Dave (planet10) has often commented on the benefits of mounting drivers on opposing sides of a box to cancel mechanical vibration transfer to the box. I was skeptical until I tried it.

For space reasons I decided to take my two AV12s out of their individual 70L sealed boxes and put them in one 70L box. My simulations told me I wouldn't need more power than I have to reach their full potential, but I would need a lot more gain on the crossover. I modified the xo to get more gain, and have them push pull mounted. One driver on the front, one driver on the back with the magnet out and polarity of wiring reversed.

I noticed by accident that their back to back mounting reduced vibration. I was surprised at how little vibration there was, so I turned one driver off and the vibration increased! The box is still an ugly crappy box, but by using this mounting method, it's actually quite acceptable.

Still, I'd say the improvement of push pull mounting does more to improve the sound.

For those who are confused ...

* back to back mounting cancels vibration transferred to the box from the drivers - I'm not quite sure how it works, but I know it does

* push pull mounting means one driver has the VC moving towards the magnet, while the other is moving out, yet both cones are moving out into the room together so that their combined acoustic output will increase, and they won't cancel each other - this reduces distortion and subjectively sounds a little tighter

Still, why choose one or the other, why not do both?

If you are considering multiple driver setups, I suggest you consider these options as well as individual subs in different locations. Of coruse, there is no one size fits all solution. But if you are choosing on the basis of performance alone, two drivers back to back and push pull will beat two in separate adjacent boxes without push pull. It won't be a huge difference, but its enough to notice even without an instant AB comparison.

Any others try any of the above and have comments to share on their experience?

For space reasons I decided to take my two AV12s out of their individual 70L sealed boxes and put them in one 70L box. My simulations told me I wouldn't need more power than I have to reach their full potential, but I would need a lot more gain on the crossover. I modified the xo to get more gain, and have them push pull mounted. One driver on the front, one driver on the back with the magnet out and polarity of wiring reversed.

I noticed by accident that their back to back mounting reduced vibration. I was surprised at how little vibration there was, so I turned one driver off and the vibration increased! The box is still an ugly crappy box, but by using this mounting method, it's actually quite acceptable.

Still, I'd say the improvement of push pull mounting does more to improve the sound.

For those who are confused ...

* back to back mounting cancels vibration transferred to the box from the drivers - I'm not quite sure how it works, but I know it does

* push pull mounting means one driver has the VC moving towards the magnet, while the other is moving out, yet both cones are moving out into the room together so that their combined acoustic output will increase, and they won't cancel each other - this reduces distortion and subjectively sounds a little tighter

Still, why choose one or the other, why not do both?

If you are considering multiple driver setups, I suggest you consider these options as well as individual subs in different locations. Of coruse, there is no one size fits all solution. But if you are choosing on the basis of performance alone, two drivers back to back and push pull will beat two in separate adjacent boxes without push pull. It won't be a huge difference, but its enough to notice even without an instant AB comparison.

Any others try any of the above and have comments to share on their experience?

It really isn't the "vibration" that is transfered that has changed the percieved sound but rather it is the non-linearities that are reduced.

"The result is that asymmetric nonlinearities, such as those caused by a single voice coil moving through a magnetic field of uneven strength or nonlinearities due to suspension system irregularities, are eliminated". Advanced speaker systems,(Ray Alden)Master Publishing Inc. 1995.

If indeed it was vibrational coupling into the enclosure itself I would say you have some serious structural problems. More so, the theory doesn't hold water as one would be increasing the mass in motion by two times which would incite an enclosure vibration even more as opposed to just one driver.

___________________________________Rick..........

"The result is that asymmetric nonlinearities, such as those caused by a single voice coil moving through a magnetic field of uneven strength or nonlinearities due to suspension system irregularities, are eliminated". Advanced speaker systems,(Ray Alden)Master Publishing Inc. 1995.

If indeed it was vibrational coupling into the enclosure itself I would say you have some serious structural problems. More so, the theory doesn't hold water as one would be increasing the mass in motion by two times which would incite an enclosure vibration even more as opposed to just one driver.

___________________________________Rick..........

Rick, there are two separate things going on here, and it seems to me you have them mixed up.

The quote you mentioned seems to be referring to push pull which reduces distortion.

What I was referring to mostly with this post is back to back mounting where two drivers are mounted on opposite sides of the box.

I challenge you to try it. Put two drivers in a box in this way and compare the vibration on the box with two vs one driver operating. You will find with two there is actually less vibration of the box - obviously the forces working in opposition are having some kind of cancellation effect. Otherwise you would expect the two drivers to cause more vibration than one.

Consider also in this example, that when you turn off one driver, it becomes like a passive radiator that is tuned too high. This will have some effect on the results. I'd expect that this would in fact make the advantage of back to back driver mounting appear less effective than it actually is.

"If indeed it was vibrational coupling into the enclosure itself I would say you have some serious structural problems."

There are no serious structural problems here. It's a simple sealed box with two drivers mounted on opposite sides - not as solid as it could be but good enough.

"More so, the theory doesn't hold water as one would be increasing the mass in motion by two times which would incite an enclosure vibration even more as opposed to just one driver."

What theory exactly?

You must not only consider the mass, but what that mass is doing. Put two drivers on one baffle and this may be significant. Put them back to back and the entire moving mass of each cone will have a net force of zero in all directions.

Consider

F = ma

The mass of the two cones is moving in opposite directions, hence their effect will be cancelled. As a result, with this back to back arrangement moving mass becomes irrelevant.

The quote you mentioned seems to be referring to push pull which reduces distortion.

What I was referring to mostly with this post is back to back mounting where two drivers are mounted on opposite sides of the box.

I challenge you to try it. Put two drivers in a box in this way and compare the vibration on the box with two vs one driver operating. You will find with two there is actually less vibration of the box - obviously the forces working in opposition are having some kind of cancellation effect. Otherwise you would expect the two drivers to cause more vibration than one.

Consider also in this example, that when you turn off one driver, it becomes like a passive radiator that is tuned too high. This will have some effect on the results. I'd expect that this would in fact make the advantage of back to back driver mounting appear less effective than it actually is.

"If indeed it was vibrational coupling into the enclosure itself I would say you have some serious structural problems."

There are no serious structural problems here. It's a simple sealed box with two drivers mounted on opposite sides - not as solid as it could be but good enough.

"More so, the theory doesn't hold water as one would be increasing the mass in motion by two times which would incite an enclosure vibration even more as opposed to just one driver."

What theory exactly?

You must not only consider the mass, but what that mass is doing. Put two drivers on one baffle and this may be significant. Put them back to back and the entire moving mass of each cone will have a net force of zero in all directions.

Consider

F = ma

The mass of the two cones is moving in opposite directions, hence their effect will be cancelled. As a result, with this back to back arrangement moving mass becomes irrelevant.

Paul,

You could of course try it with both woofers mounted with magnets inside the box and rig a solid coupling/structure between the two. I've seen this done many times through the years. This should improve the "vibration" situation a bit more but, of course, you wouldn't have the even-order distortion reduction that you would with the second driver mounted reversed.

Cheers,

Davey.

You could of course try it with both woofers mounted with magnets inside the box and rig a solid coupling/structure between the two. I've seen this done many times through the years. This should improve the "vibration" situation a bit more but, of course, you wouldn't have the even-order distortion reduction that you would with the second driver mounted reversed.

Cheers,

Davey.

Davey, yep, I could but I doubt I could hear the difference. With back to back mounting, the vibration isn't enough to warrant any extra attention. I'd have to give up push pull for this option, which I know does make a difference. When the drivers are mounted one driver to a box, the vibation is enough to warrant a more solid box.

I'm living with a fairly temporary sub box because my living arrangement is temporary. When I move out, I'll either build my huge 20 Hz bass horn or a large/tall corner vented sub with drivers both back to back and push pull configured.

If I do the bass horn, the tricky decision will be if to employ push pull. The problem with this is that the magnet may force either a larger than optimal throat, or an extra throat chamber which may create more problems than it solves. I see the sense in an arrangement like the Lab horn in dealing with vibration, since it allows the horn to be ok with 18mm walls of a size that would not normally be acceptable.

It is probably ok for 2 reasons:

* driver cones operating in opposing directions

* for a given output, excursion is much lower

I'm living with a fairly temporary sub box because my living arrangement is temporary. When I move out, I'll either build my huge 20 Hz bass horn or a large/tall corner vented sub with drivers both back to back and push pull configured.

If I do the bass horn, the tricky decision will be if to employ push pull. The problem with this is that the magnet may force either a larger than optimal throat, or an extra throat chamber which may create more problems than it solves. I see the sense in an arrangement like the Lab horn in dealing with vibration, since it allows the horn to be ok with 18mm walls of a size that would not normally be acceptable.

It is probably ok for 2 reasons:

* driver cones operating in opposing directions

* for a given output, excursion is much lower

Boo Boo

My bad....yeah, understand now & yes the two moving opposite directions will cancel out each other....how did you arrive at an ideal box shape for the two opposing drivers?

There has to be some math formulas for the two driver wavefronts traveling toward each other inside the box....Lotsa damping material, perhaps a slight offsetting of the drivers so the wavefront is skewed somewhat.

Just some ramblings.............sorry again........

_____________________________________Rick...........

My bad....yeah, understand now & yes the two moving opposite directions will cancel out each other....how did you arrive at an ideal box shape for the two opposing drivers?

There has to be some math formulas for the two driver wavefronts traveling toward each other inside the box....Lotsa damping material, perhaps a slight offsetting of the drivers so the wavefront is skewed somewhat.

Just some ramblings.............sorry again........

_____________________________________Rick...........

Rick ... ideal box shape? You might laugh if you saw the box! (It's about as ugly as they come) The box is about 320 x 320 x 900mm. The shape has a lot to do with the size of MDF I had available at the time, and that I didn't want a big footprint. The magnet sticking out the back is a pest.

No formulas needed here really. Have you ever done those highly sophisticated wave modelling techniques like you use in high school physics classes? You get one of those slinky things (like a long spring - a kids toy but quite useful for this). You make a wave that moves along it. You make one at each end made by a person holding each end. When the two opposing waves pass each other, they will either "vanish" when they pass for a moment, or become bigger, depending on if they are - and - or + and + or + and -.

Basically the waves will increase in amplitude. You will only get cancellation where one driver has its polarity reversed so that what you then have is a dipole with no net displacement.

Also we are talking about a small box where sound waves uniformly pressurise the box. Sound waves in this bandwidth don't travel as rays. Standing waves don't really get a chance to form either. Most of the output is below 60 Hz.

So in effect, while vibration appears to be reduced by some means of cancellation, I don't see how this can occur as far as box pressurisation occurs. The pressure changes would be doubled, placing additional stress on the box. This is why more power is needed to drive this sub. I had to modify my crossover to give more gain, because I was maxing out the volume control and still not getting enough.

What I don't yet understand is why back to back mounting reduces vibration. To my mind it should not make a difference.

When I was breaking in my drivers with the cones moving nearly 2" p-p, I put them on a H frame open baffle with 15 Hz tones to keep it quiet. They made the frame shake and vibrate quite a lot. I reversed polarity on them so that the cones were moving in opposite directions, hence no net force operating in any direction. This made it quieter and the thing didn't move as much. There was just the sound of air moving through the pole vent.

I suppose you could think of it this way. Think of this. You have a big thick sheet of wood fastened to the ground with one man on each side with a hammer. If they both hit the panel in the same spot, at the same time, it won't vibrate much at all. If they hit it at different times, it will vibrate a lot. When their hammers hit the same spot at the same time, the force is transferred directly through and the hammer of each takes a lot of the blow. The wood panel merely is compressed that that point, and won't flex. When they hit at different times, the panel will flex and vibrate a lot. Still, this is not the same as a speaker box.

I wonder if anyone else can come up with a good explanation of what really happens.

No formulas needed here really. Have you ever done those highly sophisticated wave modelling techniques like you use in high school physics classes? You get one of those slinky things (like a long spring - a kids toy but quite useful for this). You make a wave that moves along it. You make one at each end made by a person holding each end. When the two opposing waves pass each other, they will either "vanish" when they pass for a moment, or become bigger, depending on if they are - and - or + and + or + and -.

Basically the waves will increase in amplitude. You will only get cancellation where one driver has its polarity reversed so that what you then have is a dipole with no net displacement.

Also we are talking about a small box where sound waves uniformly pressurise the box. Sound waves in this bandwidth don't travel as rays. Standing waves don't really get a chance to form either. Most of the output is below 60 Hz.

So in effect, while vibration appears to be reduced by some means of cancellation, I don't see how this can occur as far as box pressurisation occurs. The pressure changes would be doubled, placing additional stress on the box. This is why more power is needed to drive this sub. I had to modify my crossover to give more gain, because I was maxing out the volume control and still not getting enough.

What I don't yet understand is why back to back mounting reduces vibration. To my mind it should not make a difference.

When I was breaking in my drivers with the cones moving nearly 2" p-p, I put them on a H frame open baffle with 15 Hz tones to keep it quiet. They made the frame shake and vibrate quite a lot. I reversed polarity on them so that the cones were moving in opposite directions, hence no net force operating in any direction. This made it quieter and the thing didn't move as much. There was just the sound of air moving through the pole vent.

I suppose you could think of it this way. Think of this. You have a big thick sheet of wood fastened to the ground with one man on each side with a hammer. If they both hit the panel in the same spot, at the same time, it won't vibrate much at all. If they hit it at different times, it will vibrate a lot. When their hammers hit the same spot at the same time, the force is transferred directly through and the hammer of each takes a lot of the blow. The wood panel merely is compressed that that point, and won't flex. When they hit at different times, the panel will flex and vibrate a lot. Still, this is not the same as a speaker box.

I wonder if anyone else can come up with a good explanation of what really happens.

Can't using Newton's Second Law, and treating the box as one point object explain this:

"The rate of change of the momentum of a body is directly proportional to the net force acting on it, and the direction of the change in momentum takes place in the direction of the net force. "

If i am reading you correctly and vibration is reduced when you have a driver on either side of the enclosure, the fact that the cones are moving in opposite directions means the net force is zero. The fact that it takes time for the force to travel through the enclosure probably accounts for the reduced, but not zero force. Anyway, thats my guess

"The rate of change of the momentum of a body is directly proportional to the net force acting on it, and the direction of the change in momentum takes place in the direction of the net force. "

If i am reading you correctly and vibration is reduced when you have a driver on either side of the enclosure, the fact that the cones are moving in opposite directions means the net force is zero. The fact that it takes time for the force to travel through the enclosure probably accounts for the reduced, but not zero force. Anyway, thats my guess

Noodle, I look at your post and my head is whizzing around in circles thinking about it!

My brain needs to break things down and think in more concrete terms.

Ok so each cone is moving out. Since they are back to back the net forces cancel since they are in opposite directions. Look at each individual driver and consider that the forces much equal:

moving mass (driver) x A = mass of box x A where a is acceleration

Because the box is much heavier than the mms (driver moving mass), it will not move much. Inertia comes into play here because, even at 20 Hz the cone will have moved in the opposite direction to its resting position within 1/40th of a second. In this time the box will not have had much chance to move.

Now where you have two drivers back to back, those forces that might cause the box to move just slightly are now cancelled. This, however, is not what causes box vibration that you would feel. I think what is happening here is that the vibration forces transferred are working in opposition, so its like clamping them together. Arrrrgh ... not sure if that is right!

My brain needs to break things down and think in more concrete terms.

Ok so each cone is moving out. Since they are back to back the net forces cancel since they are in opposite directions. Look at each individual driver and consider that the forces much equal:

moving mass (driver) x A = mass of box x A where a is acceleration

Because the box is much heavier than the mms (driver moving mass), it will not move much. Inertia comes into play here because, even at 20 Hz the cone will have moved in the opposite direction to its resting position within 1/40th of a second. In this time the box will not have had much chance to move.

Now where you have two drivers back to back, those forces that might cause the box to move just slightly are now cancelled. This, however, is not what causes box vibration that you would feel. I think what is happening here is that the vibration forces transferred are working in opposition, so its like clamping them together. Arrrrgh ... not sure if that is right!

IMHO we are not just talking about the Mms of the cone, it is coupled to the air its pushing against and this is much more significant than the cone alone, try holding a driver by the frame while its playing 20Hz at reasonable excrsion and feel how much force the drivers is making that the box is expected to absorb. Modern drivers have very good linear motors and the argument for clamshell mounting of pairs of drivers in a push-pull pair to reduce non-linearities is MUCH less of an issue than it used to be, where as high excursion designs mean the reaction force from the cone moving is much more than it used to be. Cast chassis/baskets on drivers are very rigid. try putting metal tube spacers between the two driver frames (ths assumes the drivers are mounted on exactly opposite sides of the box) and using threaded rod and nuts to bolth the driver frames together and putting the tubes under compression, the rod under tension and solidly coupling the drivers together. The reaction force from the drivers should now cancel each other out and your box should only have to deal with the pressure difference of the subs excursion, not having to absorb the reaction force of the sub moving.

you could also couple the drivers together with the tube/rods and without the box, try them both in and out of phase to feel the difference in vibration that is being canceled.

you could also couple the drivers together with the tube/rods and without the box, try them both in and out of phase to feel the difference in vibration that is being canceled.

Is this the design you are mentioning?

http://homepage.mac.com/tlinespeakers/FAL/box-plans/ApexJr-Super8-PP-BR-map.gif

I'm a newbie here looking for a moderate costing design and this one looks interesting. I wonder if it fits my needs?

http://homepage.mac.com/tlinespeakers/FAL/box-plans/ApexJr-Super8-PP-BR-map.gif

I'm a newbie here looking for a moderate costing design and this one looks interesting. I wonder if it fits my needs?

That design shows back to back mounting but not push pull. If it were push pull, one of the magnets would be facing out and the polarity of wiring on that driver would be reversed.

The output of that design is probably roughly equivalent of a single vented 12" driver of similar excursion. If you can get the drivers cheap at your location, then it could be a good cost effective sub.

I'd expect better performance by push pull mounting, effectively achieving the same result as a shorting ring, which is included in more expensive drivers of better quality. Push pull gives you that effect for free. You can get the vibration reduction with push pull as well, although not as effectively.

I'd consider a single larger driver in a vented box if you want maximum bang for buck on a budget.

Also consider that larger woofers, say 10 or 12" with say 9mm xmax in a vented box can still get some decent output, although you typically give up 20 Hz extension, you can normally get down to 25 Hz.

Back to that design, I would say it is a competent design, but I would do it differently, but that comes down to differing priorities I would place in designing a subwoofer.

The output of that design is probably roughly equivalent of a single vented 12" driver of similar excursion. If you can get the drivers cheap at your location, then it could be a good cost effective sub.

I'd expect better performance by push pull mounting, effectively achieving the same result as a shorting ring, which is included in more expensive drivers of better quality. Push pull gives you that effect for free. You can get the vibration reduction with push pull as well, although not as effectively.

I'd consider a single larger driver in a vented box if you want maximum bang for buck on a budget.

Also consider that larger woofers, say 10 or 12" with say 9mm xmax in a vented box can still get some decent output, although you typically give up 20 Hz extension, you can normally get down to 25 Hz.

Back to that design, I would say it is a competent design, but I would do it differently, but that comes down to differing priorities I would place in designing a subwoofer.

I've owned a number of motorcycles over the years. My favorite all around was my BMW R65 650cc "boxer". As every bike has it's quirks, this had a few. But with its opposed cylinders there are areas in the rpm range where the engine pretty much disappears beneath you - it's almost magical. Frustratingly, there always seems to be one or two areas in the rpm range where vibration is impossible to "iron out". But it's really only by comparison to the otherwise glassy smoothness. The trick ends up requiring jetting and timing adjustments to get the smoothest running in the range you spend the most time in. Boy is it worth it.

Bluebeard, I didn't imagine bikes coming into the discussion, but interesting nonetheless. Why is it that vibration is different at different rpm?

I was just cranking up Jamiroquai as it has some potent bass. I had drivers at about 1" p-p, which is quite a lot for 40 - 60 Hz bass. I measured close to 120 db nearfield, about 110 db @ 1m and 101 db @ listening position 3m away. As a sidenote, I wondered for a while if subwoofers conform to the 6db attenuation per double distance. In this case it worked exactly.

Now with back to back mounting, I find this crappy box is sufficient, even with almost no bracing. Even at high excursion, the box isn't vibrating much, but the room is another story. It complains loudly. Some parts of the room enclosure vibrate more than the box.

I was just cranking up Jamiroquai as it has some potent bass. I had drivers at about 1" p-p, which is quite a lot for 40 - 60 Hz bass. I measured close to 120 db nearfield, about 110 db @ 1m and 101 db @ listening position 3m away. As a sidenote, I wondered for a while if subwoofers conform to the 6db attenuation per double distance. In this case it worked exactly.

Now with back to back mounting, I find this crappy box is sufficient, even with almost no bracing. Even at high excursion, the box isn't vibrating much, but the room is another story. It complains loudly. Some parts of the room enclosure vibrate more than the box.

paulspencer said:Why is it that vibration is different at different rpm?

I would imagine the exhaust is acting like a transmission line and the vibration is the engine reacting to the extra (or lack of) back pressure as the line hits tuning along different areas of the rev range.

But anyway I can attest to the effectiveness of dual driver vibration canellation, I've used it in a few setups with good results.

Hello,

I'm not sure why this is such a hard concept to understand. The sum of all forces (as vectors) of the system is 0. The system is in a state of equilibrium and thus no net force = no net acceleration.

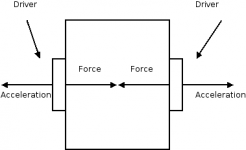

See diagram below.

As puggie mentioned, the mass that is accelerating is not only the driver, but the air itself, which should contribute significantly to box vibration if there is no vibration cancellation incorporated into the design.

The reason the motorcycle vibrates at certain rpms is the same reason drivers have the most displacement at their Fs (for a given amount of energy): Reasonance. Just as buildings move the most at different frequencies, so do engines. Strings of a piano also provide a good example.

Push-pull mounting, if the drivers are on opposite sides of the box, should give similar cancellation results to back to back designs. Back to back designs, however, still provide the best form of vibration reduction without increasing the mass of the box.

I'm not sure why this is such a hard concept to understand. The sum of all forces (as vectors) of the system is 0. The system is in a state of equilibrium and thus no net force = no net acceleration.

See diagram below.

As puggie mentioned, the mass that is accelerating is not only the driver, but the air itself, which should contribute significantly to box vibration if there is no vibration cancellation incorporated into the design.

The reason the motorcycle vibrates at certain rpms is the same reason drivers have the most displacement at their Fs (for a given amount of energy): Reasonance. Just as buildings move the most at different frequencies, so do engines. Strings of a piano also provide a good example.

Push-pull mounting, if the drivers are on opposite sides of the box, should give similar cancellation results to back to back designs. Back to back designs, however, still provide the best form of vibration reduction without increasing the mass of the box.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- dual driver vibration cancellation really does work!