop, perhaps augmenting them with some discrete parts to make them perform better.

Hi John,

Thanks for this overview on the history of JFETs for audio. It is unfortunate that many of these good JFETs for audio have disappeared. It may just be a reflection of the direction that high-volume consumer audio has taken, making it no longer profitable for Toshiba to keep those semiconductor fabrication processes going. The same thing is happening to their excellent power MOSFETs.

Although ICs have gotten a lot better for use in phono stages, the disappearance of the Toshiba JFETs, particularly the P-channel differential pairs, does not mean that we need to move in the direction of using ICs in phono stages (we certainly can, if we want, and for the appropriate markets).

For the high-end, all-discrete phono stages for both MC and MM are still totally appropriate and viable. For example, the LSK389 is an excellent performer and all-N-channel front ends can provide outstanding performance while requiring far less device matching than the complementary P/N channel designs that you pioneered. Yes, of course, it is more difficult to get the noise as low, but excellent noise performance can be achieved. Heroic noise performance for bragging rights is unnecessary unless one is using MC cartridges with unusually low output that is problematic.

For all-out best performance, separate front-ends can and should be used for the MC and MM applications. JFETs should of course be used for both, but the use of an input stage with many paralleled JFETs for MM is definitely sub-optimal. This could even mean separate entire phono stages where selection of MC vs MM is actually done at line level. Going to such an extreme to optimize separately for each application certainly adds cost, but this is offset somewhat by no longer needing to obtain and match so carefully N and P channel pairs (ESPECIALLY if one is forced to use singles).

Cheers,

Bob

Bob, thanks for your input. Of course, a first class, 'A' level phono preamp would use 2 separate jfet types to use as an input. We do it with both Constellation Audio phono stages that I am designing at the moment.

However, one IC chip can bridge the gap fairly well, and this is shown with the Parasound JC-3 phono stage now available, so long as you don't expect too much in very low noise or use phono cartridges with extremely high inductance.

However, with the jfets drying up, it might not be practical to make traditional designs such as the Parasound JC-1, or JC-2 or its siblings in future, once the limited stocks are used up.

It is a little like what happened years ago when Tetra-ethyl lead was removed from gasoline and the octane dropped in the USA. Autos, for awhile, lost power, fuel efficiency, and reliability until they could redesign the engines to work properly again.

Today, nobody hardly notices, because the compression ratios and overall performance has been considerably increased to previous levels.

I fear it will be the same for amp and preamp design. We will just have to live with what we can get, and the good stuff will be relatively expensive. Perhaps a complete rethink of the design might get us better products in the future. Let's hope so.

However, one IC chip can bridge the gap fairly well, and this is shown with the Parasound JC-3 phono stage now available, so long as you don't expect too much in very low noise or use phono cartridges with extremely high inductance.

However, with the jfets drying up, it might not be practical to make traditional designs such as the Parasound JC-1, or JC-2 or its siblings in future, once the limited stocks are used up.

It is a little like what happened years ago when Tetra-ethyl lead was removed from gasoline and the octane dropped in the USA. Autos, for awhile, lost power, fuel efficiency, and reliability until they could redesign the engines to work properly again.

Today, nobody hardly notices, because the compression ratios and overall performance has been considerably increased to previous levels.

I fear it will be the same for amp and preamp design. We will just have to live with what we can get, and the good stuff will be relatively expensive. Perhaps a complete rethink of the design might get us better products in the future. Let's hope so.

For all-out best performance, separate front-ends can and should be used for the MC and MM applications.

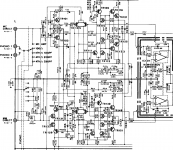

Yamaha did that in their C-70 (see attached), as to the rest of their design decisions?

Rgds

James

Attachments

Bob, thanks for your input. Of course, a first class, 'A' level phono preamp would use 2 separate jfet types to use as an input. We do it with both Constellation Audio phono stages that I am designing at the moment.

However, one IC chip can bridge the gap fairly well, and this is shown with the Parasound JC-3 phono stage now available, so long as you don't expect too much in very low noise or use phono cartridges with extremely high inductance.

However, with the jfets drying up, it might not be practical to make traditional designs such as the Parasound JC-1, or JC-2 or its siblings in future, once the limited stocks are used up.

It is a little like what happened years ago when Tetra-ethyl lead was removed from gasoline and the octane dropped in the USA. Autos, for awhile, lost power, fuel efficiency, and reliability until they could redesign the engines to work properly again.

Today, nobody hardly notices, because the compression ratios and overall performance has been considerably increased to previous levels.

I fear it will be the same for amp and preamp design. We will just have to live with what we can get, and the good stuff will be relatively expensive. Perhaps a complete rethink of the design might get us better products in the future. Let's hope so.

Hi John,

Well-stated.

Interesting you mention unleaded gasoline and the auto performance issue. I recently got a new car, a Lexus ES350, after being forced by my wife to give up my 1997 ES300. The dealer told me I must use premium in the new car or it may damage the engine. As you suggested, the new engine uses a 10.8:1 compression ratio. I haven't had a car with that compression ratio since my late-sixties Pontiac 389 (it loved Sunoco 260). I'm well aware of the ping issue, at least as it was back then.

However, I've also heard that all of the newer cars with computers controlling spark and valve timing and all sorts of other things readily adapt to different octanes of fuel, and so don't get damaged but maybe give up a bit of performance in adapting. This of course runs counter to what the dealer told me. We have also been running my wife's BMW Z4 on regular without complaint from the car.

So what do you think? Am I OK with regular? BTW, both the Lexus and BMW on regular have plenty of pep.

Cheers,

Bob

So what do you think? Am I OK with regular? BTW, both the Lexus and BMW on regular have plenty of pep.

Cheers,

Bob

You'll be fine until it knocks, at which point the ECU will retard your engine's timing into a kind of "limp home" mode. This usually only happens in summer - especially in heavy traffic. The only danger would be a faulty knock sensor, but I think they now build some redundancy into the system.

Regular in winter, 89 octane in summer.

Hi John,

So what do you think? Am I OK with regular? BTW, both the Lexus and BMW on regular have plenty of pep.

Cheers,

Bob

Your age is showing! Regular is fine for the car, the performance gets a bit better with premium. Tire life also improves!

As the years pass, it is unfortunate that 'good' component parts become difficult to obtain, and the 'usual' approaches may be almost impossible to pursue, especially in production. The CTC Blowtorch was never considered a 'production' design, but it would certainly be difficult to make another 50, that is for sure.

It is the same with really exotic phono stages. Most of the parts we use, are not even made anymore, so this is another parallel to the problem that vacuum tube designers had, perhaps 40 years ago.

It is the same with really exotic phono stages. Most of the parts we use, are not even made anymore, so this is another parallel to the problem that vacuum tube designers had, perhaps 40 years ago.

To come back to an earlier topic, especially for my friend Ed S:

Reduce acoustic noise from capacitors - 2011-02-17 11:00:00 | EDN

The link also has some comments.

jan didden

Reduce acoustic noise from capacitors - 2011-02-17 11:00:00 | EDN

The link also has some comments.

jan didden

To come back to an earlier topic, especially for my friend Ed S:

Reduce acoustic noise from capacitors - 2011-02-17 11:00:00 | EDN

The link also has some comments.

jan didden

Thanks, so piezo-electric capacitors work both ways.

I wonder whether this could be a reason for the bad rap of ceramic caps in audio?

jan didden

Jan, I though you knew that most ceramic capacitors have those problems to some extent. The NPO types have almost none. The X7R the most.

Joachim, not really. When I drop ceramic caps on the floor, their sound has considerably higher HF content than similarly dropped Teflon caps.

I substituted some 0.01uF polystyrene caps for some 2.0uF polypropylene caps in my amplifier and I can say with certainty that there was less bass.

I substituted some 0.01uF polystyrene caps for some 2.0uF polypropylene caps in my amplifier and I can say with certainty that there was less bass.

All caps sound the same.

Is that an empirical observation, or "engineering common knowledge"?

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II