Im planning on making 6" Flared ports. My question is what is an optimal curve for air flowing at a maximum of 80ft/sec. Im not looking for quiet ports, im looking for maximum efficency. I would assume a parobalic curve. My Plans are to heat PVC up in oil then push it over a mold of clay with the aid of a scafold type frame around it, controlled weights, and a heat gun.

I figured this would be the best place to ask this kind of question.

If you are thinking "80ft/sec, that is fast" this is an SPL install, im doing dual 6" ports on a frainken incriminator audio death penulty that i am building from an elemental designs e12a's TC9.

I have a goal of 147dB on term lab if you are wondering. I will be compeating dB Drag Street B.

I figured this would be the best place to ask this kind of question.

If you are thinking "80ft/sec, that is fast" this is an SPL install, im doing dual 6" ports on a frainken incriminator audio death penulty that i am building from an elemental designs e12a's TC9.

I have a goal of 147dB on term lab if you are wondering. I will be compeating dB Drag Street B.

My Plans are to heat PVC up in oil then push it over a mold of clay with the aid of a scafold type frame around it, controlled weights, and a heat gun.

This sounds like an uncontrollable mess, I seem to remember pvc getting stringy when melted. Also, once you have a clay mold you can simply lay fiberglass or carbon fiber around it.

You might be interested in the work I've done on flared ports.

I only used a circular profile for the flares, but the writeup on using a heat gun over a mold could be useful, as could the test results.

Follow the links at

http://www.users.bigpond.com/bcolliso/port-flares.htm

For 6 inch PVC pipe I found that 30mm flare radius was the best I could obtain before splitting became a problem. Here's a photo of it....

I only used a circular profile for the flares, but the writeup on using a heat gun over a mold could be useful, as could the test results.

Follow the links at

http://www.users.bigpond.com/bcolliso/port-flares.htm

For 6 inch PVC pipe I found that 30mm flare radius was the best I could obtain before splitting became a problem. Here's a photo of it....

Attachments

Very informative link.

Molding PVC is actually not a hard process if you take your time, and i want to use PVC becase then I can use PVC fittings and ends and lots of duct tape so when tuning for SPL I can swap port tuning frequincies with ease.

Fiberglass would probably cause problems, i would do that IF it where a fixed port. But I have some-what unlimited acess to a Term Lab pressure sensor so i can do a sweep, change the port and let the coils cool, then do anotehr sweep.

I could also make the fiberglass ends work with the PVC but it would be so expensive i may as well use PVC.

Molding PVC is actually not a hard process if you take your time, and i want to use PVC becase then I can use PVC fittings and ends and lots of duct tape so when tuning for SPL I can swap port tuning frequincies with ease.

Fiberglass would probably cause problems, i would do that IF it where a fixed port. But I have some-what unlimited acess to a Term Lab pressure sensor so i can do a sweep, change the port and let the coils cool, then do anotehr sweep.

I could also make the fiberglass ends work with the PVC but it would be so expensive i may as well use PVC.

Have a look at these by Guillaume Pellerin, Jean-Dominique Polack and Jean-Pierre Morkerken, from the 112th AES (Munich - 2002) and 116th AES (Berlin - 2004):

http://www.haliaetus.com/AES_112th.pdf

http://www.haliaetus.com/AES_116th.pdf

http://www.haliaetus.com/AES_112th.pdf

http://www.haliaetus.com/AES_116th.pdf

Sure do wish i understoo the advanced college calculus though...i got the gist...i just dont get all the equasions. which is ultamitly all i need. Ill probably save thoes to my computer and give my self a crash course in advanced calculus over the next few weeks to see if i can better understand it.

Or, go down to your local model rocket hobby store, take measurements (carefully) and expand them to your requirements. You'd have to a bit of experimenting with regard port length, but thats what plumbing supply stores are for. You'll probably find it's the same deal as flared ports - your 'flare' adds a specific length to the lenght of the port and calculations can be done via Unibox or WindISD after that.

I don't live in spaces big enough to need ports on my subby. I just use cone area and a bit of oomph and room gain does the rest.

Correct, for your needs (dB Dragging) you'll probably need optimisation. But the actual length and volume should be able to be determined on length and volume of the port. The shape can be formed to account for these parameters - in essence, the shape of the outer areas on the nozzle is very close to parabolic and the volume can be calculated as such.

I found some easier to read references on the design of rocket motors (they are, after all, trying to get gassed to flow in a straight line - without vortices - as you are). The gist appears to be that most efficient is whe pressure at the exit of the nozzle should be the same as amient pressure. Shape is determined by the best way to get the gases to flow along the walls of the nozzle - and it's not a parabolic, maybe hyperbolic? It's been too long since school (and I have watched too much soccer this month).

http://www.braeunig.us/space/sup1.htm

http://exploration.grc.nasa.gov/education/rocket/nozzle.html

http://members.aol.com/ricnakk/th_nozz.html

Correct, for your needs (dB Dragging) you'll probably need optimisation. But the actual length and volume should be able to be determined on length and volume of the port. The shape can be formed to account for these parameters - in essence, the shape of the outer areas on the nozzle is very close to parabolic and the volume can be calculated as such.

I found some easier to read references on the design of rocket motors (they are, after all, trying to get gassed to flow in a straight line - without vortices - as you are). The gist appears to be that most efficient is whe pressure at the exit of the nozzle should be the same as amient pressure. Shape is determined by the best way to get the gases to flow along the walls of the nozzle - and it's not a parabolic, maybe hyperbolic? It's been too long since school (and I have watched too much soccer this month).

http://www.braeunig.us/space/sup1.htm

http://exploration.grc.nasa.gov/education/rocket/nozzle.html

http://members.aol.com/ricnakk/th_nozz.html

ThomasW said:Here's a cross section of the 6" AeroPort flare. Just print it out.

Question: How can we use this as a reference? is this some guide for us when creating a mold?

here is an idea... (long)

I wish I had thought of this but a fellow over at the Asylum has a slick trick to build big horns which I suspect he got from Tom Danley. The guys name is Hudson I believe if you care to take a look.

Here we go. You go to the local fabric shom and you buy some Spandex. Now we can get into all kinds of what about this or that stuff kind of discussion but lets not ok? The reason that you want Spandex is because Spandex stretchs equally in length and width and almost as well cross corners OK. Take a piece of flat sheet wood any kind and cut a hole in it the size of the outside edge of the flair that you want. Cut a piece of Spandex large enough to cover the hole and glue or clamp it down to the wood covering the hole. Now cut a round disk the size of the inside diametre of your vent tube. Drill a hole into the middle of this puck and place it on top of the fabric exactly in the centre. With a piece of string that has a knot (big one) on one end you poke a little hole in the centre of the Spandex and thread the string through the hole in the puck and then through the little hole in the Spandex. (do you see where this is going?) Now you pull down on the string which pulls down on the knot which pulls down on the Spandex. Take a breath now. Ok we are all breathing. Now you pull the disk down till you have stretched the Spandex into the shape that spins your crank, shorter or longer what ever looks good to you. When you have stretched the profile that you want you tie off the string. Now you take a can of spray enamel paint and pick a colour that you like and spray the Spandex till it is saturated (a good wet coat). Stop now and repeat this process as many times as you need flairs. OK now they are all wet and painted now you need to check with your wife to see if she likes the color you picked, she won't but tell her that's OK you will go down to the Home Depot and buy one she likes. OH OH now she has to come with you to pick out the color herself and do some other shopping that she needs to get done YOU SAY NO WAY she say yes because she does not want to wait all afternoon for you to go and come back because she knows you will be all day and the store she needs to go to will be closed etc. etc. etc. So You say OK and you both go. $1400.00 later she is done shopping and is tired and does not want to wast any more time with you whinning for her to hurry up and she is hungry so she say you can go get what ever color paint you want because now she says she does not care any more and she will wait for you in the car but hurry up cause its getting late. You go back into Home Depot to the paint department but they dont have the color that you wanted but they do have some other crap on sale and you buy six just to be sure you will have enough cause you don't want to do this again. When you get back to the car you find your wife now wants to eat out at some weird place you know you will not like but she is getting cranky over the time you took to decide which of the crappy color paints to buy. So you go with you wife to the restaurant and have a horrible meal that costs you $68.00. OK now you are back home and you find that because of your dear wife you have taken so long (it's 9:45 PM now) running around that the paint on your spandex forms has dried had (this is a good thing) and you are feeling very positive about this Spandex project. If you did what I told you in the first place and gave the Spandex a good wet soak you will probably be able to undo the string and it should stay in form but DON'T undo the string yet just in case it dosen't stay put and gets wrecked. You know that I am right about this because your wife is always telling you that you never listen and you never do things right the first time and the really crappy part about this is that you know the SHE is right about that (just like everything else she is always right about and.... lets not go there now we are busy and its getting late now). OK so now you have six new cans of crappy paint in the color you really did not want but it was on sale (only $6.00 a can) and you figured that you would take my advice and spray another good wet coat onto the Spandex and leave it to dry over night. You should read the instructions on the label now to make sure you are doing this right cause you have never used this kind of paint before (but the kid who sold it to you said he uses it on his skate board decks and it's great stuff (that's really why you bought six cans). While you are trying to read the instructions on the can (and having a hard time cause you can't find your glasses and the ******* light over the bench is burnt out (remember you wife asked you to replace it six weeks ago and you said I will when I get some time and we don't have any bulbs any way and she said then get some now or you'll be sorry cause you'll come in here some night and you won't be able to see anything (GOD she was right again man oh man she's always right and.... lets not go there now) so you are trying to read the fine print in the dark and you find out that this kind of paint can not be applied onto the one you sprayed on to the Spandex the first time oh so long ago. Screw it you think and you are about to spray it on anyway and your wife comes down to say good night (she really loves you but neither of you knows why) and she says YOU'RE NOT SPRAYING PAINT NOW! why you ask as nicely as you can (being nice now is important if you know what's good for you) (but you don't really cause you are tired and you just want to finish these flairs for you 145 db (maybe more with these vents thier cool) speakers that will win the competition and will look great if you top coat them with that gold chrome spray paint you saw at Home Depot that cost $13.95 for just that crummy little can... anyway you are tired remember and it's late and your wife has been saying something to you but you we not really listening and she is going on about fumes and you say OK, I'll do it tomorrow and she says fine I'm going to bed dont forget to shut the garage door which is open cause that was the only light left working cause you forgot to change the burnt bulb and you can't really read anything cause the plastic cover on the grage door opener has turned all yellow and it never used to be like that and ok she's gone now. So now you can spray a good wet layer of paint on your Spandex flairs and you do. OK the paint has to dry over night and it's 1:45 AM and the whole garage stinks you must have sprayed a half a can of that crappy paint onto the flairs and the whole place stinks. You figure that you will close the door but you know if you don't leave it open your wife will smell the paint and wake up and give you grief and you know that she will be right again so you willl just have to leave the door open so the paint fumes will get out but if you do that the grage door light will stay on and some kid will come and steal your new golf clubs and there is no room to lock them in the trunk cause you forgot to clean the junk out when your wife asked you to (you tell yourself now to start listening to your wife some time soon). So the only thing you can do is to take the bulb outof the garage door opener so it will be dark and that kid won't see your new clubs and think about steaking them. Now you need to get a ladder to remove the bulb but the car is in the way so you move the car and get the ladder down from the rafters an go to remove the bulb but you can't get the yellow plastic cover plat off to get at the 15 watt christmas tree light bulb inside without a screw driver. After you find your screwdriver set (she told you to clean up and organise the grage....) and you get the cover plat off (well you had to pry it off and it broke so you are removing the bulb now and you drop it cause its hot and it breaks and its dark. You don't want to look for another bulb and you wanted it dark anyway so you leave the car where it is (it's blocking the grage door so that's good) and you open the door to the kitchen to let in enough light to spray one last insurance coat on your

spandex flairs and you go to bed. At 4:20 AM you kid wakes up puking all over the bed (some kind of alergic reaction to solvents the doctor says later) and your wife smells the paint and gets mad cause she told you not to paint this late an now look what you have done. The kid is throwing up again and your wife says you have to take him to the emergency room to make sure he is allright and you have to hurry. As you are carrying him downstairs he pukes on your shoulder but you don't have a towel or anything oh well and as you carry him out through the kitchen into the grage you step on the broken glass and cut your foot (your wife told you to put your shoes on). When you get to the hospital the kid is fine but you need three stitches in your foot. By the time you get back home it is 6:45 AM and you have to go to work and your wife is not talking to you, So go to work and finish the Spandex flairs tomorrow. I think I have given you enough information to get your flairs done now and Mr. Hudson can tell you what kind or epoxy paint he used to coat up the fabric flairs to make them hard. His really look fantastic I hope yours do. Why does everything have to be so complicated? Good luck at the competition. Best regards Moray James.

I wish I had thought of this but a fellow over at the Asylum has a slick trick to build big horns which I suspect he got from Tom Danley. The guys name is Hudson I believe if you care to take a look.

Here we go. You go to the local fabric shom and you buy some Spandex. Now we can get into all kinds of what about this or that stuff kind of discussion but lets not ok? The reason that you want Spandex is because Spandex stretchs equally in length and width and almost as well cross corners OK. Take a piece of flat sheet wood any kind and cut a hole in it the size of the outside edge of the flair that you want. Cut a piece of Spandex large enough to cover the hole and glue or clamp it down to the wood covering the hole. Now cut a round disk the size of the inside diametre of your vent tube. Drill a hole into the middle of this puck and place it on top of the fabric exactly in the centre. With a piece of string that has a knot (big one) on one end you poke a little hole in the centre of the Spandex and thread the string through the hole in the puck and then through the little hole in the Spandex. (do you see where this is going?) Now you pull down on the string which pulls down on the knot which pulls down on the Spandex. Take a breath now. Ok we are all breathing. Now you pull the disk down till you have stretched the Spandex into the shape that spins your crank, shorter or longer what ever looks good to you. When you have stretched the profile that you want you tie off the string. Now you take a can of spray enamel paint and pick a colour that you like and spray the Spandex till it is saturated (a good wet coat). Stop now and repeat this process as many times as you need flairs. OK now they are all wet and painted now you need to check with your wife to see if she likes the color you picked, she won't but tell her that's OK you will go down to the Home Depot and buy one she likes. OH OH now she has to come with you to pick out the color herself and do some other shopping that she needs to get done YOU SAY NO WAY she say yes because she does not want to wait all afternoon for you to go and come back because she knows you will be all day and the store she needs to go to will be closed etc. etc. etc. So You say OK and you both go. $1400.00 later she is done shopping and is tired and does not want to wast any more time with you whinning for her to hurry up and she is hungry so she say you can go get what ever color paint you want because now she says she does not care any more and she will wait for you in the car but hurry up cause its getting late. You go back into Home Depot to the paint department but they dont have the color that you wanted but they do have some other crap on sale and you buy six just to be sure you will have enough cause you don't want to do this again. When you get back to the car you find your wife now wants to eat out at some weird place you know you will not like but she is getting cranky over the time you took to decide which of the crappy color paints to buy. So you go with you wife to the restaurant and have a horrible meal that costs you $68.00. OK now you are back home and you find that because of your dear wife you have taken so long (it's 9:45 PM now) running around that the paint on your spandex forms has dried had (this is a good thing) and you are feeling very positive about this Spandex project. If you did what I told you in the first place and gave the Spandex a good wet soak you will probably be able to undo the string and it should stay in form but DON'T undo the string yet just in case it dosen't stay put and gets wrecked. You know that I am right about this because your wife is always telling you that you never listen and you never do things right the first time and the really crappy part about this is that you know the SHE is right about that (just like everything else she is always right about and.... lets not go there now we are busy and its getting late now). OK so now you have six new cans of crappy paint in the color you really did not want but it was on sale (only $6.00 a can) and you figured that you would take my advice and spray another good wet coat onto the Spandex and leave it to dry over night. You should read the instructions on the label now to make sure you are doing this right cause you have never used this kind of paint before (but the kid who sold it to you said he uses it on his skate board decks and it's great stuff (that's really why you bought six cans). While you are trying to read the instructions on the can (and having a hard time cause you can't find your glasses and the ******* light over the bench is burnt out (remember you wife asked you to replace it six weeks ago and you said I will when I get some time and we don't have any bulbs any way and she said then get some now or you'll be sorry cause you'll come in here some night and you won't be able to see anything (GOD she was right again man oh man she's always right and.... lets not go there now) so you are trying to read the fine print in the dark and you find out that this kind of paint can not be applied onto the one you sprayed on to the Spandex the first time oh so long ago. Screw it you think and you are about to spray it on anyway and your wife comes down to say good night (she really loves you but neither of you knows why) and she says YOU'RE NOT SPRAYING PAINT NOW! why you ask as nicely as you can (being nice now is important if you know what's good for you) (but you don't really cause you are tired and you just want to finish these flairs for you 145 db (maybe more with these vents thier cool) speakers that will win the competition and will look great if you top coat them with that gold chrome spray paint you saw at Home Depot that cost $13.95 for just that crummy little can... anyway you are tired remember and it's late and your wife has been saying something to you but you we not really listening and she is going on about fumes and you say OK, I'll do it tomorrow and she says fine I'm going to bed dont forget to shut the garage door which is open cause that was the only light left working cause you forgot to change the burnt bulb and you can't really read anything cause the plastic cover on the grage door opener has turned all yellow and it never used to be like that and ok she's gone now. So now you can spray a good wet layer of paint on your Spandex flairs and you do. OK the paint has to dry over night and it's 1:45 AM and the whole garage stinks you must have sprayed a half a can of that crappy paint onto the flairs and the whole place stinks. You figure that you will close the door but you know if you don't leave it open your wife will smell the paint and wake up and give you grief and you know that she will be right again so you willl just have to leave the door open so the paint fumes will get out but if you do that the grage door light will stay on and some kid will come and steal your new golf clubs and there is no room to lock them in the trunk cause you forgot to clean the junk out when your wife asked you to (you tell yourself now to start listening to your wife some time soon). So the only thing you can do is to take the bulb outof the garage door opener so it will be dark and that kid won't see your new clubs and think about steaking them. Now you need to get a ladder to remove the bulb but the car is in the way so you move the car and get the ladder down from the rafters an go to remove the bulb but you can't get the yellow plastic cover plat off to get at the 15 watt christmas tree light bulb inside without a screw driver. After you find your screwdriver set (she told you to clean up and organise the grage....) and you get the cover plat off (well you had to pry it off and it broke so you are removing the bulb now and you drop it cause its hot and it breaks and its dark. You don't want to look for another bulb and you wanted it dark anyway so you leave the car where it is (it's blocking the grage door so that's good) and you open the door to the kitchen to let in enough light to spray one last insurance coat on your

spandex flairs and you go to bed. At 4:20 AM you kid wakes up puking all over the bed (some kind of alergic reaction to solvents the doctor says later) and your wife smells the paint and gets mad cause she told you not to paint this late an now look what you have done. The kid is throwing up again and your wife says you have to take him to the emergency room to make sure he is allright and you have to hurry. As you are carrying him downstairs he pukes on your shoulder but you don't have a towel or anything oh well and as you carry him out through the kitchen into the grage you step on the broken glass and cut your foot (your wife told you to put your shoes on). When you get to the hospital the kid is fine but you need three stitches in your foot. By the time you get back home it is 6:45 AM and you have to go to work and your wife is not talking to you, So go to work and finish the Spandex flairs tomorrow. I think I have given you enough information to get your flairs done now and Mr. Hudson can tell you what kind or epoxy paint he used to coat up the fabric flairs to make them hard. His really look fantastic I hope yours do. Why does everything have to be so complicated? Good luck at the competition. Best regards Moray James.

Due to eye strain I was unable to finish the small novel you wrote for us, might I suggest a more liberal use of paragraphs, with blank lines in between.

might I suggest a more liberal use of paragraphs, with blank lines in between.

As for stretching material between a blank and a die, well unfortunately I think you will end up with a straight taper as opposed to a radiused flare. The material is going to try and minimize stresses by forming the lowest energy shape, this is of course a straight line.

A novel idea though and I bet if you enclosed the whole bottom in a box with air pressure you could get curvature. But then you need an impermeable fabric, and at this point you have a box so why not put modeling clay or sand in there and then just form it the usual way.

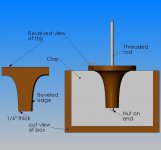

If I were to make flares I would make a flare cutter out of wood and fill a box with clay and after chucking the cutter into a drill press I would feed it in to get the desired shape. The design requires knowing the thickness of the material you want to lay in and oversizing the hole accordingly. You can attach sand paper to a smaller bit and use it for finishing/polishing.

EDIT: Typo, the cutter should be ~3/4", not 1/4" -oops

As for stretching material between a blank and a die, well unfortunately I think you will end up with a straight taper as opposed to a radiused flare. The material is going to try and minimize stresses by forming the lowest energy shape, this is of course a straight line.

A novel idea though and I bet if you enclosed the whole bottom in a box with air pressure you could get curvature. But then you need an impermeable fabric, and at this point you have a box so why not put modeling clay or sand in there and then just form it the usual way.

If I were to make flares I would make a flare cutter out of wood and fill a box with clay and after chucking the cutter into a drill press I would feed it in to get the desired shape. The design requires knowing the thickness of the material you want to lay in and oversizing the hole accordingly. You can attach sand paper to a smaller bit and use it for finishing/polishing.

EDIT: Typo, the cutter should be ~3/4", not 1/4" -oops

Attachments

Pic gallery of Les Hudson's formed horn

Pictures of the horns Les built using not very much of the information I last posted . Regards Moray James.

http://gallery.audioasylum.com/cgi/view.mpl?UserImages=33876&session=

Pictures of the horns Les built using not very much of the information I last posted . Regards Moray James.

http://gallery.audioasylum.com/cgi/view.mpl?UserImages=33876&session=

CBFryman, Cloth Ears,

I'm sure the subject abomination is long since built (or more optimistically abandoned), but before some muckety-muck kid wastes his time with this, lets inject some sense.

First, port noise is not going to increase your SPL. You are inducing excessive losses in the air flow (some resulting in audible frequency waves and many which do not) making your speaker work for noise that is unmeasured by SPL meters.

Regarding rockets, the whole converging-diverging nozzle thing is about accelerating flow to supersonic speed. At sub sonic speed, shrinking the passage that air flows through increases its velocity for a given flow rate, but for the same pressure load, it will flow less. This will decrease your SPL* (at least if you're going smaller than optimal.)

At super sonic speed, reducing the section this becomes counter-productive and slows the flow. With enough flow, the flow will choke (max out at mach 1) at the throat, or smallest section location. (Linear velocity of Mach varies with air density). At this point, the escaping gasses need to expand to accelerate. Efficiency of this expansion depends on the design of the nozzle and the environment at the back of it. (Mostly pressure.)

All of this is bad for audio. You want to minimize air velocity in your port at the inlet and outlet. This will optimize your speaker's output by flowing the most air though the port with minimal losses, while ensuring that the wave exiting the port is phase shifted enough to prevent a free-air condition (wave cancellation). When the air at these locations moves too quickly, through lossy ports large turbulent vortices are produced (chuffing). You want your port to be quiet, whether your goal is SQ or SPL. The difference is in SPL, you tune to produce a response spike in the system (so a given frequency band is naturally more efficient) at the expense of other bands.

To get the most even flow possible (IE quiet) in the region of the port inlets, use inverse elliptical. (long axis parallel with pipe, quarter ellipse flaring out) The benefit over a circular flare of similar size is probably minimal. As for sizing, my guess for a good starting point would be 150% flare minimum with a 1.5 ellipse ratio, but I've not experimented with it.

If you want to be hardcore, DREs (Discrete Roughness Elements) may help reduce chuffing further. Like dimples on a golf ball, they introduce small turbulences to help increase overall flow efficiency in the port by reducing the size of the boundary layer and creating flatter flow profile.

</rant>

Thanks for letting me geek out!

I'm sure the subject abomination is long since built (or more optimistically abandoned), but before some muckety-muck kid wastes his time with this, lets inject some sense.

First, port noise is not going to increase your SPL. You are inducing excessive losses in the air flow (some resulting in audible frequency waves and many which do not) making your speaker work for noise that is unmeasured by SPL meters.

Regarding rockets, the whole converging-diverging nozzle thing is about accelerating flow to supersonic speed. At sub sonic speed, shrinking the passage that air flows through increases its velocity for a given flow rate, but for the same pressure load, it will flow less. This will decrease your SPL* (at least if you're going smaller than optimal.)

At super sonic speed, reducing the section this becomes counter-productive and slows the flow. With enough flow, the flow will choke (max out at mach 1) at the throat, or smallest section location. (Linear velocity of Mach varies with air density). At this point, the escaping gasses need to expand to accelerate. Efficiency of this expansion depends on the design of the nozzle and the environment at the back of it. (Mostly pressure.)

All of this is bad for audio. You want to minimize air velocity in your port at the inlet and outlet. This will optimize your speaker's output by flowing the most air though the port with minimal losses, while ensuring that the wave exiting the port is phase shifted enough to prevent a free-air condition (wave cancellation). When the air at these locations moves too quickly, through lossy ports large turbulent vortices are produced (chuffing). You want your port to be quiet, whether your goal is SQ or SPL. The difference is in SPL, you tune to produce a response spike in the system (so a given frequency band is naturally more efficient) at the expense of other bands.

To get the most even flow possible (IE quiet) in the region of the port inlets, use inverse elliptical. (long axis parallel with pipe, quarter ellipse flaring out) The benefit over a circular flare of similar size is probably minimal. As for sizing, my guess for a good starting point would be 150% flare minimum with a 1.5 ellipse ratio, but I've not experimented with it.

If you want to be hardcore, DREs (Discrete Roughness Elements) may help reduce chuffing further. Like dimples on a golf ball, they introduce small turbulences to help increase overall flow efficiency in the port by reducing the size of the boundary layer and creating flatter flow profile.

</rant>

Thanks for letting me geek out!

Pulling from another discipline, Testing of carburetor velocity tubes by Vizzard suggested a full 360 degree radius if in free air, and a 11 degree initial taper of the throat.

I suspect there is a lot less to be gained here that may be assumed. This is just a guess, but a one inch round-over is probably 99% as good as you will get. The differences in air density are probably greater than the perfect flair. Toss in voice coil heating and you get the picture.

I suspect there is a lot less to be gained here that may be assumed. This is just a guess, but a one inch round-over is probably 99% as good as you will get. The differences in air density are probably greater than the perfect flair. Toss in voice coil heating and you get the picture.

To stick another nail in the coffin, the research boys at JBL Pro did a lot of actual testing (nice to have an in-house machine shop) and found that at high SPL, FLARES DID NOT HELP.

HUH?!?!

WHA!?!?

Well, at very high velocities, the air just jetted in and out of the port. The speed was so high that tapering was not affecting this (although it did help at lower SPLs).

HUH?!?!

WHA!?!?

Well, at very high velocities, the air just jetted in and out of the port. The speed was so high that tapering was not affecting this (although it did help at lower SPLs).

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Making Flared Ports

cloth ears

cloth ears