Brian I think you did it! I just checked with those dimensions, 1 would fit even INSIDE my trunk, 2 easily with only 1 seat down - with the efficiency I want, the extension I want, using a high value budget driver!

If 2 pieces of plywood needs to be used I don't mind because the extra wont be wasted, I can always use it to make some "real" tops etc. down the line.

The fact that I have not bought the amp yet I can also select accordingly. I do have a TDA3116 which goes at 50wx2 + 100w @4ohms. Which I can use to test the first one I build, then add another if I feel I need to, or, buy a more suitable amp etc.

At what wattage will I run out of excursion? And would my aim of 100W be "ok" without a highpass?

Djim: even though those bigger horns/bandpass boxes with the 18" won't work for this project, they have peaked my interest, I'll have to research more on those later and build some for my friend's basement. If you already have the correct links/files to the hornresp please direct me.

thank you all again

If 2 pieces of plywood needs to be used I don't mind because the extra wont be wasted, I can always use it to make some "real" tops etc. down the line.

The fact that I have not bought the amp yet I can also select accordingly. I do have a TDA3116 which goes at 50wx2 + 100w @4ohms. Which I can use to test the first one I build, then add another if I feel I need to, or, buy a more suitable amp etc.

At what wattage will I run out of excursion? And would my aim of 100W be "ok" without a highpass?

Djim: even though those bigger horns/bandpass boxes with the 18" won't work for this project, they have peaked my interest, I'll have to research more on those later and build some for my friend's basement. If you already have the correct links/files to the hornresp please direct me.

thank you all again

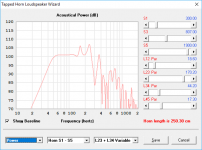

You will need a high pass filter with a tapped horn use it at the levels you want.

Using Hornresp it is easy to see the effect of different filter types and how this will help to control excursion. As I posted before I think a 4th order butterworth at 35hz is suitable but do check with your chosen driver.

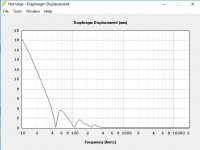

Pic shows an example driver excursion in Brian's Sim driven at 28V (100W)

As for an amplifier to drive an 8ohm driver, any bridgeable amplifier that has a 4ohm rated output will deliver 2 times its 4 ohm rated output when 2 channels are bridged into a 8 ohm driver.

If the amp is rated for 2 ohms then bridged it can be used into 2 x 8 ohm drivers paralleled to make a 4 ohm load and will achieve the 2 ohm per channel rated power into each driver

Bridging makes it easy to get the rated power of a car amplifier into pro drivers that need more volts.

Using Hornresp it is easy to see the effect of different filter types and how this will help to control excursion. As I posted before I think a 4th order butterworth at 35hz is suitable but do check with your chosen driver.

Pic shows an example driver excursion in Brian's Sim driven at 28V (100W)

As for an amplifier to drive an 8ohm driver, any bridgeable amplifier that has a 4ohm rated output will deliver 2 times its 4 ohm rated output when 2 channels are bridged into a 8 ohm driver.

If the amp is rated for 2 ohms then bridged it can be used into 2 x 8 ohm drivers paralleled to make a 4 ohm load and will achieve the 2 ohm per channel rated power into each driver

Bridging makes it easy to get the rated power of a car amplifier into pro drivers that need more volts.

Attachments

Brian I think you did it! I just checked with those dimensions, 1 would fit even INSIDE my trunk, 2 easily with only 1 seat down - with the efficiency I want, the extension I want, using a high value budget driver!

How much space do you have to play with? The workbook I use for the design work does allow for quick adjustments. The cab may perform a bit better if the width is increased to 18", for example.

Don't forget that you'd likely want to pack other stuff in the trunk too

I just want to caution again that the design is untested. The Hornresp sim looks pretty good and Hornresp does "get you into the ballpark", but the accuracy does depend on the driver meeting the published parameters (I haven't had the opportunity to measure the PA380), and the sim does not include the impact of box losses.

How much space do you have to play with? The workbook I use for the design work does allow for quick adjustments. The cab may perform a bit better if the width is increased to 18", for example.

Don't forget that you'd likely want to pack other stuff in the trunk too.

I just want to caution again that the design is untested. The Hornresp sim looks pretty good and Hornresp does "get you into the ballpark", but the accuracy does depend on the driver meeting the published parameters (I haven't had the opportunity to measure the PA380), and the sim does not include the impact of box losses.

18" would work. At 18x24x36 I can fit both inside with one seat down.

My max could be 18*30*30, though then its really tight, so I'd only do that for significant gains - like 5Hz or a few dbs or something

18" would work. At 18x24x36 I can fit both inside with one seat down.

My max could be 18*30*30, though then its really tight, so I'd only do that for significant gains - like 5Hz or a few dbs or something

Ok, I'm going to have a look at the designs again.

I noticed that the compression ratios I ended up using in my designs (basically Sd/2 in the Hornresp sim) are quite a bit higher than the original SS15 design. Compression ratios that are too high can cause cone damage at higher SPL levels. The CR for my design is around 2.5 and for the SS15 it's around 1.7. That's quite a difference.

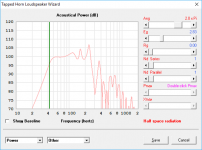

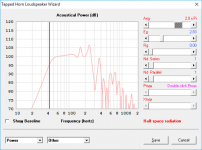

While I have another look at the designs, here's how the PA380 models in the "SS15" model that was put together by Oliver in the SS15 thread, with slight corrections made for cone correction. I've also included what the response looks like in the "modified" layout as suggested by my workbook (same external dimensions, same use of 0.5" ply all around). The response up to just over 100 Hz is just about identical. I think it should be possible to achieve something similar or better with a slimmer 18" box.

Attachments

Ok, I'm going to have a look at the designs again.

Ok, here's another option. 18" wide, 34" high. Compression ratio is 2.0 (when cone correction of 3L is taken into consideration), which is lower than my previous suggestions, but still higher than the SS15. Maybe at 100W it shouldn't be an issue - I'll let the more experienced here (particularly with that driver) chime in.

But with this design you get your 40 Hz and your 100dB/2.83V/1M (if you squint a lttle

BTW, while using the SS15 fold workbook, I've come up with a few ideas to improve it, which I will incorporate into the workbook this weekend. I don't expect that it will provide any massive improvements, but we'll see..

Attachments

For what it is worth: PA380 measured WT3 specs

Now, that's interesting. Not only are those parameters a little different from the published ones (Mmd works out to be quite a bit lower than published Mmd which makes them a little suspect though), they are different to what I have on file for the PA380.

Here's what I have on file for the PA380:

Sd: 845 cm^2

Re:6.30 Ohms

Fs: 28.3 Hz

Vas: 175.12 L

Qes: 0.27

Qms: 12.2

Qts: 0.26

Le: 4.12

Mmd works out to be 169.73 g

Here's what is currently published for the PA380:

Sd: 845 cm^2

Re: 6.3 Ohms

Fs: 31.6 Ohms

Vas: 175.35 L

Qes: 0.27

Qms: 12.20

Qts: 0.27

Le: 4.12 mH

Mmd works out to be 133.34 g (21.4% less)

...and here are the measured t/s parameters from that link:

Re: 5.81

Fs: 29.61

Qts: 0.2506

Qes: 0.2554

Qms: 13.18

Le: 3.531

Vas: 256.54

Mmd works out to be 100.50 (24.6% less than published)

That's some pretty large differences.

I've adjusted the sim to reflect the published specs of the PA380 (as they currently are on the PE site). There are some minor changes to the FR, but nothing really to worry about. However, if the measurements on that link are more accurate, it may be best to adjust the build (smaller CR).

Attachments

On the AVS forum (link) "MTG90" provides the following measured data:

Fs = 28.25 Hz

Re = 5.8 Ohm

Qes = 0.238

Qts = 0.232

Qms = 9.99

Vas = 253.2 L

BL = 23.44 TM

Sd = 845 cm^2

Mms = 127 g

Le = 3.38 mH

I've done some tweaks to the workbook, and ran it with the specs above. There are a few minor response changes, nothing really to worry about.

Attachments

Why not fit a 4-Ohm 18inch driver like a B-52 18-190X (150$ at Part Express) in a 6th order bandpass so you get 2.83V/104dB from > 40Hz?

No free lunch. what I've read & been told, many times is that an 8 ohm driver, all else being the same, is more easily controlled by the amp, because there are twice as many windings. Same for, say, 600 ohm headphones vs 250 ohm.

Maybe that's false info, (I'll bet good money that Art will come along shortly and tell me I'm wrong!) but it comes from several high end books, plus techs from companies like B&C, Tannoy, and Beyer Dynamic.

-----------

So I'm thinking: Why not modify it slightly and use two 8 ohm 12" drivers?

No free lunch. what I've read & been told, many times is that an 8 ohm driver, all else being the same, is more easily controlled by the amp, because there are twice as many windings. Same for, say, 600 ohm headphones vs 250 ohm.

Sounds like marketing-speak nonsense to me.

Woah! Just got back from the weekend. Thank you so much for taking the time to adjust the design to work. With such an affordable driver, high sensitivity and performance down to 40Hz, I'm sure others would be interested! I'll have the drivers ordered next week and update you on the build. thank you again.

Sounds like marketing-speak nonsense to me.

Why?

More windings means more hold from the magnet. (And why it's less efficient.) Makes perfect sense, actually.

I have about ten pairs of Beyer DT-770 headphones in my recording studio. Three of them are the older 600 ohm version and the rest are 250 ohm. All three of the 600 ohm ones are noticeable more defined, with better dynamic range & lower LF distortion. A Beyer tech confirmed that this was due to the extra wire.

And when companies offer their HF drivers in both 8 and 16 ohm versions, They recommend the 16 ohm if you're worried about burning them up, even though they're less efficient. The extra coils dissipate heat better, or something. (So says Radian & B&C) So another good reason to use an 8 ohm driver.

But again, I'm not the expert, so ....

Last edited:

Ton, thanks for the idea, and keep them coming as I must decide soon.

However, the Cubo is exactly what I'm trying to AVOID ! - That is, a sub in roughly cube form.

I, like many other "local" musicians and DJ's, typically have very little room on stage, yet I still want to cluster my subs in the center. thus, they HAVE to be tall & shallow.

Additionally, a cube-like sub is much harder to move around or load into your truck, than a tall-shallow one.

Several smaller companies seem to have finally realized this market in the last 5 years or so, with their dual 12" BR designs. (JTR, Line 6, Yorkville, etc)

Of course, it's child's play to make something like that with a BR design, I can even EXACTLY maximize my truck loading space, but doing this with a horn (which I would prefer) is horribly difficult.

Art's "smaller" Keystone sub, with either a 15" or dual 12", is high on my list for this reason. The weight is an issue, but I believe I can knock that down significantly with expensive composites and aluminum channel for bracing. (Price is no object for me, and if I go with 15's I will almost surely use that $750 Radian. )

)

Still, I can't quite decide yet, so thanks again.

However, the Cubo is exactly what I'm trying to AVOID ! - That is, a sub in roughly cube form.

I, like many other "local" musicians and DJ's, typically have very little room on stage, yet I still want to cluster my subs in the center. thus, they HAVE to be tall & shallow.

Additionally, a cube-like sub is much harder to move around or load into your truck, than a tall-shallow one.

Several smaller companies seem to have finally realized this market in the last 5 years or so, with their dual 12" BR designs. (JTR, Line 6, Yorkville, etc)

Of course, it's child's play to make something like that with a BR design, I can even EXACTLY maximize my truck loading space, but doing this with a horn (which I would prefer) is horribly difficult.

Art's "smaller" Keystone sub, with either a 15" or dual 12", is high on my list for this reason. The weight is an issue, but I believe I can knock that down significantly with expensive composites and aluminum channel for bracing. (Price is no object for me, and if I go with 15's I will almost surely use that $750 Radian.

Still, I can't quite decide yet, so thanks again.

Last edited:

I've done some tweaks to the workbook, and ran it with the specs above. There are a few minor response changes, nothing really to worry about.

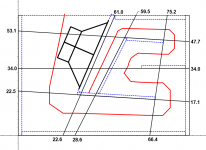

Hi Brain, this may be a stupid question, but this is my first time using your worksheet for a build - are X and Y the dimensions of each panel in cm? Is P then the thickness?, and what is the best way to transfer the positions of the internal panels from your plot onto the side panels? Do I need your xcel file or have you already given me all the info I need?

Hi Brain, this may be a stupid question, but this is my first time using your worksheet for a build - are X and Y the dimensions of each panel in cm? Is P then the thickness?

That's correct.

, and what is the best way to transfer the positions of the internal panels from your plot onto the side panels? Do I need your xcel file or have you already given me all the info I need?

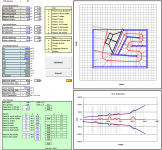

The Excel workbook is available from my site (look under "Horn Folding" link). The latest version of the SS workbook is v8.1 However, the easiest way is to cut the side panels first, draw the guide lines on them as specified in the "Layout" sheet in the workbook (see image below), and then use those to set and mark the position of each panel. The workbook assumes no beveled panels, to make the build a little easier, but feel free to cut the panels as you like, once they fall within the guide lines as specified on the "Layout sheet. And use lots of glue, etc. to make sure that there are no gaps, particularly in the first third or so of the horn's path, starting from just before the driver. The cutout for the driver should also be about 3 or 4 mm smaller in diameter than the recommended cutout, or you may end up having leaks around it, and leaks = less bass.

...and don't forget to put in bracing

Attachments

Why?

More windings means more hold from the magnet. (And why it's less efficient.) Makes perfect sense, actually.

All of that is reflected in the BL for the driver.

And when companies offer their HF drivers in both 8 and 16 ohm versions, They recommend the 16 ohm if you're worried about burning them up, even though they're less efficient. The extra coils dissipate heat better, or something. (So says Radian & B&C) So another good reason to use an 8 ohm driver.

Yeah, and that's why all of those multi-kilowatt car audio subwoofers are 8 ohms and up in impedance.

Oh, wait...

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- SS15/THAM15/keystone/other for 12v outdoor party