There's the big clue ... what happened is that the movable contact surfaces inside the pot were refreshed, which made the distortion "go away". I've done this thousands of times with pots, give them a jiggle, to "clean" the critical surfaces, which instantly "fixes" the sound, and then listened to the sound steadily degrade over a period of time. It was good training for my hearing at the time, learning to recognise the signature of a typical pot which is both quality, and time dependent. It's no good trying to get a reading of a pot's distortion if you give it a twiddle to get the right setting immediately prior to taking a reading, you'll get a "perfect" result every time. How it needs to be done is to adjust the pot to some setting, and then run a musical signal through it for some minutes, up to hours depending upon the quality of the unit, then take the distortion reading without physical disturbing the pot in any way. In other words, there's what some might call a memory effect occurring here ...Well, at one point I just said, let's test the JC-2 (we had a Crown IMA and a B&K wave analyzer in our lab). DON'T TOUCH THE SETTINGS. And I hand carried it to the test bench and found LOTS of higher order distortion. Yet, when I moved the pot, one way or another, the distortion dropped to the residual of the equipment.

Frank

That's below the belt JC. You know I'm a real beach bum.I don't need any stinkin' measurements to verify what my ears hear. What test equipment do you use today, kgrlee? Any?

But in da previous millenium, I spent a lot of time doing Double Blind Listening Tests and trying to correlate measurements to these Listening Test results.

I note JC's ears are so sensitive, that he can pronounce on sound quality without even listening to stuff. The price tag and labels on ICs etc are sufficient for JC's Golden er.rh 'Pinnae'.

It's a pity, he won't let such sensitive tools be used as part of a true golden pinnae Listening Panel.

I'm also confused, JC. Are you now spurning Hirata, Quan, 1ppzillion 7th harm distortion tests? I seem to remember you pontificating at length on these tests and dissing some true gurus for not understanding or carrying out these tests.

Are you saying you didn't carry out ANY tests on Blowtorch? Even Hirata, Quan & 7th harm. which you touted ad nauseum as important?

Or is it simply that your test results must NEVER be viewed by us Unwashed Masses who are incapable of interpreting them properly.

Actually its JC who doesn't care about measurements ... even measurements that he's at pains to tell us ad nauseum, are important like Hirata, Quan & even simple THD & 7th harm.

I'm pleased to see that in Jurassic times, JC actually did measure things but this millenium, he's got out of the habit. And when he does measure things, they are certainly not for the consumption of us Unwashed Masses.

Pavel, on the other hand, has posted many measurements to support his views. Maybe, in the next millenium, JC will do likewise.

JC's stance is pretty clear and consistent.

We can agree or disagree with his modus operandi but he is certainly successful in what he does.

I, for one, am not part of his clientèle and will never be, but he (and the HiEnd industry in general) seem to be doing alright and can certainly afford to ignore "technocratic pr1cks" like myself.

Anyway, there are options for everyone and we can all be happy with our gear (or whatever gear is the flavor of the month, for those loyal to the "HiEnd camp").

On the other hand, it's disappointing to see people who are (supposedly) on the "objective camp" and with whom I generally agree, "turning John Curl" on us when certain chords are struck (Class D amps, for example).

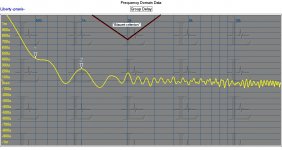

Gpapag, what do you think of this enclosure's group delay:

http://www.moonaudio.fr/Photos%20taille%20affichage/group%20delay.jpg

Christophe

I can only say that it surpasses the “Blauert criterion” for an on axis measurement.

Alas, in my opinion this criterion runs the risk of becoming a new “THD figure” case (for the speaker industry).

My understanding after careful reading Blauert-Laws paper is that there are more than one reason that this criterion –as stems out from that paper- is immature for to be adopted as a well tested GD figure of merit.

The complexity of the subject, the startling differences between theoretical predictions and actual measurements, as well as the painful result discrepancies from using artificial signals and musical signals for evaluating x-overs/speakers, are summarized in this exemplary work, which sites and discusses almost everything that has been tried so far

http://lib.tkk.fi/Dipl/2008/urn011933.pdf

George

Attachments

Last edited:

JC does- not even evaluate PGAs, despite they are cheap and ready to try with few mods:I am sure that a PLENTY of comparative listening tests had been performed ...

eBay | NEW Version LCD PGA2311 Volume Remote Controller + Memory Save and Custom Texts

I ask myself what would be the interest to hire JC's efforts if nothing innovative never comes out. "I use what i know WORKS".

At Least, Mr Pass pretend he has provided his own solution to this interesting volume control question.

One of the solutions i could imagine would be to vary the DC voltages of the power FETS of a class D amp in order to tune the Level. And i have an other one to explore.

John provided a little Polaroid : " It appears that many people do not know how audio designers, like me, do their job."

I'm sorry, but when i was involved with audio design, we where 50% of the time exploring, imagining new solutions, sharing ideas etc. Under the acronym "R&D" is the word "Research".

Last edited:

Notice it is a DIY collaborative project. systme triamplifi miniMaXChristophe

I can only say that it surpasses the “Blauert criterion” for an on axis measurement.

I wonder how much overpriced/poor sounding so calling "high end" loudspeakers (like Wilson Audio ?) could even approch this kind of results.

THIS kind of work *is* audio design, not arguing endless about resistance's sound.

Last edited:

Fas42, while your opinions are useful, it is NOT what I was measuring with the Waters precision pots that were originally the potentiometer in the LMP-2 and JC-2. There were DISTINCT defects in the coating that when the pot was set in a specific position, would add significant distortion. No amount of wiping helped the problem.

ALLEN BRADLEY square bodied pots had a different problem. They produced second harmonic over a wide range of operation. A completely different distortion mechanism.

Now when it comes to R&D: NO, I wrote my papers over 30 years ago. I did my time doing original research. That doesn't mean that I don't have a dozen or more remote controls in my living room, and I suffer through with their sound quality, marginal as it is.

ALLEN BRADLEY square bodied pots had a different problem. They produced second harmonic over a wide range of operation. A completely different distortion mechanism.

Now when it comes to R&D: NO, I wrote my papers over 30 years ago. I did my time doing original research. That doesn't mean that I don't have a dozen or more remote controls in my living room, and I suffer through with their sound quality, marginal as it is.

That's interesting to know. Obviously the quality of manufacture is absolutely crucial to having a pot perform acceptably; every time I've been able to more thoroughly explore the audible behaviour of them I've always heard the characteristic I mentioned above, but none of them would have been of the top quality level you have been exposed to. Are there any papers or other writings which document the sort of behaviours you just mentioned, per brand and model?

Thanks,

Frank

Thanks,

Frank

All the potentiometers, or adjustable resistances, suffer from contact's problem with time (with associated distortion and noise) even with the most prestigious of them (Penny & Gilles). No one wear in a nice way, even if you do not move them. Remember those adjustable in Revox whose cursor fell all alone due to oxidation.

The reason why i'm looking so hard about solid state solutions is the number of bottles of spray cleaner i had emptied in my life followed by a quick replacement..

If i'm satisfied with PGAs or similar, it is because , even if some found marginal losses in sound quality, they are clear winners after little time.

Now, the interesting question remains: how to improve them.

The reason why i'm looking so hard about solid state solutions is the number of bottles of spray cleaner i had emptied in my life followed by a quick replacement..

If i'm satisfied with PGAs or similar, it is because , even if some found marginal losses in sound quality, they are clear winners after little time.

Now, the interesting question remains: how to improve them.

Last edited:

This pot was in a JC-2 preamp a few months old, at best. It was a MANUFACTURING DEFECT and it was UNIVERSIAL with every pot that Mark Levinson and I tested. I didn't have to 'cherry pick' one, I just took one off the assembly line at random and showed the problem to Mark. This potentiometer was the MOST EXPENSIVE pot I had ever been associated with at the time. It cost Mark Levinson $20 for each dual unit in 1973.

Also, I had a lab stock of a number of ALLEN BRADLEY square (not round) pots that I had ordered for this the lab at the time. Virtually all of the Allen Bradley pots of this type suffered a measurable amount of distortion (IM) as well.

Now, what about other pots? Well: Bourns was OK, and looked and seemed physically identical to the AB pots, Clarostat too, etc. Alps, (later) seems OK.

I personally have never found any distortion in a P&G linear throw pot, like we use for studio boards, BUT George Massenburg, who designed with hundreds of them, told me decades ago, that he found that some P&G distorted straight from the factory in certain positions, generally do to poor soldering of the contact points, and that he had to test every one, in advance.

This is not some sort of easily fixable problem, with these specific brands that we found wanting, in every situation. However, loading the WIPER aggravates the problem considerably and is a good way to test for it.

While 'loading the wiper' with a low impedance is usually discouraged, it is sometimes necessary to do a job, such as being a variable load. It is often difficult to 'work around' but it is worth doing so, if possible.

Also, I had a lab stock of a number of ALLEN BRADLEY square (not round) pots that I had ordered for this the lab at the time. Virtually all of the Allen Bradley pots of this type suffered a measurable amount of distortion (IM) as well.

Now, what about other pots? Well: Bourns was OK, and looked and seemed physically identical to the AB pots, Clarostat too, etc. Alps, (later) seems OK.

I personally have never found any distortion in a P&G linear throw pot, like we use for studio boards, BUT George Massenburg, who designed with hundreds of them, told me decades ago, that he found that some P&G distorted straight from the factory in certain positions, generally do to poor soldering of the contact points, and that he had to test every one, in advance.

This is not some sort of easily fixable problem, with these specific brands that we found wanting, in every situation. However, loading the WIPER aggravates the problem considerably and is a good way to test for it.

While 'loading the wiper' with a low impedance is usually discouraged, it is sometimes necessary to do a job, such as being a variable load. It is often difficult to 'work around' but it is worth doing so, if possible.

Noisey Pots/Faders

One of the failure mechanisms that I have encountered in pots and faders is emulsifying/hardening of the contact grease that is applied at factory.

On many a mixing console I have had to remove and dismantle the faders in order to gain access to the carbon tracks and metal tracks and vigorously clean them..

Treatment with contact lubricant spray after reassembly restored correct operation, ditto with rotary pots.

In these cases spraying with various contact cleaner sprays was insufficient to remove the hardened lubricant film causing intermittent/signal variant mis-operation.

I am suspicious that leaky coupling capacitors accelerate the process.

Dan.

One of the failure mechanisms that I have encountered in pots and faders is emulsifying/hardening of the contact grease that is applied at factory.

On many a mixing console I have had to remove and dismantle the faders in order to gain access to the carbon tracks and metal tracks and vigorously clean them..

Treatment with contact lubricant spray after reassembly restored correct operation, ditto with rotary pots.

In these cases spraying with various contact cleaner sprays was insufficient to remove the hardened lubricant film causing intermittent/signal variant mis-operation.

I am suspicious that leaky coupling capacitors accelerate the process.

Dan.

Last edited:

Unfortunately, PMA, many CREATIVE applications with pots require significant loading of the pot wiper. This is what brought Mark Levinson a big problem.

Apparently, Dick Burwen, when helping Mark design the LMP-2, (before my time), he recommended using 100K dual linear pots, loaded with 50K.

This created a good audio type taper, reasonably high input Z, and good tracking between the two pot sections, as linear is easier to control than audio taper.

Looked OK to me, at first, too!

Later, Mark L. had to change to a wirewound that was loaded with a corresponding load, and finally he got P&G to make quality rotary audio taper pots with no significant loading.

Apparently, Dick Burwen, when helping Mark design the LMP-2, (before my time), he recommended using 100K dual linear pots, loaded with 50K.

This created a good audio type taper, reasonably high input Z, and good tracking between the two pot sections, as linear is easier to control than audio taper.

Looked OK to me, at first, too!

Later, Mark L. had to change to a wirewound that was loaded with a corresponding load, and finally he got P&G to make quality rotary audio taper pots with no significant loading.

One of the solutions i could imagine would be to vary the DC voltages of the power FETS of a class D amp in order to tune the Level.

That was essentially the only means for adjusting the gain of wholly open-loop switchmode amps with digital-domain modulators and was extensively investigated many years ago (see the TacT Millennium from 1997 for example). What it did, in a nutshell, was push back the intricacies of the power amp to stringent requirements on the power supply.

One of the failure mechanisms that I have encountered in pots and faders is emulsifying/hardening of the contact grease that is applied at factory.

On many a mixing console I have had to remove and dismantle the faders in order to gain access to the carbon tracks and metal tracks and vigorously clean them..

Treatment with contact lubricant spray after reassembly restored correct operation, ditto with rotary pots.

In these cases spraying with various contact cleaner sprays was insufficient to remove the hardened lubricant film causing intermittent/signal variant mis-operation.

I am suspicious that leaky coupling capacitors accelerate the process.

Dan.

PMA: I have never had any problems with blue Alps's. Even after years of operation. Avoid any dc current through wiper and if possible also across the pot.

Possibly an interesting point, involving coupling caps' leakage. Would parallel caps have more total leakage than a single equivalent value? Could using an equivalent set of series caps have less leakage? Or does the leakage vary with value such that the effects would tend to cancel? (I assume that electrolytics are the type in question.)

Interesting point, Dan. This was NOT the problem that I came across, but it is a failure mechanism.

Interestingly enough, the Mark Levinson problem was aggravated by very tight matching requirement between the two linear pots that lead to a 'single finger' wiper rather than a multiple finger wiper, and then with the very high value and relatively low (1/2 pot value) loading cause BIG and relatively easily audible problems with the Waters (one of the best in the industry at the time) pots.

Interestingly enough, the Mark Levinson problem was aggravated by very tight matching requirement between the two linear pots that lead to a 'single finger' wiper rather than a multiple finger wiper, and then with the very high value and relatively low (1/2 pot value) loading cause BIG and relatively easily audible problems with the Waters (one of the best in the industry at the time) pots.

It seems a bit curious, yes, but it supress a problem: speed. We just have to deal with noise. And the feedback loop continue to help rejecting distortion and PSU ripples with full efficiency.What it did, in a nutshell, was push back the intricacies of the power amp to stringent requirements on the power supply.

I don't have any nutshell, but thought about this since two days.

As i use mainly Digital sources, my next solution for volume control will be exclusively in the digital domain. And i will add a ADC to deal with my analog sources.

JC will kill-me

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II