Opinions about gain are numerous. However Joao got the gist of the problem, which is an upsetting change in level between sources. Unfortunately, attenuators cause more noise, and a need for higher intrinsic preamp gain. This would be a problem with the CTC Blowtorch, no problem with the Parasound JC-2.

Asseblief, vir die audio wildebees van die Natal, ek denk es tog geen moeite nie.[/QUOTE

LOL.

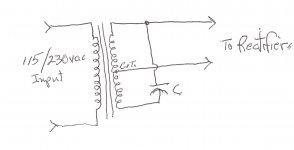

Attached are the FFT results for six different transformers of different construction but all about the same ratings. They are imposing a voltage on the chassis as shown in my test setup (Prior Post.) There is a duplicate of one transformer but using an aluminum chassis.

Four of the transformers (All Signal Brand) are mounted on PC cards. The R core came with a bracket and the Triad Torroid uses a single bolt. The ac cord is the same shielded 6' type with the safety ground connected to the chassis. The R core has a shield that is also grounded.

ES

It looks like your sensitive to external fields. I suspect you are picking up external field becasue your tap wires are not intimate with the chassis, but have a loop.

Tape the wire to the chassis, and twist the two as they leave.

jn

It looks like your sensitive to external fields. I suspect you are picking up external field becasue your tap wires are not intimate with the chassis, but have a loop.

Tape the wire to the chassis, and twist the two as they leave.

jn

Too a bit, but as mentioned I did jiggle and remeasure and the error is less than the difference between transformers. The wires are shielded and twisted as close as possible. (There just ain't much room to sag.)

I want to avoid giving the impression that typical measurements are absolute. In the same series of transformers, but with different models I see variances, so as long as my measurement error is below that, it should be good enough.

There were few surprises about coupling and leakage. The interesting issue was diode switching noise is affected by transformer type. (Lossy transformers have much less noise...Duh!) The interwinding screen provided 6 db of isolation even with the high impedance ground connection. (But J.N. you know why and why it is 6 db.) of course hooking the screen up wrong can make things much worse!

Another interesting item was that the noise induced resonances peaked at the same level even with different drive level.

Dick,

Increasing the load on the transformers to 20% of rating increases the leakage to the core by about 5%. As this is at the limit of my measurement accuracy, I'll give you the gold star for getting that right. But I won't show numbers as they are to me an indication not a true reading.

So did anyone else not interesting stuff from the measurements?

ES

There were few surprises about coupling and leakage. The interesting issue was diode switching noise is affected by transformer type. (Lossy transformers have much less noise...Duh!) The interwinding screen provided 6 db of isolation even with the high impedance ground connection. (But J.N. you know why and why it is 6 db.) of course hooking the screen up wrong can make things much worse!

Another interesting item was that the noise induced resonances peaked at the same level even with different drive level.

Dick,

Increasing the load on the transformers to 20% of rating increases the leakage to the core by about 5%. As this is at the limit of my measurement accuracy, I'll give you the gold star for getting that right. But I won't show numbers as they are to me an indication not a true reading.

ES

For worse case (and UL) transformer testing at rated load for an actual product is done and the leakage noted if it is below the UL/IEEE spec. Also the radiated emi gets a lot worse.

So, did you get curious yet as to 'what to do about it' yet? EMI/RFI and an open door in both directions - pass thru - of unwanted freqs thru the xfmr?

THx-RNMarsh

Too a bit, but as mentioned I did jiggle and remeasure and the error is less than the difference between transformers. The wires are shielded and twisted as close as possible. (There just ain't much room to sag.)

I want to avoid giving the impression that typical measurements are absolute. In the same series of transformers, but with different models I see variances, so as long as my measurement error is below that, it should be good enough.

There were few surprises about coupling and leakage. The interesting issue was diode switching noise is affected by transformer type. (Lossy transformers have much less noise...Duh!) The interwinding screen provided 6 db of isolation even with the high impedance ground connection. (But J.N. you know why and why it is 6 db.) of course hooking the screen up wrong can make things much worse!

Another interesting item was that the noise induced resonances peaked at the same level even with different drive level.

ES

For non toroid, mount a 1/8th aluminum sheet between the chassis and the iron. It will resist flux intrusion. Isolate it electrically from the chassis, and bond it to ground.

jn

For worse case (and UL) transformer testing at rated load for an actual product is done and the leakage noted if it is below the UL/IEEE spec. Also the radiated emi gets a lot worse.

So, did you get curious yet as to 'what to do about it' yet? EMI/RFI and an open door in both directions - pass thru - of unwanted freqs thru the xfmr?

THx-RNMarsh

The article I am doing is on linear power supplies for audio use. It keeps getting longer and longer. That is from going from input to output and seeing new things and starting all over.

I have a nice list of techniques to minimize EMI pass through. One method I am pursuing for a patent, so I will not mention anything about it. There is a second method that may go that way or get published mostly depending on the difficulty I have with the first patent. The rest of the techniques should be well known, but strangely enough some are not.

My approach is that basic knowledge of how to keep things clean and reduce the noise you make is better than using "Magic" parts. Of course for extreme results the better parts do yield better results.

JN

I will post more when JC runs out of his current line of discourse.

Of course for extreme results

Mr. Simon,

how lovely sir, does it also include transformer blueprinting ?

Indubitably, not very likely in the economic feasibility portfolio of a professional manufacturer, but strictly reserved for DIY's with Horny hands.

(there, perfectly delightful and unobtrusive sentences, if you grant me the pleasure to ascertain as such myself)

Last edited:

I will post more when JC runs out of his current line of discourse.

Ed you are finally posting on something that I have absolutely no interest.

<snip>One method I am pursuing for a patent, so I will not mention anything about it. There is a second method that may go that way or get published mostly depending on the difficulty I have with the first patent. <snip>

John, this is the comment I was referencing.. My position is that if a poster is unwilling to share the details on this forum it would be better not to mention it at all.

For non toroid, mount a 1/8th aluminum sheet between the chassis and the iron. It will resist flux intrusion. Isolate it electrically from the chassis, and bond it to ground.

jn

True for both aluminum and steel chassis? Would copper work? Silver for the loonies that crave precious metals? (Finally some intrinsic value for an audio product.)

1- As long it is not magnetic and conduct electricity, but coper is expensive and need painting, because it it oxidizes.Would copper work? Silver for the loonies that crave precious metals?

2- Gold is better because it is more expensive. I wonder why nobody sells audiophile chassis in plain machined gold.

some simple things can help in certain places for certain issues:

What else can be done?

There will be an article in the next Linear Audio which you may find interesting. Strategically placed small parts can do wonders.

If you design the phono stage for circa 150mV out, assuming it feeds into a standard 16dB gain line stage, you should be about right. No point in designing the phono output stage for much more than that IMO.

BTW for normal listening levels, my volume control is between 11 o'clock (comfortably loud) and say 2:30 (wifey complaining bitterly).

For a standart line stage yes.

Sorry I didn't explain it correct. I mean using a line stage with low gain / buffer stage with gain around 1 or up to 6dB (or a passive unit like a TVC / autoformer).

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II