I had a Dayton 100w plate amp hanging around and wanted to figure out something to do with it. I heard the Dayton Audio SD215A-88 has a good reputation for a budget driver (80w RMS), so I snatched one up and set to work.

WinISD models a 1.47 ft^3 box tuned to 32.5Hz via a 3"ID port at 10"L to have an F3 of 30Hz, and an F10 at 24Hz. Seems like a tall order from a $30 8". So, I decided to give it a whirl aiming more for the 'boutique' side of things focusing more on SQ and looking nice than power and thump-thump.

This is also my first time working with solid wood, and my new toy - a Dewalt planer. I ran to the lumber store and picked up some Purpleheart, Cherry, and Mahogany. I cut them up into some strips, glued them all up together, and stuffed them through the planer. Once I'd gotten it flat, it was a little thin for my liking at ~.75". So, I backed it with some 1/2" Oak plywood, which should also help with stability, I would think. I decided to rear-mount the driver since they look way cleaner back-mounted IMO, so I sketched up a CAD drawing, cranked it out on my CNC machine, and managed to get a decent result.

The port is 3"ID (3.5"OD) PVC pipe mounted as flush as I could in the baffle. Once thing I noticed is that PVC is not perfectly round and that I should use actual port tubing in the future for better aesthetics. Anyways, I cut it to 11" long, which is an inch longer than the designed 10". I did that just to have some wiggle room since I can always cut some off. After listening to it, I just left it at 11" and glued it in place with epoxy and gorilla glue.

Here are some sparse pics. I should've taken more, but lighting is awful and I just don't stop to think about it when I'm in the shop.

Milling out the speaker and port holes on the baffle from the back side. If you look closely, you can see the hardwoods glued underneath the plywood. The whole baffle is about 1.6" thick. The driver and port are set into the baffle by about .65" to mate against the hardwoods so I wouldn't get a weird looking ring of plywood from the front.

I put a 3/8" roundover on the driver and port flairs and took it for a test spin. Sets right in there nice and snug. This shot is all friction fit - no screws holding anything in place.

I built the rest of the box with 3/4" MDF, added the bracing, took it for a little test spin before gluing it all up. I concluded that my measurements are junk in my basement and that I really need to measure it outside, but it sounds full and rich for an 8".

I liked what I heard, so I glued it all up, threw some shellac and lacquer at it, slapped on some vinyl wrap, and called it done. The lighting is junk and it looks better in person, but oh well. That's what I get when using a potato phone, I guess.

I ran this sub as my computer sub for a couple days and it totally sounds like a 10, or 12. It doesn't go terribly loud, but it hits the mid-upper 20Hz neighborhood solidly, sounds smooth and natural doing it, and can even shake my floorboards a little bit in some circumstances. It really does have some good SQ and proper depth from a 'little' 8" and is very nicely suited for easy jazz, R&B, orchestral, etc at no more than 'moderate' volume. The weird thing is, my Dayton 100w plate amp can easily overpower the driver even when the driver is rigged up in 16ohm mode when the amp's theoretical max output is ~55w@16ohms. Oh well. Overall, I would do a couple things different (like a smoother port), but I'm quite pleased with this little driver. It looks, and sounds, very nice indeed.

WinISD models a 1.47 ft^3 box tuned to 32.5Hz via a 3"ID port at 10"L to have an F3 of 30Hz, and an F10 at 24Hz. Seems like a tall order from a $30 8". So, I decided to give it a whirl aiming more for the 'boutique' side of things focusing more on SQ and looking nice than power and thump-thump.

This is also my first time working with solid wood, and my new toy - a Dewalt planer. I ran to the lumber store and picked up some Purpleheart, Cherry, and Mahogany. I cut them up into some strips, glued them all up together, and stuffed them through the planer. Once I'd gotten it flat, it was a little thin for my liking at ~.75". So, I backed it with some 1/2" Oak plywood, which should also help with stability, I would think. I decided to rear-mount the driver since they look way cleaner back-mounted IMO, so I sketched up a CAD drawing, cranked it out on my CNC machine, and managed to get a decent result.

The port is 3"ID (3.5"OD) PVC pipe mounted as flush as I could in the baffle. Once thing I noticed is that PVC is not perfectly round and that I should use actual port tubing in the future for better aesthetics. Anyways, I cut it to 11" long, which is an inch longer than the designed 10". I did that just to have some wiggle room since I can always cut some off. After listening to it, I just left it at 11" and glued it in place with epoxy and gorilla glue.

Here are some sparse pics. I should've taken more, but lighting is awful and I just don't stop to think about it when I'm in the shop.

Milling out the speaker and port holes on the baffle from the back side. If you look closely, you can see the hardwoods glued underneath the plywood. The whole baffle is about 1.6" thick. The driver and port are set into the baffle by about .65" to mate against the hardwoods so I wouldn't get a weird looking ring of plywood from the front.

An externally hosted image should be here but it was not working when we last tested it.

I put a 3/8" roundover on the driver and port flairs and took it for a test spin. Sets right in there nice and snug. This shot is all friction fit - no screws holding anything in place.

An externally hosted image should be here but it was not working when we last tested it.

I built the rest of the box with 3/4" MDF, added the bracing, took it for a little test spin before gluing it all up. I concluded that my measurements are junk in my basement and that I really need to measure it outside, but it sounds full and rich for an 8".

An externally hosted image should be here but it was not working when we last tested it.

I liked what I heard, so I glued it all up, threw some shellac and lacquer at it, slapped on some vinyl wrap, and called it done. The lighting is junk and it looks better in person, but oh well. That's what I get when using a potato phone, I guess.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I ran this sub as my computer sub for a couple days and it totally sounds like a 10, or 12. It doesn't go terribly loud, but it hits the mid-upper 20Hz neighborhood solidly, sounds smooth and natural doing it, and can even shake my floorboards a little bit in some circumstances. It really does have some good SQ and proper depth from a 'little' 8" and is very nicely suited for easy jazz, R&B, orchestral, etc at no more than 'moderate' volume. The weird thing is, my Dayton 100w plate amp can easily overpower the driver even when the driver is rigged up in 16ohm mode when the amp's theoretical max output is ~55w@16ohms. Oh well. Overall, I would do a couple things different (like a smoother port), but I'm quite pleased with this little driver. It looks, and sounds, very nice indeed.

Last edited:

Nice work.

I noticed a comment you made "can easily overwhelm when max is 55W@16ohm " that has me curious. Is the woofer movement excessive and causing distortion ?

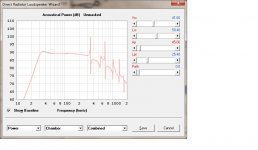

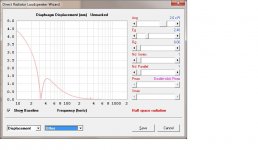

These graphs are from HornResp and should be comparable to the program you used. The issue I'm interested in, is the low freq <20Hz where the displacement is excessive, even for low power. Do you see this? movement more than the Xmax=6mm ? like its flopping back and forth at low frequency?

I noticed a comment you made "can easily overwhelm when max is 55W@16ohm " that has me curious. Is the woofer movement excessive and causing distortion ?

These graphs are from HornResp and should be comparable to the program you used. The issue I'm interested in, is the low freq <20Hz where the displacement is excessive, even for low power. Do you see this? movement more than the Xmax=6mm ? like its flopping back and forth at low frequency?

Attachments

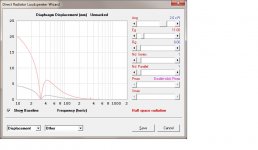

Partially answered my own question in the PartExpress Q&A for the plate amp. There is a subsonic filter @18Hz, but it might be too low for this arrangement, allowing excess movement up to 30Hz with very little power.

"Is there a subsonic filter? What is it set at?

FD001 on Apr 24, 2011 BEST ANSWER: Yes, this amplifier does have a subsonic filter at 18Hz."

I attached another graph predicting the power when Xmax is reached. If we assume there is no music content below 30Hz, you can see Xmax=6mm at 45Hz using 35W. I'm struggling with a similar issue, that's why it caught my attention.

"Is there a subsonic filter? What is it set at?

FD001 on Apr 24, 2011 BEST ANSWER: Yes, this amplifier does have a subsonic filter at 18Hz."

I attached another graph predicting the power when Xmax is reached. If we assume there is no music content below 30Hz, you can see Xmax=6mm at 45Hz using 35W. I'm struggling with a similar issue, that's why it caught my attention.

Attachments

It doesn't take a whole lot to bottom it out, but I'm hearing some distortion just from too much power when it's nowhere near xmax (think kick drum).

I also had that plate amp running 2x Tang Band 5.25's wired in series for an 8 ohm load for a year or two. At 8 ohms, the specs say the amp is pushing 75w RMS. The drivers are 40w each for 80w total RMS on tap, so the amp was technically under-powering the drivers just a tiny bit. In reality, the amp could overpower those TB's too if I wasn't careful. A quick model doesn't show the pair of TB's getting anywhere near their xmax on 75w. I'm thinking the amp may be rated a bit on the conservative side and is really capable of pushing a bit more than spec.

I also had that plate amp running 2x Tang Band 5.25's wired in series for an 8 ohm load for a year or two. At 8 ohms, the specs say the amp is pushing 75w RMS. The drivers are 40w each for 80w total RMS on tap, so the amp was technically under-powering the drivers just a tiny bit. In reality, the amp could overpower those TB's too if I wasn't careful. A quick model doesn't show the pair of TB's getting anywhere near their xmax on 75w. I'm thinking the amp may be rated a bit on the conservative side and is really capable of pushing a bit more than spec.

Last edited:

Pmax is certainly one consideration, but I don't think you'll have to worry about that.

The cone travel (ie. displacement) depends on box design, driver, frequency, and power. A kick drum or even kettle drum or old church organ can generate the very low freq I'm referring to. Have a look at the displacement graph in post #3 for your design @35W power. At 40Hz the cone is moving 6mm, which is your Xmax. At 20Hz the cone is trying to move 12mm which will certainly bottom it out. In fact depending on the frequency you can bottom out with alot less power than 35w. I'm wondering if that is happening? It certainly sounds like it is.

The cone travel (ie. displacement) depends on box design, driver, frequency, and power. A kick drum or even kettle drum or old church organ can generate the very low freq I'm referring to. Have a look at the displacement graph in post #3 for your design @35W power. At 40Hz the cone is moving 6mm, which is your Xmax. At 20Hz the cone is trying to move 12mm which will certainly bottom it out. In fact depending on the frequency you can bottom out with alot less power than 35w. I'm wondering if that is happening? It certainly sounds like it is.

Last edited:

The opposite could be true, the amp may simply sound bad (like an over-driven speaker) when it clips.I'm thinking the amp may be rated a bit on the conservative side and is really capable of pushing a bit more than spec.

Had a Crest CC2800 which sounded fine up until the clip light would flicker, then would instantly sound terrible- none of the many other Crest models that I had owned before had that problem. After replacing the amp with much higher powered amplifiers, was surprised how much louder the speakers could go without sounding "distressed".

Looks like you've got a good mic. How about doing some linearity testing? Run the subwoofer at different SPL levels and use REW to measure its frequency response and distortion. Stop when THD starts to exceed 10%.

The box does look a little big for an 8" driver. PE recommends 0.94 cu.ft. for it.

The DCS205-4 is a bit more of a subwoofer driver (Xmax is just under 50% more than that of the SD215), but it's a bit less pretty. I used one in my last build.

The box does look a little big for an 8" driver. PE recommends 0.94 cu.ft. for it.

The DCS205-4 is a bit more of a subwoofer driver (Xmax is just under 50% more than that of the SD215), but it's a bit less pretty. I used one in my last build.

Great to see another user of Dayton SD215A-88. It's a good woofer for the price.

I tested mine in a 24 liters bass reflex and a 25 liters Bandpass. The bandpass is much better for music.

Regars

Mike

I tested mine in a 24 liters bass reflex and a 25 liters Bandpass. The bandpass is much better for music.

Regars

Mike

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- My Dayton SD215A-88 8" build