Thank you bjorno, I really appreciate your input. The thing is, for my use this isn't exactly what I'm looking for. I'm hoping to make the sub as efficient as possible (only because I'd have to start looking for big amps) while still maintaining superior sq compared to a badly done ported sub. The sub you recommended is great for someone who needs a small sub, but that isn't a primary factor for my build.

From what I've stalked around, bjorno, you tend to recommend a t-qwp and I've been playing around with a lot of different drivers. Does the "horn" part reduce subjective sq? I've read that the pre-pulse is more noticable and some other arguments that favor a tapped pipe system, possible with stuffing.

Does the improved SQ come from reducing the taper, with negative taper sounding even better? Obviously this comes at the cost of efficiency, and I've found out that some drivers do better in horns, and some do better in negative-taper enclosures. I might have to abandon the tangband as it really does like it's horn, and when going for a tqwp, the enclosure size and therefore efficiency get really small.

I can buy a cheap driver off a friend that I've been modelling with reasonable power handling and xmax, that seems to like a negative taper with a reasonable efficiency. You guys might be seeing some of that in this thread

Final question, is there any advantage for mass loading a tqwt other than extension, and are the effects detrimental to sq?

So much stuff to learn

From what I've stalked around, bjorno, you tend to recommend a t-qwp and I've been playing around with a lot of different drivers. Does the "horn" part reduce subjective sq? I've read that the pre-pulse is more noticable and some other arguments that favor a tapped pipe system, possible with stuffing.

Does the improved SQ come from reducing the taper, with negative taper sounding even better? Obviously this comes at the cost of efficiency, and I've found out that some drivers do better in horns, and some do better in negative-taper enclosures. I might have to abandon the tangband as it really does like it's horn, and when going for a tqwp, the enclosure size and therefore efficiency get really small.

I can buy a cheap driver off a friend that I've been modelling with reasonable power handling and xmax, that seems to like a negative taper with a reasonable efficiency. You guys might be seeing some of that in this thread

Final question, is there any advantage for mass loading a tqwt other than extension, and are the effects detrimental to sq?

So much stuff to learn

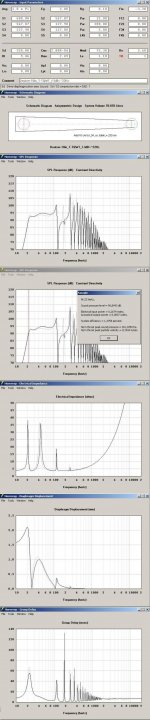

Just reading all around this forum I've learned a lot, and realised that in a TQWT, the special magic is in the box, not the driver. So I simmed a cheap 10" car sub, and wow, does it look nice in hornresp (atleast to me, still learning)

Picture contains some important points that I've been thinking, if something is wrong I'd like to know

TQWT is the way to go (for this driver) and I have to say thank you to everyone on this forum, especially bjorno as his time and effort is spread all around this forum, and his posts are always informative.

If no problems arise I will be building this next weekend, by then I'll have hopefully figured out the folding in sketchup.

An externally hosted image should be here but it was not working when we last tested it.

Picture contains some important points that I've been thinking, if something is wrong I'd like to know

TQWT is the way to go (for this driver) and I have to say thank you to everyone on this forum, especially bjorno as his time and effort is spread all around this forum, and his posts are always informative.

If no problems arise I will be building this next weekend, by then I'll have hopefully figured out the folding in sketchup.

Just reading all around this forum I've learned a lot, and realised that in a TQWT, the special magic is in the box, not the driver. So I simmed a cheap 10" car sub, and wow, does it look nice in hornresp (atleast to me, still learning)

An externally hosted image should be here but it was not working when we last tested it.

Picture contains some important points that I've been thinking, if something is wrong I'd like to know

TQWT is the way to go (for this driver) and I have to say thank you to everyone on this forum, especially bjorno as his time and effort is spread all around this forum, and his posts are always informative.

If no problems arise I will be building this next weekend, by then I'll have hopefully figured out the folding in sketchup.

Hi Skiivari,

Good work!

Despite the very high Qts value for a T-TQWT to start with I think if you stuff your box a little denser at the rear side of the cone(acoustical mass loading that shifts Qm down) the effective Qts would lower a bit and the inband FR would show up smoother.

Take a look at my simulation compared with your:The light grey color:

b

Ps: Keep L34 ~5 cm but in the reality: Add 10 cm to the simulated picture

Attachments

Hi there B: Re post 3823, I've been wondering if a short L34 (like 5cm in your example with the driver partially exposed) is viable? Your comment is to extend L34 by 10cm (total 15cm) really blows-up the simulation. I gather that you have built some of these within the numerous builds you have done and have found this technque to be workable (?). Necking down the terminus ahead of the exit seems to have dramatic results. Is there some rule for minimum size termimus exit? I've been reluctant to build one of these, and pump 100+- watts through such a small opening (?). regards, Michael

..Hi there B: Re post 3823, I've been wondering if a short L34 (like 5cm in your example with the driver partially exposed) is viable? Your comment is to extend L34 by 10cm (total 15cm) really blows-up the simulation...

Hi Michael,

Actually the internal length is not shortened but instead increased a bit(10 cm while(then) the original S4 is closed and replaced with a new terminus(Mass loading Port) that should be placed .at ~ 5 cm from the center of the driver front.

If you divide the area at that point with the driver frame width you will find a number must be close to 5 cm.This new location is then checked to be a good choise using one of MJK: programs

I gather that you have built some of these within the numerous builds you have done and have found this technque to be workable (?). Necking down the terminus ahead of the exit seems to have dramatic results. Is there some rule for minimum size termimus exit?

I've built quite a few..My fingers and toes is not enough to keep track of all..

I usually try to pick a terminus(Port) area larger or equal to Driver Sd/3: This works fine with most large excursion Drivers I prefer (xmax< ~ 20 mm though)

I've been reluctant to build one of these, and pump 100+- watts through such a small opening (?). regards, Michael

You shouldn't worry If you use a good driver. IMO,IME an Alu coned Driver is the best choise for an internally high pressurised T-TQWT/T-QWP.. and if the pressure is lower than 5000 Pascal's: The subs show no auible (IME) difference in SQ at low or at high SPL's (Of cource when working below x-max at any time).

b

Ps Sorry for my language, My spell checker doesn't worK despite reloading the proper plugins many times...

Hi there B: Re post 3825: Thank you for the information, and especially the explanation of exit port for TQ and TH enclosures, I never could find that in HR. I marvel at the community members able to communicate in many languages. I'm constrained to English and not very good at that. By the way, I hve trouble reading charts and graphs posted in multiples. When I blow them-up with the windows +150 or so, my screen resolution gets so bad that I can not read the numbers and text. Is there a trick or do I need a different computer with a better screen? ....regards, Michael

By the way, I have trouble reading charts and graphs posted in multiples. When I blow them-up with the windows +150 or so, my screen resolution gets so bad that I can not read the numbers and text. Is there a trick or do I need a different computer with a better screen?

Hi Michael,

1. Click anywhere on the composite picture to cause an initial expansion.

2. Move your mousepointer to the bottom left-hand corner of the expanded picture.

3. Click on the "four arrows" icon.

Kind regards,

David

I don't understand this description.Actually the internal length is not shortened but instead increased a bit(10 cm while(then) the original S4 is closed and replaced with a new terminus(Mass loading Port) that should be placed .at ~ 5 cm from the center of the driver front.

If you divide the area at that point with the driver frame width you will find a number must be close to 5 cm.This new location is then checked to be a good choise using one of MJK: programs

Can it be explained in a different way for me?

resolution

Hi there DB: Fantastic, many thanks....regards, Michael

Hi Michael,1. Click anywhere on the composite picture to cause an initial expansion.2. Move your mousepointer to the bottom left-hand corner of the expanded picture.3. Click on the "four arrows" icon.Kind regards,David

Hi there DB: Fantastic, many thanks....regards, Michael

Hi guys. I'm a bit tired now that I have had the wood cut, and I have a few questions

I chose 12mm BB ply for this project, 15mm for the middle baffle. Only one of my 400mm clamps has the needed 412mm range for gluing the rear panel on.. I have now been thinking if screws are the way to go for this build. I was thinking of using some screws with a flat head and maybe even a washer so that I could remove them later once the glue had set. The holes wouldn't hopefully destroy the nice-looking ply and there wouldn't be anything sticking out (visually).

I'll be mounting the driver with M6 T-nuts. I have no idea how to stuff the line, I'll probably go with what bjorno said, a bit more stuffing behind the driver, but should I damp the whole line or just the rear portion? I'll be using polyfill and obviously I get to decide but pointers from more experienced members would be nice

One thing I'm worried about is with the line width being 40cm the "height" of the line in front of the driver is only 3.5 cm, and the surround of the driver protrudes about 2cm.. It still has room on top and on the bottom of the driver and hornresp doesn't show major changes, at most lowering the tuning and efficiency a little.

I'll show you some pics at some point but later asI'm pretty sure its obvious from the integrity of the text that I am very tired (I only had to have the plywood cut THREE times.. protip: NEVER give dimensions over the phone.)

(I only had to have the plywood cut THREE times.. protip: NEVER give dimensions over the phone.)

I chose 12mm BB ply for this project, 15mm for the middle baffle. Only one of my 400mm clamps has the needed 412mm range for gluing the rear panel on.. I have now been thinking if screws are the way to go for this build. I was thinking of using some screws with a flat head and maybe even a washer so that I could remove them later once the glue had set. The holes wouldn't hopefully destroy the nice-looking ply and there wouldn't be anything sticking out (visually).

I'll be mounting the driver with M6 T-nuts. I have no idea how to stuff the line, I'll probably go with what bjorno said, a bit more stuffing behind the driver, but should I damp the whole line or just the rear portion? I'll be using polyfill and obviously I get to decide but pointers from more experienced members would be nice

One thing I'm worried about is with the line width being 40cm the "height" of the line in front of the driver is only 3.5 cm, and the surround of the driver protrudes about 2cm.. It still has room on top and on the bottom of the driver and hornresp doesn't show major changes, at most lowering the tuning and efficiency a little.

I'll show you some pics at some point but later asI'm pretty sure its obvious from the integrity of the text that I am very tired

Hi guys. I'm a bit tired now that I have had the wood cut, and I have a few questions

I chose 12mm BB ply for this project, 15mm for the middle baffle. Only one of my 400mm clamps has the needed 412mm range for gluing the rear panel on.. I have now been thinking if screws are the way to go for this build. I was thinking of using some screws with a flat head and maybe even a washer so that I could remove them later once the glue had set. The holes wouldn't hopefully destroy the nice-looking ply and there wouldn't be anything sticking out (visually).

I'll be mounting the driver with M6 T-nuts. I have no idea how to stuff the line, I'll probably go with what bjorno said, a bit more stuffing behind the driver, but should I damp the whole line or just the rear portion? I'll be using polyfill and obviously I get to decide but pointers from more experienced members would be nice

One thing I'm worried about is with the line width being 40cm the "height" of the line in front of the driver is only 3.5 cm, and the surround of the driver protrudes about 2cm.. It still has room on top and on the bottom of the driver and hornresp doesn't show major changes, at most lowering the tuning and efficiency a little.

I'll show you some pics at some point but later asI'm pretty sure its obvious from the integrity of the text that I am very tired(I only had to have the plywood cut THREE times.. protip: NEVER give dimensions over the phone.)

When I did mine, I used glue and countersunk 2" screws all the way around it. If you're looking to keep the wood nice, you might be able to put a little wood filler in the screw holes and sand it down. As far as getting a little more breathing room for the surround on the driver if it's that tight might be to countersink the driver, or even back-mount-countersink, if that makes any sense.

As far as stuffing goes, I also took B's advice and stuffed the rear chamber behind the driver with 2 layers of thick insulation, going down to one layer about halfway up the back and slowly tapered it off, stopping at the top fold.

Waddya mean "insulation"?

The fibre stuff to keep you or your house warm.

Makes good damping material in a speaker.

Long fibre wool, BAF wadding, etc.

Yeah, this was some new stuff I got from Lowes. I don't remember exactly what it was called, but it resembled the itchy fiberglass on a roll (no backing), however this stuff didn't seem to itch and didn't shed much when cut with scissors. It was pretty cheap too, I think I got 4 rolls which amounted to about 20 feet of material 14 inches wide and 3 inches thick for around 25 dollars.

Yeah, this was some new stuff I got from Lowes. I don't remember exactly what it was called, but it resembled the itchy fiberglass on a roll (no backing), however this stuff didn't seem to itch and didn't shed much when cut with scissors. It was pretty cheap too, I think I got 4 rolls which amounted to about 20 feet of material 14 inches wide and 3 inches thick for around 25 dollars.

That sounds dangerous

That sounds dangerous

Nah, it wasn't bad at all. I still have some spare here, I can roll it up by hand and it doesn't leave particles or itch if you handle it gently.

Attachments

Your right it's not, and I misspoke, it's not cancer but fibrosis. The difference with asbestos is that it is also cancer causing. My point in short is: putting that crap in the air is bad for your lungs.

Well, I suppose you'd be pleased to know that the TH's I'm listening to now don't have any damping material in them at all.

My whiskey and cigarette habit will probably kill me long before airborne particles, anyway. You only live once!

- Home

- Loudspeakers

- Subwoofers

- Collaborative Tapped horn project