Hi Zero D,@ paulronanqed

Nice to see someone Actually building one

What driver are you using ?

Earlier on in this thread i posted several things about it. And that i purchased the plans way back when. I seem to recall that this gap was a lot smaller in the plans ?

View attachment 256667

Have you modified the original design ? or is my memory fading

Looking forward to some test results on this

Regards

Just spotted the arrow on the picture, the fillets were cut to 1.75" (44.5mm) as per dim's on the table front to back and I left them at CLS width to give them a little more meat and glue surface, might be a bit of an optical illusion with the 25mm upstand at the back and angle the picture was taken at.

Many thanks for the heads up

Paul

Hi,

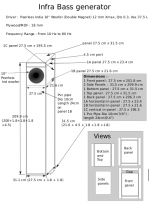

Look at the submitted picture where a 10” Dayton speaker driver Dayton Audio RSS265HF-4 10" Reference HF Subwoofer 4 Ohm 295-460 is modeled in a double bas reflex (BIB?) enclosure, capable in room SPL of more than 90 dB at 8 Hz and low ripple that any room will hide.

Not a Holiman but this less than 1 Litres total stroke-volume (2 x X-max x Sd) 10” based infra DBR driver covers 8 - 80 Hz and will work in any room because of the built in air velocity conversion. J

The size is quite large (427 L), but more than + 8dB is gained at 8 Hz compared to the corresponding IB type and the driver is within linear X-max with a low 16 W RMS input when producing 90 dB SPL at 8 Hz.

With typical + 9dB ‘room gain’ at 10 Hz an f-3dB at 6 Hz can be expected in most living rooms even if doors not are closed.

B

Perhaps the volume calculation is wrong in the proposed enclosure it appears to be 350 Liters to me,but has impressive frequency range, if the sim results are right for the proposed Dayton 10" enclosure then what would be the results for this Peerless India 10" woofer which has comparable specifications and would be a cheap option (i don't know it's price but it's definitely cheap as it is not an imported one ) ? :- Products - PeerlessAudio.com

Perhaps the volume calculation is wrong in the proposed enclosure it appears to be 350 Liters to me,but has impressive frequency range, if the sim results are right for the proposed Dayton 10" enclosure then what would be the results for this Peerless India 10" woofer which has comparable specifications and would be a cheap option (i don't know it's price but it's definitely cheap as it is not an imported one ) ? :- Products - PeerlessAudio.com

Hi abhihemu,

I looked up my Dayton DAYTON RSS265HF-4 DBR designs and found the smallest suggestion had a 486L volume but as I recently/presently have had and have computer problems , I could have missed the right sim.

The driver you posted looks good for a large deep FR digging DBR.

Please post a link to the simulation you are referring to and I will recalculate the DBR volume and later(this day or tomorrow) post a sim. using the Peerless India driver instead.

b

Hi b,

i was referring to your Attachment in the same post #190 (http://www.diyaudio.com/forums/atta...ss-speaker-dayton10inrss265hf-4-infra_dbr.gif) , which says that the lower volume is 152.9x60x40 (cm) = 367 L, which actually is 300.84 L (60.1x23.6x15.7 inches=310 L), and upper volume 25x60x40 cm = 60L which is 41.4 L (9.8x23.6x15.7 inches =41.4 L) if i am not missing something. I was just pointing that and nothing else

actually i liked your plan more than holliman box, and perhaps in a month i'll get that Peerless India driver for your design. I am no expert in sims and such frequency graphs so i am hoping that someone will post the sim graphs for your design with PeerlessIndia driver

thanks for replying

i was referring to your Attachment in the same post #190 (http://www.diyaudio.com/forums/atta...ss-speaker-dayton10inrss265hf-4-infra_dbr.gif) , which says that the lower volume is 152.9x60x40 (cm) = 367 L, which actually is 300.84 L (60.1x23.6x15.7 inches=310 L), and upper volume 25x60x40 cm = 60L which is 41.4 L (9.8x23.6x15.7 inches =41.4 L) if i am not missing something. I was just pointing that and nothing else

actually i liked your plan more than holliman box, and perhaps in a month i'll get that Peerless India driver for your design. I am no expert in sims and such frequency graphs so i am hoping that someone will post the sim graphs for your design with PeerlessIndia driver

thanks for replying

..Hi b,..i was referring to your Attachment in the same post #190 (http://www.diyaudio.com/forums/attac...-infra_dbr.gif) , which says that the lower volume is 152.9x60x40 (cm) = 367 L, which actually is 300.84 L (60.1x23.6x15.7 inches=310 L), and upper volume 25x60x40 cm = 60L which is 41.4 L (9.8x23.6x15.7 inches =41.4 L) if i am not missing something. I was just pointing that and nothing else..

I finally found that simulation and let the program to calculate the volumes:

For the moment: See the attached picture.

b

Attachments

FYI: Here's a DBR simulation using the Peerless of India 10" driver.

b

b

Attachments

FYI: Here's a DBR simulation using the Peerless of India 10" driver.

b

Thanks for simulation b

it means that Peerless India driver can produce 10Hz to 80Hz with your design,now i am happy ! but this time volume is only 205 Liters !!? and it looks like a TL. Though i didn't understand the dimensions completely, but this is not a huge box, yet efficient. Thanks

[book=it means that Peerless India driver can produce 10Hz to 80Hz with your design,now i am happy !]%[/book]

Yes, but you have to HPF at ~8Hz ..

Correct,the whole enclosure will be dependent on quarter-wave behavior.

To understand the dimensioning: visit MJK:s site

www.quarter-wave.com

b

Yes, but you have to HPF at ~8Hz ..

but this time volume is only 205 Liters !!? and it looks like a TL. Though i didn't understand the dimensions completely, but this is not a huge box, yet efficient.

Correct,the whole enclosure will be dependent on quarter-wave behavior.

To understand the dimensioning: visit MJK:s site

www.quarter-wave.com

b

[book=[book=..Yes, but you have to HPF at ~8Hz ..]%[/book]

Ops,

b

Ops,should be ~10 Hz

b

Hi b

just one more question ! what would be the diameter and the length of the Pvc port pipe ?

Thanks

Abhi

Hi b

just one more question ! what would be the diameter and the length of the Pvc port pipe ?

Thanks

Abhi

The internal port is L= 24 cm, Internal diameter = 10 cm.

b

The internal port is L= 24 cm, Internal diameter = 10 cm.

b

Hi b,

i am attaching the plan suggested by you.

Thanks

Abhi

Attachments

Hi b,

i am attaching the plan suggested by you.

Thanks

Abhi

Hi Abhi,

Sorry, almost missed your answer...

You've got it right!

Note: The internal panel = 1B in your drawing has a thickness of 21 mm.. as I can see :If using 18 mm here too would not alter the performance of this box ..

You need also to internally brace the box ,random irregularly cross-bracing should work just fine.

I would spray-glue a~ 1/4" wool felt internally ,at least on the insides of the rear panels.. Covering all internal panels would too be a good idea as a lot of energy is transfered to the wood..

You really don't want to hear any localization cues from a sub like this one. I would definitively place this sub as close to a corner as possible.. with the driver and port preferably oriented close to the floor level.

b

excellent looking design Bjono!

Hi freddi,

Thank you freddie

I noticed that in post #307

Here is the correct one:

b

Attachments

[U]Have I been living in a parallel universe?[/U]

Hi Guys,

My first post. Wow what a thread! I don’t know quite where to begin…..

Hope that this will not be considered “off topic”?

But I will finally get around to the point when I telephoned THE Mr Graham Holliman!

Around 23 years ago when I was the tender age of 23, I met a friend who was a loudspeaker designer.

Till then I had just been blindly tinkering with loudspeakers, both hi-fi & PA.

My new friend, Geoff was at a completely different level. Geoff was 19 years my senior and he became my greatest mentor & friend. Sadly he passed away last Christmas Eve, probably taking far too much knowledge with him.

Geoff had an amazing pair of hideous looking prototype hi-fi speakers which always amazed me, they sounded far superior to anything I had ever heard, even at Abbey Road Studios.

Over the years I learned that they were based upon Graham Holliman’s design. At least should I say the Sub-bass element.

Geoff had followed the detailed build instructions in the Hi-fi World article (think it was 1974 & I can scan & post).

Geoff had a great knack of thinking laterally, so had turned the Holliman enclosure on its end, on a floor stand so that the 15-inch driver faced the back wall. He then inserted an extra 15-inch upper bass driver, a 6.5-inch mid driver & tweeter array into the front, in what had been the bottom. He multiplied this twice & he had a stereo, true full-range monitoring system.

This he had achieved before I met him, I cannot express how good this sounded, so extremely quick with a very smooth response with an utterly clean never ending bass extension to die for. Totally musical and plenty of boogieing SPL for a living room.

Over the years I learnt more as you do, & with Geoff’s help along the way I later formed a PA company which in turn became a small bespoke PA loudspeaker manufacturer, this then resulted in me having company facilities like open doors to driver manufacturers. Oh to be a kid in the sweet shop again.

The highlight of this great adventure was with Geoff’s help we designed a ground-breaking high powered club system in the early 1990’s which utilised a different band-pass sub bass cabinet that pumped out over 135dBA , flat down to 20 cycles and below if I switched off the safety filter! This bespoke installation was at Turnmills club, home of Trade. At the time it really kicked the established PA brands and the club’s main competitor, The Ministry Of Sound.

I helped Geoff with many mods to his Holliman’s over the years which included all manner of drivers, crossovers and tweaking. Many happy hours were spent listening and discussing the merits of our tweaks. We even joked about booking a room at the Heathrow Hi-fi Show with the Holliman’s under an acoustically transparent dustsheet just to throw the cats amongst the pigeons.

We had always wondered why Graham Holliman he had not pursued the design further. We discussed this in great detail including the totally unfair dismissal he had received from the hi-fi industry. It had been a witch hunt and burning. I had always sensed that Geoff had felt a little guilty over poaching Graham’s design, although it had been published for personal use.

We were always going to make a finished, veneered pair for each of us with a stock pile of the next round of drivers that we had spent years choosing and gathering. Sadly that was not to be.

The good news for me is that Geoff’s speakers are safe and have been left to me so that I can keep them alive & moving forward with our original plan. I just need to make space to accommodate them in my lounge. (Can’t wait)

When I arranged Geoff’s funeral, when going through his “loudspeaker” phone book I found Graham Holliman’s telephone number, thought it rude not to call really although it did seem odd that Geoff had never mentioned speaking to him.

Mr Holliman could not remember Geoff, but was a really cool guy to speak with. We spoke for a good while and Mr Holliman & I left things hanging so that I could call again, which I would thoroughly enjoy. We did talk about getting together for him to have a listen. OH WHAT AN HONOUR!

So you now know why I have been living in a parallel universe, having read this thread back to 2004 today.

I am so pleased that Mr Holliman is still provoking interest & debate to this day, I can only tell you that I have been told by others that I have “golden ears” and believe me, I’m not a boom & tiss kind of guy at home.

His design is the best I have ever heard, yes there is debate because the available technology around 40 years ago was very limited, particularly in the bass & elctronics department. I know that from my own experience in the 90’s when we were pushing the design envelope and constantly taking drivers back to where they were made and asking for design changes.

It wasn’t until relatively recently when advanced & high temperature materials, low resonant frequencies & high Xmax have become the norm for high end bass products.

For those wanting to know what drivers Geoff had used; the default had been some vintage Audax 15 inch units which had been mass loaded with bitumen sheet. We were next planning to try some Precision Devices 158’s, which we sensed would be an upgrade.

Our general consensus was that the cabinets were not too driver fussy, nor did he have to close doors & windows for the full effect. So I guess this suggests that following the cabinet design accurately and maintaining construction quality is more important than with most designs.

I remember Geoff stating that when I remade the cabinets that I should use the thinnest/strongest sheet material for the loading aperture ring. I have noticed that some of you appear to have used hardboard? this I think could be flapping/ trying to tear itself apart when level is increased?

I should also state that the ultra-sub bandwidth was actively driven via large mono-blocks via a studio quality Tannoy crossover with 24dB/octave slope to filter nasty out of band break up. And obviously there was room gain by the fact that the speakers backed into the corners.

I can remember the day we wired one up to a 2 watt transistor FM radio, the result was quite amazing, and so I think it fair to say there’s no problem with efficiency that is in the mid to upper 90’s

I now look forward to installing Geoff’s Holliman’s and reading through his notes and returning here for any more gratefully received and shared wisdom before I draw up the next version of cabinets. If anybody has any doubt, you are most welcome to visit and make your own opinion.

Thank you Geoff and thank you Graham.

PS Does that qualify for the third or fourth known working cabinet?http://files.diyaudio.com/forums/images/smilies/scratch1.gif

Hi Guys,

My first post. Wow what a thread! I don’t know quite where to begin…..

Hope that this will not be considered “off topic”?

But I will finally get around to the point when I telephoned THE Mr Graham Holliman!

Around 23 years ago when I was the tender age of 23, I met a friend who was a loudspeaker designer.

Till then I had just been blindly tinkering with loudspeakers, both hi-fi & PA.

My new friend, Geoff was at a completely different level. Geoff was 19 years my senior and he became my greatest mentor & friend. Sadly he passed away last Christmas Eve, probably taking far too much knowledge with him.

Geoff had an amazing pair of hideous looking prototype hi-fi speakers which always amazed me, they sounded far superior to anything I had ever heard, even at Abbey Road Studios.

Over the years I learned that they were based upon Graham Holliman’s design. At least should I say the Sub-bass element.

Geoff had followed the detailed build instructions in the Hi-fi World article (think it was 1974 & I can scan & post).

Geoff had a great knack of thinking laterally, so had turned the Holliman enclosure on its end, on a floor stand so that the 15-inch driver faced the back wall. He then inserted an extra 15-inch upper bass driver, a 6.5-inch mid driver & tweeter array into the front, in what had been the bottom. He multiplied this twice & he had a stereo, true full-range monitoring system.

This he had achieved before I met him, I cannot express how good this sounded, so extremely quick with a very smooth response with an utterly clean never ending bass extension to die for. Totally musical and plenty of boogieing SPL for a living room.

Over the years I learnt more as you do, & with Geoff’s help along the way I later formed a PA company which in turn became a small bespoke PA loudspeaker manufacturer, this then resulted in me having company facilities like open doors to driver manufacturers. Oh to be a kid in the sweet shop again.

The highlight of this great adventure was with Geoff’s help we designed a ground-breaking high powered club system in the early 1990’s which utilised a different band-pass sub bass cabinet that pumped out over 135dBA , flat down to 20 cycles and below if I switched off the safety filter! This bespoke installation was at Turnmills club, home of Trade. At the time it really kicked the established PA brands and the club’s main competitor, The Ministry Of Sound.

I helped Geoff with many mods to his Holliman’s over the years which included all manner of drivers, crossovers and tweaking. Many happy hours were spent listening and discussing the merits of our tweaks. We even joked about booking a room at the Heathrow Hi-fi Show with the Holliman’s under an acoustically transparent dustsheet just to throw the cats amongst the pigeons.

We had always wondered why Graham Holliman he had not pursued the design further. We discussed this in great detail including the totally unfair dismissal he had received from the hi-fi industry. It had been a witch hunt and burning. I had always sensed that Geoff had felt a little guilty over poaching Graham’s design, although it had been published for personal use.

We were always going to make a finished, veneered pair for each of us with a stock pile of the next round of drivers that we had spent years choosing and gathering. Sadly that was not to be.

The good news for me is that Geoff’s speakers are safe and have been left to me so that I can keep them alive & moving forward with our original plan. I just need to make space to accommodate them in my lounge. (Can’t wait)

When I arranged Geoff’s funeral, when going through his “loudspeaker” phone book I found Graham Holliman’s telephone number, thought it rude not to call really although it did seem odd that Geoff had never mentioned speaking to him.

Mr Holliman could not remember Geoff, but was a really cool guy to speak with. We spoke for a good while and Mr Holliman & I left things hanging so that I could call again, which I would thoroughly enjoy. We did talk about getting together for him to have a listen. OH WHAT AN HONOUR!

So you now know why I have been living in a parallel universe, having read this thread back to 2004 today.

I am so pleased that Mr Holliman is still provoking interest & debate to this day, I can only tell you that I have been told by others that I have “golden ears” and believe me, I’m not a boom & tiss kind of guy at home.

His design is the best I have ever heard, yes there is debate because the available technology around 40 years ago was very limited, particularly in the bass & elctronics department. I know that from my own experience in the 90’s when we were pushing the design envelope and constantly taking drivers back to where they were made and asking for design changes.

It wasn’t until relatively recently when advanced & high temperature materials, low resonant frequencies & high Xmax have become the norm for high end bass products.

For those wanting to know what drivers Geoff had used; the default had been some vintage Audax 15 inch units which had been mass loaded with bitumen sheet. We were next planning to try some Precision Devices 158’s, which we sensed would be an upgrade.

Our general consensus was that the cabinets were not too driver fussy, nor did he have to close doors & windows for the full effect. So I guess this suggests that following the cabinet design accurately and maintaining construction quality is more important than with most designs.

I remember Geoff stating that when I remade the cabinets that I should use the thinnest/strongest sheet material for the loading aperture ring. I have noticed that some of you appear to have used hardboard? this I think could be flapping/ trying to tear itself apart when level is increased?

I should also state that the ultra-sub bandwidth was actively driven via large mono-blocks via a studio quality Tannoy crossover with 24dB/octave slope to filter nasty out of band break up. And obviously there was room gain by the fact that the speakers backed into the corners.

I can remember the day we wired one up to a 2 watt transistor FM radio, the result was quite amazing, and so I think it fair to say there’s no problem with efficiency that is in the mid to upper 90’s

I now look forward to installing Geoff’s Holliman’s and reading through his notes and returning here for any more gratefully received and shared wisdom before I draw up the next version of cabinets. If anybody has any doubt, you are most welcome to visit and make your own opinion.

Thank you Geoff and thank you Graham.

PS Does that qualify for the third or fourth known working cabinet?http://files.diyaudio.com/forums/images/smilies/scratch1.gif

WelcomeThe highlight of this great adventure was with Geoff’s help we designed a ground-breaking high powered club system in the early 1990’s which utilised a different band-pass sub bass cabinet that pumped out over 135dBA , flat down to 20 cycles and below if I switched off the safety filter! This bespoke installation was at Turnmills club, home of Trade. At the time it really kicked the established PA brands and the club’s main competitor, The Ministry Of Sound.

135dBA eh? That's LOUD, could it be a typo?

135dBA eh? That's LOUD, could it be a typo? A-weighting - Wikipedia, the free encyclopedia

- Home

- Loudspeakers

- Subwoofers

- Graham Holliman Velocity Coupled Infra Bass Speaker?