If it were me and I wanted something weather proof, I would consider a Community R6, a fiberglass six ea 12" driver front loaded bass horn with a three foot wide four foot tall mouth as a start and go out from there. Food for thought.

Barry.

Hi there B: Community R6-Max looks like an interesting implementation, however, it falls short on low bass requirement stated by OP in post #1 (20hz vers R6-minimum of 44hz)., as found on Community's web site specification sheet. ...regards, Michael

Voicing the Horns

Requires adjustment of:

1) Back chamber Volume

2) Throat Area

3) Front Chamber Volume

Especially if driver selection remains a fourth degree of freedom.

Materials to be used for this purpose includes pressure treated plywood I suppose. Just do not like abandoning concrete to enclose this high pressure area.

Instead I would design for a set of drivers that can deliver the desired operating parameters so that the nominal adjustments needed can be easily implemented.

For this application, where cost is apparently no object, the Power Soft M-Force 01 driver [1] looks most attractive.

WHG

[1] PSMF01/03

Hello Michael;

Certainly right if the R6 was used by itself. I was thinking to use it as a horn throat (starting point) connected to the 20Hz concrete horn the OP imagines.

Barry.

Requires adjustment of:

1) Back chamber Volume

2) Throat Area

3) Front Chamber Volume

Especially if driver selection remains a fourth degree of freedom.

Materials to be used for this purpose includes pressure treated plywood I suppose. Just do not like abandoning concrete to enclose this high pressure area.

Instead I would design for a set of drivers that can deliver the desired operating parameters so that the nominal adjustments needed can be easily implemented.

For this application, where cost is apparently no object, the Power Soft M-Force 01 driver [1] looks most attractive.

WHG

[1] PSMF01/03

Attachments

Bill,Materials to be used for this purpose includes pressure treated plywood I suppose. Just do not like abandoning concrete to enclose this high pressure area.

Instead I would design for a set of drivers that can deliver the desired operating parameters so that the nominal adjustments needed can be easily implemented.

For this application, where cost is apparently no object, the Power Soft M-Force 01 driver [1] looks most attractive.

WHG

As previously stated, LP SmartSide is a wood product that is basically completely impervious to the environment- I have used it, unpainted, as an outdoor sidewalk directly on the termite infested ground with virtually no degradation over a period of 16 years.

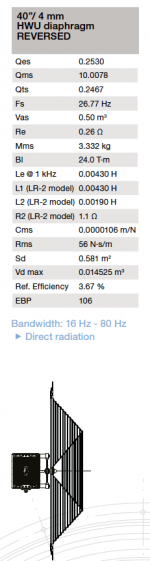

The M-Force 01 with the 40" cone appears most impressive at a 3.67% efficiency as a direct radiator.

I have been reading about the M-Force moving motor concept for a few years, but have not heard any of their units yet, have you?

Art

Attachments

Comments

Hi Art,

Comments follow:

Bill

This paneling cannot be used alone to cover a shear wall. Other problems are discussed here: Many problems with installations of LP SmartSide siding - StarTribune.com. At the frequencies of interest, concrete is a far superior construction material. If the OP builds just one horn, its scale is going to dominate performance. If needed, replaceable driver manifold

segments can be designed to accommodate various multi-driver alternatives.

Not yet. During my discussions with Power-Soft's US representative, the 30" cone was recommended for use in a large bass horn. The polypropylene cone is ideal for this particular outdoor application as it is impervious to all the hazards. The TSPs look suitable for driving a horn load as well.

For this project, how the frequencies above say 80 Hz. are reproduced is where the acoustic challenges are to be found. Below, the challenges are primarily those of concrete placement.

Hi Art,

Comments follow:

Bill

Bill,

As previously stated, LP SmartSide is a wood product that is basically completely impervious to the environment- I have used it, unpainted, as an outdoor sidewalk directly on the termite infested ground with virtually no degradation over a period of 16 years.

This paneling cannot be used alone to cover a shear wall. Other problems are discussed here: Many problems with installations of LP SmartSide siding - StarTribune.com. At the frequencies of interest, concrete is a far superior construction material. If the OP builds just one horn, its scale is going to dominate performance. If needed, replaceable driver manifold

segments can be designed to accommodate various multi-driver alternatives.

The M-Force 01 with the 40" cone appears most impressive at a 3.67% efficiency as a direct radiator.

I have been reading about the M-Force moving motor concept for a few years, but have not heard any of their units yet, have you?

Art

Not yet. During my discussions with Power-Soft's US representative, the 30" cone was recommended for use in a large bass horn. The polypropylene cone is ideal for this particular outdoor application as it is impervious to all the hazards. The TSPs look suitable for driving a horn load as well.

For this project, how the frequencies above say 80 Hz. are reproduced is where the acoustic challenges are to be found. Below, the challenges are primarily those of concrete placement.

The linked (midhorn) build uses petals of 3mm ply for the shape, and then wraps it in synthetics (mostly fibreglass).

That seems like a good way to get a waterproof horn:

- fairly low material / effort / infrastructure / money requirements, relative to the result.

- could be kept light & mobile, or encased in other materials (such as concrete) for a permanent installation.

I have not worked with fibreglass before. For, say, a 150cm long throat section, or a 150cm long midbass horn, would anyone who knows fibreglass be able to give a guesstimate on how long the fibreglass part would take, and how much goo you'd need?

doityourselfaudio: 140Hz Petal Horns

That seems like a good way to get a waterproof horn:

- fairly low material / effort / infrastructure / money requirements, relative to the result.

- could be kept light & mobile, or encased in other materials (such as concrete) for a permanent installation.

I have not worked with fibreglass before. For, say, a 150cm long throat section, or a 150cm long midbass horn, would anyone who knows fibreglass be able to give a guesstimate on how long the fibreglass part would take, and how much goo you'd need?

doityourselfaudio: 140Hz Petal Horns

Bill,Hi Art,

Comments follow:

Bill

1)This paneling cannot be used alone to cover a shear wall. Other problems are discussed here: Many problems with installations of LP SmartSide siding - StarTribune.com.

2) At the frequencies of interest, concrete is a far superior construction material. If the OP builds just one horn, its scale is going to dominate performance. If needed, replaceable driver manifold

segments can be designed to accommodate various multi-driver alternatives.

3)Not yet. During my discussions with Power-Soft's US representative, the 30" cone was recommended for use in a large bass horn. The polypropylene cone is ideal for this particular outdoor application as it is impervious to all the hazards. The TSPs look suitable for driving a horn load as well.

4)For this project, how the frequencies above say 80 Hz. are reproduced is where the acoustic challenges are to be found. Below, the challenges are primarily those of concrete placement.

1) Reuben Saltzman's October 6, 2015 article mentions "LP SmartSide® is the new high-end siding of choice here in Minnesota" and then goes on to list the installation errors, primarily unpainted surfaces.

I don't know how "new" LP SmartPanel was to my former Twin Cities location, but in the 17 years the LP SmartPanel laid in unpainted 18" wide cut strips (24' of sidewalk from one sheet ;^) ) on the ground in Madrid, New Mexico, there was virtually no wear, in fact, I brought some of the 17 year old pieces along to Florida to use for under trailer jacks.

The James Hardie siding, which looks so much like LP SmartPanel that I purchased some, went "wild" on the edges in a mater of a few years even though they were painted. It has little shear strength, while the LP SmartPanel is strong enough to make cable ramps from and have trucks drive over it (damn it...) all day.

2) Agreed, though the cost ratio of the cost of concrete, forms, rebar & labor for the marginal improvement compared to laminated LP SmartPanel is staggering.

3) I have been considering trying the 22" cone in the Keystone "B-Low".

4) Agreed.

Cheers,

Art

Bill,

1) Reuben Saltzman's October 6, 2015 article mentions "LP SmartSide® is the new high-end siding of choice here in Minnesota" and then goes on to list the installation errors, primarily unpainted surfaces.

I don't know how "new" LP SmartPanel was to my former Twin Cities location, but in the 17 years the LP SmartPanel laid in unpainted 18" wide cut strips (24' of sidewalk from one sheet ;^) ) on the ground in Madrid, New Mexico, there was virtually no wear, in fact, I brought some of the 17 year old pieces along to Florida to use for under trailer jacks.

The James Hardie siding, which looks so much like LP SmartPanel that I purchased some, went "wild" on the edges in a mater of a few years even though they were painted. It has little shear strength, while the LP SmartPanel is strong enough to make cable ramps from and have trucks drive over it (damn it...) all day.

My experience with engineered wood products is that when moisture invades the wood fibers, they expand and break the resin bonds that hold them together. Your experience with the LP Smart Panel product is encouraging.

3)2) Agreed, though the cost ratio of the cost of concrete, forms, rebar & labor for the marginal improvement compared to laminated LP SmartPanel is staggering.

The much smaller manifold segments can be formed using remnant materials, thus the costs of building the much larger horn bodies prevail.

For segment design, see attachment [1] from an earlier post

I have been considering trying the 22" cone in the Keystone "B-Low".

SWAG: Unless you need the higher mass roll-off frequency, recommend the use of 30" diaphragms.

>snip<

Regards,

Bill

Reference [1]

Attachments

M-Force Revisited

Thanks for the input.

I am aware of Tony Andrews effort to use M-Force drivers. Funktion-One | News | Funktion-One and Powersoft combine for new level of bass performance

Note that even when arrayed, the footprint will be much smaller that what the OP is considering. WHG

@Whgeiger The Powersoft Cones and M-drive are already used in different horn applications, bandpass and frontloaded designs from different brands. Function one F132, PK sound Gravity, D.A.S. Audio SF30 are a few of them that used the Powersoft design.

Thanks for the input.

I am aware of Tony Andrews effort to use M-Force drivers. Funktion-One | News | Funktion-One and Powersoft combine for new level of bass performance

Note that even when arrayed, the footprint will be much smaller that what the OP is considering. WHG

Project update:

I am about 1 year behind schedule in building my concrete horns. We were supposed to build our new house back in April (2018), but it took 7 months to get our stupid building permit - at which point it was too late in the season to secure contractors. Hopefully we'll be building this spring (2019) - with the horn project following shortly thereafter.

The good news is that I've acquired an assortment of power amplifiers for this project:

(qty 9) Macro-Tech 2400

(qty 4) Macro-Tech 24x6

(qty 3) Macro-Tech 3600VZ

(qty 2) Macro-Tech 5002VZ

Thus I've got roughly 52 kW of power available (as of now) - should be plenty of headroom for a backyard system.

I am about 1 year behind schedule in building my concrete horns. We were supposed to build our new house back in April (2018), but it took 7 months to get our stupid building permit - at which point it was too late in the season to secure contractors. Hopefully we'll be building this spring (2019) - with the horn project following shortly thereafter.

The good news is that I've acquired an assortment of power amplifiers for this project:

(qty 9) Macro-Tech 2400

(qty 4) Macro-Tech 24x6

(qty 3) Macro-Tech 3600VZ

(qty 2) Macro-Tech 5002VZ

Thus I've got roughly 52 kW of power available (as of now) - should be plenty of headroom for a backyard system.

No M-Force Drivers

Too bad! They would have been the best for your application..

Have you finalized the sub-horn design?

You will need a building permit for it as well.

Do not forget to add additional capacity to your house service panel and power connection.

Use distribution panels with isolated ground bars to support your technical loads.

Out-Building Sub-panels should be bonded back to your building entrance ground rods.

Regards,

WHG

Project update:

I am about 1 year behind schedule in building my concrete horns. We were supposed to build our new house back in April (2018), but it took 7 months to get our stupid building permit - at which point it was too late in the season to secure contractors. Hopefully we'll be building this spring (2019) - with the horn project following shortly thereafter.

The good news is that I've acquired an assortment of power amplifiers for this project:

(qty 9) Macro-Tech 2400

(qty 4) Macro-Tech 24x6

(qty 3) Macro-Tech 3600VZ

(qty 2) Macro-Tech 5002VZ

Thus I've got roughly 52 kW of power available (as of now) - should be plenty of headroom for a backyard system.

Too bad! They would have been the best for your application..

Have you finalized the sub-horn design?

You will need a building permit for it as well.

Do not forget to add additional capacity to your house service panel and power connection.

Use distribution panels with isolated ground bars to support your technical loads.

Out-Building Sub-panels should be bonded back to your building entrance ground rods.

Regards,

WHG

Last edited:

I'm confused. What would've been the best for my application?

I'm leaning towards building a single 15 Hz exponential horn from concrete. The horn will require a permit for two reasons: one, the driver-end of the horn will be enclosed in a small building, and the building will be wired for 200 amp service (both the building and electrical require a permit). Also, the horn itself, while technically not a dwelling, is capable of injuring people should it fail & collapse (requiring a seismic design review - aka a permit). It will be quite interesting to see the looks on the county permitting officials faces - when I attempt to explain this project. . .

I've been doing a lot of reading on CBT arrays. Seeing as my listening field is relatively close, I might construct a large half-space CBT stereo line-array - which is why a purchased a bunch of amplifiers - so that I may shade the array on the amplification stages - without passive components. I don't think my project warrants hanging a line array high up in the air. Again, I'm not covering a large area. I'm willing to experiment to find what works best. The only thing set in stone (pun intended) is the bass horn. . .

I'm leaning towards building a single 15 Hz exponential horn from concrete. The horn will require a permit for two reasons: one, the driver-end of the horn will be enclosed in a small building, and the building will be wired for 200 amp service (both the building and electrical require a permit). Also, the horn itself, while technically not a dwelling, is capable of injuring people should it fail & collapse (requiring a seismic design review - aka a permit). It will be quite interesting to see the looks on the county permitting officials faces - when I attempt to explain this project. . .

I've been doing a lot of reading on CBT arrays. Seeing as my listening field is relatively close, I might construct a large half-space CBT stereo line-array - which is why a purchased a bunch of amplifiers - so that I may shade the array on the amplification stages - without passive components. I don't think my project warrants hanging a line array high up in the air. Again, I'm not covering a large area. I'm willing to experiment to find what works best. The only thing set in stone (pun intended) is the bass horn. . .

No M-Force Drivers Used (Revisited)

The subject of this and my last post to you.

Recommend horn bottom wall be formed by a slab on grade with footers for two flared side walls and a center wall to further support a roof wall that implements a slope of say 4/12.

For best low frequency performance use Salmon's hyperbolic horn design formulas coupled with Le Cleac'h's method to determine side-wall flare dimensions. You want to annual driver reactance at the low end. Note also that driver [fs] will be pulled down by the horn's air column load.

As I expect you will build plywood forms for pour-in-place construction, form curvature required for the side-wall pour can be accommodated by laminating thinner plywood layers and kerfing.

According the Keele, "if the horns are big enough", you get the same results using them instead of a CBT array. The concrete sectorial horns (or equivalent), addressed in an article provided earlier, and scaled to fit your venue, should get the job done, without sustaining the additional complexity required by CMT. However, recommend use of a center fill channel as well for HF reproduction.

Regards,

WHG

I'm confused. What would've been the best for my application?

The subject of this and my last post to you.

I'm leaning towards building a single 15 Hz exponential horn from concrete. The horn will require a permit for two reasons: one, the driver-end of the horn will be enclosed in a small building, and the building will be wired for 200 amp service (both the building and electrical require a permit). Also, the horn itself, while technically not a dwelling, is capable of injuring people should it fail & collapse (requiring a seismic design review - aka a permit). It will be quite interesting to see the looks on the county permitting officials faces - when I attempt to explain this project. . .

Recommend horn bottom wall be formed by a slab on grade with footers for two flared side walls and a center wall to further support a roof wall that implements a slope of say 4/12.

For best low frequency performance use Salmon's hyperbolic horn design formulas coupled with Le Cleac'h's method to determine side-wall flare dimensions. You want to annual driver reactance at the low end. Note also that driver [fs] will be pulled down by the horn's air column load.

As I expect you will build plywood forms for pour-in-place construction, form curvature required for the side-wall pour can be accommodated by laminating thinner plywood layers and kerfing.

I've been doing a lot of reading on CBT arrays. Seeing as my listening field is relatively close, I might construct a large half-space CBT stereo line-array - which is why a purchased a bunch of amplifiers - so that I may shade the array on the amplification stages - without passive components. I don't think my project warrants hanging a line array high up in the air. Again, I'm not covering a large area. I'm willing to experiment to find what works best. The only thing set in stone (pun intended) is the bass horn. . .

According the Keele, "if the horns are big enough", you get the same results using them instead of a CBT array. The concrete sectorial horns (or equivalent), addressed in an article provided earlier, and scaled to fit your venue, should get the job done, without sustaining the additional complexity required by CMT. However, recommend use of a center fill channel as well for HF reproduction.

Regards,

WHG

Last edited:

I don't want to do a flat slab-on-grade, simply because we have wind-driven rain, and I don't want the horn to collect rain water. The bottom slab must have a taper.

We're on the same page with using a flat top and bottom, with curved side-walls. The final achieved angle between the top and bottom walls are a simple function of the horn mouth's aspect ratio.

Is there any reason to use a hyperbolic horn over a pure exponential design? My estimated upper crossover frequency for the bass horn is 90 Hz, with a 15 Hz cutoff.

Is a center channel necessary for a stereo sound system? There was a recommendation to install a big projection screen, and be able to play movies for my friends. That does sound interesting, but honestly not something I see myself doing. . . Another recommendation was made to have a center channel for when people played live music at my house. Again, probably not going to happen. Most of my friends are nerds, not musicians. . . .

We're on the same page with using a flat top and bottom, with curved side-walls. The final achieved angle between the top and bottom walls are a simple function of the horn mouth's aspect ratio.

Is there any reason to use a hyperbolic horn over a pure exponential design? My estimated upper crossover frequency for the bass horn is 90 Hz, with a 15 Hz cutoff.

Is a center channel necessary for a stereo sound system? There was a recommendation to install a big projection screen, and be able to play movies for my friends. That does sound interesting, but honestly not something I see myself doing. . . Another recommendation was made to have a center channel for when people played live music at my house. Again, probably not going to happen. Most of my friends are nerds, not musicians. . . .

Mega-Horn Notes

Slab slope only need be 1/4" per foot for drainage. This massive horn elevated above grade will present seismic problems much larger than those associated with rain water drainage. Run a French drain across the front if necessary.

Note that the bottom wall of the horn continues forever. Slope needed for drainage only except for the round to rectangular throat transition.

Yes, increased output near cut-off, exactly where needed.

Once you have selected your driver candidates, run David McBean's program for various [T] values, say starting at about 0.6.

Note that, depending on filter slope, significant output will extend to about 180 Hz.

It will depend on the spread between left and right units. If you want a wide stage then a center channel is recommended, particularly for vocals and solos, center stage.

With these facilities in place, your system becomes a performance venue of significant merit. It would be a shame if it is not used that way from time to time.

Once the locals find out about it, you will have ample opportunity to acquire musically inclined friends if you want them.

I have hosted song writer concerts, jam sessions, and various Karaoke events and found the effort to be socially rewarding. On some of these occasions, guests have numbered over a hundred.

Regards,

WHG

I don't want to do a flat slab-on-grade, simply because we have wind-driven rain, and I don't want the horn to collect rain water. The bottom slab must have a taper.

Slab slope only need be 1/4" per foot for drainage. This massive horn elevated above grade will present seismic problems much larger than those associated with rain water drainage. Run a French drain across the front if necessary.

We're on the same page with using a flat top and bottom, with curved side-walls. The final achieved angle between the top and bottom walls are a simple function of the horn mouth's aspect ratio.

Note that the bottom wall of the horn continues forever. Slope needed for drainage only except for the round to rectangular throat transition.

Is there any reason to use a hyperbolic horn over a pure exponential design?

Yes, increased output near cut-off, exactly where needed.

Once you have selected your driver candidates, run David McBean's program for various [T] values, say starting at about 0.6.

My estimated upper crossover frequency for the bass horn is 90 Hz, with a 15 Hz cutoff.

Note that, depending on filter slope, significant output will extend to about 180 Hz.

Is a center channel necessary for a stereo sound system? There was a recommendation to install a big projection screen, and be able to play movies for my friends. That does sound interesting, but honestly not something I see myself doing. . . Another recommendation was made to have a center channel for when people played live music at my house. Again, probably not going to happen. Most of my friends are nerds, not musicians. . . .

It will depend on the spread between left and right units. If you want a wide stage then a center channel is recommended, particularly for vocals and solos, center stage.

With these facilities in place, your system becomes a performance venue of significant merit. It would be a shame if it is not used that way from time to time.

Once the locals find out about it, you will have ample opportunity to acquire musically inclined friends if you want them.

I have hosted song writer concerts, jam sessions, and various Karaoke events and found the effort to be socially rewarding. On some of these occasions, guests have numbered over a hundred.

Regards,

WHG

Last edited:

A hyperbolic horn is less adjustable on the driver end.

The advantage of a true exponential horn is that I may lengthen or shorten the back end of the horn, to achieve various throat cross-sectional areas, and various driver configurations - to see what sounds best.

I'll have to give this more thought. My biggest hesitation with this project, is that any mistakes are set in stone. . . .

The advantage of a true exponential horn is that I may lengthen or shorten the back end of the horn, to achieve various throat cross-sectional areas, and various driver configurations - to see what sounds best.

I'll have to give this more thought. My biggest hesitation with this project, is that any mistakes are set in stone. . . .

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Concrete Bass Horn Design Question